Titanium slag-based solid waste cementing material and preparation method thereof

A technology of cementitious materials and titanium slag, which is applied in the field of concrete materials to achieve low carbon emissions, good economic and social benefits, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

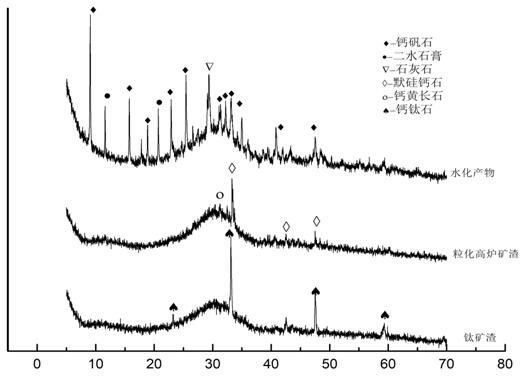

Image

Examples

Embodiment 1-12

[0044] It mainly involves a titanium slag-based solid waste cementitious material, and the raw material configuration is shown in Table 1 below.

[0045] Table 1 Raw material configuration table

[0046]

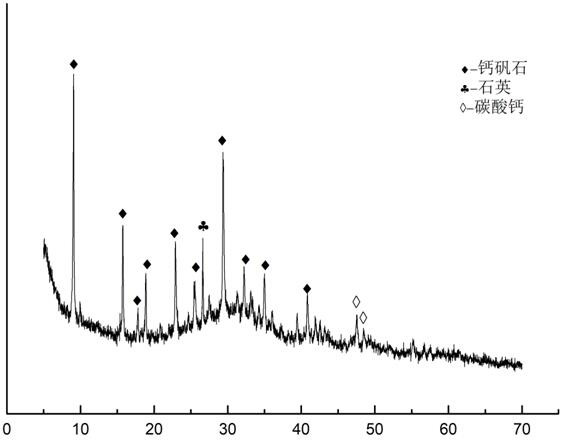

[0047] In the above raw material configuration table, granulated blast furnace slag is slag that meets the requirements of the standard GB / T 203 "Granulated Blast Furnace Slag Used in Cement"; titanium slag is obtained from blast furnace smelting pig iron and contains silicate and aluminosilicate The melt, after quenching and granulating TiO 2 Slag with a content greater than 10%; modified desulfurized gypsum and modified phosphogypsum are desulfurized gypsum and modified gypsum obtained under the conditions of burning temperature of 650-850°C and holding time greater than 20 minutes; high belite sulfur The main minerals in aluminate clinker include: C 4 A 3 、C 2 S, C 4 AF, CaSO 4 、 CT and f-CaO, the weight percentage of its mineral composition is: C 4 A 3 20-...

Embodiment 13

[0050] This embodiment mainly relates to a preparation method of titanium slag-based solid waste cementitious material, which specifically includes the following steps:

[0051]S1: First dry and grind the raw materials used for titanium slag-based materials. Considering the inconsistency of the grindability of each material, the materials used can be ground individually or mixed according to the actual situation, such as granulated blast furnace slag and titanium slag , silicomanganese slag, etc. are ground in an appropriate proportion. Fly ash and modified electrolytic manganese slag can also be mixed in an appropriate proportion before grinding, and gypsum and clinker can be mixed in an appropriate proportion before grinding. The specific surface area of the ground titanium slag-based material is required to be greater than 420m 2 / kg; Gypsum and cement clinker are ground to a specific surface area greater than 420 m 2 / kg.

[0052] S2: After the ground materials are ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com