Carbon dioxide capture pressure swing adsorption tower

A technology of pressure swing adsorption and carbon dioxide, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of lower adsorption efficiency, fluctuation of adsorption amount, uneven distribution, etc., and achieve improved adsorption efficiency, improved stability, Favorable Effects on Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] The detailed implementation is as follows:

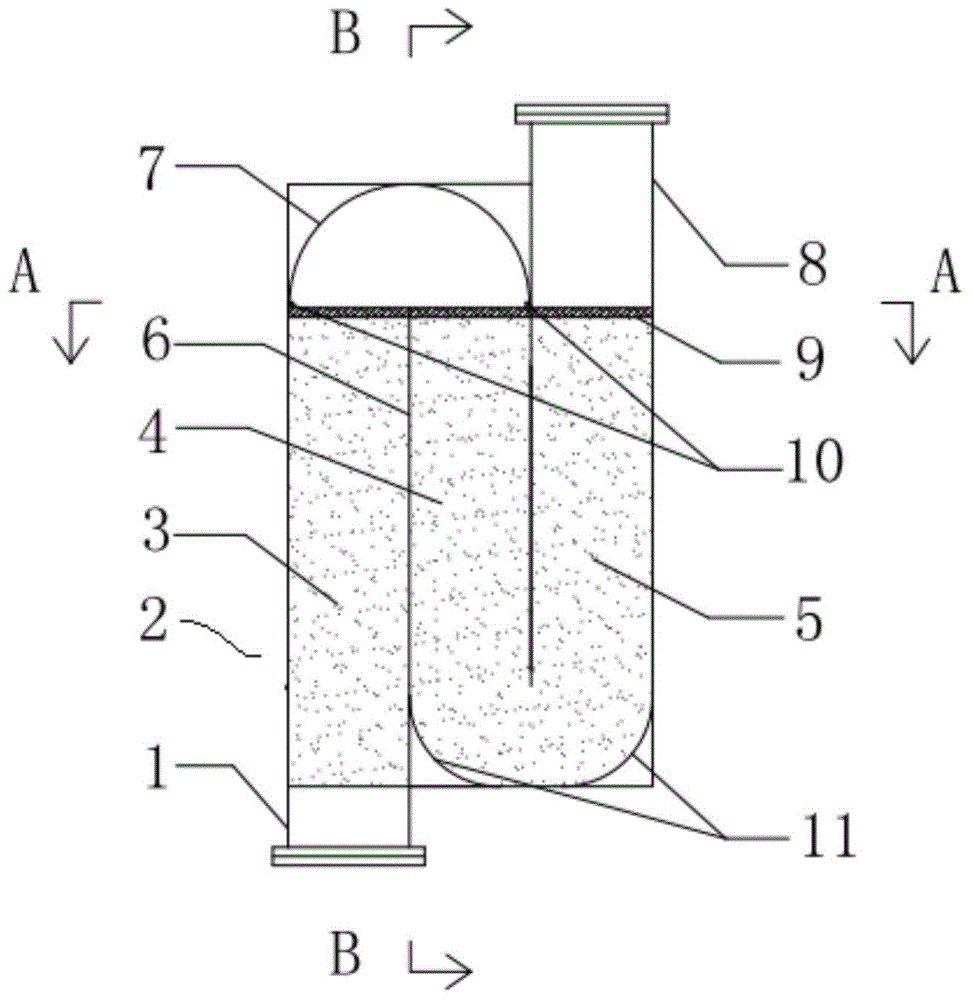

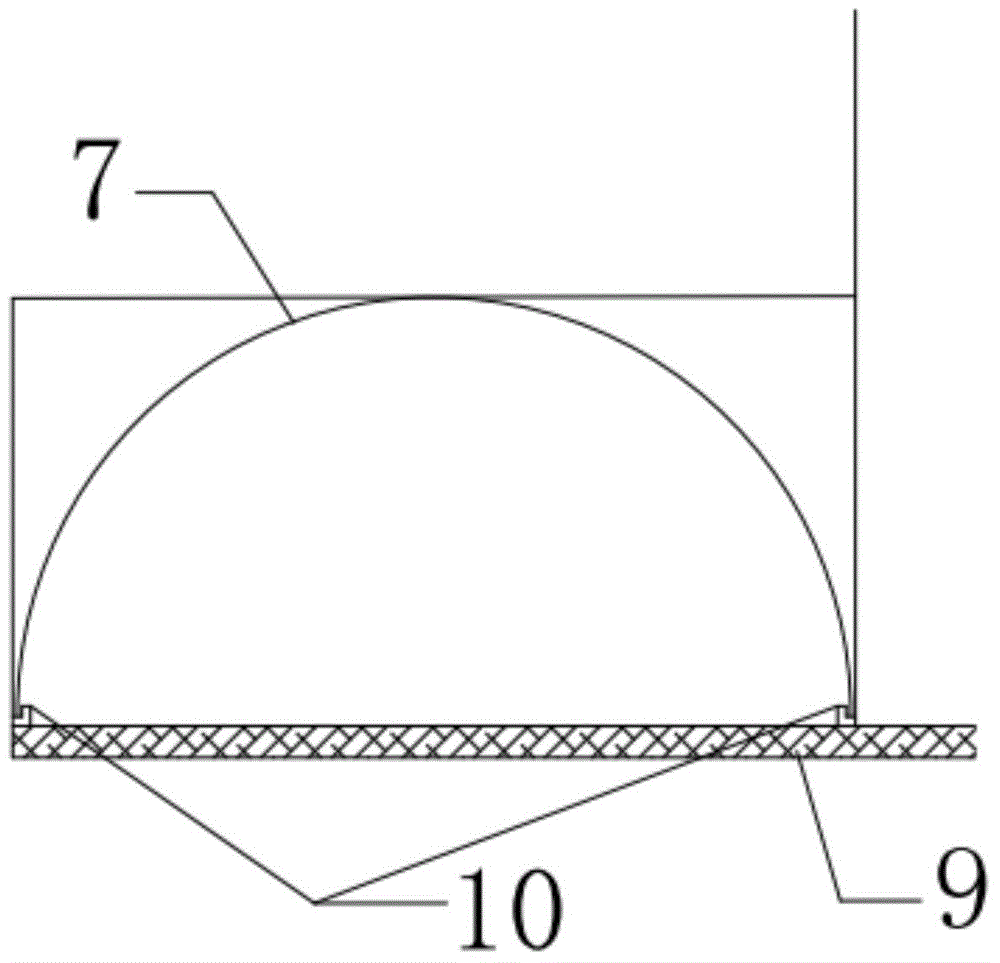

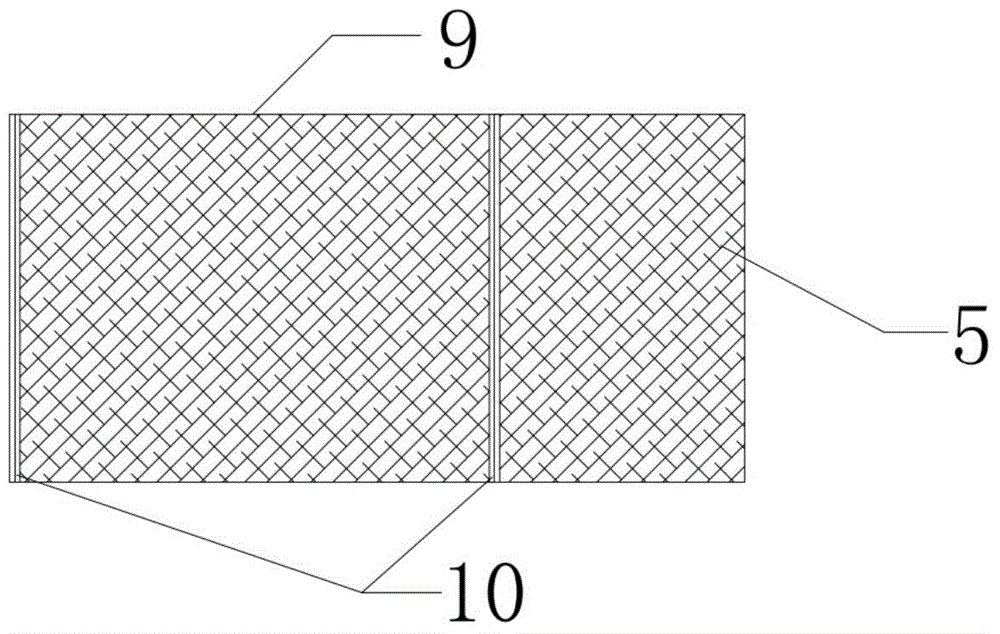

[0032] Such as figure 1 , figure 2 , image 3 As shown, a carbon capture pressure swing adsorption tower proposed in this embodiment is a parallel combination of multiple baffled fixed bed adsorption towers, and the baffled fixed bed adsorption tower 2 divides the fixed bed into multiple baffles 6 In the gas adsorption channel, a compression pad 9 is arranged above the bed, an annular deflector 7 is arranged at the corner of the first gas adsorption channel 3 and the second gas adsorption channel 4, and an annular deflector 7 is arranged at the corner of the second gas adsorption channel 4 and the third gas adsorption channel 5 Two bent plates 11 are arranged.

[0033] combine Figure 4 with Figure 5 , the baffled fixed-bed adsorption tower 2 of the present embodiment has a rectangular structure, the inlet flue 1 and the outlet flue 8 are rectangular or square flues, and the number n≥1 of the baffled fixed-bed adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com