Modification method of sludge ceramsite for enhancing formaldehyde adsorption performance

A technology of sludge ceramsite and formaldehyde adsorption, applied in chemical instruments and methods, ceramic products, ceramic material production and other directions, can solve the problems of complex process, danger and high concentration of lye, achieve simple and convenient operation and good removal of indoor formaldehyde Effect of improving gas capacity and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

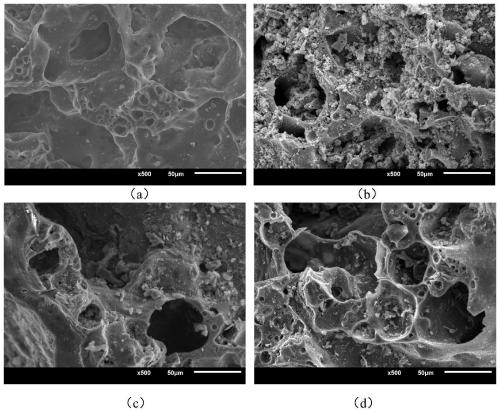

[0030] A method for modifying sludge ceramsite that enhances the performance of adsorbing formaldehyde, comprising the following steps: using refractory activated sludge and clay from sewage treatment plants as raw materials, mixing them in a ratio of 1:1, and heating them at a high temperature of 1250°C Calcining to make sludge ceramsite, and then pulverizing the fired sludge ceramsite through a 2mm sieve to prepare dry sludge ceramsite; adding sludge ceramsite to potassium permanganate solution, wherein, the The mass volume ratio of dry sludge ceramsite to potassium permanganate solution is 3:20, and the concentration of potassium permanganate solution is 20g L -1 . Immerse in an oven at 45°C for 18 hours, then let it stand for 30 minutes and filter, then put the filter material in an oven, dry it at 105°C, transfer it to a muffle furnace, and roast it at 450°C for 2 hours to obtain a manganese-loaded modified sex ceramsite.

Embodiment 2

[0032] A method for modifying sludge ceramsite that enhances the performance of adsorbing formaldehyde, comprising the following steps: mixing activated sludge that is difficult to treat in a sewage treatment plant with clay, wherein the mass ratio of activated sludge to clay is 1:2, and the Calcined at 1200°C to make sludge ceramsite, and then crush the fired sludge ceramsite through a 3mm sieve to prepare dry sludge ceramsite; add sludge ceramsite to potassium permanganate solution , wherein, the mass volume ratio of described dry sludge ceramsite and potassium permanganate solution is 1:10, and the concentration of potassium permanganate solution is 10g L -1 . Immerse in an oven at 40°C for 8 hours, then let it stand for 45 minutes and filter, then put the filter material in an oven, dry it at 100°C, transfer it to a muffle furnace, and roast it at 440°C for 2.5 hours to obtain loaded manganese Modified ceramsite.

Embodiment 3

[0034] A method for modifying sludge ceramsite that enhances the performance of adsorbing formaldehyde, comprising the following steps: mixing activated sludge that is difficult to treat in a sewage treatment plant with clay, wherein the mass ratio of activated sludge to clay is 3:2. Calcined at 1300°C to make sludge ceramsite, and then crush the fired sludge ceramsite through a 1mm sieve to prepare dry sludge ceramsite; add sludge ceramsite to potassium permanganate solution , wherein, the mass volume ratio of described dry sludge ceramsite and potassium permanganate solution is 2.2:20, and the concentration of potassium permanganate solution is 5g L -1 . Immerse in an oven at 50°C for 12 hours, then let it stand for 15 minutes and filter, then put the filter material in an oven, dry it at 110°C, transfer it to a muffle furnace, and roast it at 460°C for 1.5h to obtain loaded manganese Modified ceramsite.

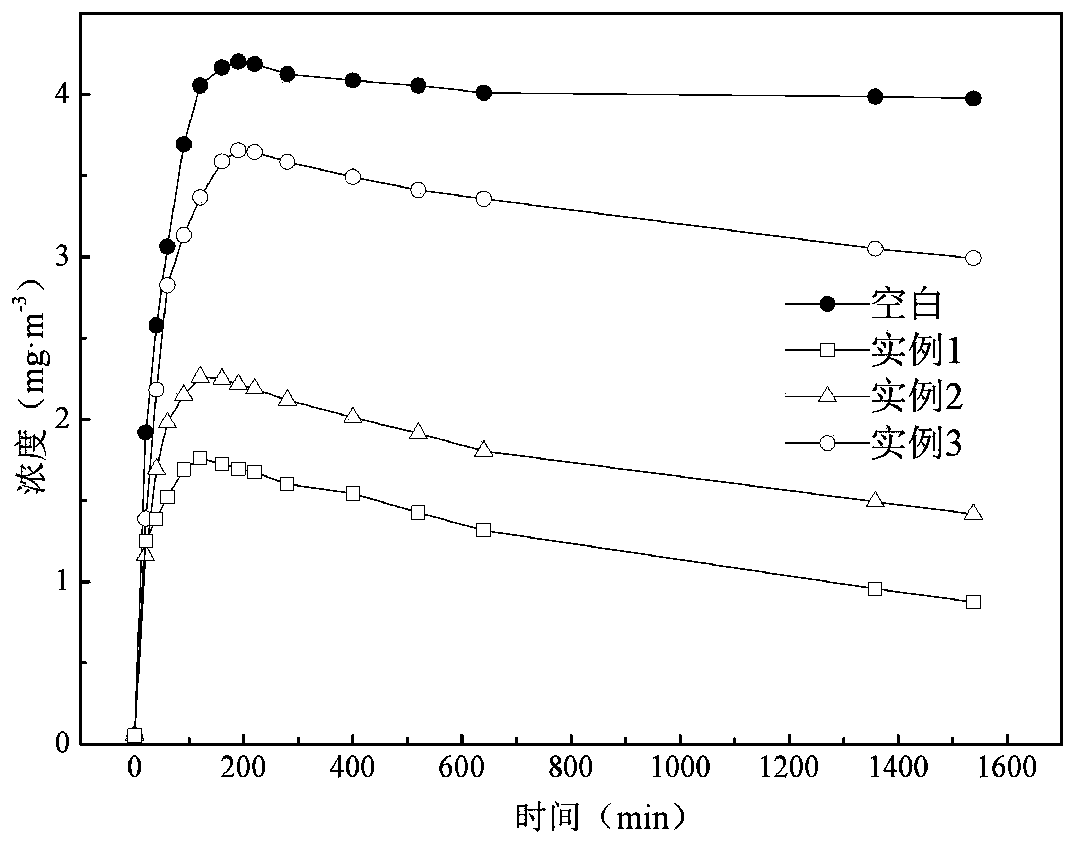

[0035] The technical effect of the present invention is illustrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com