Patents

Literature

55results about How to "Meet engineering applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

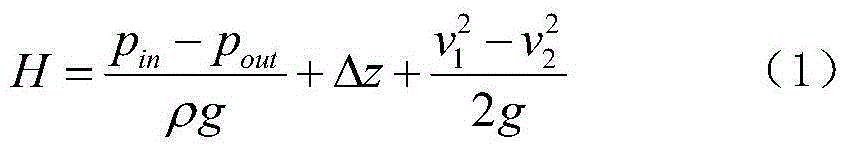

Method for hydraulically optimizing centrifugal pump under working conditions based on loss

ActiveCN101956710AMeet engineering applicationsShorten the design cycleRadial flow pumpsNon-positive displacement fluid enginesProcess engineeringMaximum efficiency

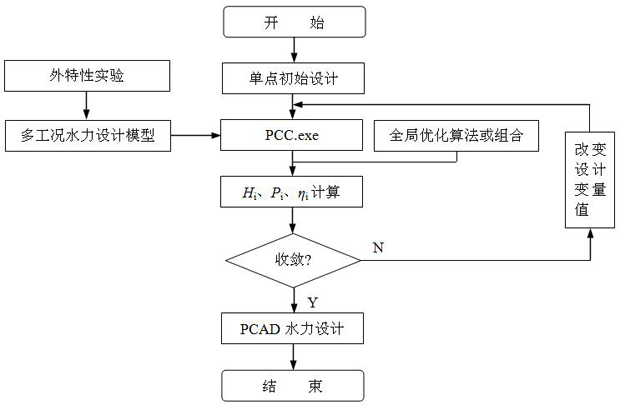

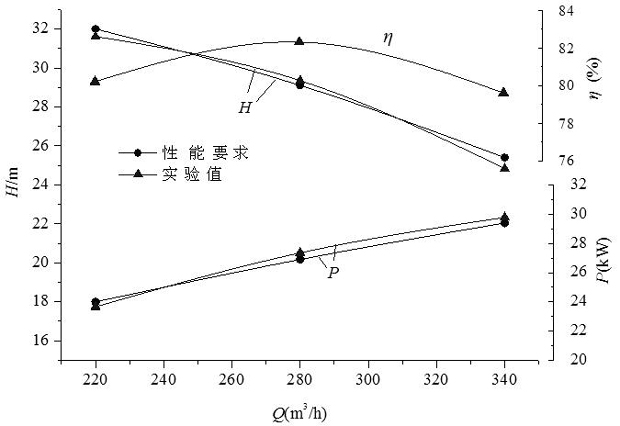

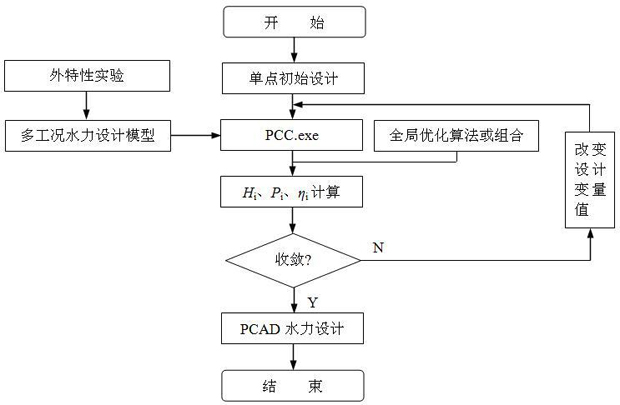

The invention discloses a method for hydraulically optimizing a centrifugal pump under a plurality of working conditions based on loss, which comprises the following steps of: establishing a multi-working condition hydraulic optimization model of the centrifugal pump based on various loss formulae; establishing relationships among various loss coefficients, specific speeds and flows of the centrifugal pump at different specific speeds under the different working conditions by external characteristic experiments; compiling multi-working condition hydraulic optimization programs PCC.exe of the centrifugal pump by adopting Visual C++; integrating the PCC.exe by adopting iSIGHT, taking parameter values of single-point design as initial values, taking heads and power under the plurality of working conditions as constraint conditions, taking maximum efficiency under the plurality of working conditions as a target, and optimizing the centrifugal pump by adopting a global optimization algorithm or combination; and designing a multi-working condition hydraulic model by adopting PCAD according to an optimal solution set obtained in the optimization. The method has the advantages of not only performing multi-working condition hydraulic design on the centrifugal pump according to performance requirements under the plurality of working conditions, but also performing energy-saving alternation on the conventional centrifugal pump.

Owner:JIANGSU UNIV

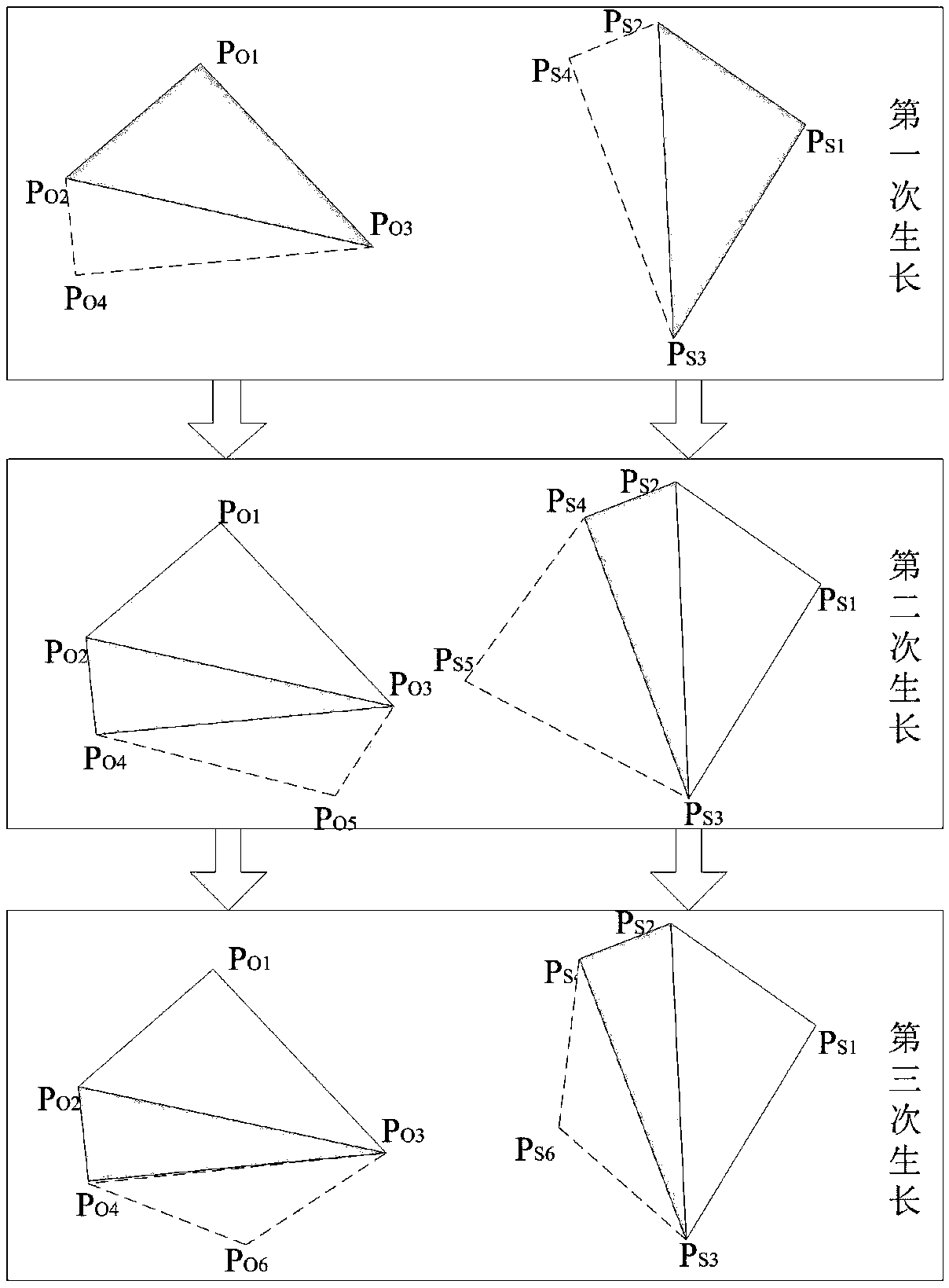

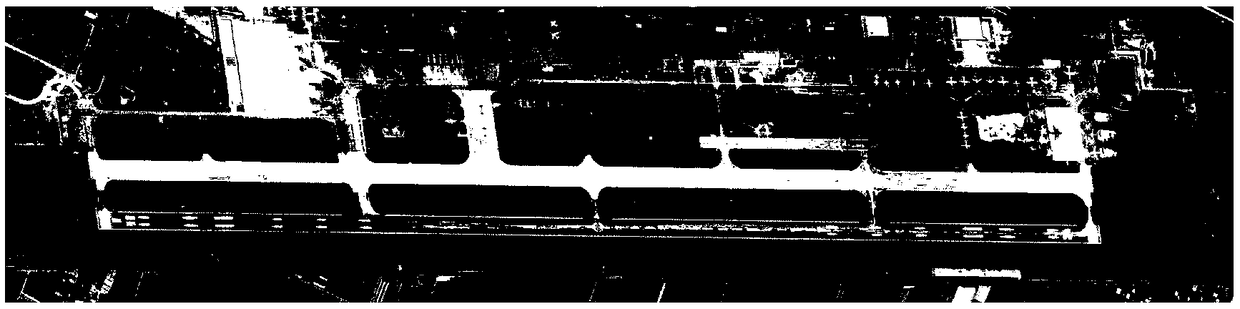

A heterogeneous image matching method based on refined feature optimization extraction

ActiveCN109409292AGuaranteed validityGuaranteed matching accuracyImage analysisScene recognitionTemplate matchingGradient operators

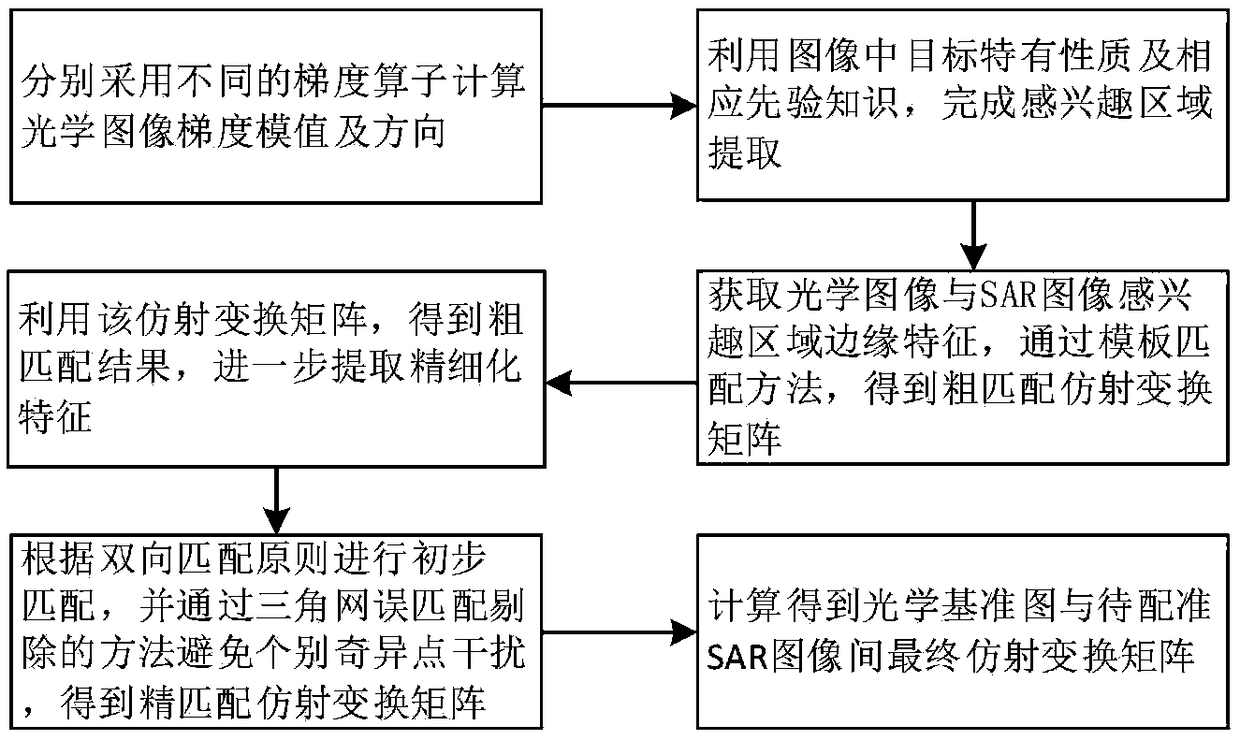

The invention discloses a different-source image matching method based on refined feature optimization extraction, which mainly solves the problem of low matching precision in the prior art, and adopts the technical scheme that 1, gradient moduli and directions of an optical image and an SAR image are calculated by adopting different gradient operators respectively; 2, completing region-of-interest calibration by utilizing the specific property of the target in the image; 3, according to the result of the step 1, obtaining edge features of the interested areas of the two images, and obtaininga coarse matching affine transformation matrix between the two images through template matching; 4, obtaining a transformed optical image by using the coarse matching affine transformation matrix, andthen extracting refined features; 5, performing preliminary matching on the refined features, and eliminating singular point interference to obtain a fine matching affine transformation matrix; and 6, obtaining a final affine transformation relation matrix between the optical image and the SAR image according to the results of the steps 3 and 5. The method can achieve the precise registration ofa heterologous image, and can be used for the guidance of an aircraft.

Owner:XIDIAN UNIV

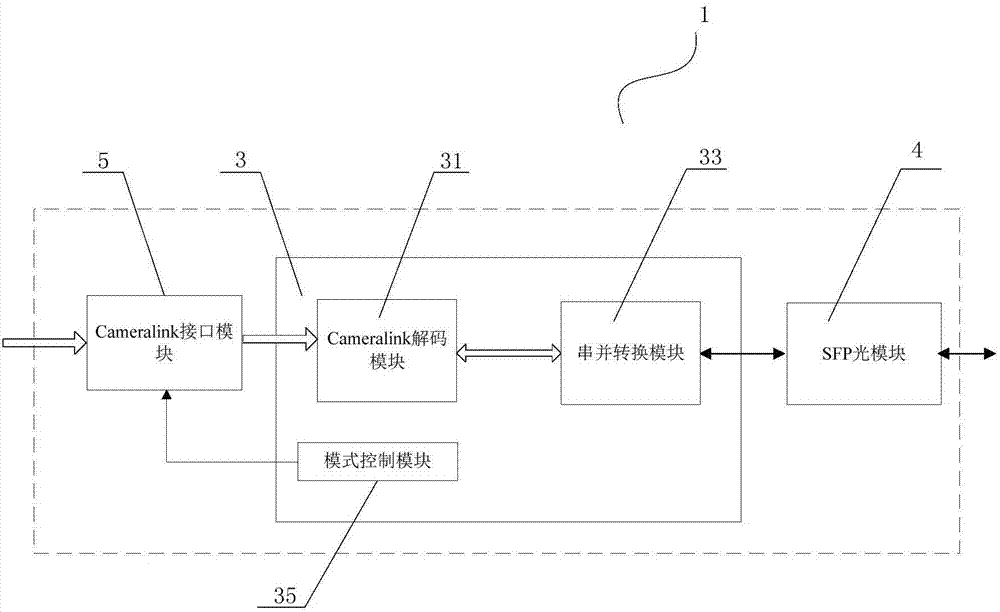

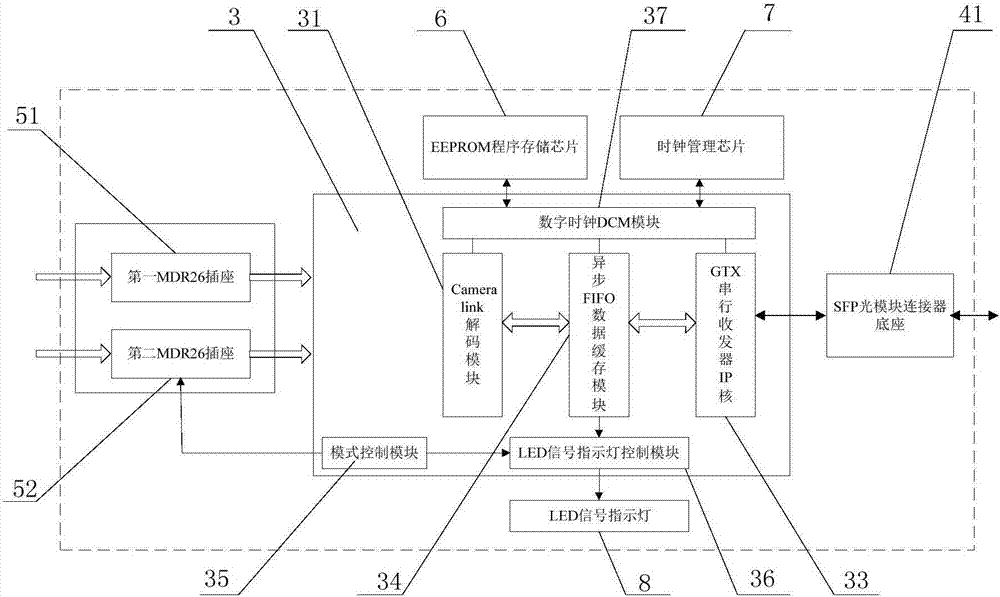

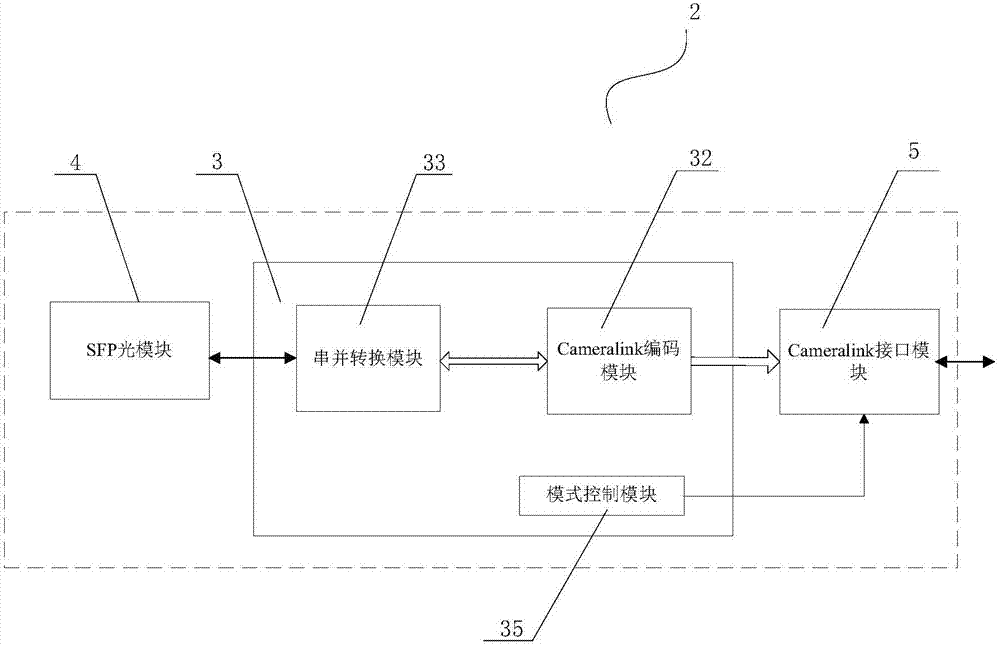

FPGA-based full-mode Cameralink digital image optical transceiver receiving terminal and transmitting terminal

ActiveCN107426551AFlexible configuration functionEasy to integrateOptical transmission adaptationsElectrical cable transmission adaptationHardware structureComputer hardware

The invention relates to the technical field of Cameralink high-speed digital image long distance transmission, and particularly discloses an FPGA-based full-mode Cameralink digital image optical transceiver transmitting terminal comprising an FPGA chip, a Cameralink interface module and an SFP optical module. The FPGA chip comprises a series-to-parallel signal conversion module, a Cameralink decoding module and a mode control module. The Cameralink interface module receives a Cameralink signal and transmits the Cameralink signal to the Cameralink decoding module. The Cameralink decoding module decodes serial data and transmits the decoded serial data to the series-to-parallel signal conversion module. The series-to-parallel signal conversion module performs series-to-parallel conversion on the received digital image signal so as to form the serial data stream. The SFP optical module receives the serial data stream and converts the serial data stream into an optical fiber signal. The mode control module controls the work mode of the transmitting terminal. Correspondingly, the invention also discloses an FPGA-based full-mode Cameralink digital image optical transceiver receiving terminal. FPGA chip software setting is utilized to replace the conventional coding and decoding chip so that the transmitting terminal and the receiving terminal of the optical transceiver are enabled to be identical in hardware structure, and the beneficial effect of increasing system integration can be achieved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

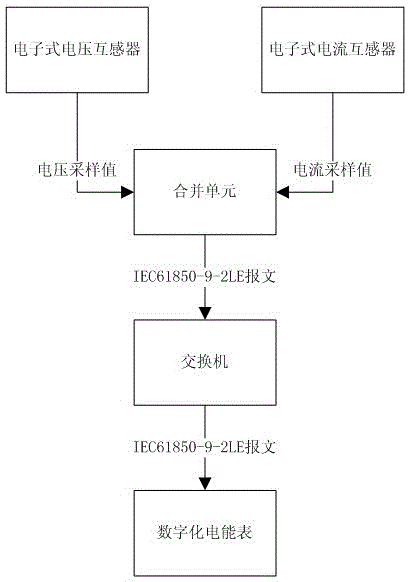

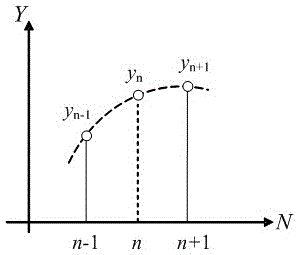

Correction method for digital quantity input electric energy information sampling data loss

ActiveCN103424733AThe effect of interpolation is smallSave data storage spaceNon-electrical signal transmission systemsElectrical measurementsPower gridCurve fitting

The invention discloses a correction method for digital quantity input electric energy information sampling data loss. The method is an interpolation method based on a sine curve and comprises the steps of: judging the serial number of sampling points in electric energy information sampling data and capturing sampling points with frame loss; recording the latest sampling point value as a sample value used for interpolation; when the number of the sampling points of a cyclic wave is 80, processing the sample value by adopting a median interpolation way once information of a sampling point is lost; when the number of the sampling points of a cyclic wave is 256, processing the sample value by adopting a recursive extrapolation way and calculating a target sampling point value which needs to be supplemented once the information of 8 sampling points is lost. As a fundamental wave of a power grid is a sine curve, the interval of the sampling points is fixed, the number of the sampling points of the cyclic wave is known, interpolation can be carried out by adopting a sine curve fitting way, and high reliability is achieved. The calculation amount and the needed data storage space of the method are small, so that the specific engineering application can be satisfied well.

