Gap design method used for automobile covering part die

A technology for automotive panels and design methods, applied in the direction of calculation, 3D modeling, special data processing applications, etc., can solve problems such as unexplained, unexplained how to design the surface, etc., to achieve convenient and flexible use, ensure continuity and quality , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

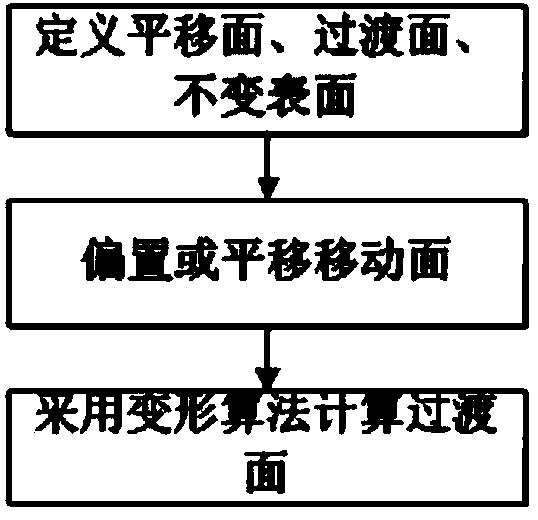

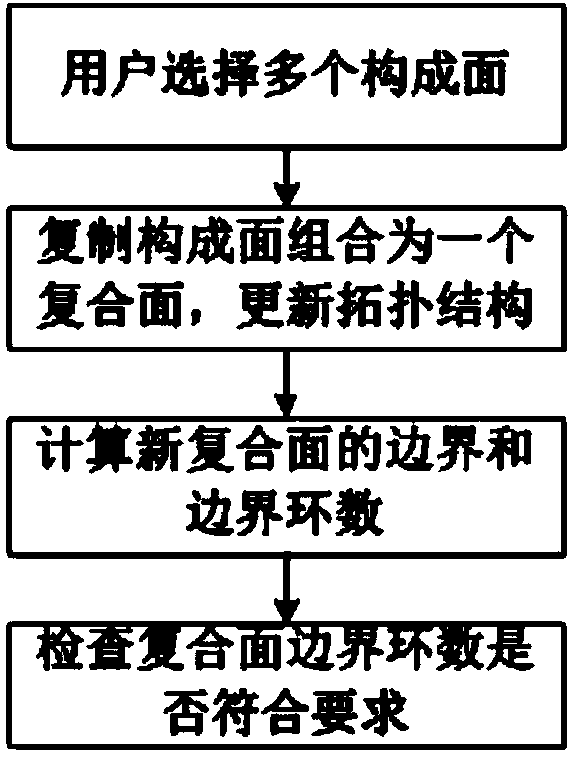

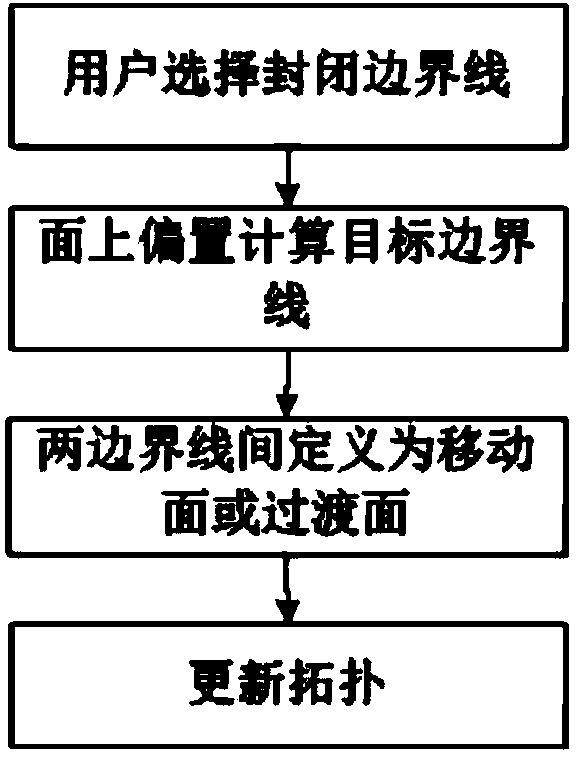

Method used

Image

Examples

Embodiment 1

[0068] (1) Read the parametric three-dimensional surface model of the automobile panel into the computer, analyze the file format, and obtain the surface primitives, topological structure and parameter information of the surface model;

[0069] (2) The implementation steps of the die edge opening processing are: the user selects the intersection line between the product surface and the non-product surface through the interactive operation in the graphics area, that is, several edge lines on the outer periphery of the product, and connects end to end to form a closed and continuous outer peripheral edge line ; Then, set the following parameters: the adjustment amount is the offset or translation distance of the moving surface when the air is open, the open direction is the direction of the translation offset of the moving surface, and the area value is the length value used for the surface offset to form the transition surface , the color and layer of the surface after blanking,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com