Bituminous mixture modifier and preparation method thereof

An asphalt mixture and modifier technology, which is applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of low temperature performance defects and poor rutting resistance, and achieves improved low temperature crack resistance, economical and Considerable social benefits and simple addition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

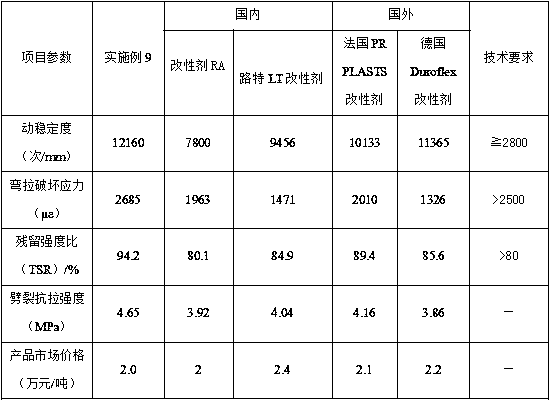

Examples

Embodiment 1

[0037] According to the mass ratio of each component, 65 parts of waste polyethylene recovered from industrial, agricultural and daily necessities, 15 parts of waste polypropylene recycled from industrial, agricultural and daily necessities, and 3 parts of polysulfide rubber Powder, 0.2 parts of cumene hydroperoxide, 1.5 parts of 2,5-dimethyl-2,5-di-tert-butyl peroxyhexane, 0.2 parts of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 15 parts of 325-400 mesh heavy calcium carbonate powder, 0.1 part of carbon black in a high-speed mixer at a low speed of 1000r / min for 10min, and a high-speed 1800r / min for 5min. After mixing evenly, use a single-screw feeder to lift it into the silo of a twin-screw extruder, extrude a columnar product with a diameter of 5mm at 200°C and enter it into a circulating water cooling tank at room temperature, then blow dry, bake, pelletize, Packing means to obtain the asphalt mixture modifier.

[0038] Accor...

Embodiment 2

[0040]According to the mass ratio of each component, 65 parts of waste polyethylene recovered from industrial, agricultural and daily necessities, 18 parts of waste polypropylene recovered from industrial, agricultural and daily necessities, and 3 parts of polysulfide rubber Powder, 0.2 parts of cumene hydroperoxide, 1.5 parts of 2,5-dimethyl-2,5-di-tert-butyl peroxyhexane, 0.2 parts of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 12 parts of 325-400 mesh heavy calcium carbonate powder, 0.1 part of carbon black in a high-speed mixer at a low speed of 1000r / min for 10min, and a high-speed 1800r / min for 5min, After mixing evenly, use a single-screw feeder to lift it into the silo of a twin-screw extruder, extrude a columnar product with a diameter of 5mm at 200°C and enter it into a circulating water cooling tank at room temperature, then blow dry, bake, pelletize, Packing means to obtain the asphalt mixture modifier.

[0041] Accor...

Embodiment 3

[0043] According to the mass ratio of each component, 65 parts of waste and old polyethylene recovered from industrial, agricultural and daily necessities, 20 parts of waste and old polypropylene recycled from industrial, agricultural and daily necessities, and 3 parts of polysulfide rubber Powder, 0.2 parts of cumene hydroperoxide, 1.5 parts of 2,5-dimethyl-2,5-di-tert-butyl peroxyhexane, 0.2 parts of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 10 parts of 325-400 mesh heavy calcium carbonate powder, 0.1 part of carbon black in a high-speed mixer at a low speed of 1000r / min for 10min, and a high-speed 1800r / min for 5min, After mixing evenly, use a single-screw feeder to lift it into the silo of a twin-screw extruder, extrude a columnar product with a diameter of 5mm at 200°C and enter it into a circulating water cooling tank at room temperature, then blow dry, bake, pelletize, Packing means to obtain the asphalt mixture modifier....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com