Method of treating organic wastewater based on Fenton-like reaction of iron-based organic-framework material

A technology of organic wastewater and metal skeleton materials, applied in chemical instruments and methods, water treatment of special compounds, oxidized water/sewage treatment, etc., can solve the problems of low loading of transition metals, easy loss of metal ions, and improvement of catalytic activity , to achieve the effects of easy access, broad practical application prospects, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

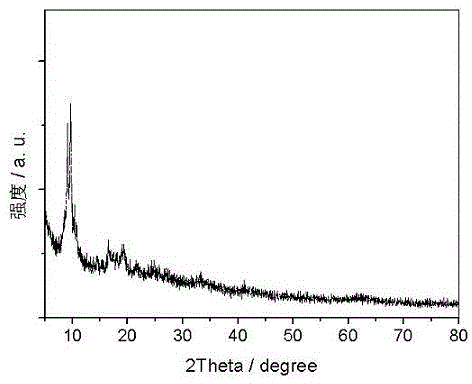

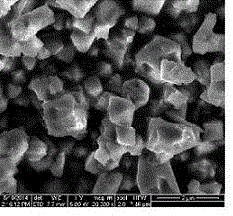

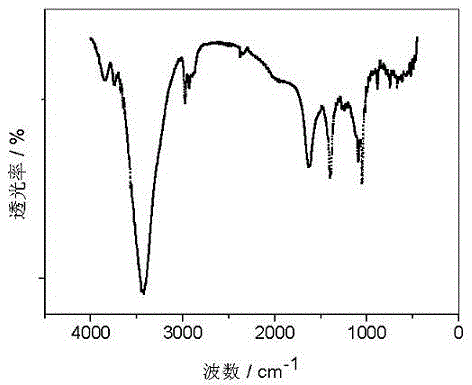

[0023] The preparation of catalyst MIL-53 (Fe): with 1.081g FeCl 3 ·6H 2 O and 0.665 g of terephthalic acid were dissolved in 20 mL of N, N-dimethylformamide (DMF), stirred at room temperature for 10 min, mixed evenly, and then packaged in a reaction vessel with a Teflon liner, in React at 150°C for 5h, cool to room temperature; centrifuge, wash with deionized water, pour the obtained tan powder into 200mL deionized water and let it stand for 12h, then centrifuge, and finally vacuum dry at 60°C for 24h. The prepared catalyst MIL-53(Fe) has a specific surface area of 1095m 2 / g, the pore diameter is 0.74nm.

[0024] Degradation of organic wastewater: Prepare 50 mL of rhodamine B dye wastewater with a concentration of 10.0 mg / L, adjust the pH value to 2.3 with HCl or NaOH, add 20 mg MIL-53 (Fe) and 162 mg potassium persulfate as catalyst and oxidant respectively, Stir magnetically at room temperature. After 120 minutes, the degradation rate of Rhodamine B was 91.0%.

Embodiment 2

[0026] The preparation of catalyst MIL-101 (Fe): 0.675g FeCl 3 ·6H 2 O and 0.206 g of terephthalic acid were dissolved in 15 mL of N, N-dimethylformamide (DMF), stirred at room temperature for 10 min, mixed well, and then packaged in a reaction vessel with a Teflon liner, in React at 110°C for 20h, cool to room temperature; centrifuge, then heat-treat in 50ml ethanol at 60°C for 3h, perform a total of two heat-treatments to remove adsorbed impurities, and finally vacuum-dry at 60°C for 24h. The prepared catalyst MIL-101(Fe) has a specific surface area of 3400m 2 / g, the pore size is 1.2 and 1.4nm.

[0027] Degradation of organic wastewater: prepare 50mL of rhodamine B dye wastewater with a concentration of 1.0mg / L, adjust the pH value to 11.0 with HCl or NaOH, add 10.0mg MIL-101(Fe) and 50mg potassium persulfate as catalyst and oxidant respectively , magnetically stirred at room temperature. After 120 minutes, the degradation rate of rhodamine B was 69.7%.

Embodiment 3

[0029] The preparation of catalyst MIL-100 (Fe): with 0.676g FeCl 3 ·6H 2 O and 0.347g of trimesic acid were dissolved in 15mL of deionized water, stirred at room temperature for 10min, mixed evenly, then packaged in a polytetrafluoroethylene-lined reactor, reacted at 160°C for 12h, and cooled to room temperature; After centrifugation, heat treatment in 50ml ethanol at 60°C for 3h, a total of two heat treatments to remove adsorbed impurities, and finally vacuum drying at 60°C for 24h. The specific surface area of the prepared catalyst MIL-100(Fe) is 2210m 2 / g, the pore size is 0.55 and 0.86nm.

[0030] Degradation of organic wastewater: Prepare 50mL of 2,4-dichlorophenol wastewater with a concentration of 10.0mg / L, adjust the pH value to 2.0 with HCl or NaOH, add 50mg MIL-100(Fe) and 125mg potassium hydrogen persulfate to compound Salt as catalyst and oxidant, magnetic stirring at room temperature. After 120 minutes, the degradation rate of 2,4-dichlorophenol was 85.3%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com