Owner:JIANGSU LINYANG ENERGY CO LTD

Angle-variable fan

PendingCN105971712AImprove efficiencySpeed up heat dissipationCoolant flow controlMachines/enginesEngineeringElectromagnetic valve

The invention discloses an angle-variable fan. An electromagnetic valve is used for controlling oil pressure to achieve control over parallelism and non-parallelism of blade angles. The problem of changing airflow intensity is solved at low cost, and therefore the effect of changing the airflow direction is achieved by means of positive and negative angle adjustment of non-parallel angles, and the purposes of automatically cleaning a water tank and improving the heat dissipation efficiency are achieved. Compared with the prior art, the angle-variable fan is simple in structure, low in cost and capable of meeting requirements of engineering application.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

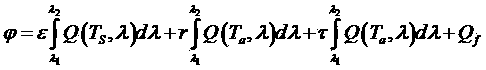

Method for measuring material surface emissivity by virtue of thermal infrared imager rapidly

ActiveCN103675019ADetection speedMeet engineering applicationsMaterial heat developmentEmissivityFast measurement

The invention discloses a method for measuring the material surface emissivity by a thermal infrared imager rapidly, and relates to the technical field of thermal infrared imaging temperature measurement. A thermal infrared imager, a black box and a heating platform are included. The method comprises the following testing steps: 1) acquiring the response of the black box by the thermal infrared imager under a temperature environment, wherein the process is enough once under the condition of invariable environment temperature, and storing data into a computer for preservation; 2) heating a measured objected to relatively high temperature greater than or equal to 70 DEG C generally, and acquiring the response of the measured object by the thermal infrared imager; 3) operating according to a formula, thereby obtaining an accurate emissivity measurement result. Regarding to the thermal infrared imager, according to the measurement method, only an auxiliary device is required to be added for the thermal infrared imager; the emissivity of complex material surfaces can be measured rapidly; the detection speed and the detection efficiency of emissivity of the thermal infrared imager are improved; meanwhile, the precision and reliability of the detection result are ensured; the using range of the thermal infrared imager is expanded.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

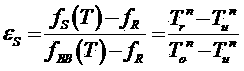

Integrated steam generator of reactor

ActiveCN103177783APromote engineering applicationLower the altitudeNuclear energy generationNuclear power plant detailsWater storageEngineering

The invention provides an integrated steam generator of a reactor. The integrated steam generator is characterized in that a tube bundle sleeve which is of an omega-shaped structure is arranged on an inner-wall barrel and an outer-wall barrel of the integrated steam generator, and heat transfer tube bundles are arranged between the tube bundle sleeve and the inner-wall barrel; the tube bundle sleeve comprises an outer sleeve of the tube bundle sleeve and an inner sleeve of the tube bundle sleeve, and the top of the inner sleeve of the tube bundle sleeve is hermetically connected with the top of the outer sleeve of the tube bundle sleeve; a steam connecting tube is arranged on a lower section of the outer-wall barrel, and a water supply connecting tube is arranged on an upper section of the outer-wall barrel and extends to the outer sleeve of the tube bundle sleeve; and the bottom of the outer sleeve of the tube bundle sleeve and the outer-wall barrel are connected with each other to form a connected section, and the connected section is positioned below the steam connecting tube. The integrated steam generator with the structure has the advantages that heat expansion among the tube bundles and the outer-wall barrel is balanced, and the water supply connecting tube is positioned at a high location, and accordingly is high in water storage capacity and accident mitigation capacity when broken; and water and steam are physically isolated from each other owing to the tube bundle sleeve structure, and water supply distribution space and steam buffer space are provided.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

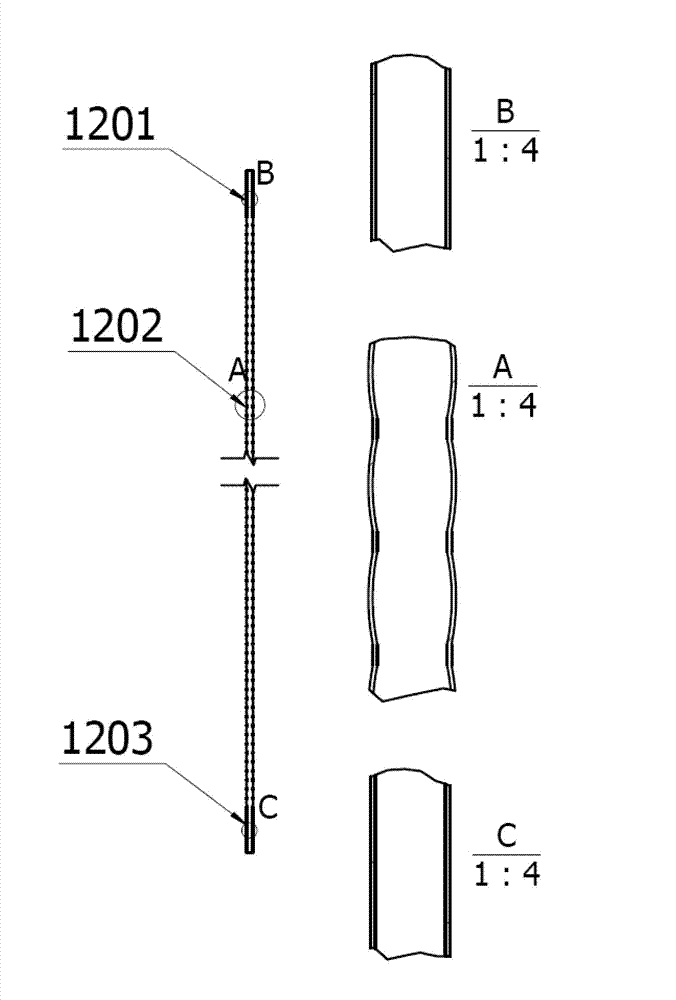

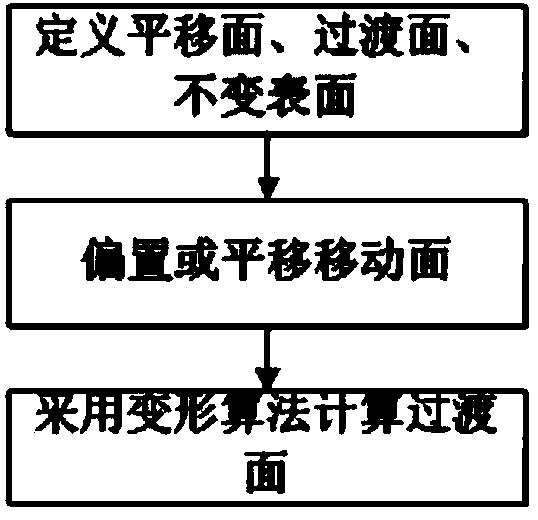

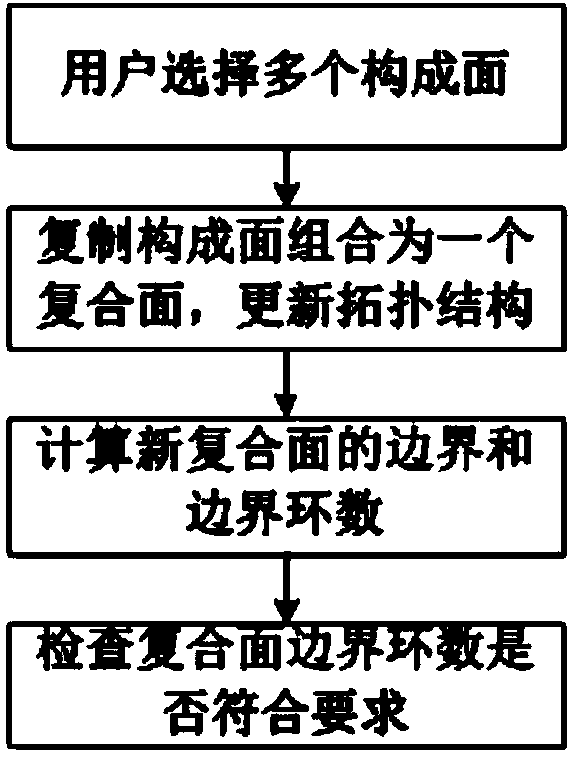

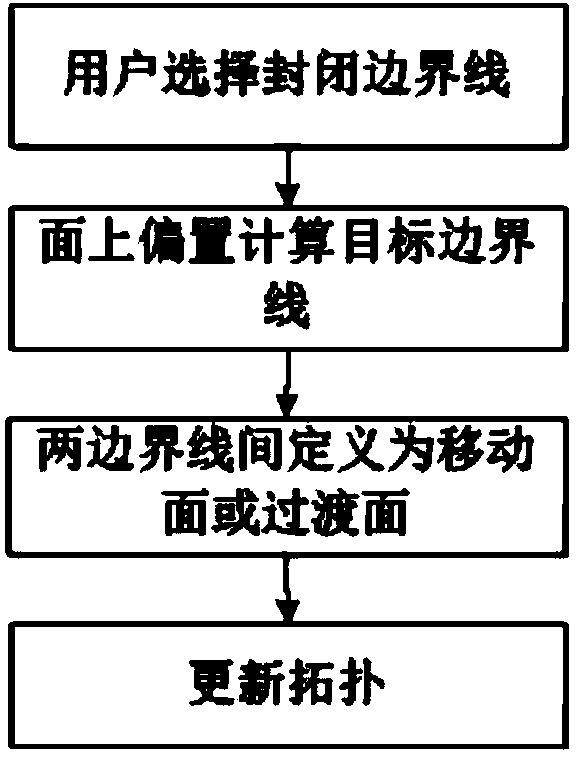

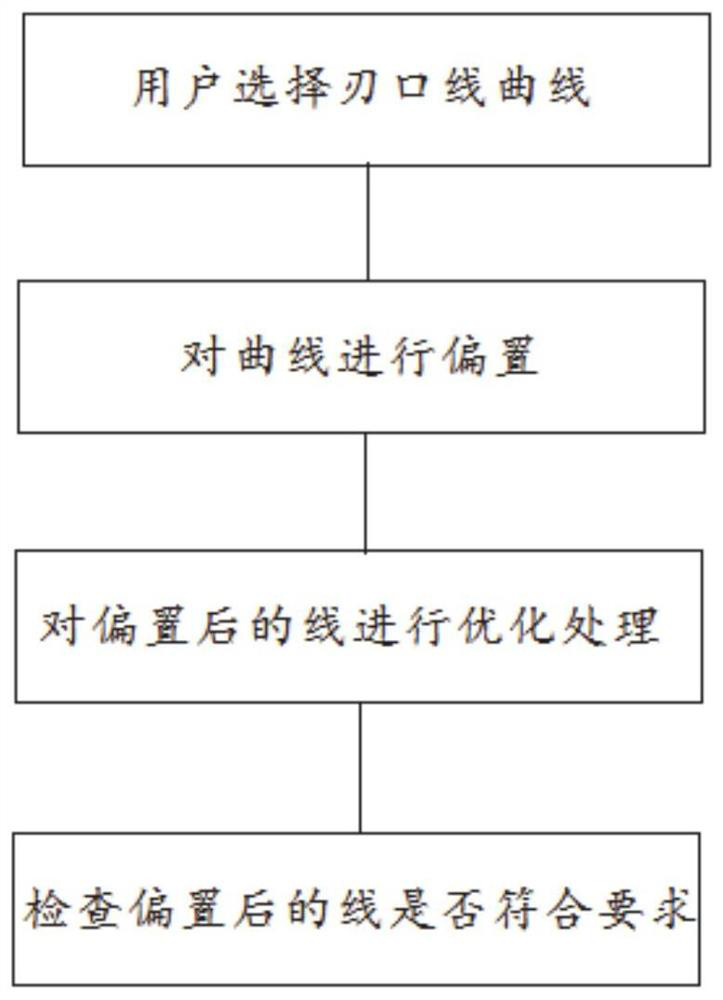

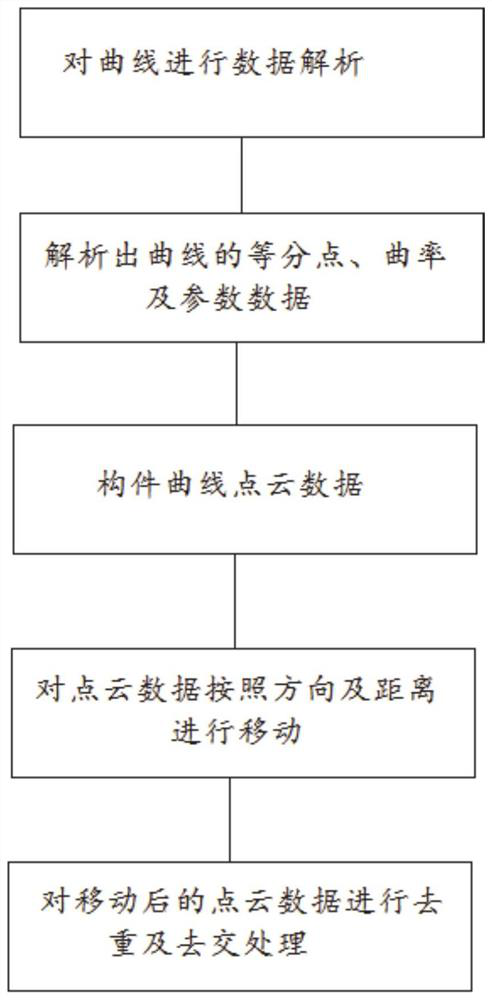

Gap design method used for automobile covering part die

ActiveCN104200054AMeet engineering applicationsImprove applicabilitySpecial data processing applications3D modellingReduction treatmentEngineering

Owner:山东山大华天软件有限公司

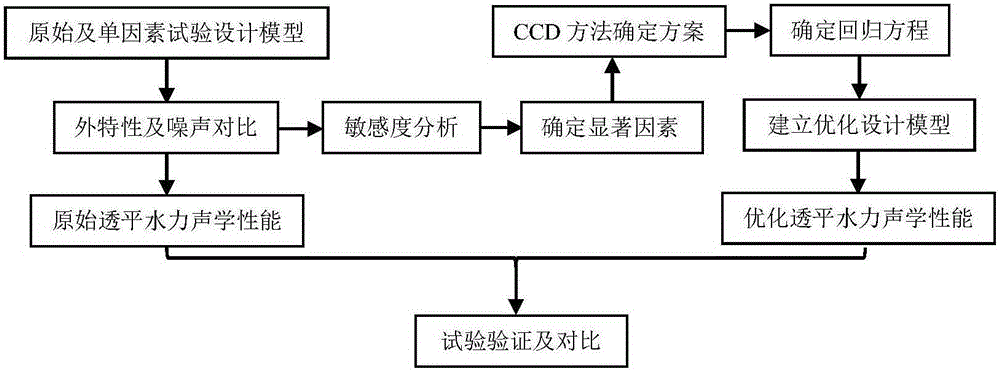

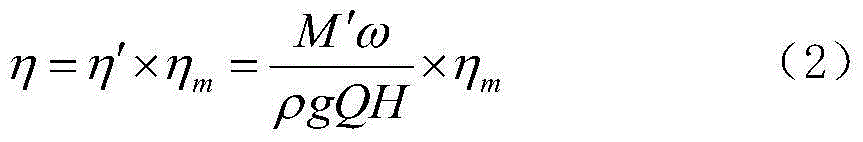

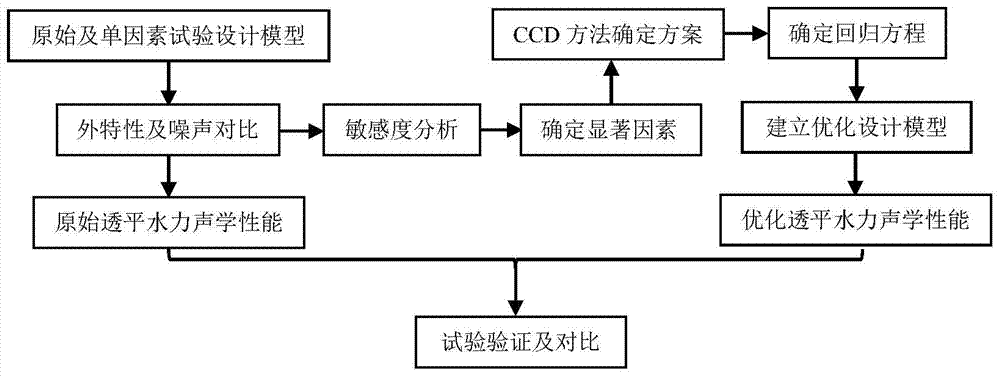

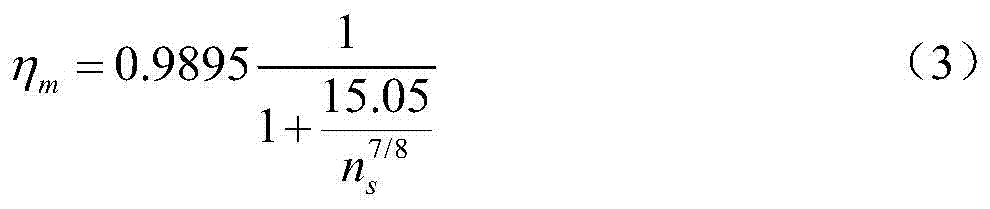

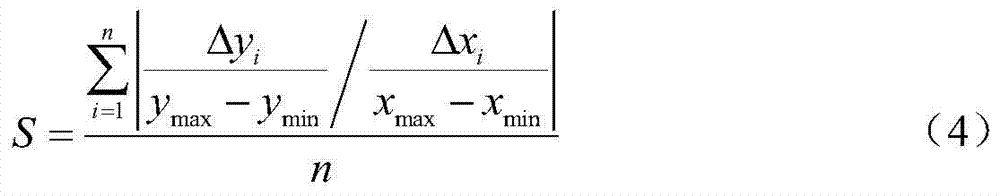

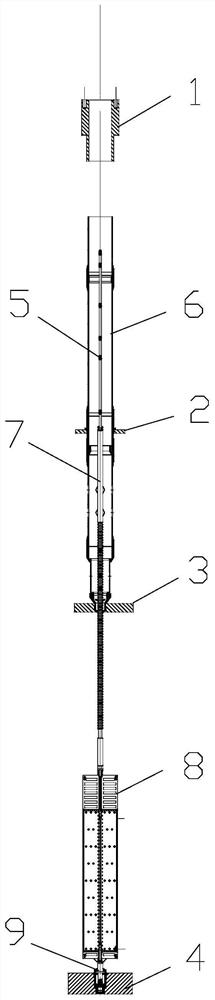

Multiple-target optimization method for hydraulic performance and outer field flow-induced noise for centrifugal pump as turbine

ActiveCN105201729AMeet engineering applicationsShorten the design cycleHydro energy generationReaction enginesCouplingEngineering

The invention belongs to the technical field of design for a centrifugal pump as a turbine and discloses a multiple-target optimization method for hydraulic performance and outer field flow-induced noise for the centrifugal pump as the turbine. The method comprises the following steps: step I, defining a determination method for a multiple-target optimization design variable value range for the centrifugal pump as the turbine; step II: through external characteristic experiment, building a computing method for mechanical efficiency required in CFD numerical calculation for the centrifugal pump as the turbine, so as to accurately calculate the efficiency of the centrifugal pump as the turbine; for different characteristics of the inner and outer media for the centrifugal pump as the turbine, adopting an FEM / AML sound-vibration coupling method for solving outer field flow-induced noise; step III: building sensitivity analysis models of different geometrical parameters for the efficiency of the centrifugal pump as the turbine and the outer field total noise power level; step IV: on the basis of a response surface method, carrying out multiple-target optimization on the hydraulic performance and outer field flow-induced noise. By adopting the method, the design efficiency is improved, the design period for the centrifugal pump as the turbine is shortened, the efficiency of the centrifugal pump as the turbine can be effectively improved and meanwhile, the noise of the centrifugal pump as the turbine can be reduced.

