Preparation method of modified biochar with improved ammonia nitrogen removal ability

A technology of biochar modification, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of environmental secondary pollution, waste of resources, poor effect, etc., and achieve improved removal efficiency, sufficient raw materials, and the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the modified biochar that improves ammonia nitrogen removal ability described in this embodiment specifically comprises the following steps:

[0028] (1) Collect yak dung, air-dry it, and then crush it to 0.5~3cm;

[0029] (2) The yak manure obtained in step (1) was heated to 600°C at a heating rate of 5°C / min under the protection of nitrogen gas, and then kept at a constant temperature for 60 minutes, and then naturally cooled with the furnace under the condition of continuous nitrogen flow;

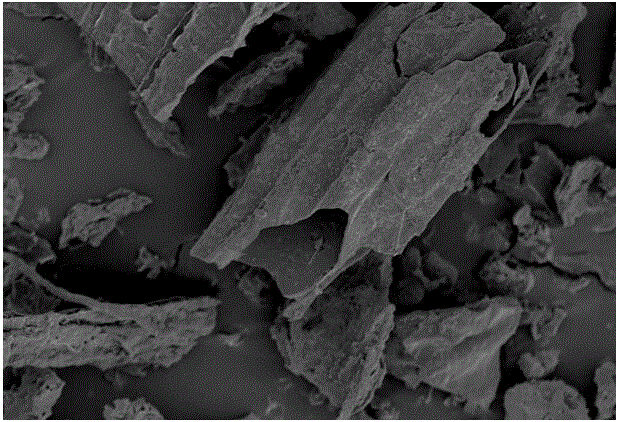

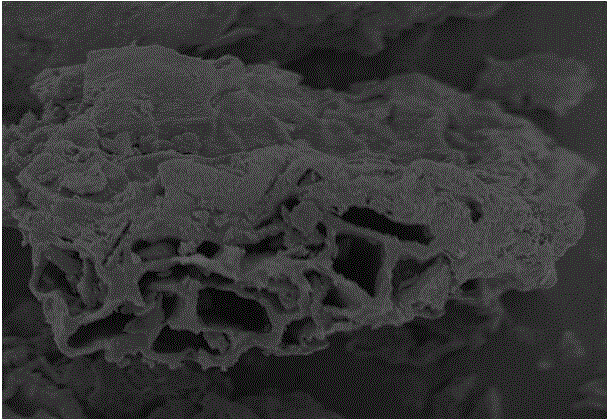

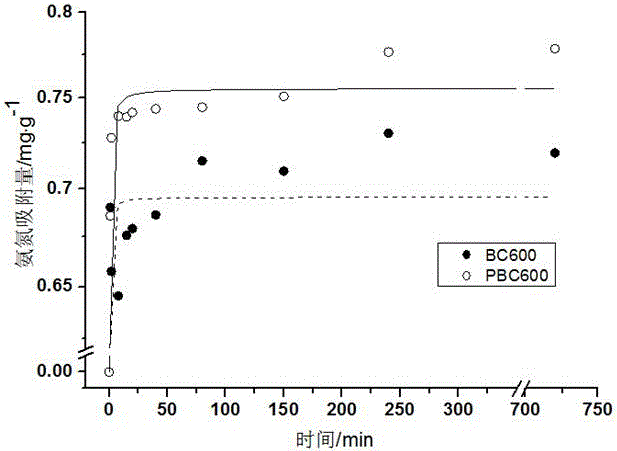

[0030] (3) The biochar obtained in step (2) is pulverized and passed through a 100-mesh sieve to obtain conventional biochar, which is recorded as BC600. Mix the biochar and water evenly at a ratio of 1:4 by mass to volume, and then add the mixture with a volume of 1 The concentration of % is the sodium azide sterilization of 20g / L, and mixes;

[0031] (4) The sterilized mixture in step (3) is subjected to cyclic freezing and thawing, with 24 hours as a...

Embodiment 2

[0041] The preparation method of the modified biochar that improves ammonia nitrogen removal ability described in this embodiment specifically comprises the following steps:

[0042] (1) Collect yak dung, air-dry it, and crush it to 0.5-3 cm;

[0043] (2) The yak manure obtained in step (1) is protected by argon gas, the heating rate is 4°C / min, and the temperature is raised to 450°C for 100 minutes. The furnace is naturally cooled, and the argon is kept open during the cooling period;

[0044] (3) The biochar obtained in step (2) is crushed and passed through a 100-mesh sieve to obtain conventional biochar, denoted as BC450, and the biochar is physically modified. The mass-volume ratio of yak dung biochar to water is 1:3. The ratio is mixed evenly, and the biochar mixed with water is heated to 121°C in a high-temperature sterilization pot for 45 minutes, and then cooled naturally to complete the sterilization;

[0045] (4) The sterilized biochar and water mixture in step (3)...

Embodiment 3

[0049] The preparation method of the modified biochar that improves ammonia nitrogen removal ability described in this embodiment specifically comprises the following steps:

[0050] (1) Collect yak dung, air-dry it, and crush it to 0.5-3 cm;

[0051] (2) The yak manure obtained in step (1) is fed with nitrogen protection, the heating rate is 3°C / min, and the temperature is raised to 300°C for 150 minutes, the furnace is naturally cooled, and the nitrogen is kept open during the cooling period;

[0052] (3) The biochar obtained in step (2) is pulverized and passed through a 100-mesh sieve to obtain conventional biochar, which is denoted as BC300. The biochar is physically modified, and the mass-volume ratio of yak dung biochar to water is 1:2. Mix evenly in proportion, then add 2% of the volume of the mixture to sterilize with sodium azide at a concentration of 15g / L, and mix evenly;

[0053] (4) Step (3) The mixture of sterilized biochar and water is cyclically frozen and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com