Method for obtaining high-efficiency low-noise impeller of centrifugal pump volute

A centrifugal pump and pump volute technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluid, can solve the problem that the impeller cannot meet the requirements of the design, the performance cannot be guaranteed, and the centrifugal pump is not considered. Unsteady performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

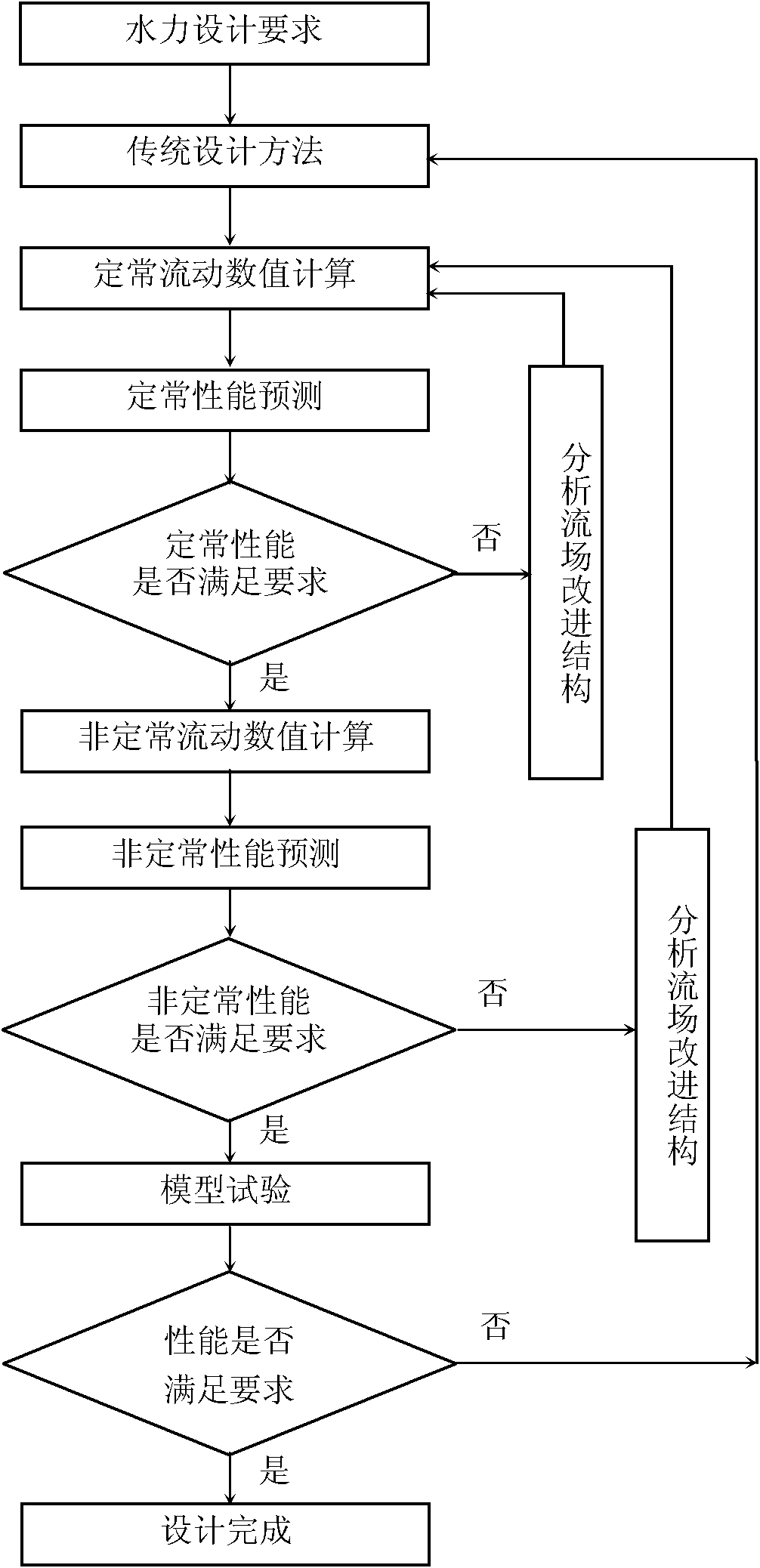

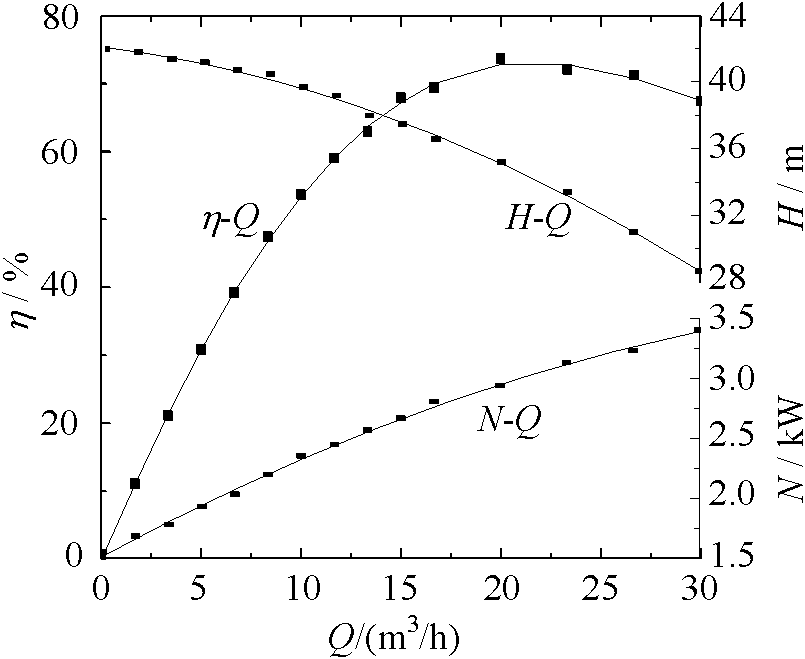

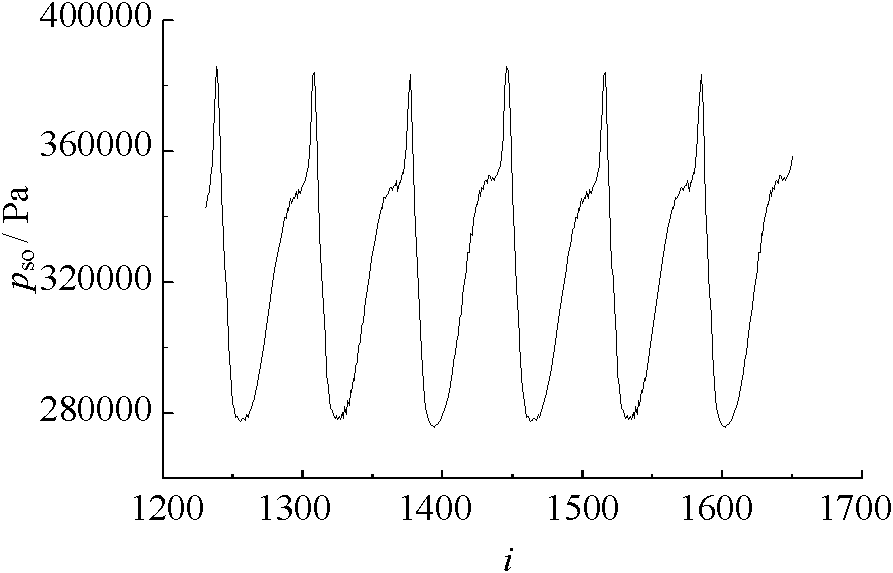

[0089] The main structural dimensions and design conditions of a pump are listed in Table 1. The impeller is modified and designed on the basis of the volute of the existing centrifugal pump. After the modified design, the head flow rate is required to be unchanged, the efficiency is above 70%, the fluctuation range of the static pressure at the outlet is within 0.06MPa, and the maximum negative peak of the static pressure fluctuation at the inlet is required. higher than the saturated vapor pressure.

[0090] Table 1 Main dimensions and design conditions of centrifugal pumps

[0091]

[0092]

[0093] The main structural dimensions of the impeller designed by the traditional design method are: the impeller inlet diameter is 80mm, the impeller outer diameter is 315mm, the number of blades is 6, the blade thickness is 5.0mm, the blade inlet placement angle is 20°, the outlet placement angle is 42°, and the blade wrap angle is 90° °, blade length 160mm.

[0094] (1) Stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com