Process for extracting calcium chloride from waste incineration fly ash

A waste incineration fly ash and calcium chloride technology, applied in the direction of alkali metal chloride, calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of low economic value and high processing cost of calcium carbonate , comprehensive operating costs and other issues, to achieve the effect of reducing operating costs, reducing processing costs, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

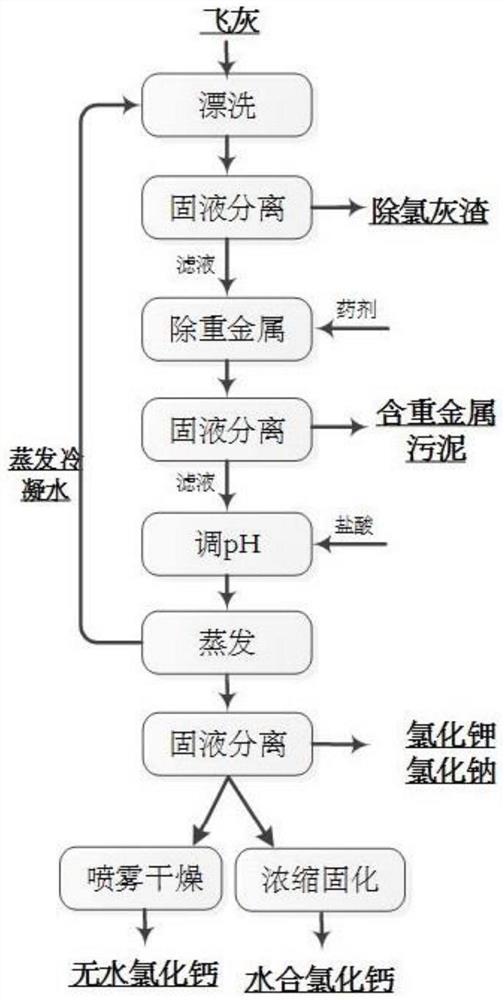

Image

Examples

Embodiment 1

[0039] 1) Use evaporative condensed water as the washing water to carry out 3 times of countercurrent washing on the waste incineration fly ash, and then separate the washed aqueous solution into solid and liquid to obtain chlorine-removing ash slag and washing water.

[0040] 2) Adding a heavy metal removing agent to the washing water, performing solid-liquid separation again to remove the heavy metal precipitate.

[0041] 3), adding hydrochloric acid to adjust the pH value to pH=7, and then sending it into the subsequent evaporation process.

[0042] 4), evaporate and concentrate the solution until the calcium chloride concentration of the concentrated solution is concentrated to 40% (wt.), sodium chloride and potassium chloride are crystallized, and the solid mixed salt of sodium chloride and potassium chloride is separated by filtration and calcium chloride solution. The condensed water obtained when evaporating the concentrate is returned to step 1 for reuse as new water...

Embodiment 2

[0045] 1) Use evaporative condensed water as the washing water to carry out 3 times of countercurrent washing on the waste incineration fly ash, and then separate the washed aqueous solution into solid and liquid to obtain chlorine-removing ash slag and washing water.

[0046] 2) Adding a heavy metal removing agent to the washing water, performing solid-liquid separation again to remove the heavy metal precipitate.

[0047] 3), adding hydrochloric acid to adjust the pH value to pH=8, and then sending it into the subsequent evaporation process.

[0048] 4), evaporate and concentrate the solution until the calcium chloride concentration of the concentrated solution is concentrated to 38% (wt.), sodium chloride and potassium chloride crystallize, and the solid mixed salt of sodium chloride and potassium chloride is separated by filtration and calcium chloride solution. The condensed water obtained when evaporating the concentrate is returned to step 1 for reuse as new water.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com