Owner:JIANGSU UNIV

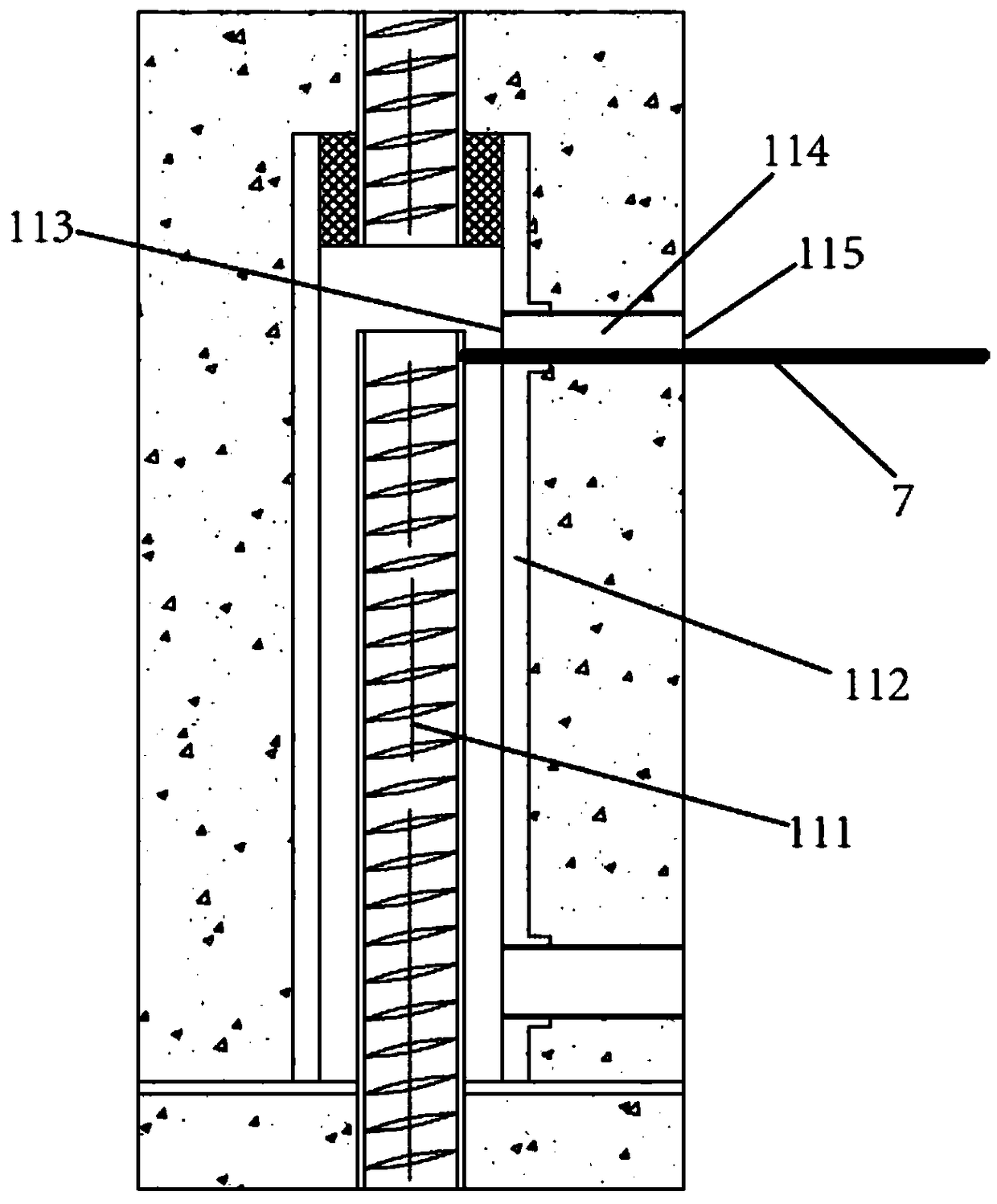

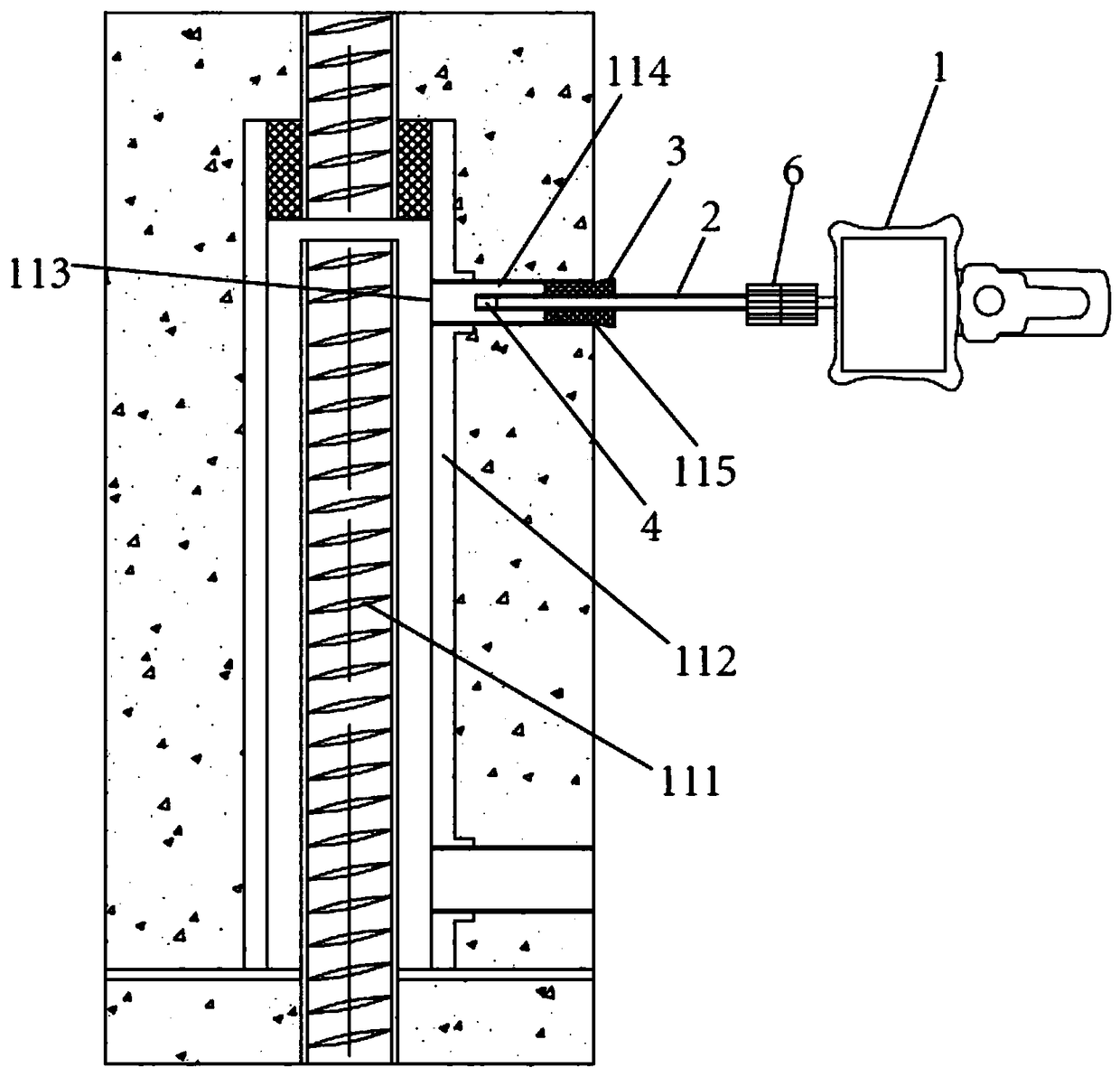

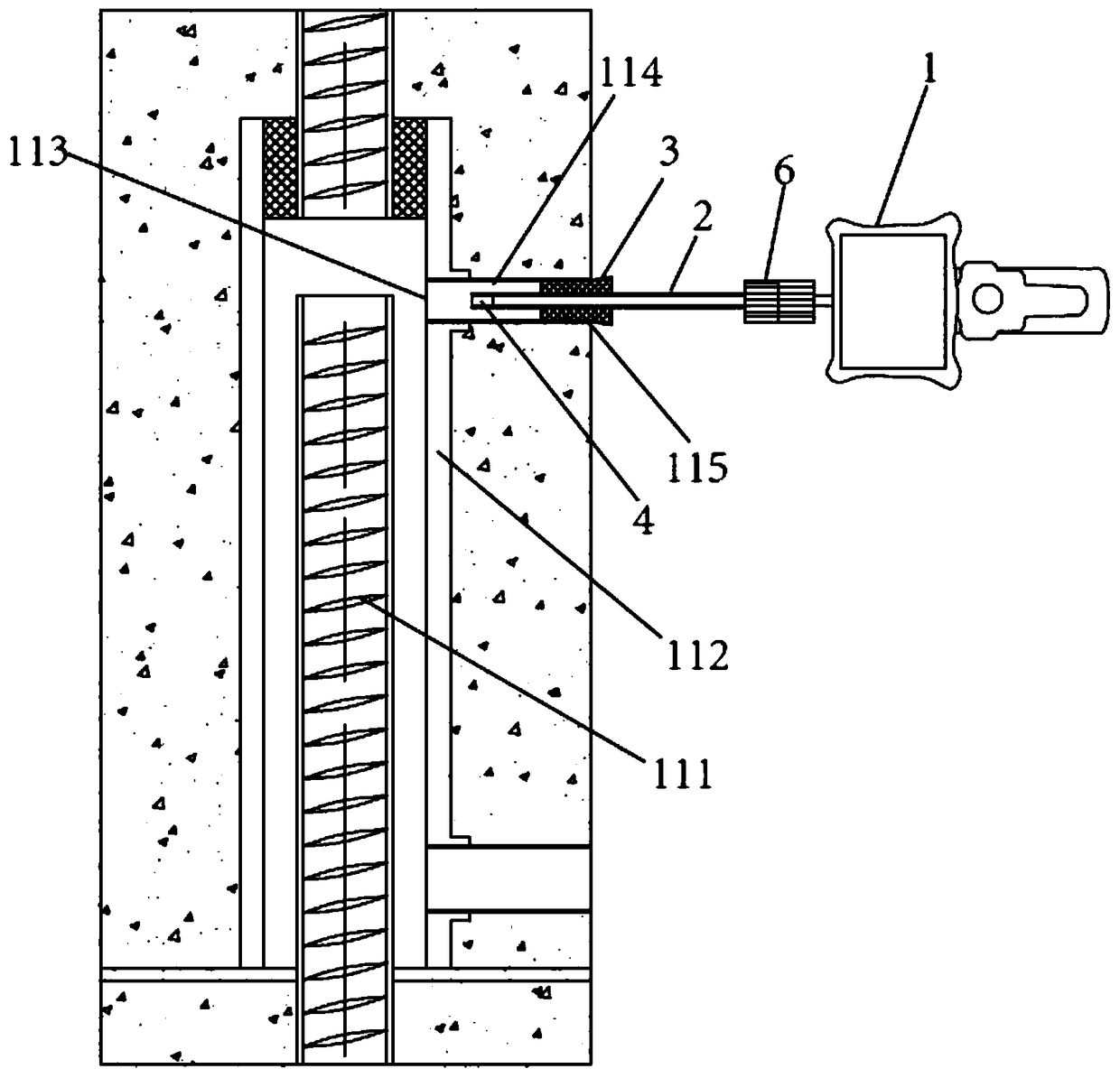

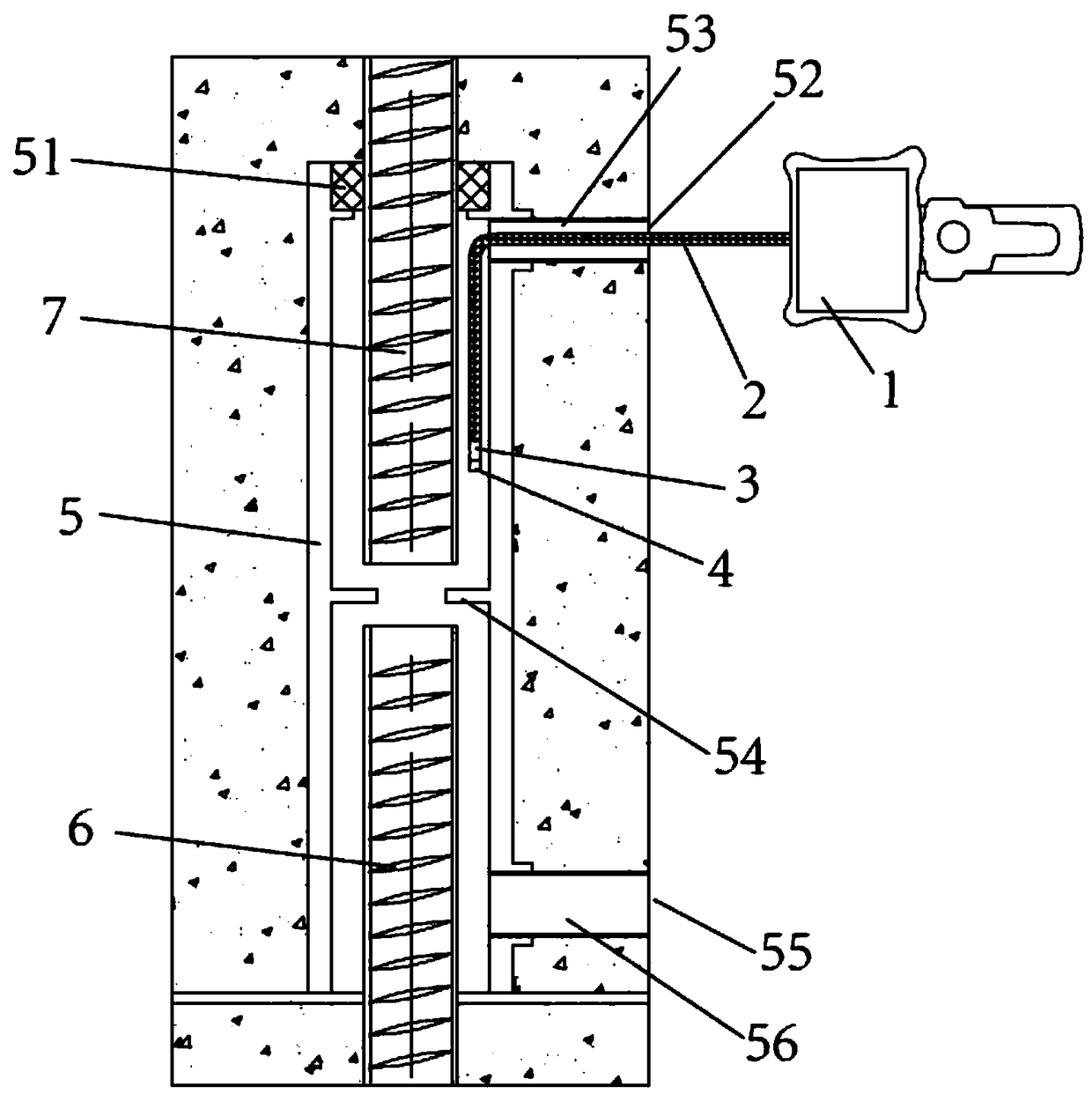

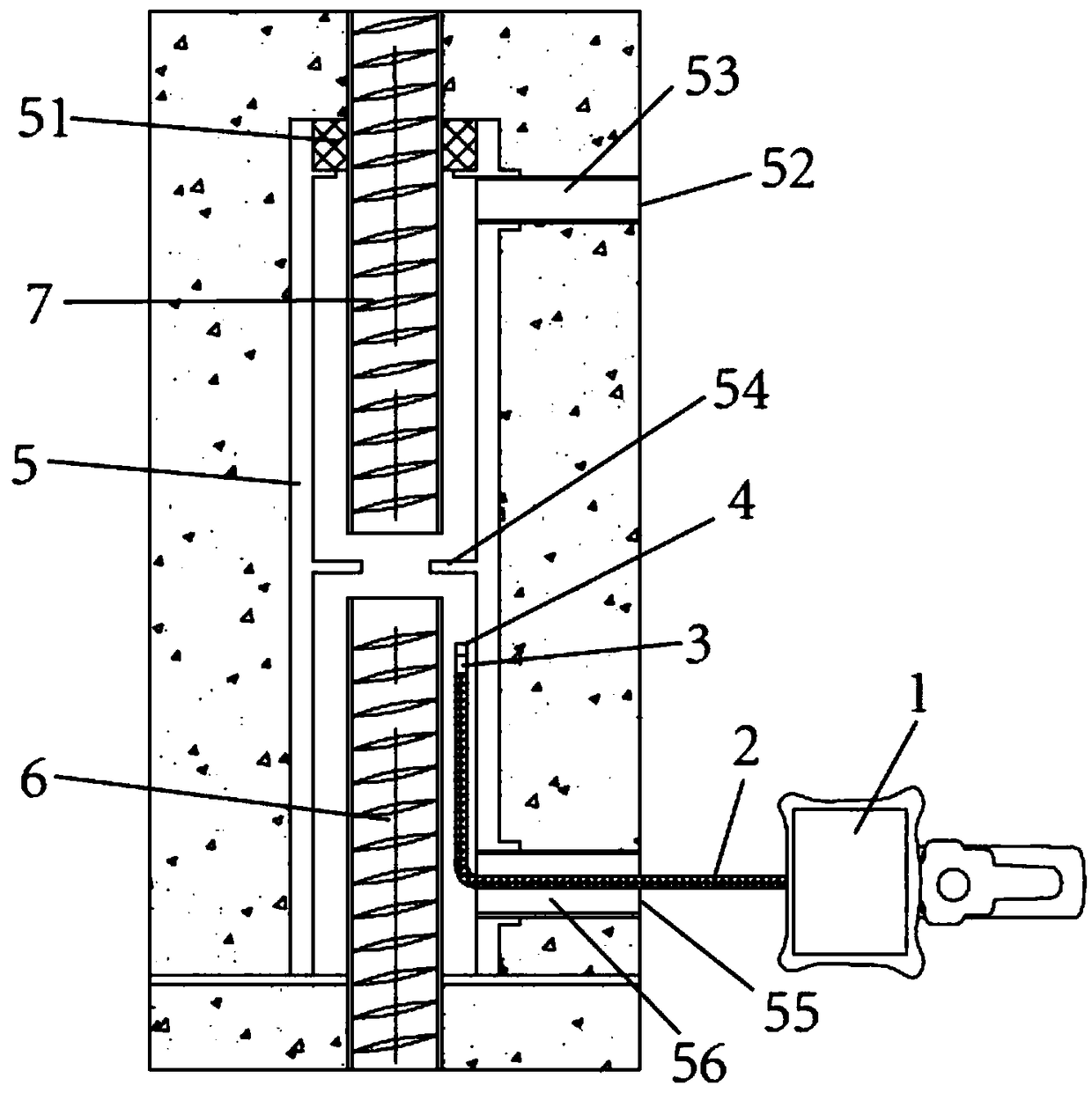

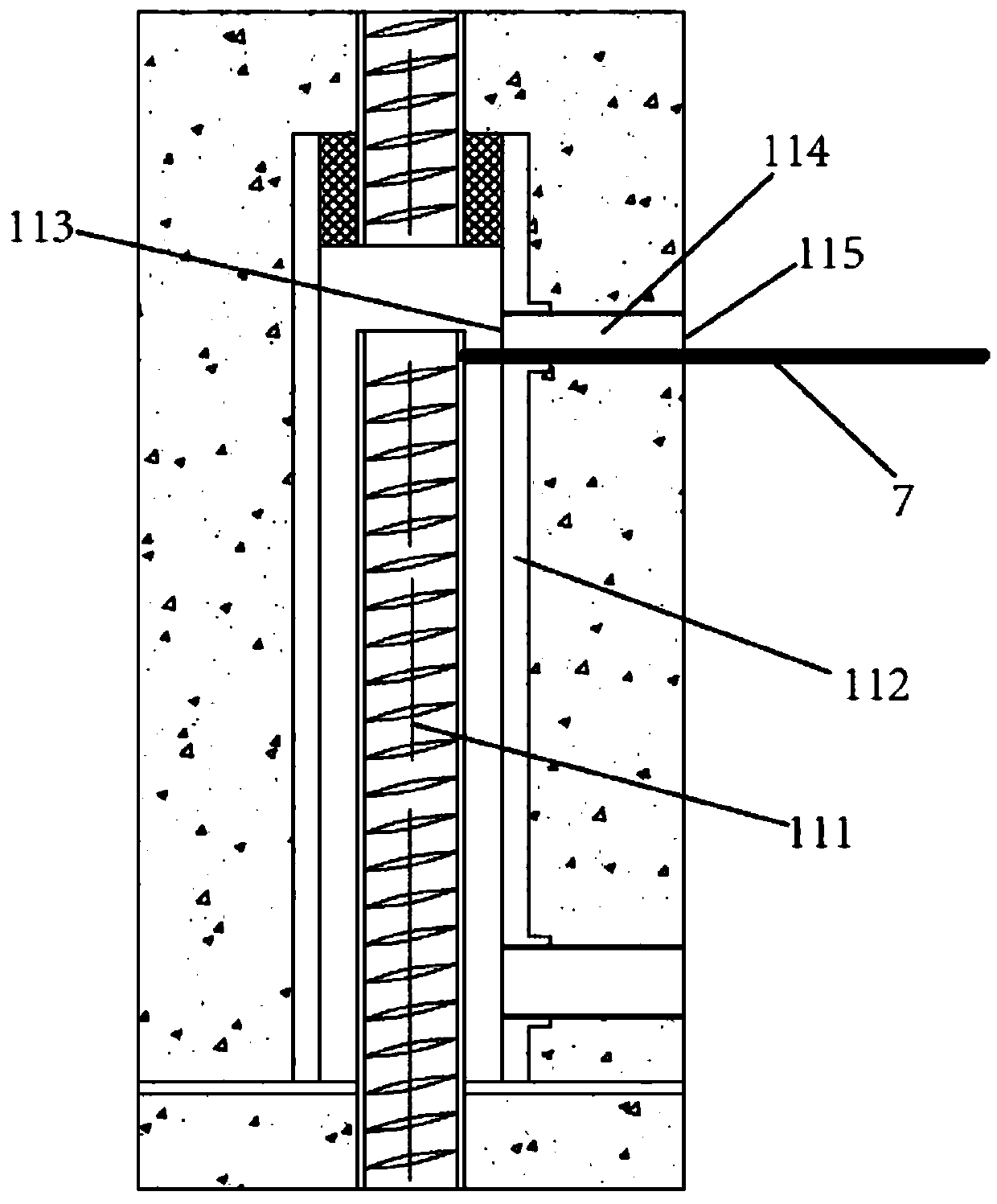

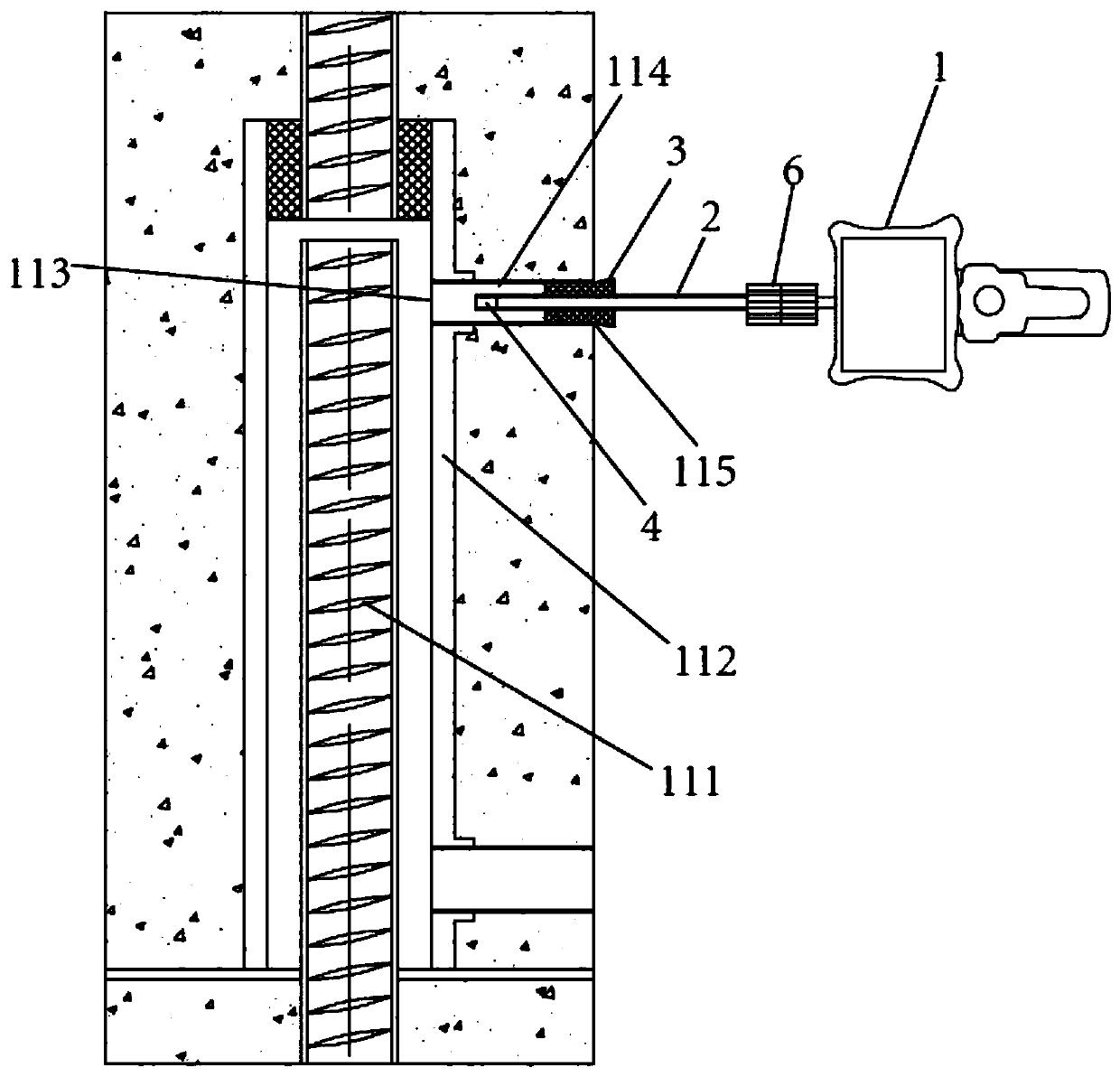

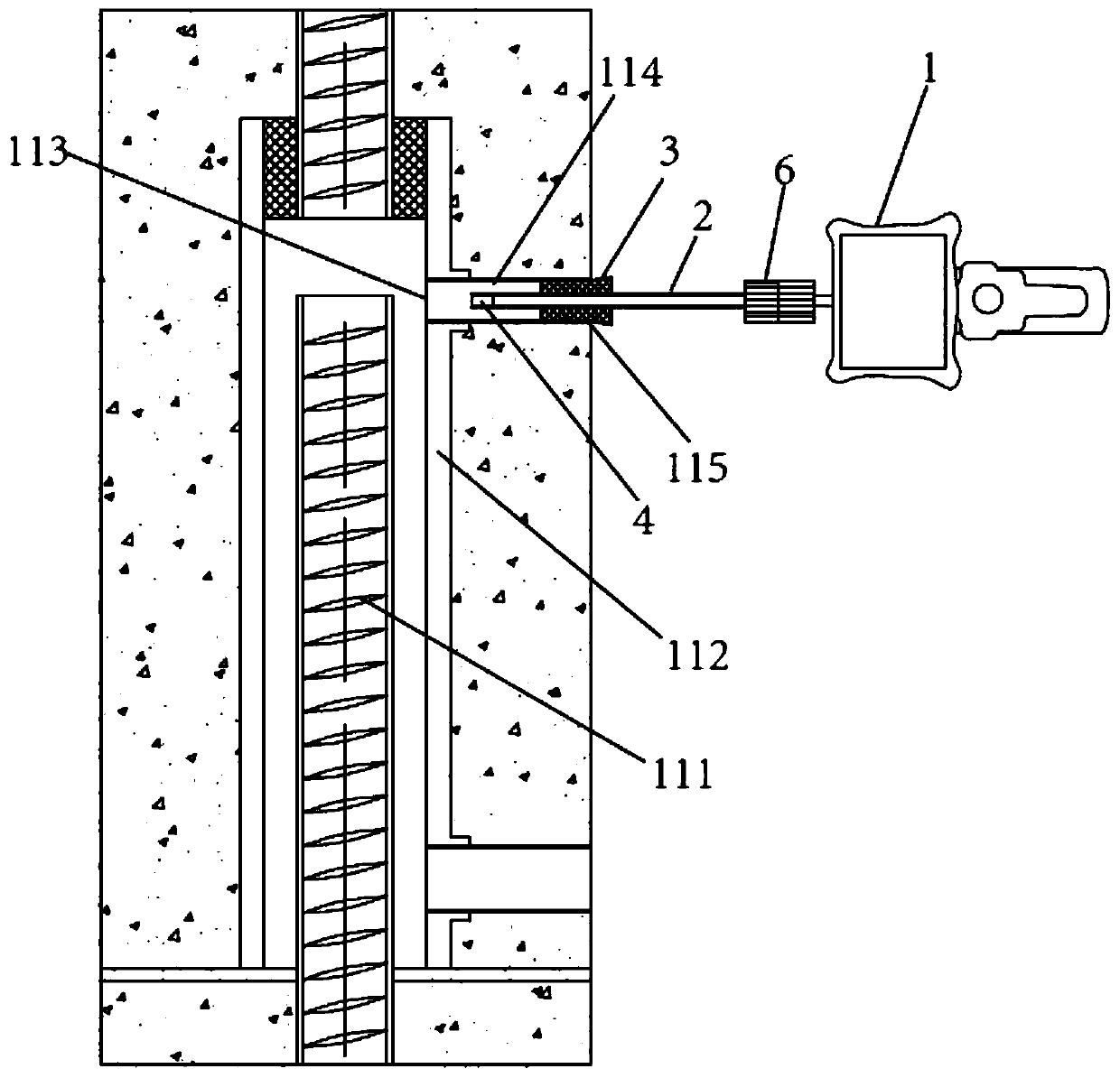

Method for detecting insertion depth of connecting steel bar in semi-grouting sleeve steel bar joint

ActiveCN109141274AShorten the measuring distanceMeet engineering applicationsUsing optical meansInsertion depthThree dimensional measurement

The invention discloses a method for detecting the insertion depth of a connecting steel bar in a semi-grouting sleeve steel bar joint. A three-dimensional measurement endoscope, a rigid sleeve pipe and a rubber plug. The three-dimensional measurement endoscope comprises an endoscope host, a connection hose, a probe and lenses connected in sequence, and the lenses comprise a front-view three-dimensional measuring lens and a side-view three-dimensional measuring lens. A central hole is arranged in the middle of the rubber plug, and the rigid sleeve can be inserted into the rubber plug through the central hole. The relative position of an end of an inserted section of the connecting steel bar and the bottom of a sleeve grout discharging port is judged by using an auxiliary tool. When a judgment result is that the end of the inserted section of the connecting steel bar is above the bottom of the sleeve grout discharging port, the front-view three-dimensional measuring lens is used to measure and calculate to obtain a result, and when the judgment result is that the end of the inserted section of the connecting steel bar is under the bottom of the sleeve grout discharging port, the side-view three-dimensional measuring lens is used to measure and calculate to obtain a result. According to the method, the insertion depth of the steel bar can be intuitively, clearly and quantitatively obtained, and the detection efficiency is improved.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

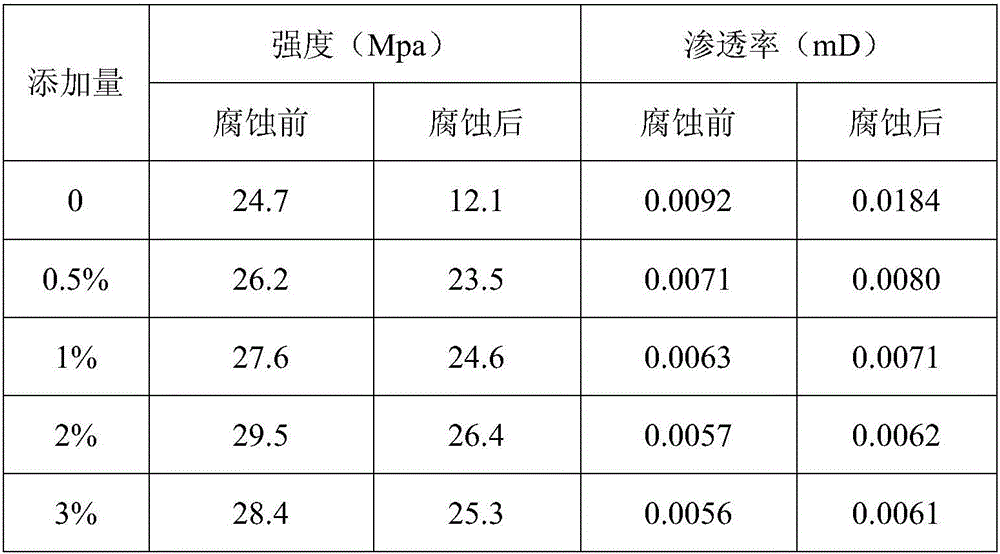

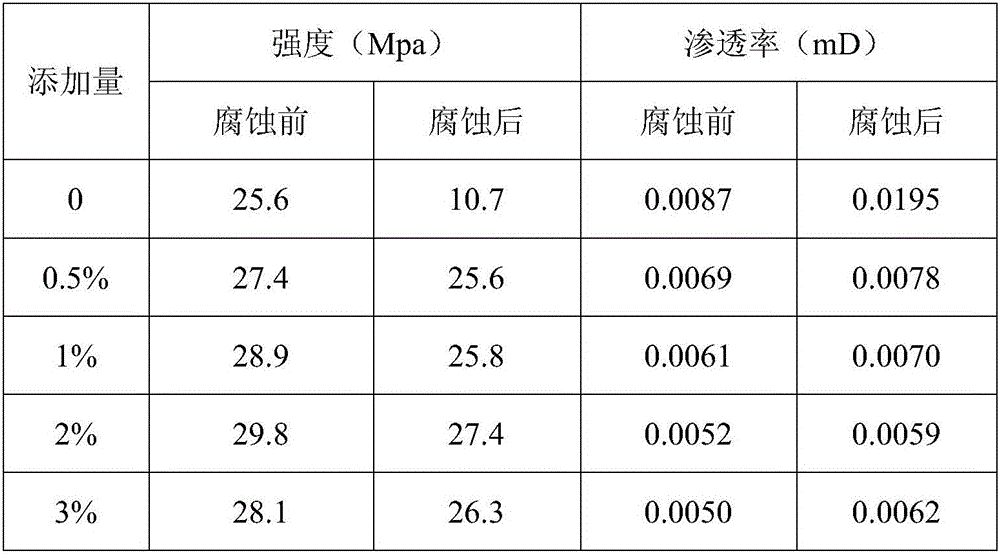

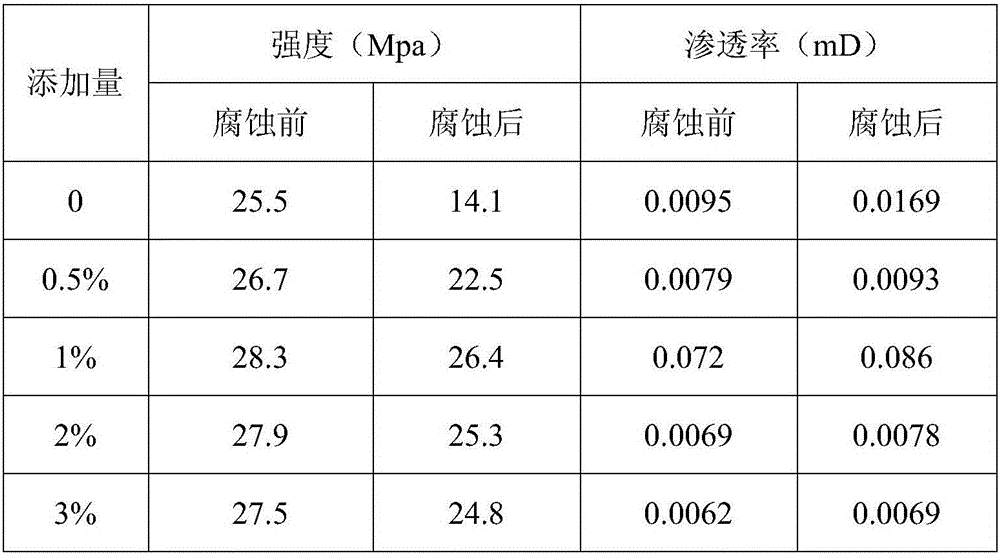

Composite cement additive

