Angle-variable fan

A fan and angle technology, applied in the control of coolant flow, engine components, machines/engines, etc., can solve the problems of easy vibration and noise, unacceptable to consumers, and large impact of electromagnetic drive, so as to reduce fuel waste and vibration. Small, meet the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

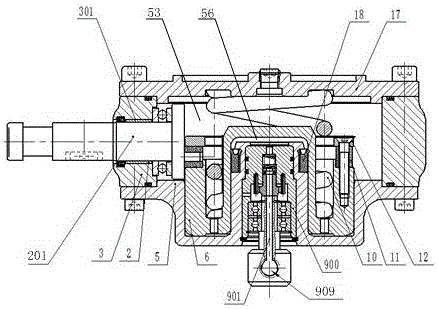

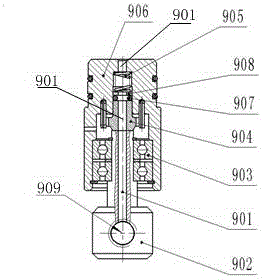

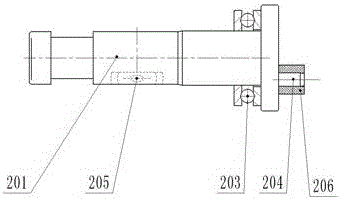

[0021] Embodiment 1, see attached Figure 1-4 : A variable-angle fan, comprising a base body, 6 fan blade shafts 201 that can rotate within 30° clockwise and counterclockwise relative to the base body, and 1 fan blade fixedly connected to each fan blade shaft 201, the fan blade A fan blade installation groove 205 is opened in the middle of the shaft 201 for fixing the fan blade. The positioning pin 204 is arranged eccentrically on the inner end surface of the fan blade shaft 201; the base body includes the cylinder body 5, the connection plate 17 and the fan seat body 3 between the cylinder body 5 and the connection plate 17, and the three are fixedly connected Together and surround the cavity 53; the cylinder 5 has an inner annular groove and an outer central hole, and an oil inlet part 900 that can be fixed relative to the cylinder 5 is arranged in cooperation with the outer central hole; an annular ring is arranged in cooperation with the inner annular groove. Piston 6, an...

Embodiment 2

[0031] Example 2, see Figure 1-3 , 5 Others are the same as embodiment 1, the difference is that because the oil pressure of the hydraulic source exceeds the working range of the variable angle hydraulic fan oil pressure, a pressure reducing valve is arranged in front of the two-position three-way solenoid valve. In order to realize automatic control, the manual self-resetting switch can also be removed, and its control line is connected with the automobile ECU, so as to realize automatic control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com