Three-dimensional design method and system for piercing knife of vehicle stamping die

A stamping die and three-dimensional design technology, applied in the field of computer-aided design, can solve the problems of difficult quality assurance, low production efficiency, and high labor intensity of workers, so as to improve precision and efficiency, high accuracy and efficiency, and improve design quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

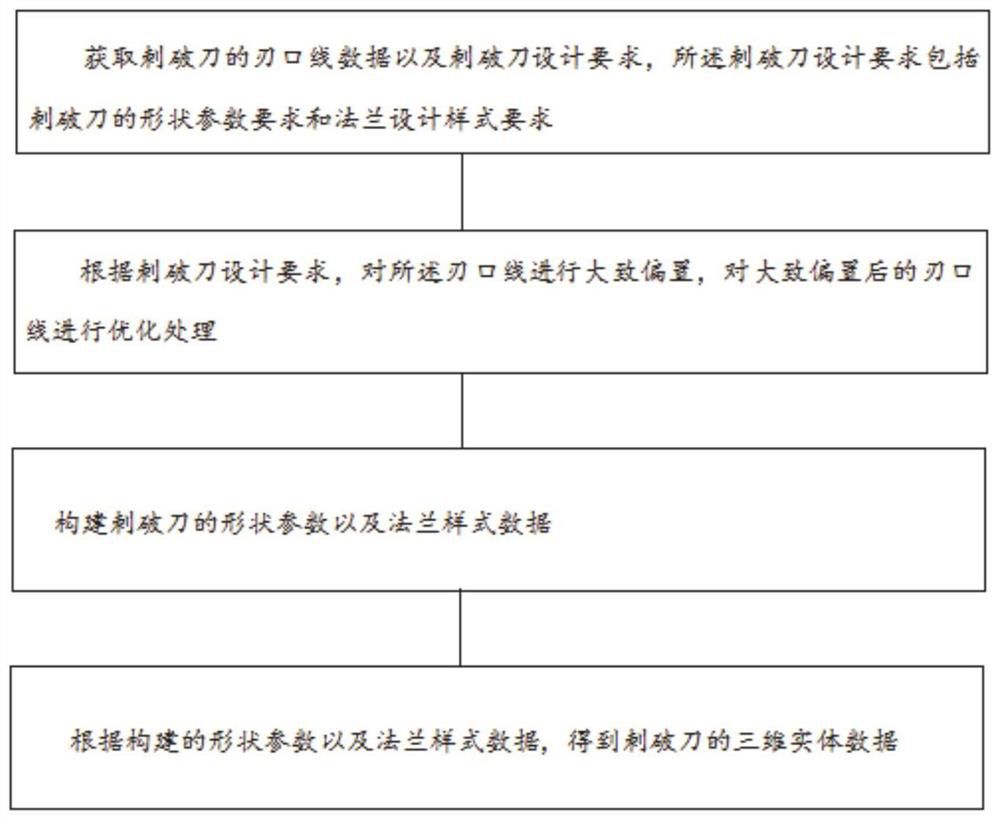

[0039] Such as figure 1 As shown, the present embodiment provides a three-dimensional design method for the piercing knife of the automobile stamping die, including:

[0040] Obtain the edge line data of the piercing knife and the design requirements of the piercing knife. The design requirements of the piercing knife include the shape parameter requirements and flange design style requirements of the piercing knife; specifically, when obtaining the edge line data, apply For various parametric curves, including quadratic curves, Bezier curves, B-spline curves and NURBS curves, it can receive UG, ProE, CATIA, STEP and IGES curve models in Step format data exchange.