The invention discloses a composite cement additive. The cement additive is prepared by mixing, by weight, 16-22 parts of calcium hydroxide, 10-16 parts of isopropanol, 8-12 parts of zinc chloride, 2-8 parts of 2-methyl-dodecane-5-one, 4-10 parts of dodecyl dimethyl betaine, 2-6 parts of lignosulfonate, 1-5 parts of alkyl succinimide, 6-10 parts of acetophenone, 2-8 parts of ammonium sulfate, 4-10 parts of tetrabutylammonium borohydride, 5-9 parts of palmitic acid and 6-12 parts of stigmastenol. The prepared cement additive can increase cement yield and enhance cement strength, has small influences on early-stage compressive strength of cement, can meet engineering requirements, can improve cement mechanical properties and a pore structure, improves anti-freezing and grinding assisting performance of the cement, reduces permeability of the cement, adjusts cement setting time, increases concrete compactness, and achieves the functions of energy conservation and environmental protection. Compared with additives sold in the market, the cement additive is remarkable in performance improvement and has wide market popularization prospects.

Owner:绍兴鼎峰水泥有限公司

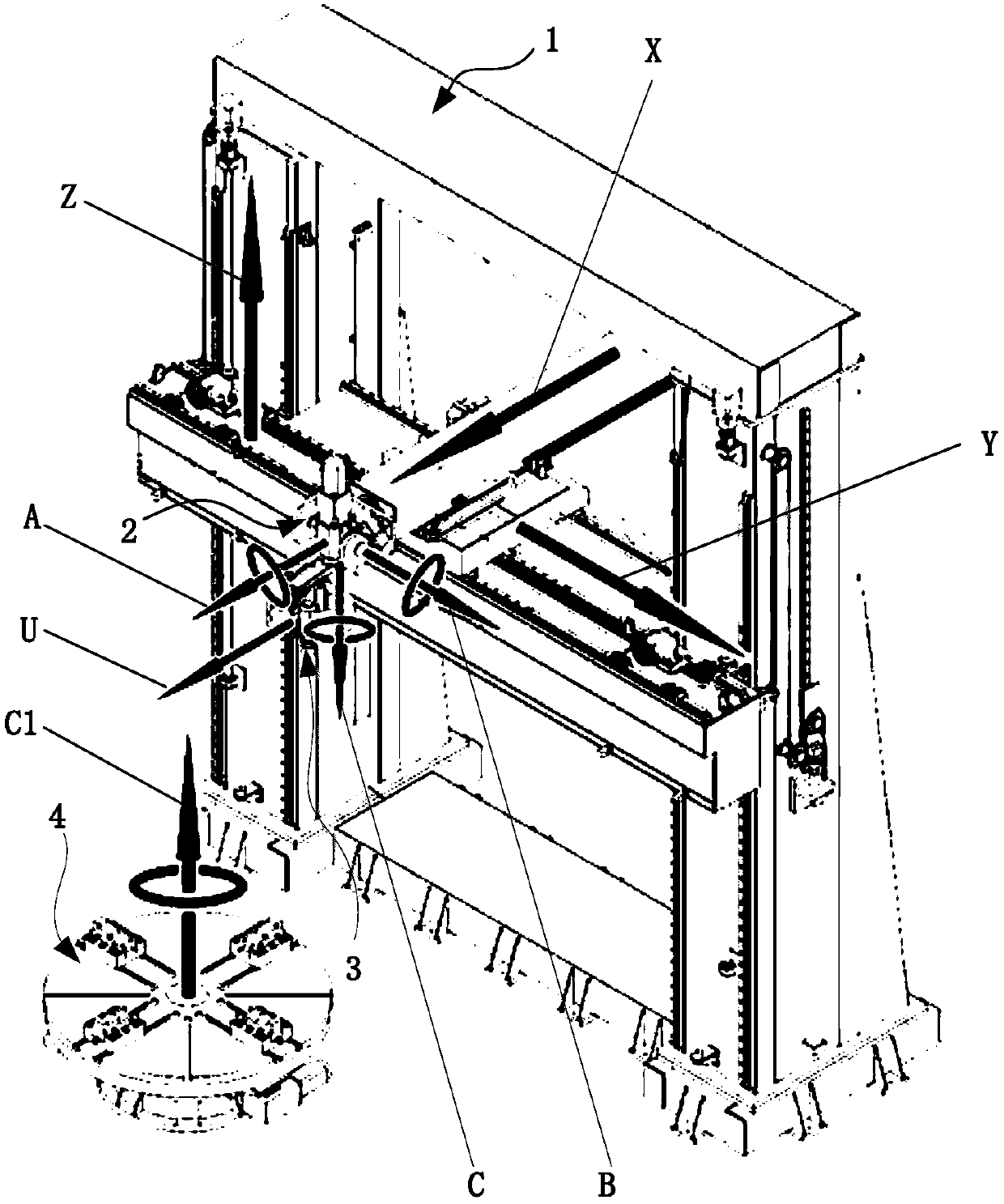

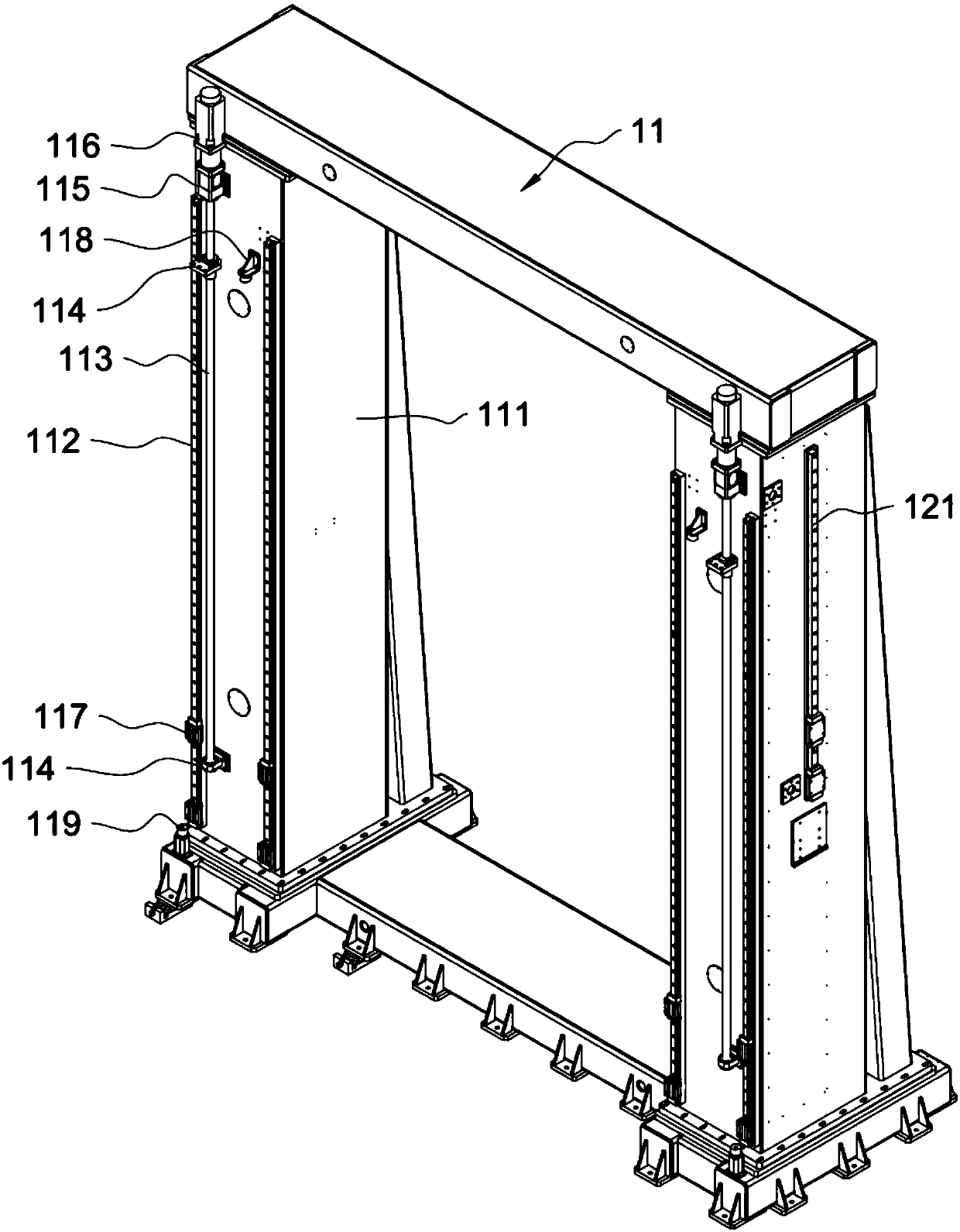

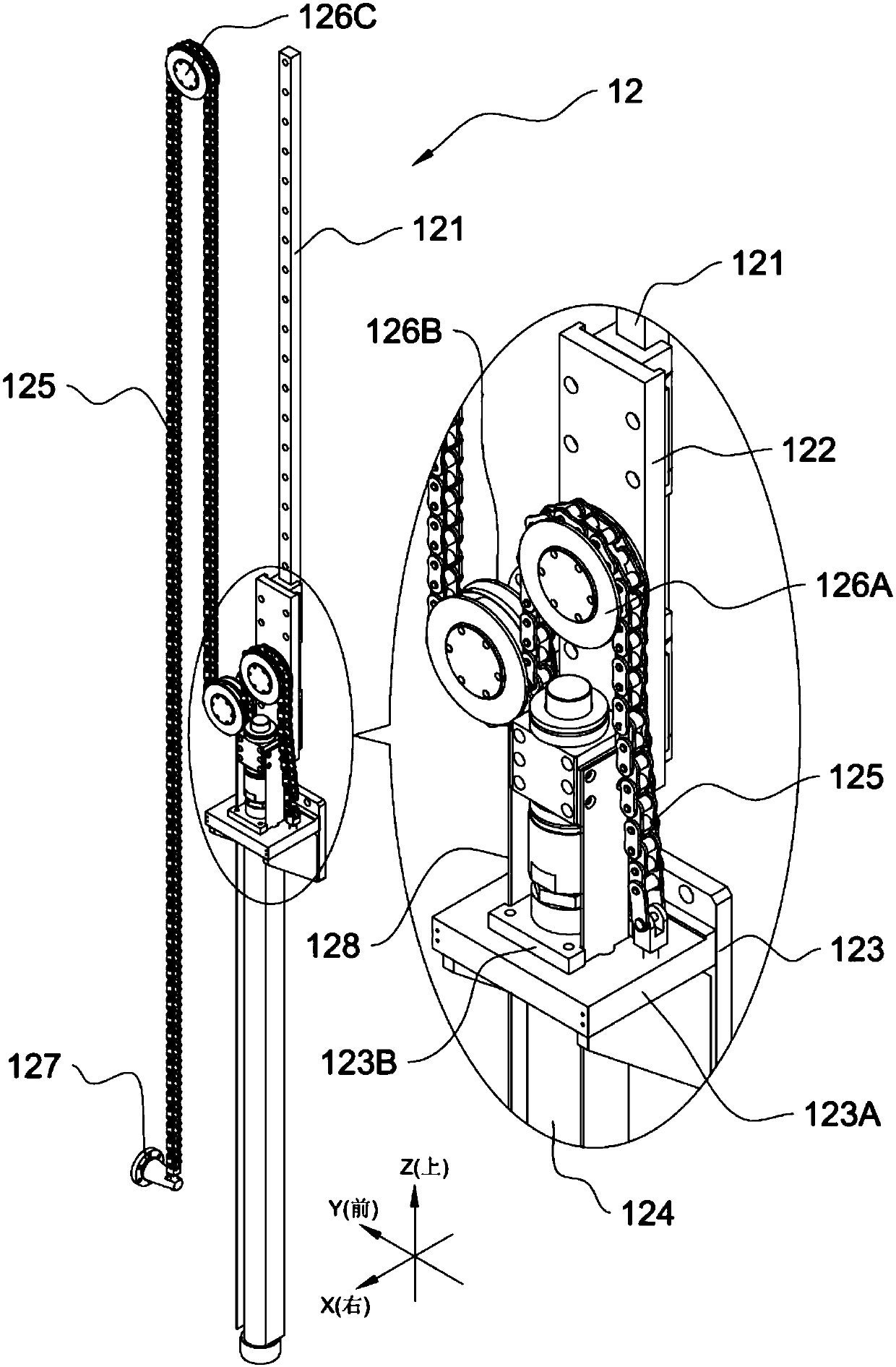

Large-scale seven-shaft linkage numerical control laying and winding integrated forming equipment

The invention belongs to the field of machine design and manufacturing-high grade numerical control machine tool and basic manufacturing equipment, and relates to large-scale seven-shaft linkage numerical control laying and winding integrated forming equipment. A main machine which is formed by three linear shafts and one rotating working table rotating shaft, and a laying and winding head which is driven by three rotating shafts are adopted to composite three translation movement and four rotation movement to achieve laying and winding head spatial motion track control and workpiece rotation.A conveying belt u shaft is adopted to drive winding and rewinding of a cloth belt and speed adjustment to achieve eight-shaft control seven-shaft linkage laying, and therefore automatic forming of acomposite material skin structure with all kinds of spacial special-shaped hook surfaces is achieved. The spatial motion track of the laying winding head can be directly controlled, even a workpiecewith the special-shaped hook surface can be accurately attached to the surface of the laying winding head for laying and winding, and therefore forming operation of material cutting after solidifyingand forming can be reduced and even avoided. Pollution is reduced, the cost is saved, and efficiency is improved. The automatic tow placing technology provides an equipment platform suitable for engineering application research and manufacture.

