Preparation method of grape special purpose seaweed fertilizer

A seaweed fertilizer and grape technology, which is applied in the direction of nitrogen fertilizer, application, organic fertilizer, etc., can solve the problems of environmental pollution, waste of resources, high cost of raw materials for seaweed fertilizer production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

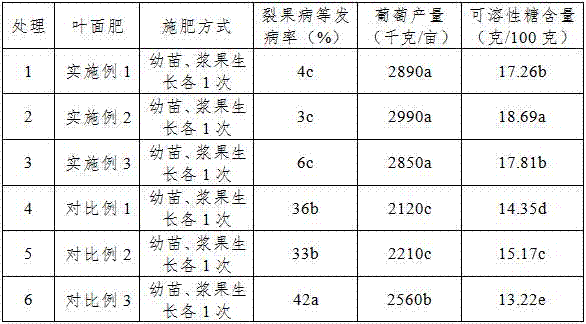

Examples

Embodiment 1

[0021] Kelp slag and distilled water were mixed at a mass ratio of 1:20, stirred with a magnetic stirrer at 100 rpm for 10 minutes, then centrifuged at 8000 rpm for 5 minutes, and the supernatant was removed after centrifugation; the above process was repeated 3 times, and freeze-dried. After pretreatment, mix the kelp slag and distilled water with a mass ratio of 1:30, place it in the reactor, add enzyme according to the mass ratio of kelp slag and enzyme 100:1, adjust the pH to 4.5, stir at 100 rpm, and stir for 5 minutes Finally, the stirring speed was adjusted to 50 rpm, and the entire enzyme biocatalytic conversion reaction process was 3 hours, and the temperature was controlled at 45°C; 15 minutes after the start of the reaction, the strategy of continuously adding kelp residue and enzyme was adopted, cellulase and β- The glucosidase is mixed at a mass ratio of 1:1; the added kelp slag and enzyme are mixed at a mass ratio of 5:1, and the kelp slag and enzyme mixture are c...

Embodiment 2

[0023] Kelp slag and distilled water were mixed at a mass ratio of 1:6, stirred with a magnetic stirrer at 100 rpm for 10 minutes, then centrifuged at 8000 rpm for 5 minutes, and the supernatant was removed after centrifugation; the above process was repeated 3 times, and freeze-dried. After pretreatment, mix the kelp slag and distilled water at a mass ratio of 1:10, place it in the reactor, add enzyme according to the mass ratio of kelp slag and enzyme 10:1, adjust the pH to 6.5, stir at 200 rpm, and stir for 15 minutes Finally, the stirring speed was adjusted to 150 rpm, and the entire enzyme biocatalytic conversion reaction process was 3 hours, and the temperature was controlled at 65°C; 30 minutes after the start of the reaction, the strategy of continuously adding kelp residue and enzyme was adopted, cellulase and β- The glucosidase is mixed at a mass ratio of 5:1; the added kelp slag and enzyme are mixed at a mass ratio of 100:1, and the kelp slag and enzyme mixture are c...

Embodiment 3

[0025] Kelp slag and distilled water were mixed at a mass ratio of 1:10, stirred with a magnetic stirrer at 100 rpm for 10 minutes, then centrifuged at 8000 rpm for 5 minutes, and the supernatant was removed after centrifugation; the above process was repeated 3 times, and freeze-dried. After pretreatment, the kelp slag and distilled water are mixed at a mass ratio of 1:20, placed in the reactor, and the enzyme is added according to the mass ratio of kelp slag and enzyme of 40:1, the pH is adjusted to 6.0, the stirring speed is 150 rpm, and stirring is carried out for 10 minutes Finally, the stirring speed was adjusted to 100 rpm, and the entire enzyme biocatalytic conversion reaction process was 3 hours, and the temperature was controlled at 60°C; 30 minutes after the start of the reaction, the strategy of continuously adding kelp slag and enzymes, cellulase and β- The glucosidase is mixed at a mass ratio of 2:1; the added kelp slag and enzyme are mixed at a mass ratio of 20:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com