Method for hydraulically optimizing centrifugal pump under working conditions based on loss

A hydraulic optimization and centrifugal pump technology, applied in the direction of pumps, non-variable pumps, non-displacement pumps, etc., can solve the problem of scheme optimization without considering the influence of guide vanes, so as to improve design efficiency and shorten design cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

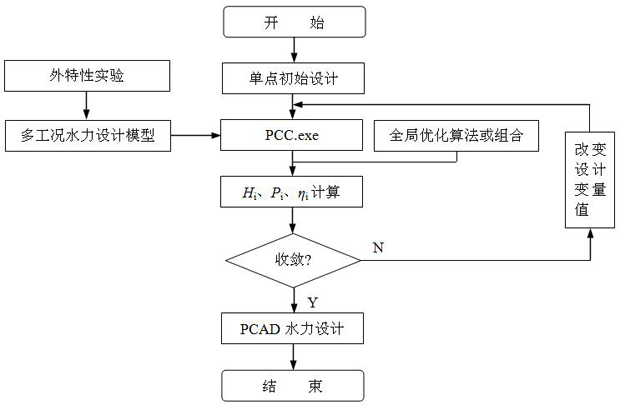

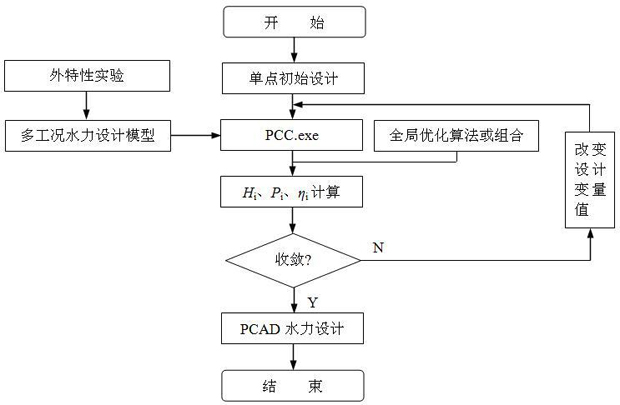

Method used

Image

Examples

Embodiment

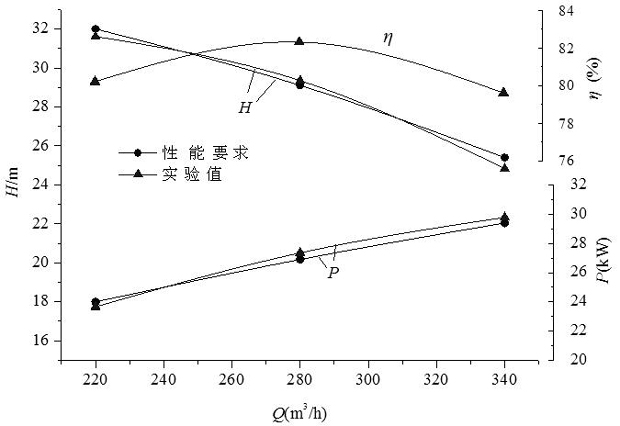

[0024] For a centrifugal pump with a specific speed of 117.8, its performance parameters under three working conditions are: small flow condition Q 1 =220m 3 / h, H 1 =32m, P 1 =24kW; design conditions Q 2 =280m 3 / h, H 2=29.1m, P 2 =26.9kW; large flow condition Q 3 =340m 3 / h, H 3 =25.4m, P 3 =29.4kW.

[0025] (1) Based on various loss formulas of centrifugal pumps, a multi-condition hydraulic optimization model of centrifugal pumps is established.

[0026] Theoretical head formula based on centrifugal pump H t , and the hydraulic loss in the impeller and volute Δ h , to establish the relationship expression between head and flow H = H t -Δ h = f 1 ( Q , key geometric parameters).

[0027] Theoretical Head of Centrifugal Pump with Finite Number of Vanes H t for:

[0028] (1)

[0029] In the formula: D 2 is the outer diameter of the impeller; n is the rotational speed; σ is the Stodola slip coefficient, ; z is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com