Owner:HUAZHONG UNIV OF SCI & TECH +4

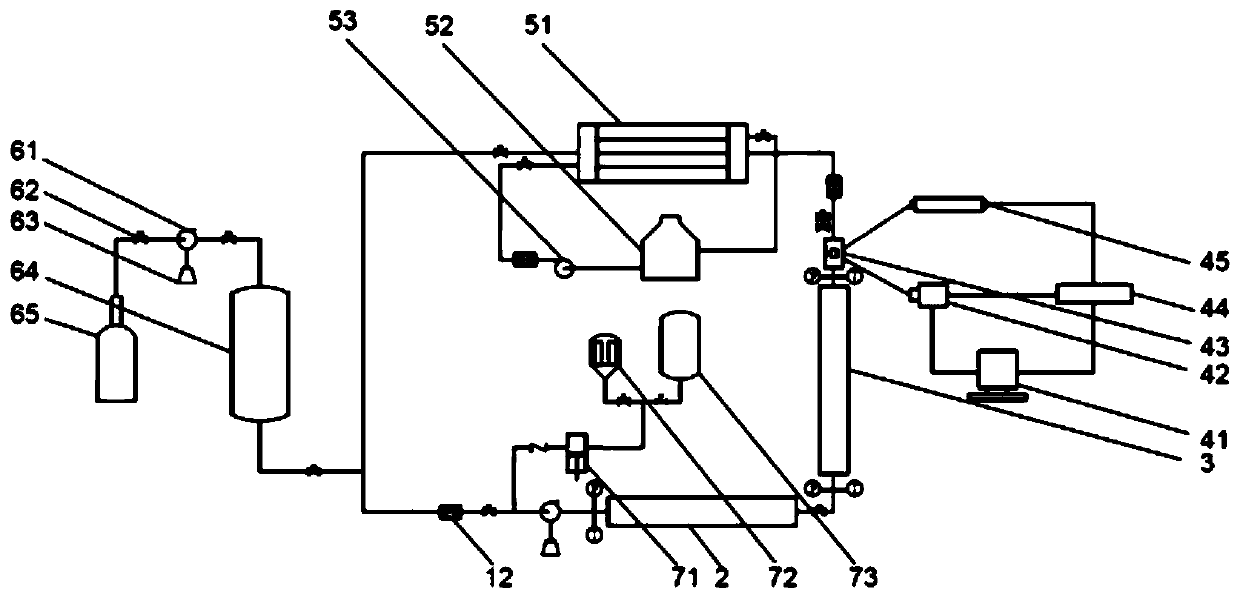

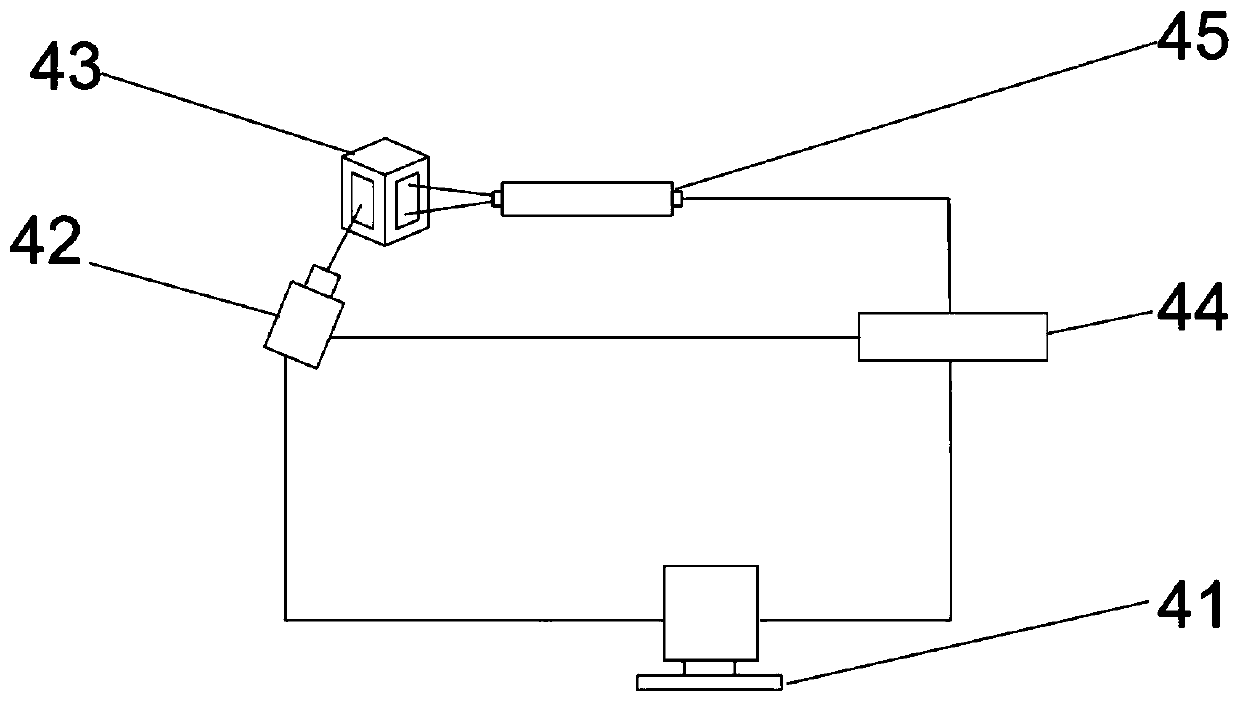

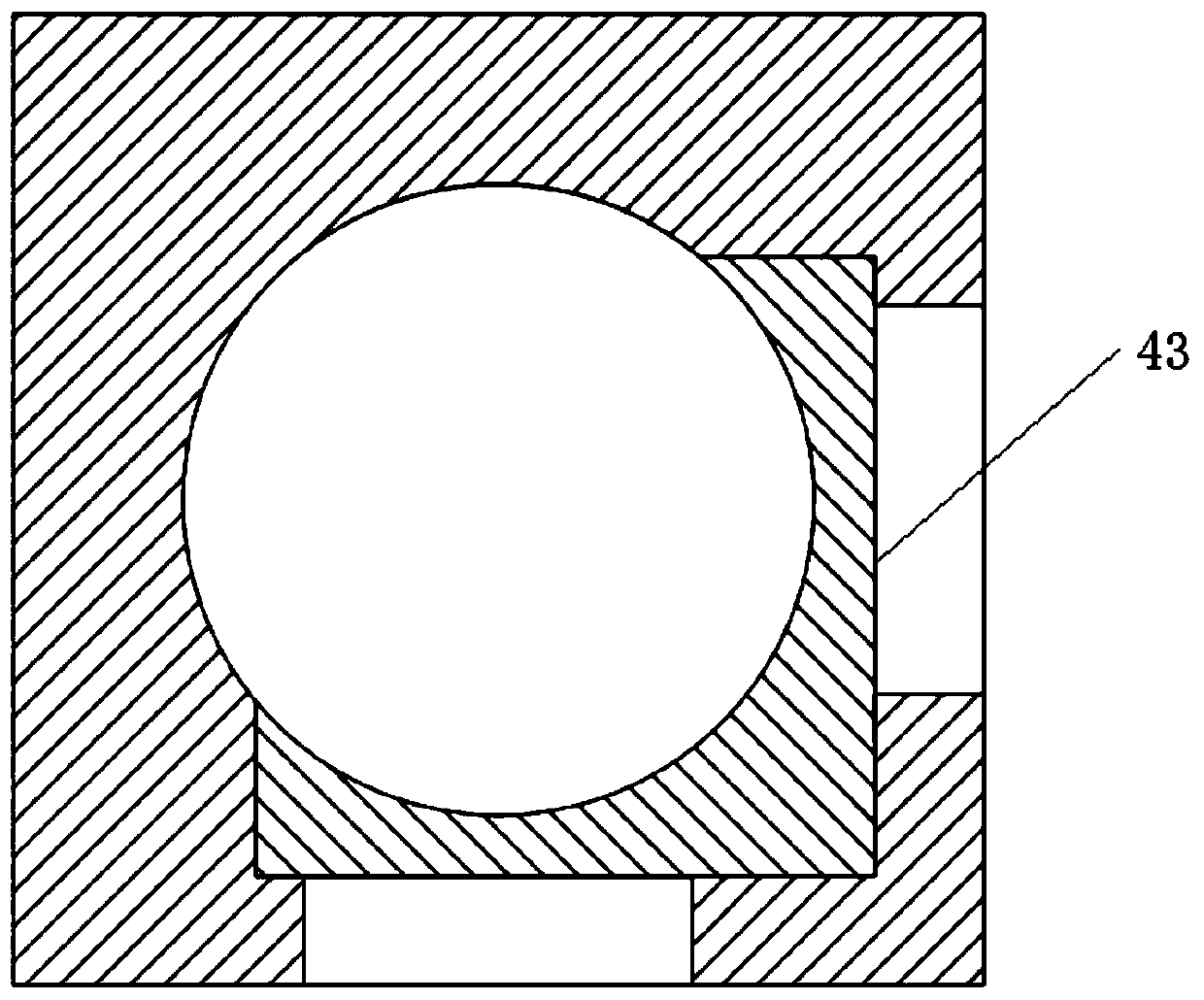

Supercritical water particulate matter visual measurement experimental device and method

ActiveCN110411898ASolve the difficult to observeImprove operational efficiencyFlow propertiesParticulatesEngineering

The invention provides a supercritical water particulate matter visual measurement experimental device and method. The device comprises a preheating section for primarily heating fluid in a pipeline,a heating section for secondarily heating the fluid in the pipeline, a visual section for observing particulate matters, a cooling section for cooling the fluid in the pipeline, a pressure stabilizingsection for adjusting the pressure of a loop and a feeding section for adding water and particulate matters into the loop. The experimental device can study the flowing condition of fluid in the pipeline and the deposition movement condition of particulate impurities in the fluid in a visual measurement mode, is visual in observation, can accurately and effectively measure related data, and meetsexperimental requirements and engineering application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

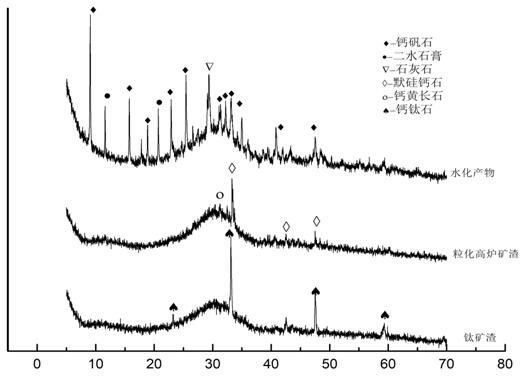

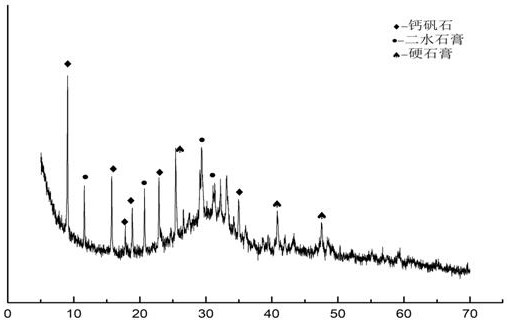

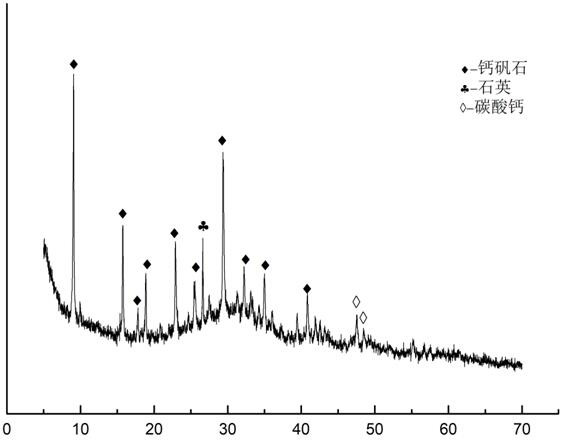

Titanium slag-based solid waste cementing material and preparation method thereof

The invention discloses a titanium slag-based solid waste cementing material and a preparation method thereof. The titanium slag-based solid waste cementing material comprises the following raw materials by weight: 70-80% of a titanium slag-based material, 15-25% of gypsum, and 2.5-7.5% of cement clinker. The preparation method is simple, and the used materials are subjected to separate or mixed grinding according to different types of grindability differences, and then are mixed and stirred. In the raw materials, the titanium-containing slag-based material is used as a main component and is matched with the cement clinker and the gypsum to form the gel material, so that effective comprehensive utilization of a large amount of high-titanium-containing slag and industrial byproduct gypsum resources produced by iron and steel enterprises in Panzhihua, Leshan sand bay and the like in the southwest region can be realized, most of conventional engineering applications can be met, and the material can also be used in a construction environment with rich tunnel terrestrial heat.