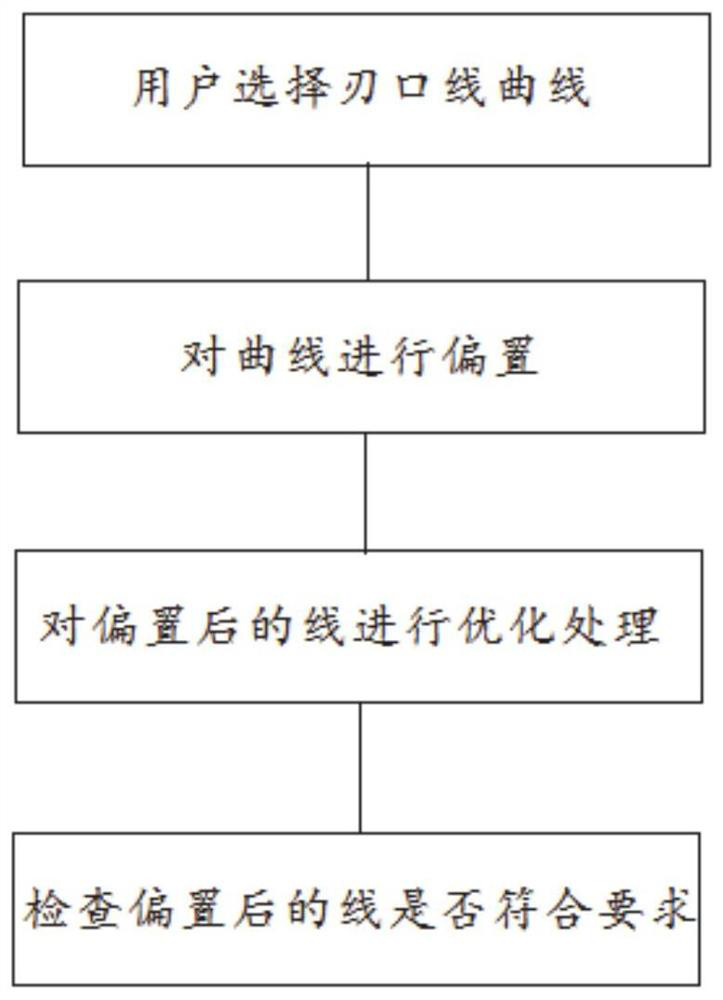

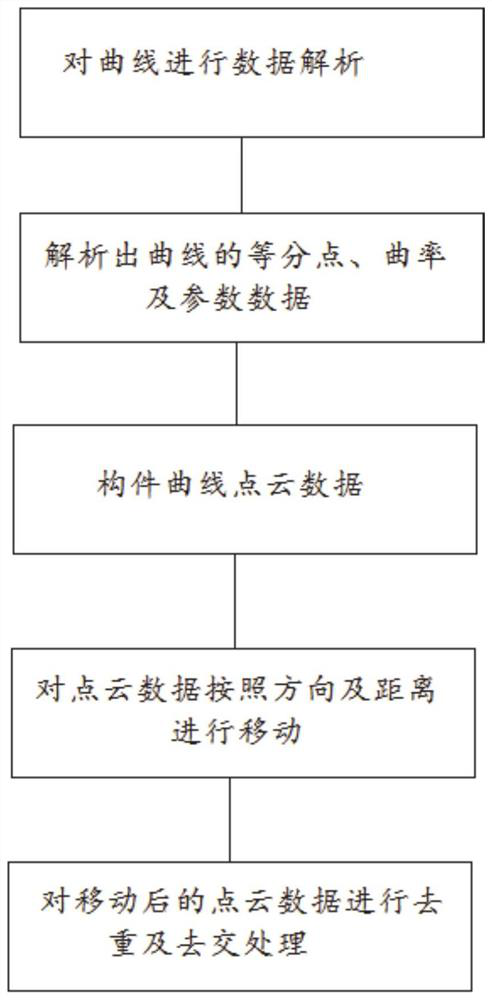

[0041] According to the design requirements of the piercing knife, the cutting edge line is roughly offset, and the roughly offset cutting edge line is optimized;

[0042] Construct the shape parameters and flange style data of the piercing knife; specifically, construct the cutting edge surface data, elevation su...

Embodiment 2

[0053] The present embodiment provides a kind of three-dimensional design system of the piercing knife that is used for automobile stamping die, comprises data acquisition module, optimization module and data reconstruction module and design module;

[0054] The data acquisition module is configured to: obtain the edge line data of the puncture knife and the design requirements of the puncture knife, the design requirements of the puncture knife include the shape parameter requirements and the flange design style requirements of the puncture knife;

[0055] The optimization module is configured to: according to the design requirements of the piercing knife, roughly offset the cutting edge line, and optimize the roughly offset cutting edge line;

[0056] The data reconstruction module is configured to: construct shape parameters and flange style data of the piercing knife;

[0057] The design module is configured to: obtain the three-dimensional solid data of the puncture knife...

Embodiment 3

[0059] This embodiment provides a computer-readable storage medium, on which a computer program is stored. When the program is executed by a processor, the steps of the three-dimensional design method for a puncture knife for an automobile stamping die described in Embodiment 1 are realized. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com