Integrated steam generator of reactor

A technology of steam generators and reactors, which is applied in steam generation methods using heat carriers, nuclear power generation, nuclear power plants, etc., to achieve the effects of reducing height, high water storage and accident mitigation capabilities, and enhancing heat transfer capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An integrated reactor steam generator according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

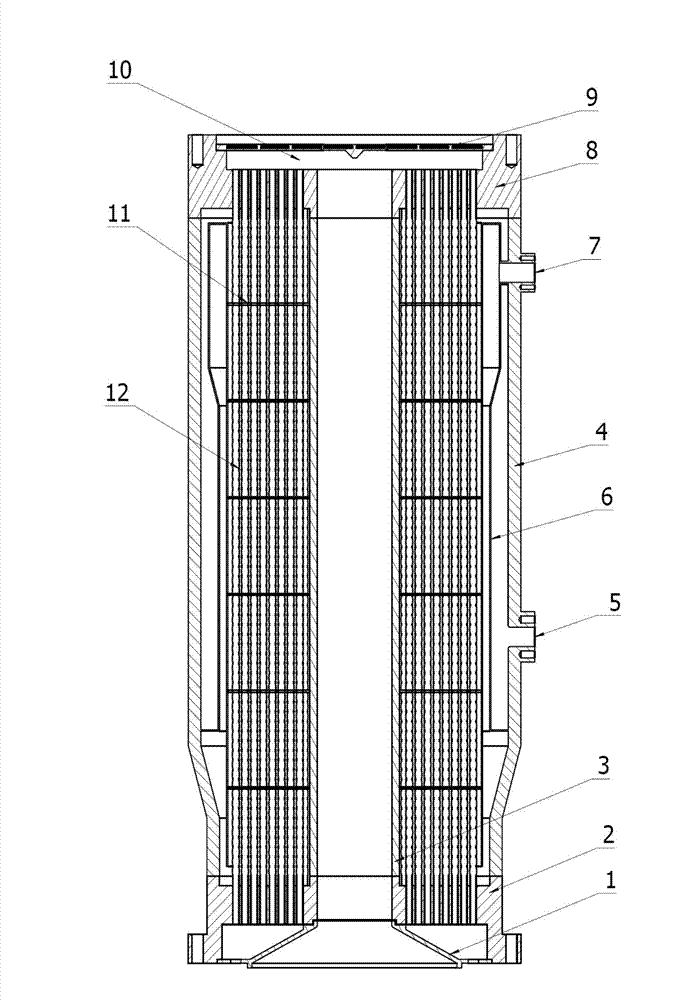

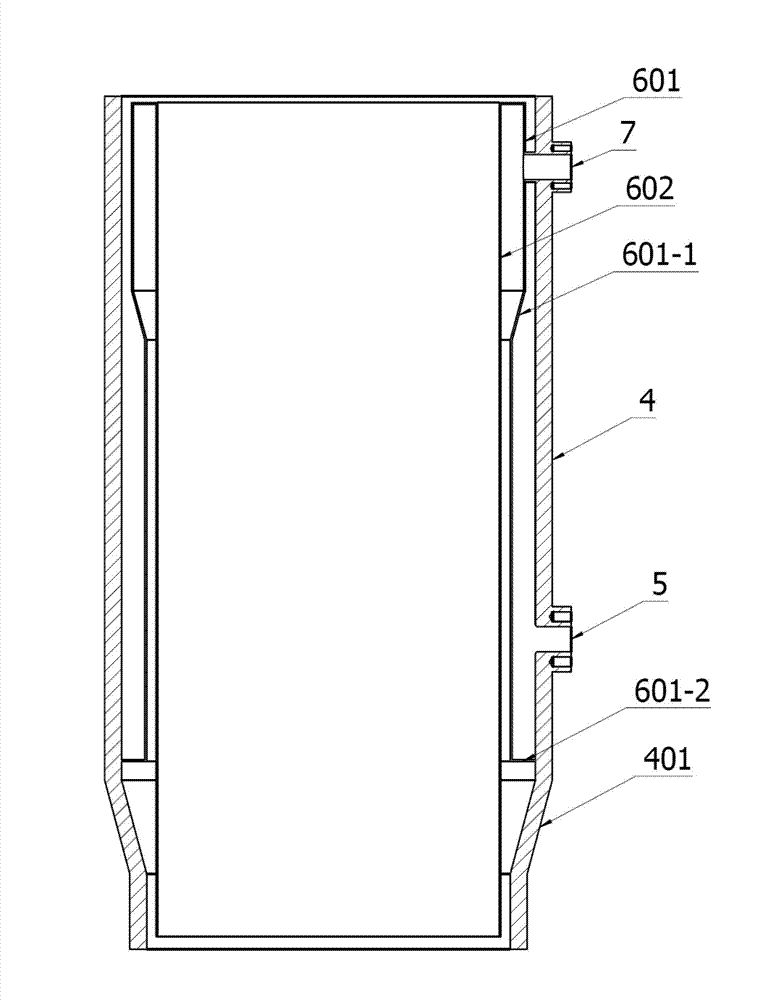

[0021] Such as figure 1 As shown, the steam generator of the integrated reactor of the present invention has a double-layer cylinder, that is, an inner wall