Owner:JIAHUA SPECIAL CEMENT

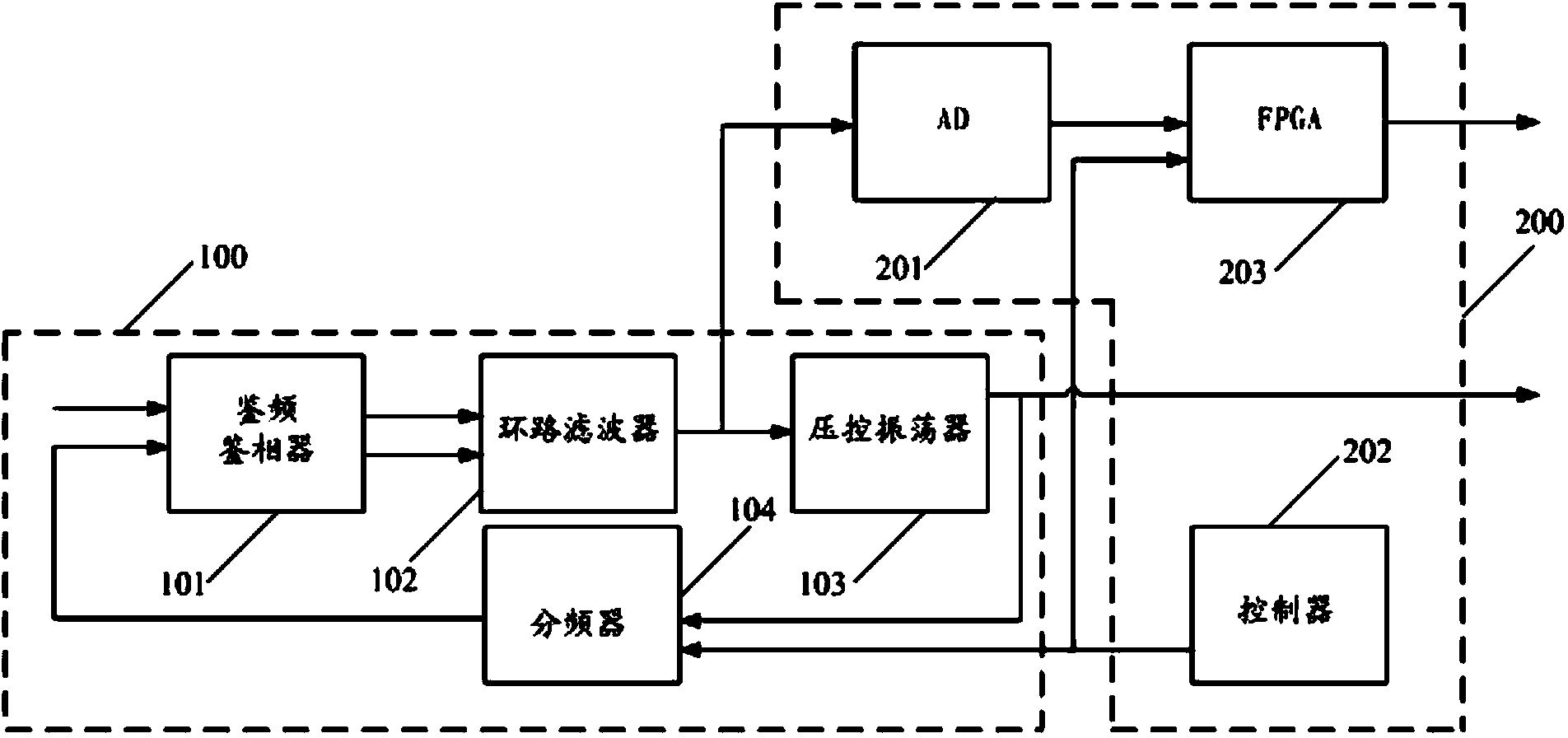

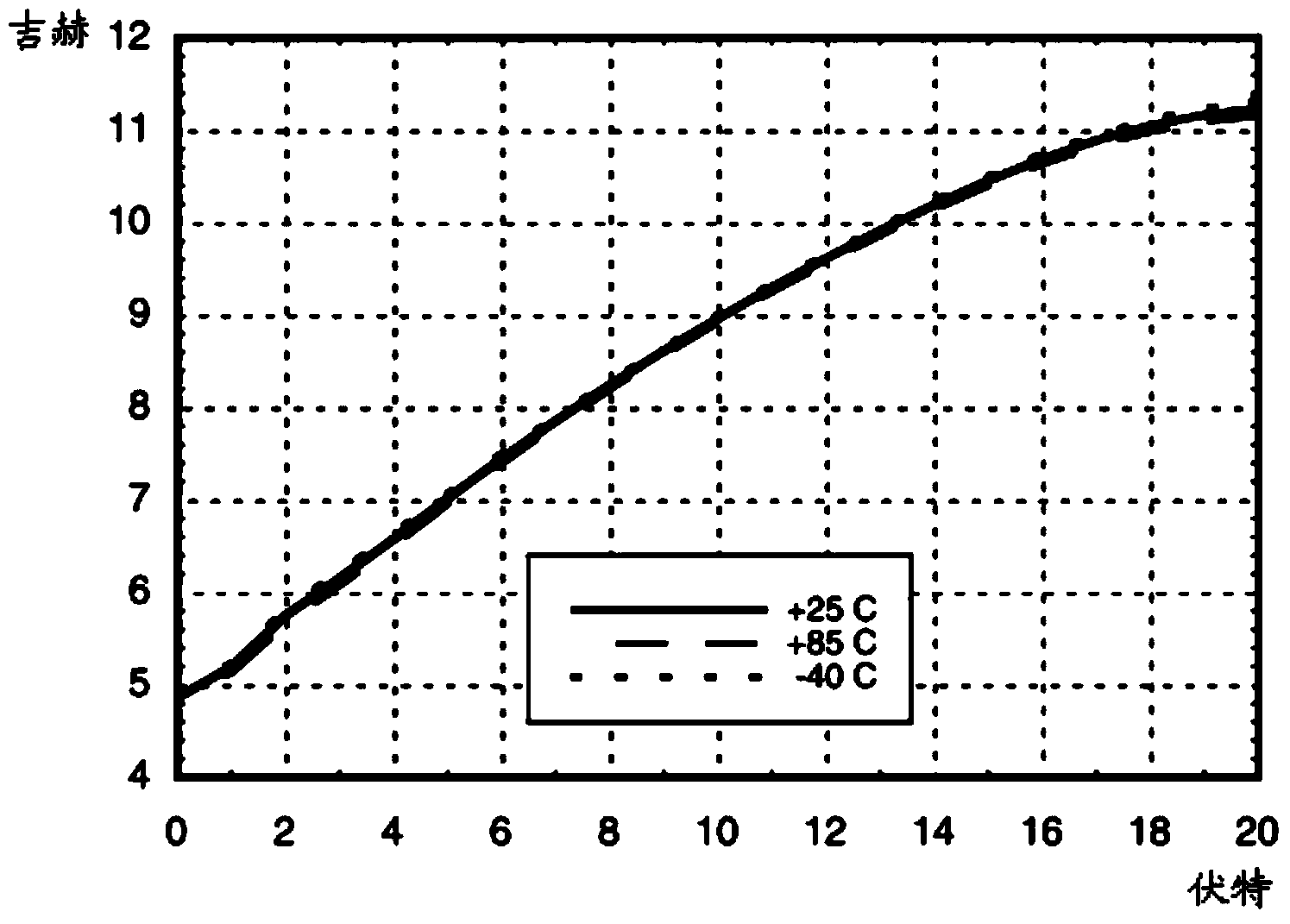

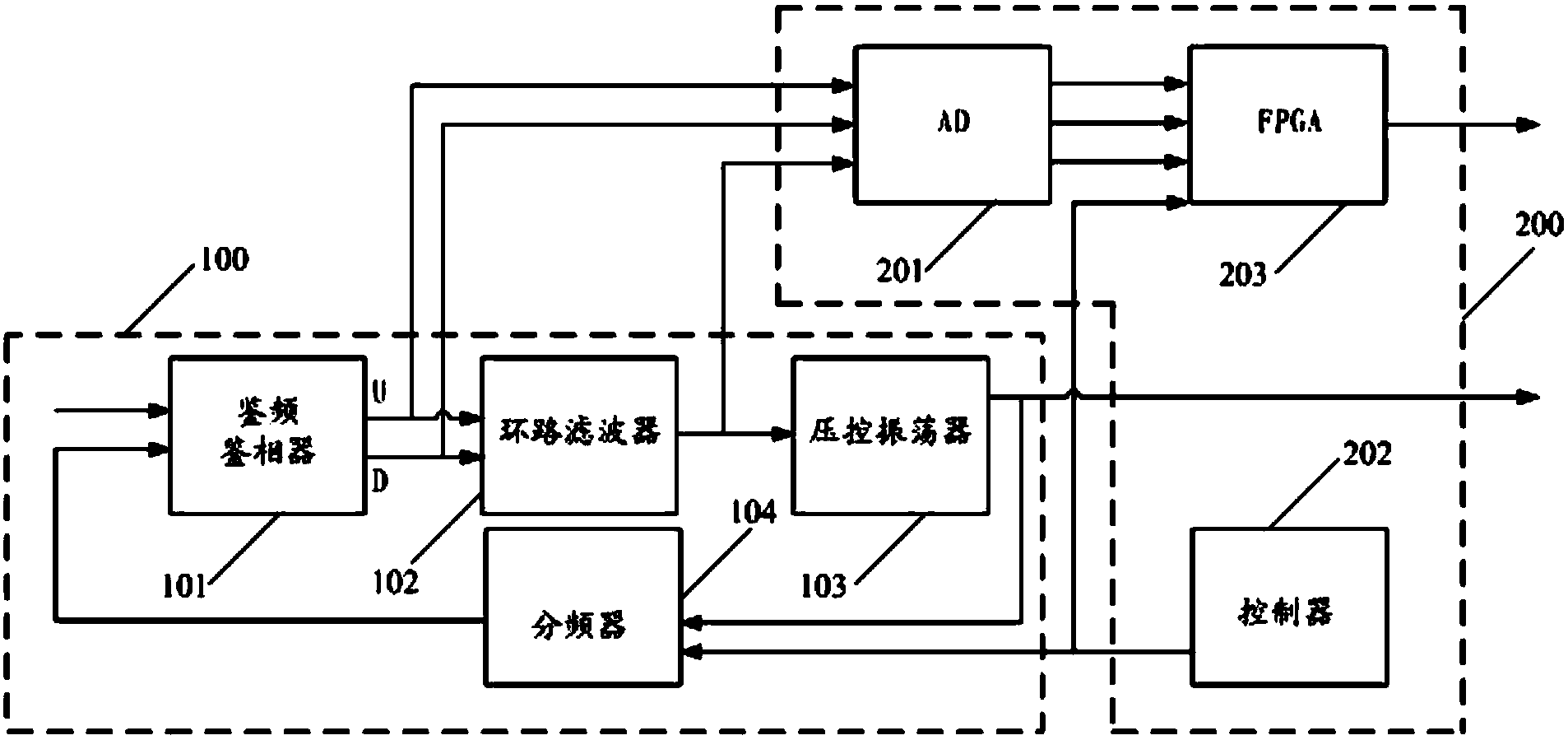

Phase-locked loop locking indication circuit and phase-locked loop

ActiveCN103873051ARealize the lock indication functionMeet engineering applicationsPulse automatic controlControl signalEngineering

The invention discloses a phase-locked loop locking indication circuit. An analog-digital converter receives a voltage control signal, conducts analog-digital conversion on the voltage control signal and outputs the voltage control signal; a frequency control signal is output by a controller; the voltage control signal acquired after analog-digital conversion and the frequency control signal are received by a field programmable logic array, and when the difference between the voltage control signal acquired after analog-digital conversion and the frequency control signal is smaller than a first threshold value, a locking indication signal is output, and locking indication of the phase-locked loop is achieved; because locking indication is achieved by the phase-locked loop locking induction circuit by detecting the voltage control signal and the frequency control signal and is not related to the value of the output frequency of the phase-locked loop, engineering application on broadband and high frequency application occasions can be achieved, and the phase-locked loop locking indication circuit can be applied to locking indication under high output frequency or broadband frequency synthesis conditions without additional complex circuits.

Owner:BEIJING RUNKE GENERAL TECH

A method for detecting the insertion depth of connecting steel bars in fully grouted sleeve steel bar joints

ActiveCN108663006BShorten the measuring distanceMeet engineering applicationsMeasurement devices3d imageInsertion depth

The invention discloses a method for detecting the insertion depth of a connecting reinforcement in a full grouting sleeve reinforcement joint. The method is characterized in that a three-dimensionalstereoscopic measuring endoscope is used for detecting the insertion depth of the connecting reinforcement joint in the full grouting sleeve, involving the reinforcement at a grouting inlet end and ata grouting outlet end, and the detecting time is after the on-site splicing of a prefabricated member and before the construction of the sleeve grouting; an endoscope probe provided with a forward-looking three-dimensional measuring lens is protruded from a grouting opening and a grouting outlet in the surface of the prefabricated member, and the guiding bending function of the endoscope probe and a gap between the connecting reinforcement and the inner wall of the sleeve are utilized to protrude the endoscope probe into the sleeve to shoot a 3D image of the middle part of an inner cavity ofthe sleeve. By measuring the relative distance between the tail end of an insertion section of the connecting reinforcement in the 3D image and a limiting stopper in the middle of the sleeve, the characteristic of high precision of sleeve production and manufacturing is used to calculate the insertion depth of the connecting reinforcement. The method can be used for visually, clearly and quantitatively obtaining the insertion depth of the reinforcement and improving the detection efficiency.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

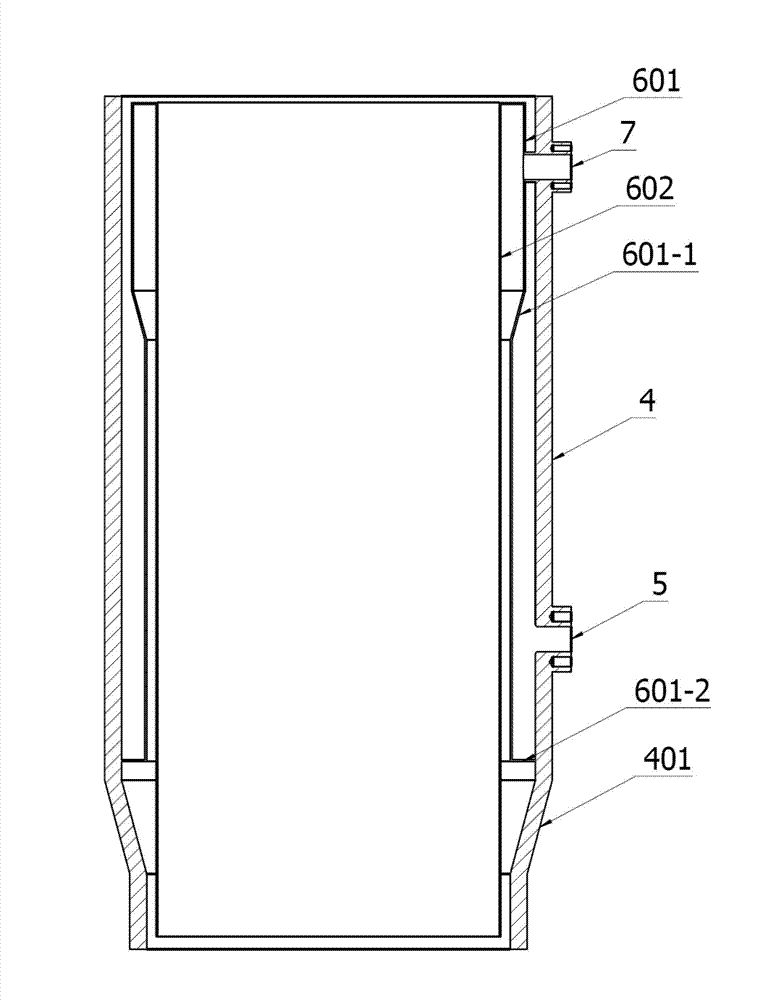

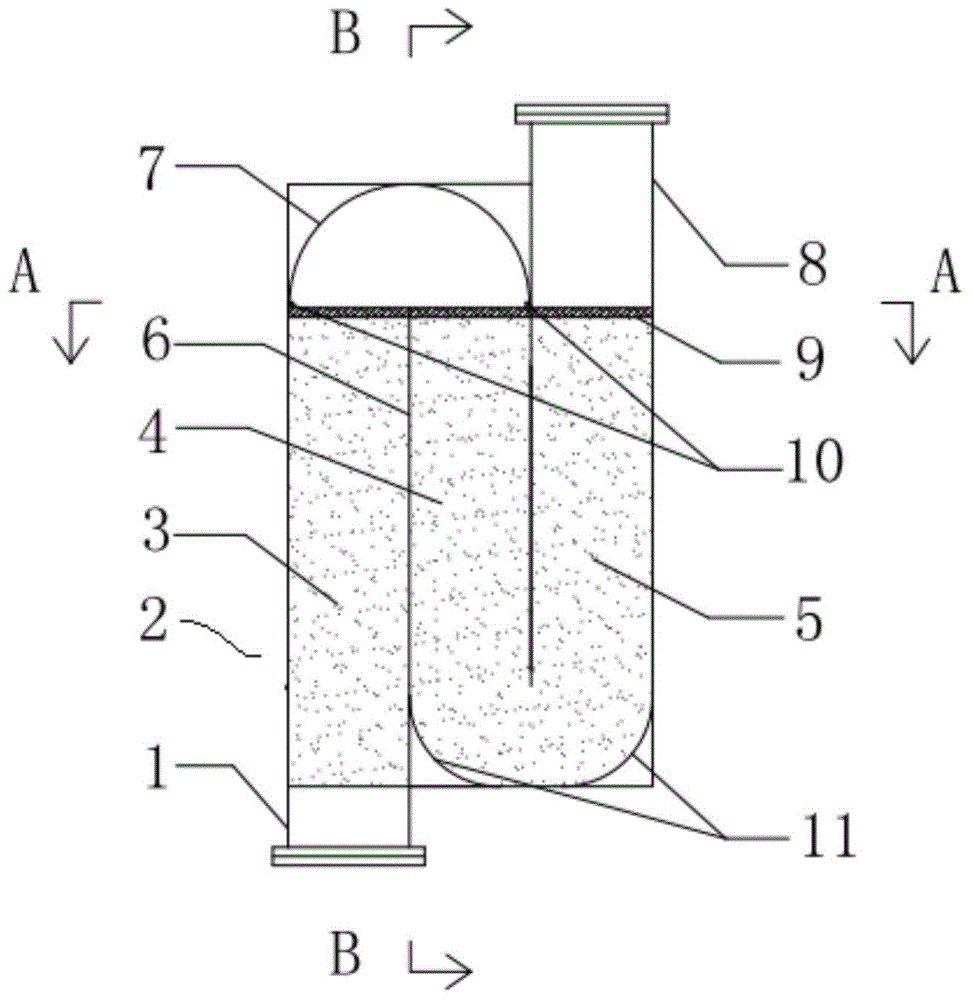

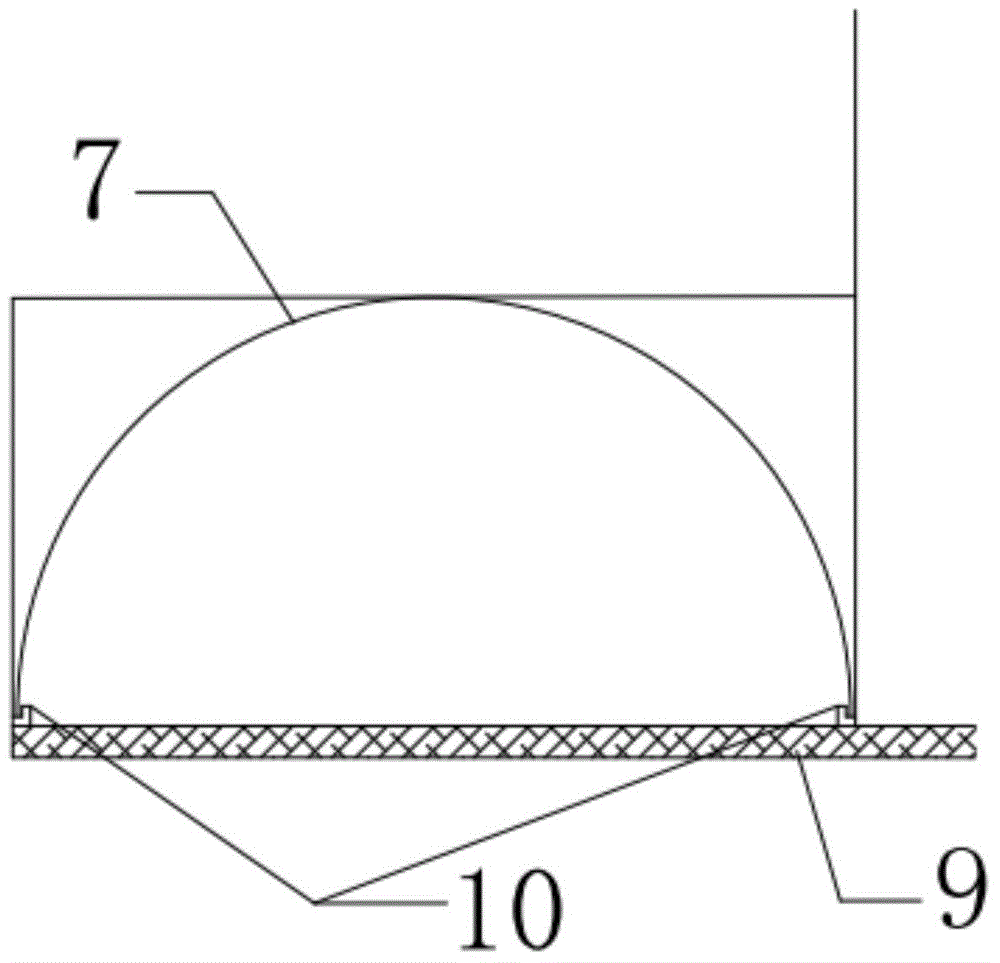

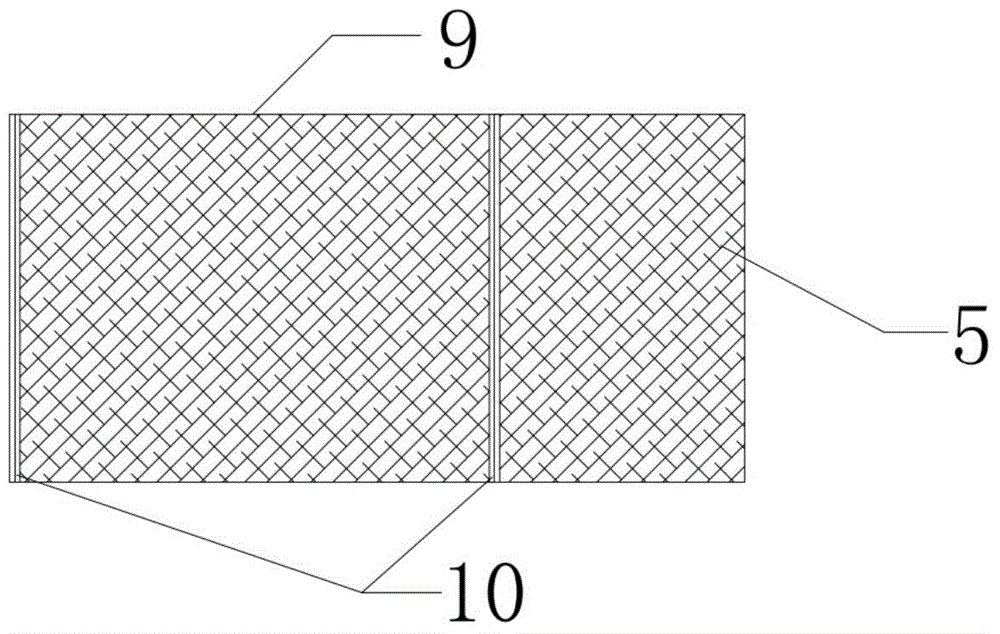

Carbon dioxide capture pressure swing adsorption tower

ActiveCN104128072AHigh adsorption rateExtended gas flowDispersed particle separationSorbentFixed bed

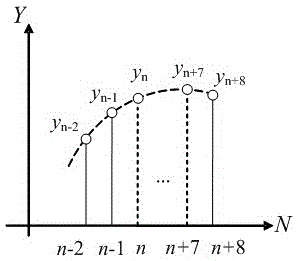

The invention relates to a carbon dioxide capture pressure swing adsorption tower which is characterized by comprising an inlet flue (1), an outlet flue (8) and at least two rectangular gas adsorption channels, adjacent gas adsorption channels are separated by a baffle (6), and the upper parts of the gas adsorption channels are fixed and pressed by pressing pads (9); an odd gas adsorption channel is set as n gas adsorption channel, an even gas adsorption channel which is sequentially adjacent to the odd gas adsorption channel is set as n+1 gas adsorption channel, n is more than or equal to 1, the upper part of the pressing pads (9) of the n gas adsorption channel and the n+1 gas adsorption channel is provided with a ring shaped guide plate (7); and the inlet flue (1) is rectangular, and is matched with a first gas adsorption channel (3) with the same diameter. The carbon dioxide capture fold-flow fixed bed adsorption tower has the advantages of uniform gas distribution, long gas flow length, high adsorbent utilization rate, bed stability and the like, and is suitable for various kinds of large, medium and small size of carbon dioxide capture pressure swing adsorption engineering.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

A method for detecting the insertion depth of connecting steel bars in half-grouting sleeve steel bar joints

ActiveCN109141274BShorten the measuring distanceMeet engineering applicationsUsing optical meansInsertion depthThree dimensional measurement

The invention discloses a method for detecting the insertion depth of a connecting steel bar in a semi-grouting sleeve steel bar joint. A three-dimensional measurement endoscope, a rigid sleeve pipe and a rubber plug. The three-dimensional measurement endoscope comprises an endoscope host, a connection hose, a probe and lenses connected in sequence, and the lenses comprise a front-view three-dimensional measuring lens and a side-view three-dimensional measuring lens. A central hole is arranged in the middle of the rubber plug, and the rigid sleeve can be inserted into the rubber plug through the central hole. The relative position of an end of an inserted section of the connecting steel bar and the bottom of a sleeve grout discharging port is judged by using an auxiliary tool. When a judgment result is that the end of the inserted section of the connecting steel bar is above the bottom of the sleeve grout discharging port, the front-view three-dimensional measuring lens is used to measure and calculate to obtain a result, and when the judgment result is that the end of the inserted section of the connecting steel bar is under the bottom of the sleeve grout discharging port, the side-view three-dimensional measuring lens is used to measure and calculate to obtain a result. According to the method, the insertion depth of the steel bar can be intuitively, clearly and quantitatively obtained, and the detection efficiency is improved.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

