Purification treatment and pure-salt recovery process for strong-salt wastewater in coal chemical industry

A technology for purification treatment and coal chemical industry, which is applied in the fields of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems that solid phase products cannot meet market demand, short life and poor strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

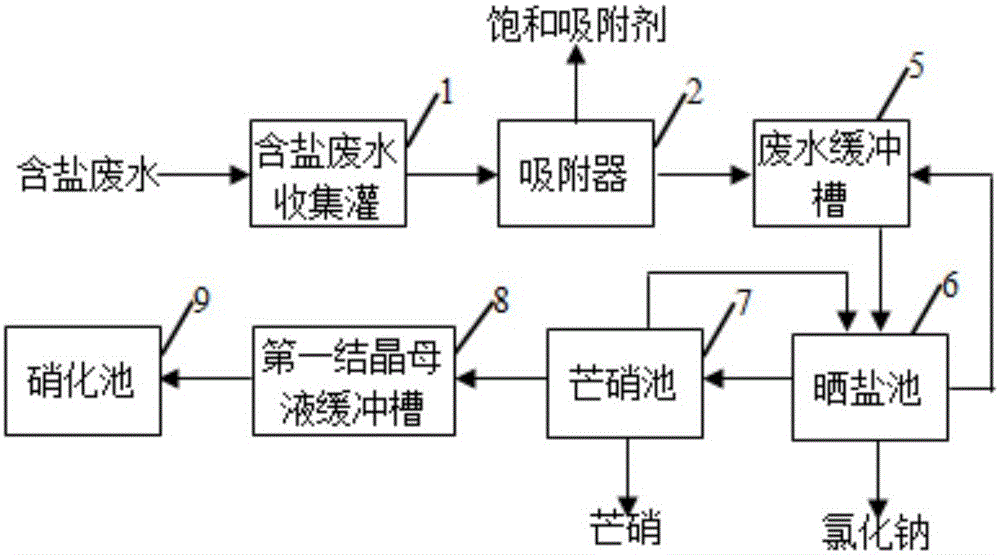

[0043] A purification treatment and salt recovery process of concentrated salt wastewater in coal chemical industry. The treatment method is based on the original coal chemical industry wastewater treatment process, and is improved for the shortcomings of the salty wastewater treatment process. First, the wastewater is reused After the multi-stage reverse osmosis treatment process, an adsorption treatment process is added to adsorb the macromolecular organic matter and heavy metals in the high-concentration brine obtained from reverse osmosis, so as to remove the COD in the saline wastewater. Cr , Heavy metals, ammonia nitrogen, color and turbidity and other index control effects; after the adsorption treatment process, a natural evaporation crystallization and freezing crystallization device is added to realize the treatment and separation of coal chemical industry salty wastewater. The specific processing method is carried out according to the following steps:

[0044] First...

