Composite cement additive

A cement admixture and composite technology, applied in the field of cement additives, can solve the problems of poor comprehensive efficiency and single function, and achieve the effect of small impact, meeting engineering requirements and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

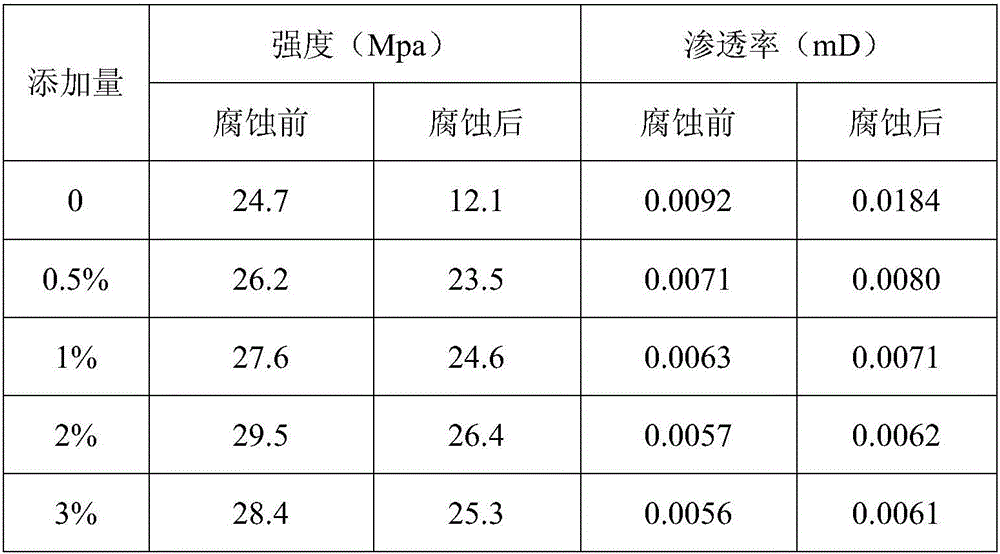

Embodiment 1

[0018] A composite cement admixture, made of the following raw materials in parts by weight: 16 parts of calcium hydroxide, 10 parts of isopropanol, 8 parts of zinc chloride, 2 parts of 2-methyl-dodecan-5-one, 4 parts of dodecyl dimethyl betaine, 2 parts of lignosulfonate, 1 part of alkyl succinimide, 6 parts of acetophenone, 2 parts of ammonium sulfate, 4 parts of tetrabutylammonium borohydride, 5 parts of palmitic acid, 6 parts of stigmasterol.

[0019] The preparation method of described composite cement admixture comprises the following steps:

[0020] 1) Mix the lauryl dimethyl betaine, lignin sulfonate, alkyl succinimide and isopropanol solution in the formula amount and put them into the reaction kettle to heat up and react;

[0021] 2) Dissolve the ammonium sulfate and zinc chloride solution of formula quantity in water respectively to obtain ammonium sulfate solution and zinc chloride solution, slowly pour ammonium sulfate solution and zinc chloride solution into the...