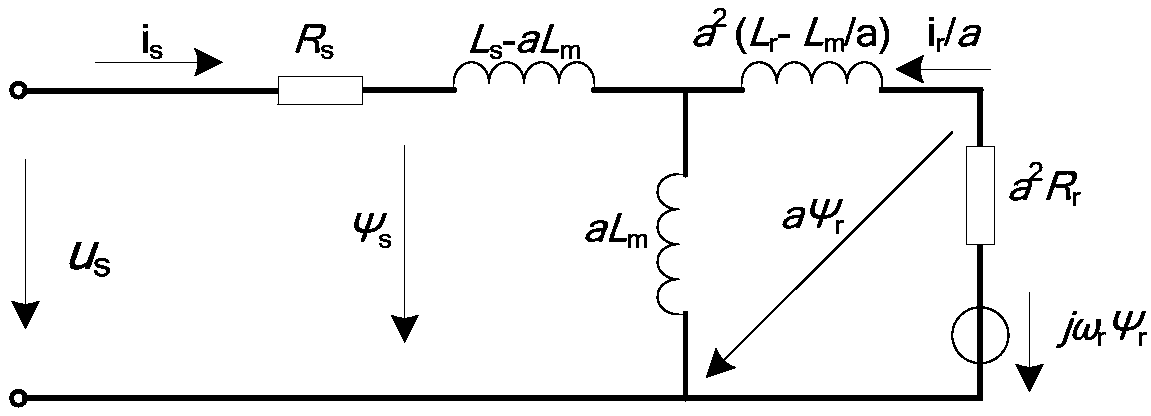

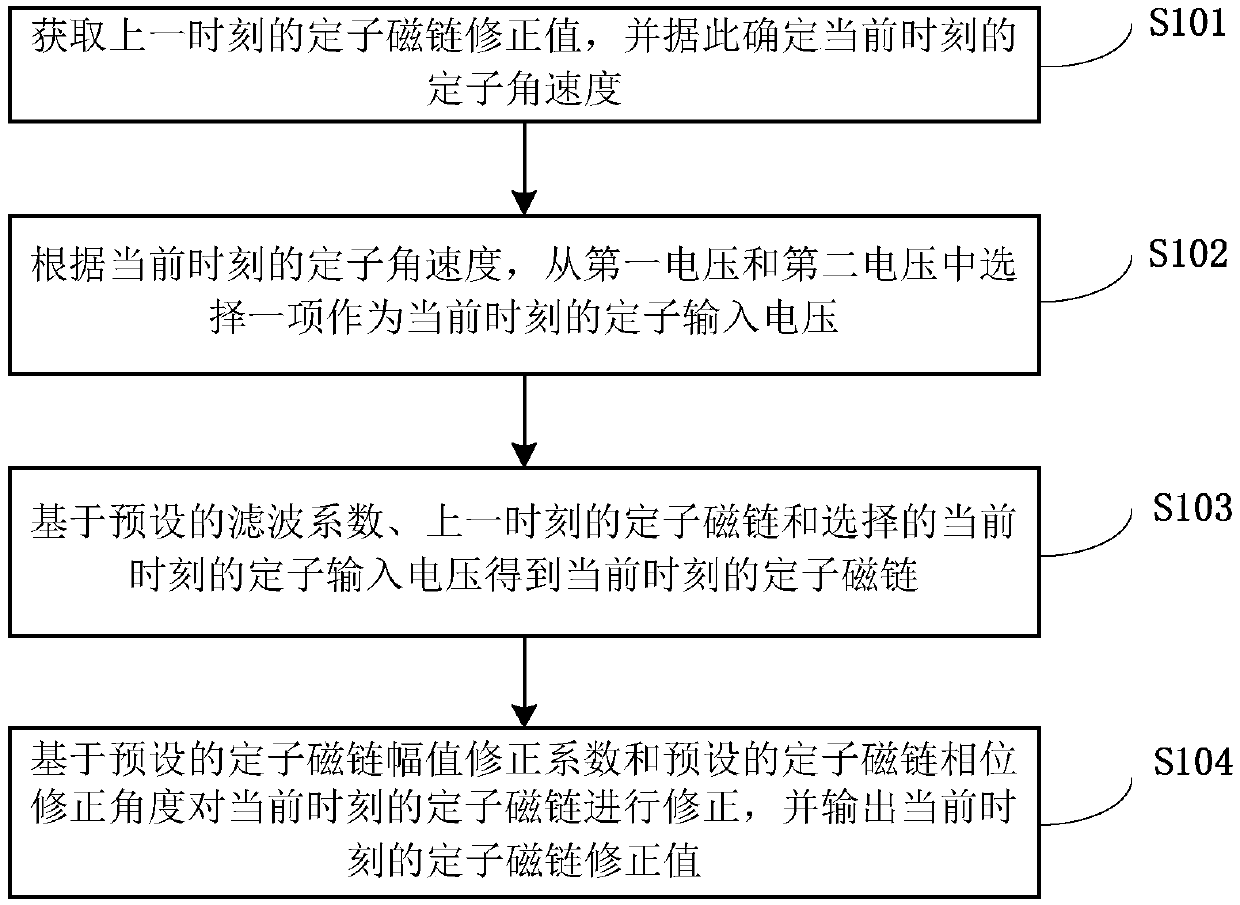

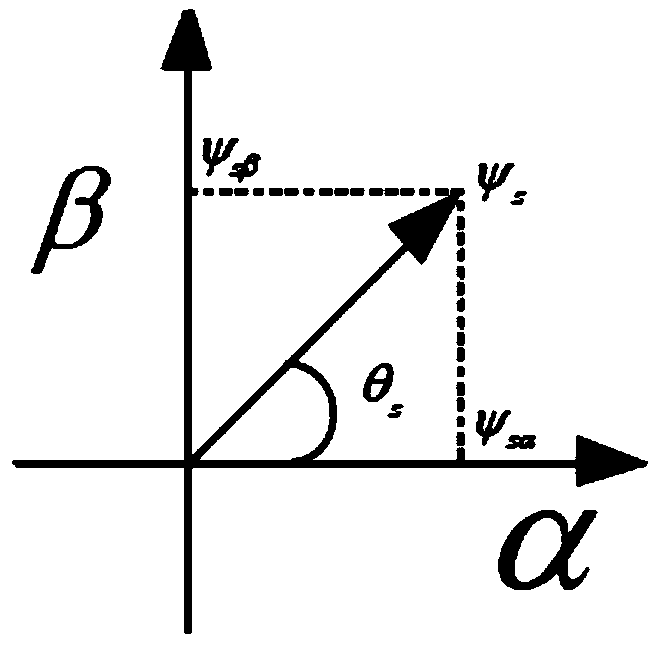

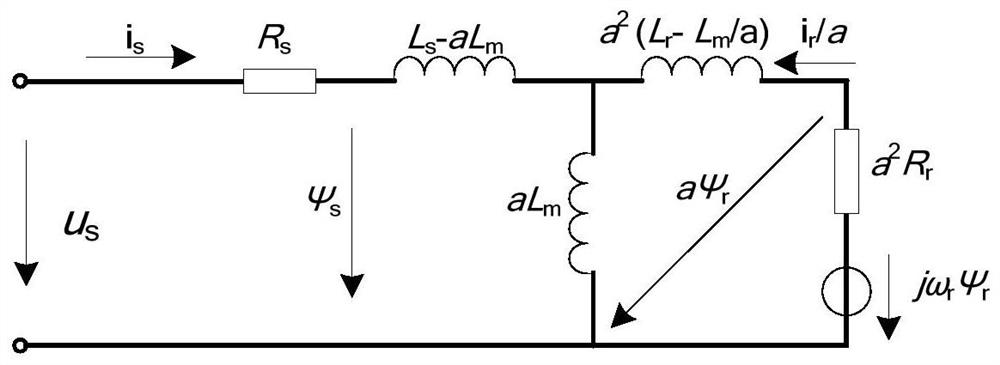

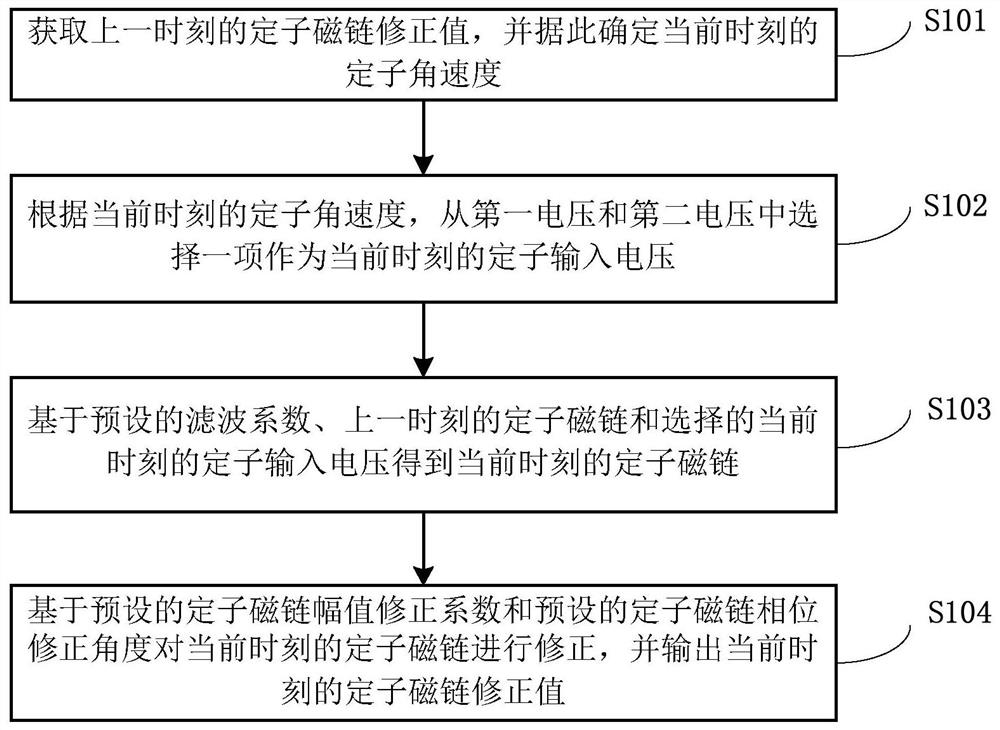

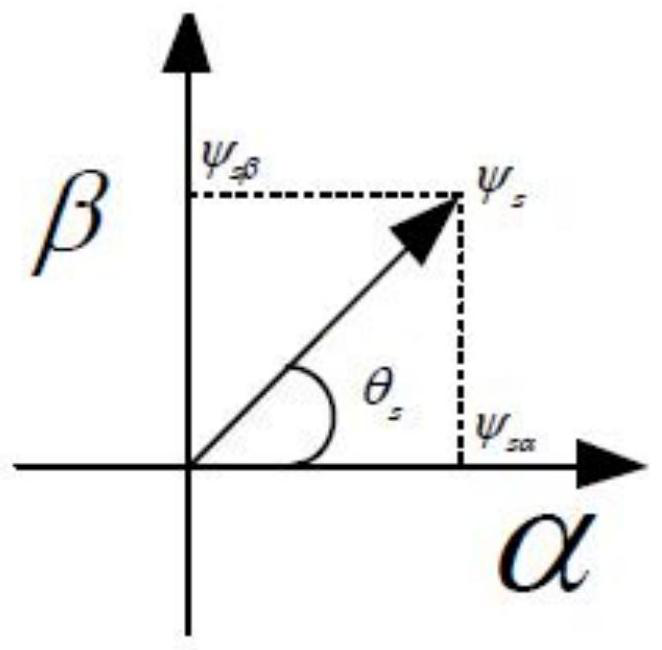

Method for determining stator flux linkage of dual-mode voltage model

ActiveCN110649850AHigh precisionMeet engineering applicationsElectronic commutation motor controlVector control systemsControl systemElectric machinery

The invention discloses a method for determining a stator flux linkage of a dual-mode voltage model. The method comprises the steps of determining a stator flux linkage at the current moment accordingto a stator flux linkage correction value at the previous moment of the current moment: obtaining the stator flux linkage correction value at the previous moment, and determining a stator angular velocity at the current moment according to the stator flux linkage correction value; selecting one of the first voltage and the second voltage as a stator input voltage at the current moment according to the stator angular velocity at the current moment; obtaining a stator flux linkage at the current moment based on a preset filter coefficient, the stator flux linkage at the previous moment and theselected stator input voltage at the current moment; and correcting the stator flux linkage at the current moment based on a preset stator flux linkage amplitude correction coefficient and a preset stator flux linkage phase correction angle, and outputting a stator flux linkage correction value at the current moment. According to the method, a high-precision stator flux linkage value can be obtained in a full-speed range, so that the engineering application of most speed sensorless motor control systems can be met.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

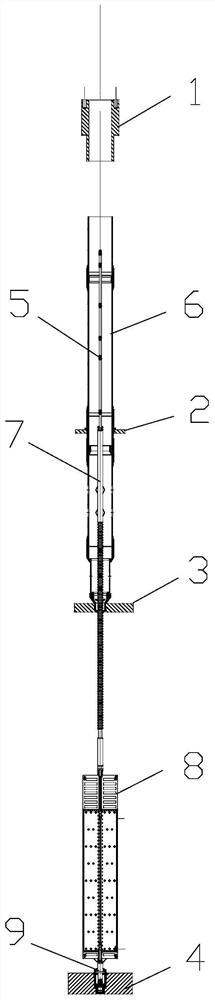

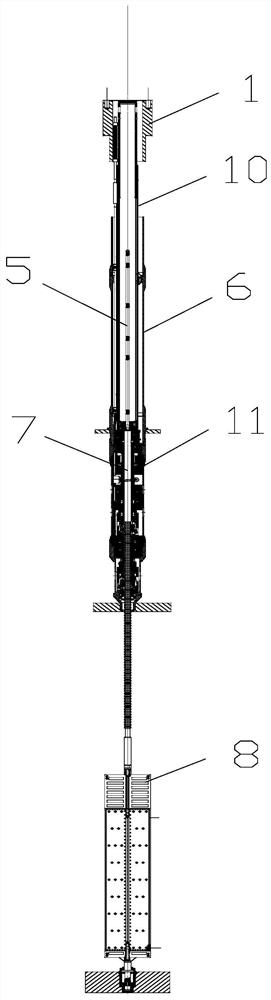

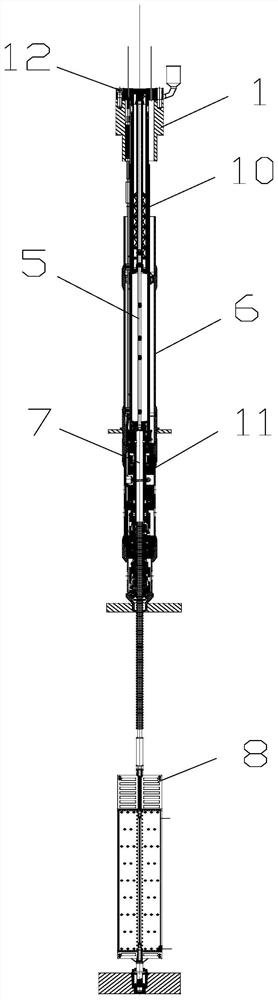

Limited space installation method of built-in control rod driving line

PendingCN112037940AGuaranteed uptimeFirmly assembledNuclear energy generationNuclear reaction controlConfined spaceEngineering

The invention relates to the technical field of built-in control rod driving, and provides a limited space installation method of a built-in control rod driving line. According to the method, a springbox lower section is assembled on a driving mechanism component, then a buffer lock and a reset spring are mounted in the spring box lower section, then a spring box upper section is assembled on thespring box lower section to form a spring box component, and then a combined body of the spring box component and the driving mechanism component is mounted in a driving line guide cylinder. Then a buffer lock in the spring box part is locked with a rod position measuring rod of a control rod component , so that stable and reliable assembly among the control rod component , the driving wire guidecylinder, the spring box component and the driving mechanism component is realized. The assembling method is simple and convenient, the efficiency of loading and unloading work and maintenance work is improved, the safety and reliability of the limited space installation and operation process can be guaranteed, and then safe and reliable operation of the built-in control rod driving wire after assembling is guaranteed.

Owner:TSINGHUA UNIV

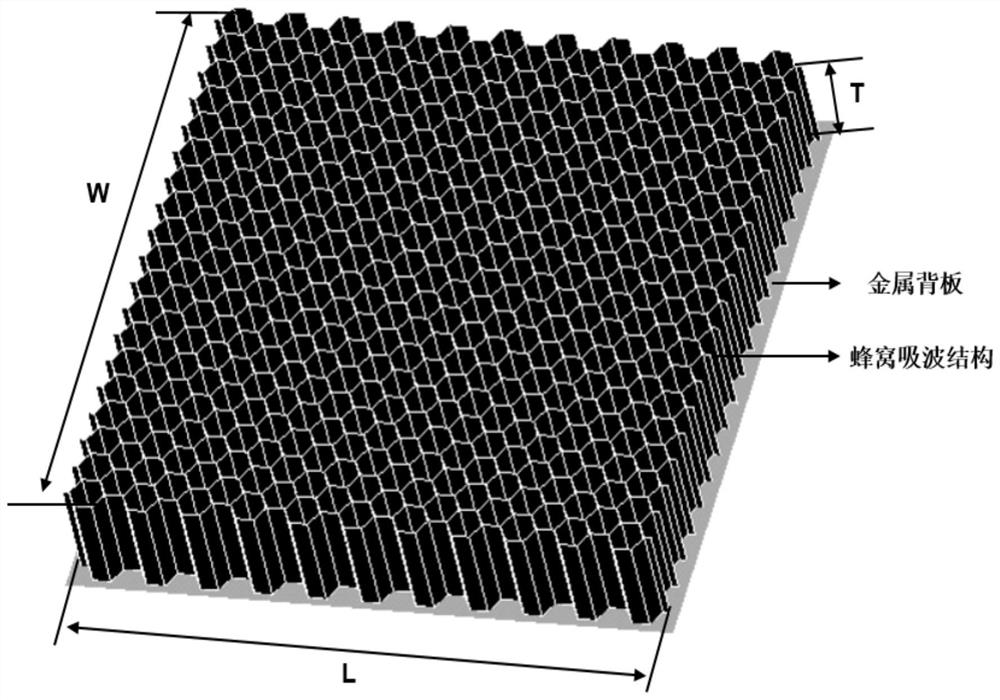

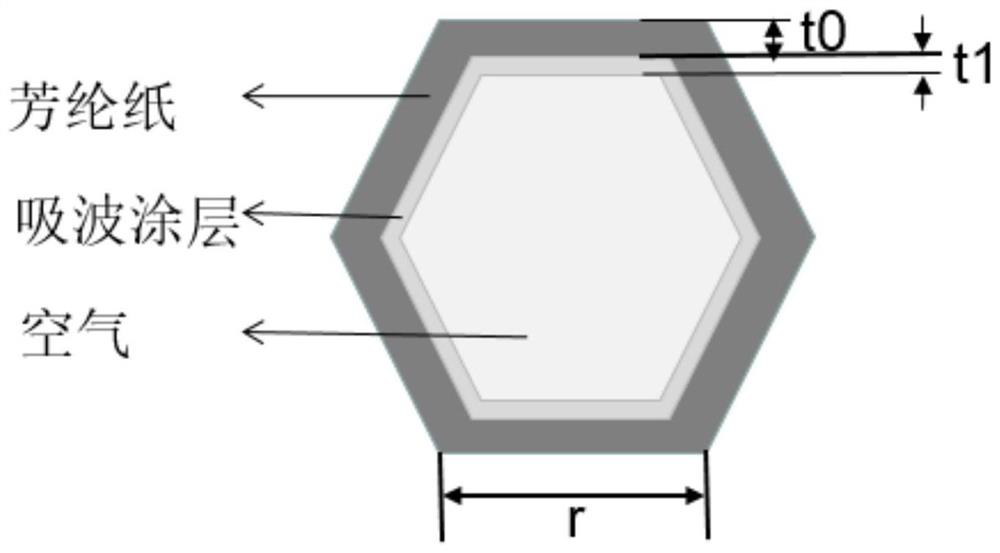

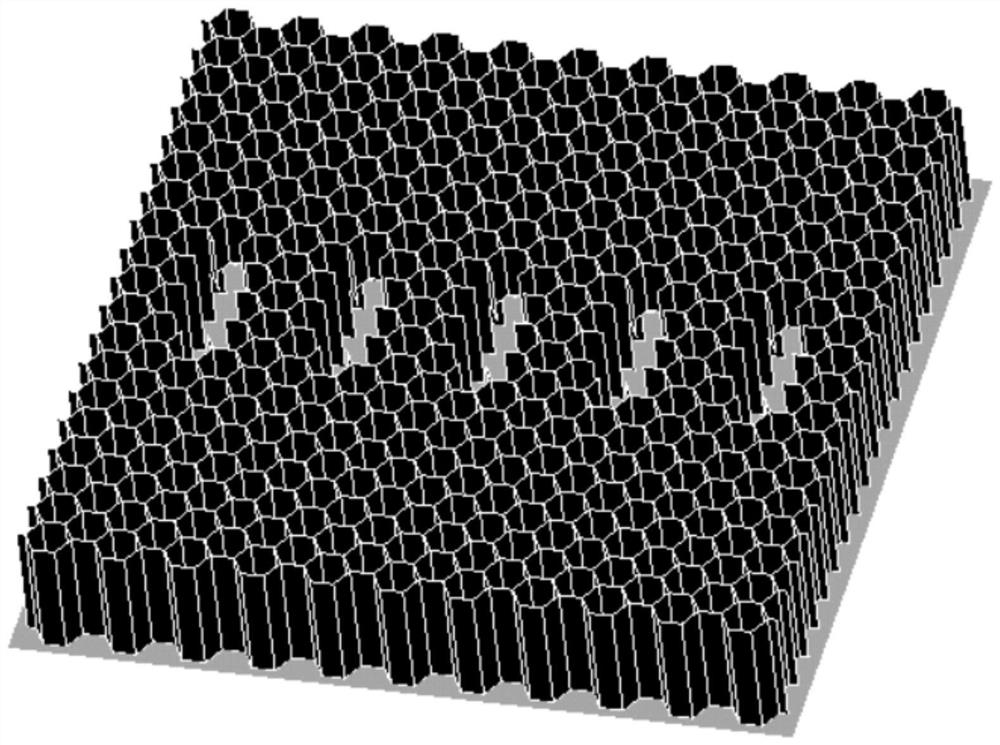

Slotted honeycomb wave-absorbing structure

ActiveCN112635964AAffects electromagnetic propertiesPeak impactMagnetic/electric field screeningAntenna supports/mountingsRadarEngineering

The invention belongs to the technical field of electronic materials, and particularly relates to a slotted honeycomb wave-absorbing structure. N identical irregular gaps are formed in a periodic honeycomb structure, a space for embedding electronic modules such as antennas and radars in the honeycomb structure is provided, the design method based on honeycomb wave-absorbing structure embedding is achieved, namely, the honeycomb core is subjected to local hollowing treatment, a highly integrated electronic module is embedded into the core and is subjected to protection design, so that the spacecraft design has qualitative leap in the aspects of light weight and multiple functions. The key problem of the pre-embedded design is to evaluate the electromagnetic / mechanical strength of the slotted honeycomb structure, so that under a reasonable slotting method, the weight of the honeycomb structure is reduced, and the honeycomb structure has good electromagnetic / mechanical properties.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

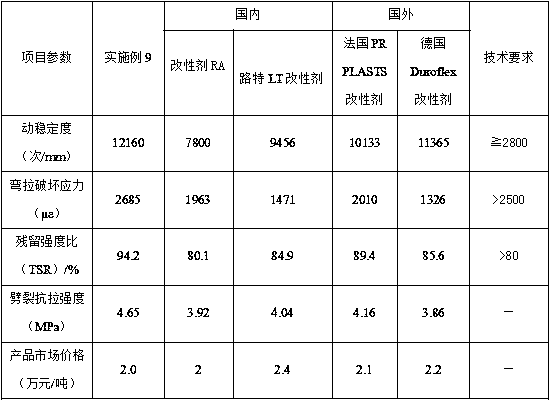

Bituminous mixture modifier and preparation method thereof

InactiveCN109320978AImprove low temperature crack resistanceImprove water damage resistanceBuilding insulationsForeign technologyRoad surface

The invention discloses a bituminous mixture modifier and a preparation method thereof. The bituminous mixture modifier is prepared from waste polyethylene, waste polypropylene, a toughening agent, aninitiator, a modifier, an anti-ageing agent, filler and pigment. According to the bituminous mixture modifier and the preparation method thereof, by adopting modification technologies of blending, grafting, toughening and the like, the industrial, agricultural and domestic recovered waste PE and PP, the other modifier, the filler and the like are mixed evenly according to a certain ratio to prepare black solid particles, according to 0.3-0.5% of total mass of a bituminous mixture, the black solid particles, pitch and mineral aggregate are stirred and mixed evenly at a mixing station under technology conditions of certain temperature, mixing time and the like, thus paving can be conducted, the rut resistance capability of a bituminous pavement can be greatly improved, and meanwhile, both the moisture damage resistance performance and the low temperature resistance performance are obviously improved. By adopting the modification technologies, not only is the cost reduced, but also the high temperature stability of the bituminous mixture can be greatly improved, the foreign technology monopoly is broken, and the bituminous mixture modifier and the preparation method thereof have profound significance in the aspects of positively responding to national waste material resource recycling and the like.