specific Embodiment approach 2

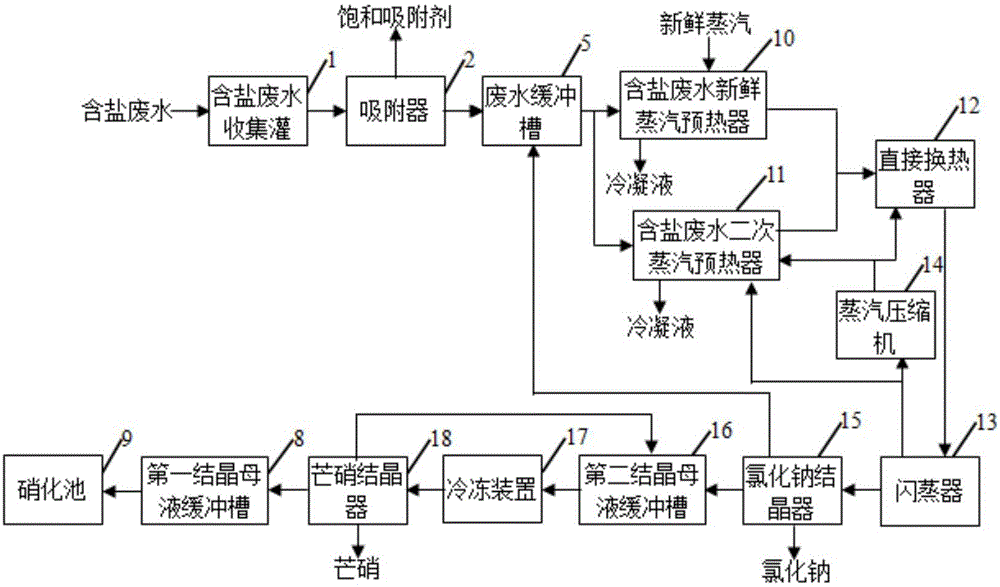

[0045] A purification treatment and salt recovery process of concentrated salt wastewater in coal chemical industry. The treatment method is based on the original coal chemical industry wastewater treatment process, and is improved for the shortcomings of the salty wastewater treatment process. First, the wastewater is reused After the multi-stage reverse osmosis treatment process, an adsorption treatment process is added to adsorb the organic macromolecules and heavy metals in the high-concentration brine obtained from reverse osmosis, so as to remove the COD in the saline wastewater. Cr , heavy metals, ammonia nitrogen, color and turbidity and other index control effects; after the adsorption treatment process, a full phase change direct heat exchange evaporation crystallization device and a freezing crystallization device are added to achieve rapid and economical treatment of salty wastewater from the factory, shortening the Production cycle, reduce floor area, increase remo...

specific Embodiment approach 3

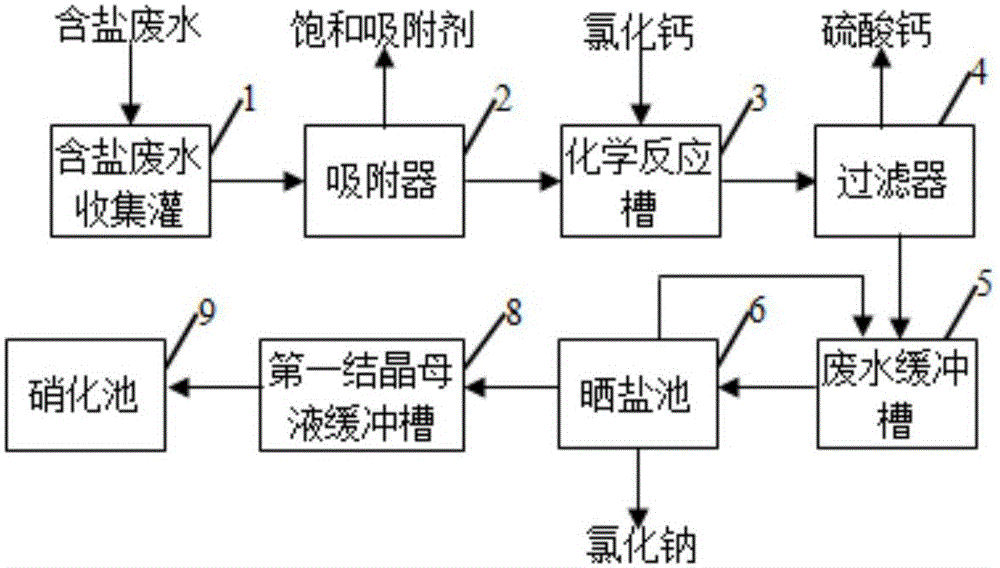

[0047] A purification treatment and salt recovery process of concentrated salt wastewater in coal chemical industry. The treatment method is based on the original coal chemical industry wastewater treatment process, and is improved for the shortcomings of the salty wastewater treatment process. First, the wastewater is reused After the multi-stage reverse osmosis treatment process, an adsorption treatment process is added to adsorb the organic macromolecules and heavy metals in the high-concentration brine obtained from reverse osmosis, so as to remove the COD in the saline wastewater. Cr , heavy metals, ammonia nitrogen, color and turbidity and other index control effects; after the adsorption treatment process, a chemical separation process is added to realize the purification of saline wastewater and the preparation of a single salt, and the treated saline wastewater is naturally evaporated Crystallization and freezing crystallization devices to achieve the purpose of treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com