cylinder 3 and an outer wall cylinder 4, and the top and bottom ends of the inner wall cylinder 3 and the outer wall cylinder 4 are respectively connected and fixed. There are upper tube plate 8 and lower tube plate 2, the upper water chamber partition plate 9 seals the top of the inner wall cylinder 3 and the outer wall cylinder body 4, and the upper water chamber 10 is formed between the upper water chamber partition plate 9 and the upper tube plate 8. The primary side shroud 1 is fixed at the bottom of the inner wall cylinder 3 .

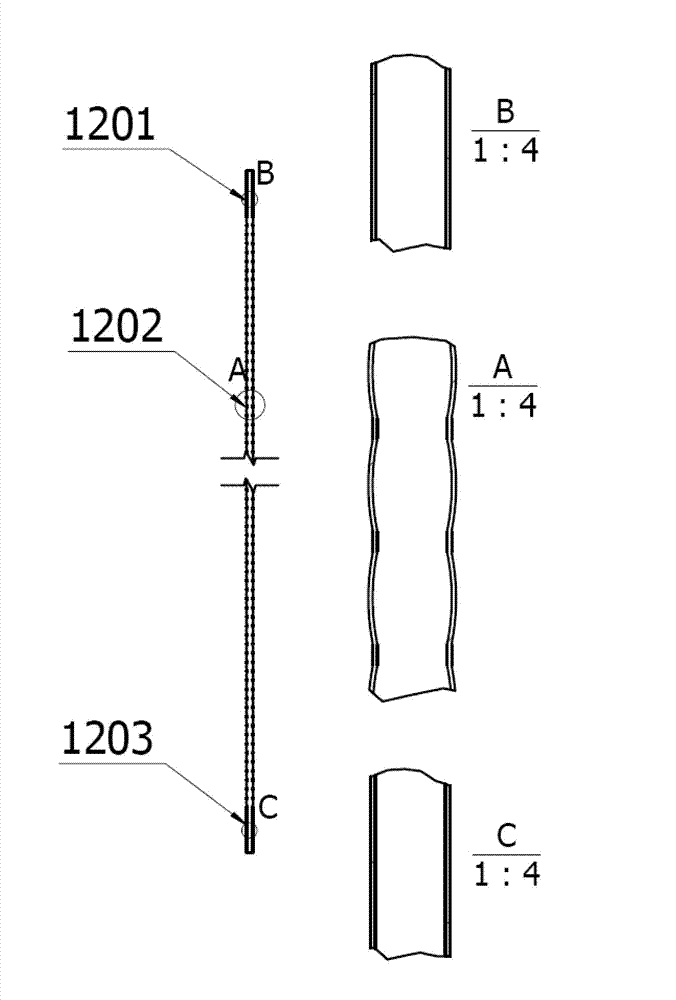

[0022] The tube bundle sleeve 6 is arranged between the inner wall cylinder 3 and the outer wall cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com