Owner:TAIYUAN UNIV OF TECH

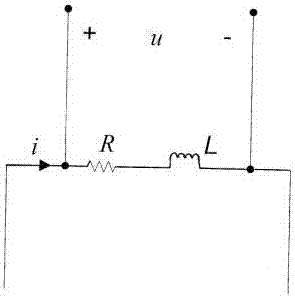

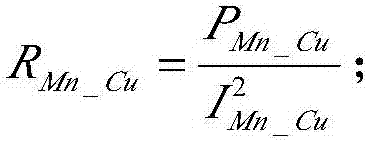

Programmed calculation method of diverter impedance parameters

InactiveCN107967374AImprove calculation accuracyAccurate calculationResistance/reactance/impedenceDesign optimisation/simulationElement analysisProgram calculation

The invention discloses a programmed calculation method of diverter impedance parameters and solves the problem that in the prior art, the diverter impedance parameters cannot be accurately measured at different frequencies. According to the method, programmed calculation is achieved through automatic data interaction of electromagnetic field finite element analysis software and mathematical operation software, it is achieved that finite element modules of a diverter are built, a calculation frequency is input, then the programmed calculation of the diverter impedance parameters can be achieved, and a result of the diverter impedance parameters is directly output. Through finite element analysis, the resistance of a single copper-manganese slice of the diverter and a diverter inductance matrix parameter are calculated, a loop voltage equation is edited according to all the parameters, and the diverter impedance parameters are solved through mathematical operation. According to the calculation process, it is achieved that the mathematical operation software calls the finite element analysis software, receives the finite element analysis result, performs the next operation and finally directly outputs the operation result of the diverter impedance parameters, it is achieved that the quantitative relation between the diverter impedance parameters and the frequencies is built, andengineering application is facilitated.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

Multi-objective optimization method for centrifugal pump turbine hydraulic performance and external field flow-induced noise

ActiveCN105201729BMeet engineering applicationsShorten the design cycleHydro energy generationReaction enginesNoise fieldCoupling

The invention belongs to the technical field of design for a centrifugal pump as a turbine and discloses a multiple-target optimization method for hydraulic performance and outer field flow-induced noise for the centrifugal pump as the turbine. The method comprises the following steps: step I, defining a determination method for a multiple-target optimization design variable value range for the centrifugal pump as the turbine; step II: through external characteristic experiment, building a computing method for mechanical efficiency required in CFD numerical calculation for the centrifugal pump as the turbine, so as to accurately calculate the efficiency of the centrifugal pump as the turbine; for different characteristics of the inner and outer media for the centrifugal pump as the turbine, adopting an FEM / AML sound-vibration coupling method for solving outer field flow-induced noise; step III: building sensitivity analysis models of different geometrical parameters for the efficiency of the centrifugal pump as the turbine and the outer field total noise power level; step IV: on the basis of a response surface method, carrying out multiple-target optimization on the hydraulic performance and outer field flow-induced noise. By adopting the method, the design efficiency is improved, the design period for the centrifugal pump as the turbine is shortened, the efficiency of the centrifugal pump as the turbine can be effectively improved and meanwhile, the noise of the centrifugal pump as the turbine can be reduced.

Owner:JIANGSU UNIV

Built-in control rod driving wire mounting method

PendingCN112037939AGuaranteed uptimeFirmly assembledNuclear energy generationNuclear reaction controlDrive shaftEngineering

The invention relates to the technical field of built-in control rod driving, and provides a built-in control rod driving line mounting method. According to the method, a spring box component and a driving mechanism component are assembled to form a driving line assembly, the driving line assembly is hoisted into a driving line guide cylinder, and a driving shaft of a control rod component is locked through a spring box buffer lock. The method is convenient to assemble, the efficiency of loading and unloading work and maintenance work is improved, the safety and reliability of the installationand operation process can be guaranteed, and then safe and reliable operation of the built-in control rod driving line after assembly is guaranteed.

Owner:TSINGHUA UNIV

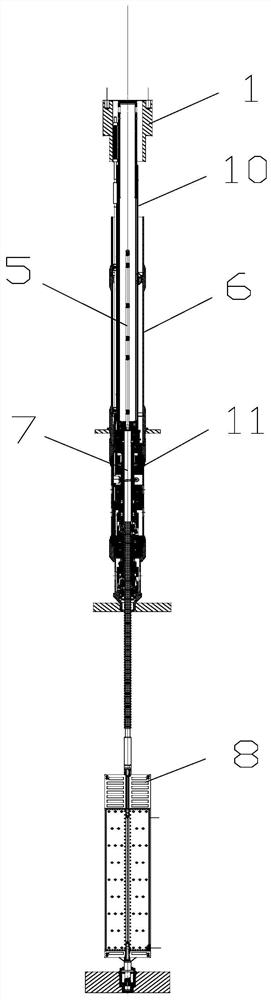

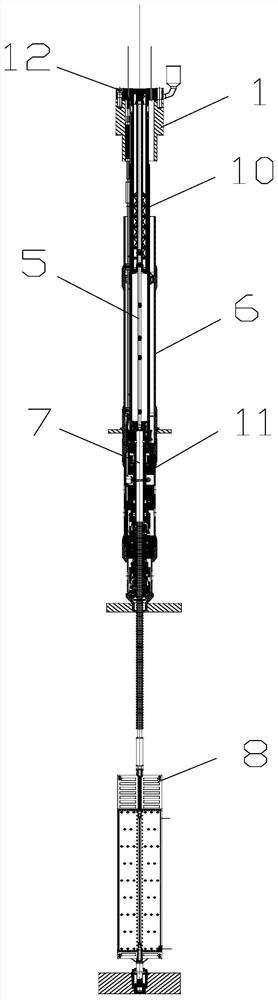

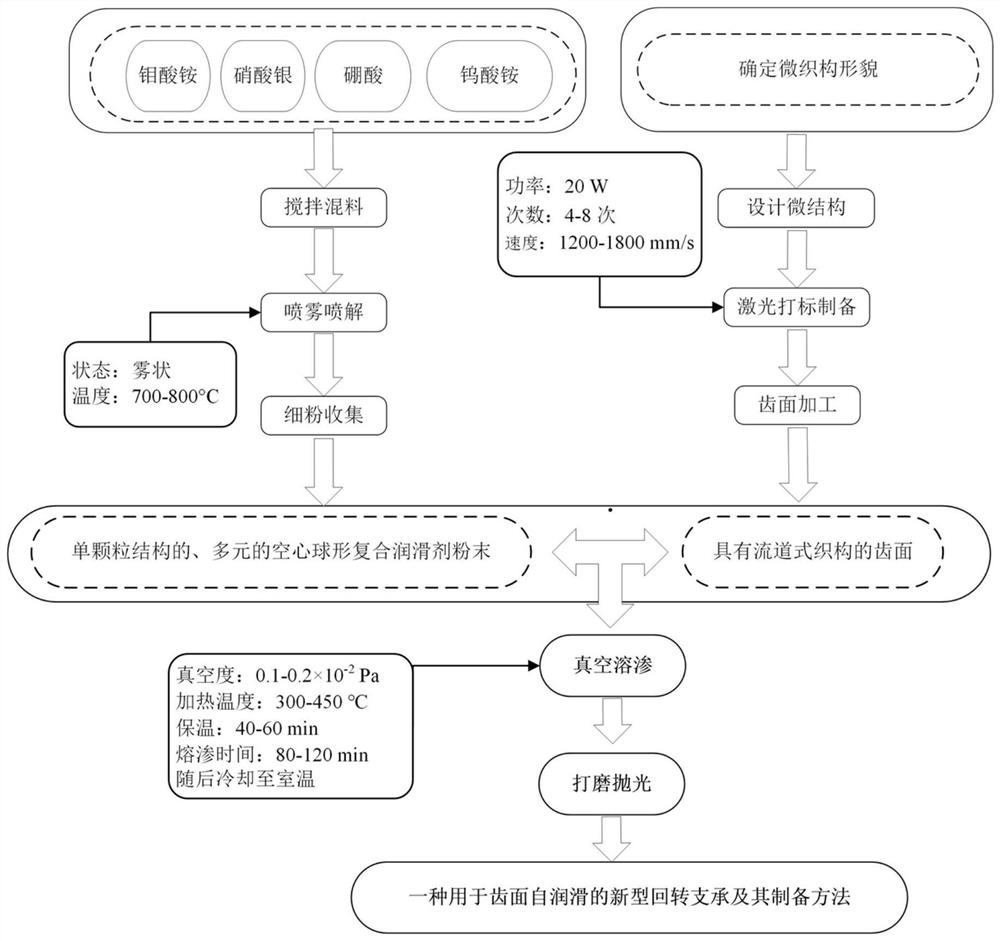

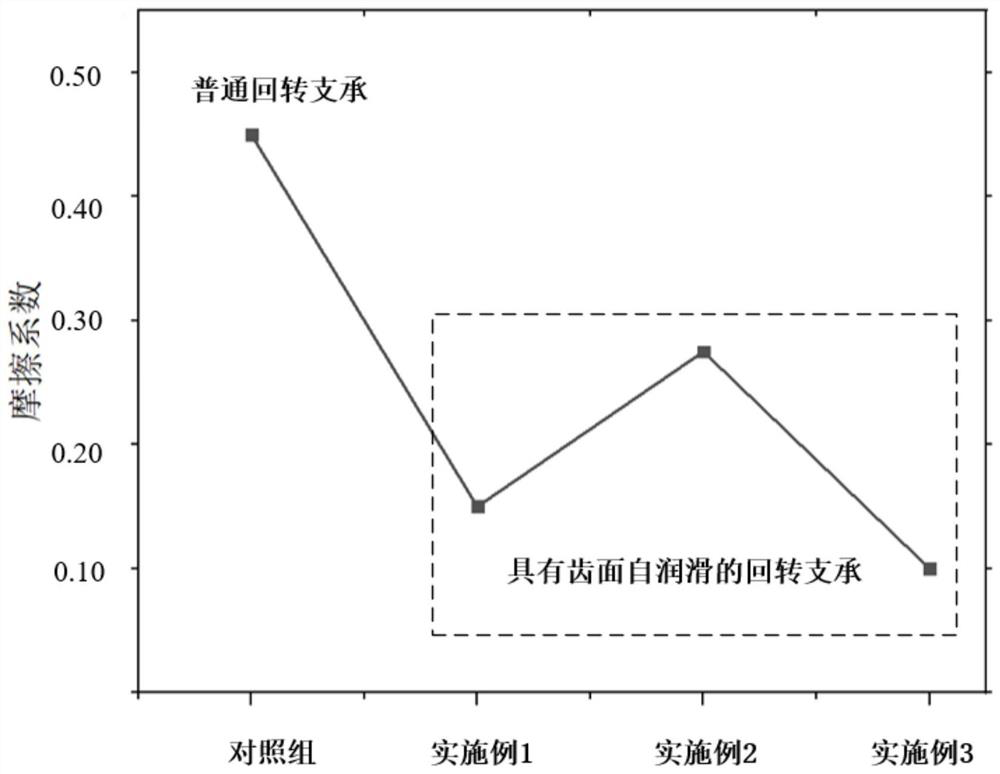

Novel slewing bearing for tooth surface self-lubrication and preparation method of novel slewing bearing

PendingCN114083230AImprove tribological propertiesReduce coefficient of frictionTransportation and packagingMetal-working apparatusLubricationMaterials science

The invention discloses a novel slewing bearing for tooth surface self-lubrication and a preparation method of the novel slewing bearing. A flow channel micro-texture is machined on the tooth surface of the slewing bearing through a laser marking technology, a solid lubricant can be more fully spread on the surface of a base body through the bionic micro-texture, so that a layer of lubricating film is formed, and the effects of reducing friction and reducing material abrasion are achieved. the composite solid lubricant is multi-element hollow spherical composite lubricant powder with a single-particle structure, and is prepared by spraying a mixed solution of ammonium molybdate, silver nitrate, boric acid and ammonium tungstate into a high-temperature atmosphere of 700-800 DEG C in a vaporific manner and carrying out thermal decomposition synthesis. The composite spherical power, serving as the solid lubricant phase, fills the micro-texture through vacuum dissolution and permeation, so that the obtained tooth surface is provided with a self-lubrication composite material with a self-lubrication phase. Compared with a traditional slewing bearing, the novel slewing bearing with the tooth surface self-lubrication function has the advantages of excellent friction reduction and wear resistance, low friction coefficient, low wear rate, higher use stability and longer fatigue life.

Owner:XUZHOU WANDA SLEWING BEARING

Determination Method of Stator Flux Linkage in Dual Mode Voltage Model

ActiveCN110649850BHigh precisionMeet engineering applicationsElectronic commutation motor controlVector control systemsControl systemElectric machine

The invention discloses a method for determining the stator flux linkage of a double-mode voltage model. The method includes determining the stator flux linkage at the current moment according to the stator flux linkage correction value at the previous moment by using the following steps: obtaining the stator flux linkage correction value at the previous moment, and determining the stator angular velocity at the current moment accordingly; The angular velocity of the stator at the moment, select one of the first voltage and the second voltage as the stator input voltage at the current moment; based on the preset filter coefficient, the stator flux linkage at the previous moment and the selected stator input voltage at the current moment, the current the stator flux linkage at the moment; and correct the stator flux linkage at the current moment based on the preset stator flux linkage amplitude correction coefficient and the preset stator flux linkage phase correction angle, and output the stator flux linkage correction value at the current moment. This method can obtain high-precision stator flux linkage values in the full speed range, which can meet the engineering applications of most speed sensorless motor control systems.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Built-in control rod drive wire assembling method

ActiveCN111968762AGuaranteed uptimeEasy to operateNuclear energy generationLoad-engaging elementsDrive shaftControl engineering

The invention relates to the technical field of built-in control rod driving, and provides a built-in control rod driving line assembling method. According to the method, a control rod driving shaft is mounted in a buffer cylinder; the lower end of the control rod driving shaft penetrates through the buffer cylinder and is connected with a cross-wing control rod; a driving line guide cylinder is mounted on a reactor internal structure, then a rod position measuring component and a driving mechanism component are assembled to form a driving line assembly, then the driving wire assembly is hoisted into the driving line guide cylinder, and a combined valve component is mounted on the rod position measuring component. The assembly operation is simple and convenient, the efficiency of loading and unloading work and maintenance work is improved, the safety and reliability of the installation operation process can be guaranteed, and then safe and reliable operation of the built-in control roddrive line after assembly is guaranteed.

Owner:TSINGHUA UNIV

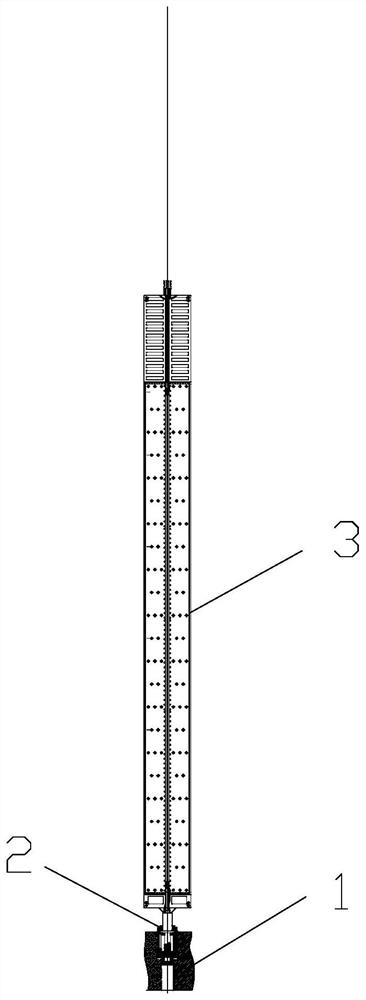

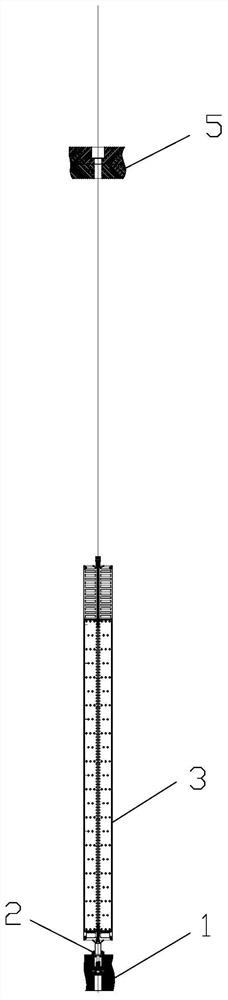

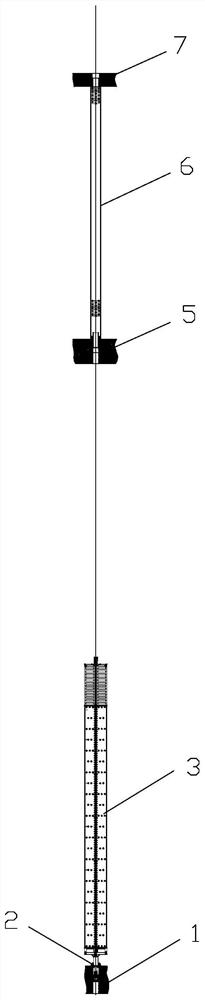

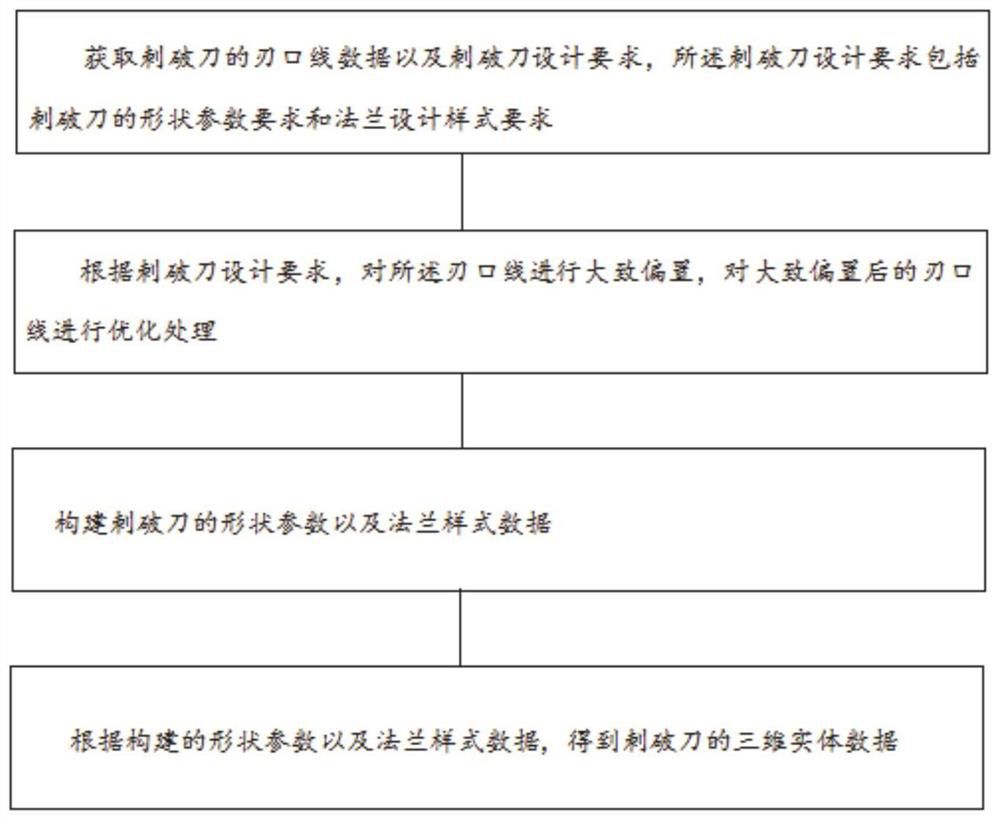

Three-dimensional design method and system for piercing knife of vehicle stamping die

ActiveCN114049440AImprove design qualityHigh precisionGeometric CADSpecial data processing applicationsEngineeringStructural engineering

The invention provides a three-dimensional design method and system for a piercing knife of an vehicle stamping die. The method comprises the steps: obtaining the cutting edge line data of the piercing knife and the design requirements of the piercing knife, and the design requirements of the piercing knife comprise the shape parameter requirements of the piercing knife and the design style requirements of a flange; according to the design requirement of the piercing knife, the cutting edge line is roughly biased, and the cutting edge line which is roughly biased is optimized; constructing shape parameters of the piercing knife and flange style data; obtaining three-dimensional entity data of the piercing knife according to the constructed shape parameters and the flange style data; according to the method and the device, the cutting edge line is roughly biased and the roughly biased cutting edge line is optimized according to the design requirements of the piercing knife, so that the accuracy of the shape parameters of the constructed piercing knife and the accuracy of the flange style data are greatly improved, and the design quality of the piercing knife is improved; Meanwhile, the mode that the knife is punctured by splicing is avoided, and the design efficiency is improved.

Owner:山东山大华天软件有限公司

A Correction Method for Data Loss of Digital Input Electric Energy Information Sampling

ActiveCN103424733BThe effect of interpolation is smallSave data storage spaceNon-electrical signal transmission systemsElectrical measurementsAlgorithmPower grid

The invention discloses a correction method for digital quantity input electric energy information sampling data loss. The method is an interpolation method based on a sine curve and comprises the steps of: judging the serial number of sampling points in electric energy information sampling data and capturing sampling points with frame loss; recording the latest sampling point value as a sample value used for interpolation; when the number of the sampling points of a cyclic wave is 80, processing the sample value by adopting a median interpolation way once information of a sampling point is lost; when the number of the sampling points of a cyclic wave is 256, processing the sample value by adopting a recursive extrapolation way and calculating a target sampling point value which needs to be supplemented once the information of 8 sampling points is lost. As a fundamental wave of a power grid is a sine curve, the interval of the sampling points is fixed, the number of the sampling points of the cyclic wave is known, interpolation can be carried out by adopting a sine curve fitting way, and high reliability is achieved. The calculation amount and the needed data storage space of the method are small, so that the specific engineering application can be satisfied well.

Owner:JIANGSU LINYANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com