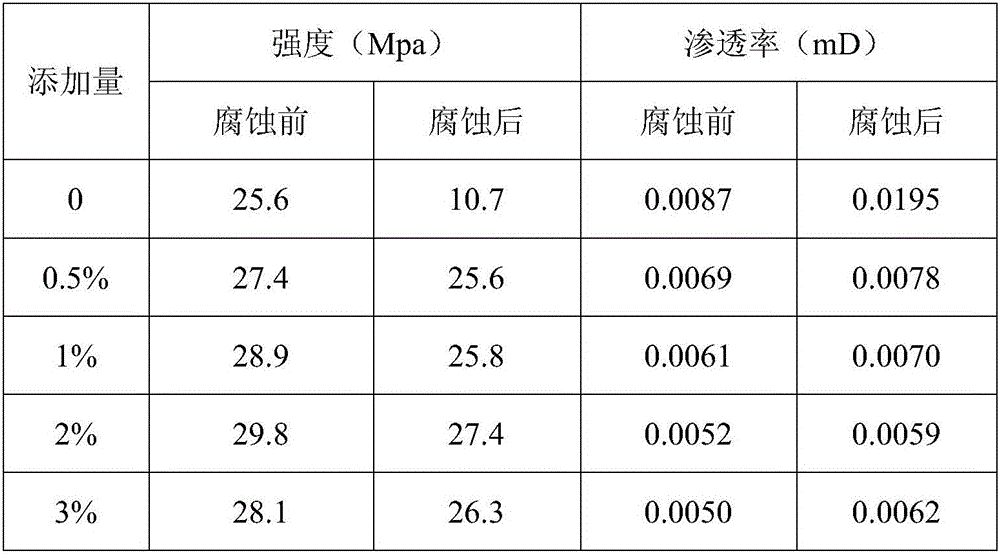

Embodiment 2

[0031] A composite cement admixture, made of the following raw materials in parts by weight: 22 parts of calcium hydroxide, 16 parts of isopropanol, 12 parts of zinc chloride, 8 parts of 2-methyl-dodecan-5-one, 10 parts of dodecyl dimethyl betaine, 6 parts of lignosulfonate, 5 parts of alkyl succinimide, 10 parts of acetophenone, 8 parts of ammonium sulfate, 10 parts of tetrabutylammonium borohydride, 9 parts of palmitic acid, 12 parts of stigmasterol.

[0032] The preparation method of described composite cement admixture comprises the following steps:

[0033] 1) Mix the lauryl dimethyl betaine, lignin sulfonate, alkyl succinimide and isopropanol solution in the formula amount and put them into the reaction kettle to heat up and react;

[0034] 2) Dissolve the ammonium sulfate and zinc chloride solution of formula quantity in water respectively to obtain ammonium sulfate solution and zinc chloride solution, slowly pour ammonium sulfate solution and zinc chloride solution in...

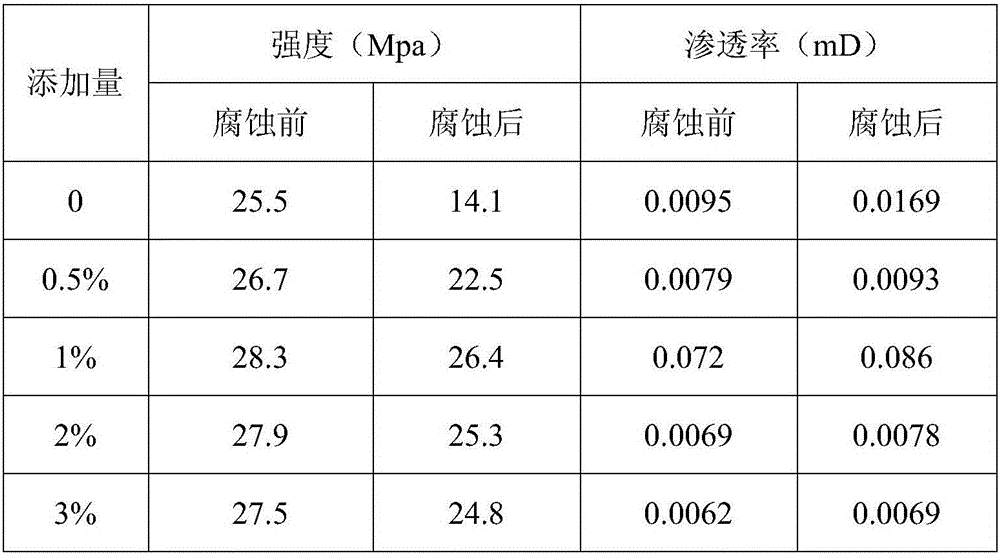

Embodiment 3

[0044] A composite cement admixture, consisting of the following parts by weight: 18 parts of calcium hydroxide, 12 parts of isopropanol, 9 parts of zinc chloride, 4 parts of 2-methyl-dodecan-5-one, ten parts 6 parts of dialkyl dimethyl betaine, 3 parts of lignosulfonate, 2 parts of alkyl succinimide, 7 parts of acetophenone, 4 parts of ammonium sulfate, 6 parts of tetrabutyl ammonium borohydride, palm 6 parts of acid, 8 parts of stigmasterol.

[0045] The preparation method of described composite cement admixture comprises the following steps:

[0046] 1) Mix the lauryl dimethyl betaine, lignin sulfonate, alkyl succinimide and isopropanol solution in the formula amount and put them into the reaction kettle to heat up and react;

[0047] 2) Dissolve the ammonium sulfate and zinc chloride solution of formula quantity in water respectively to obtain ammonium sulfate solution and zinc chloride solution, slowly pour ammonium sulfate solution and zinc chloride solution into the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com