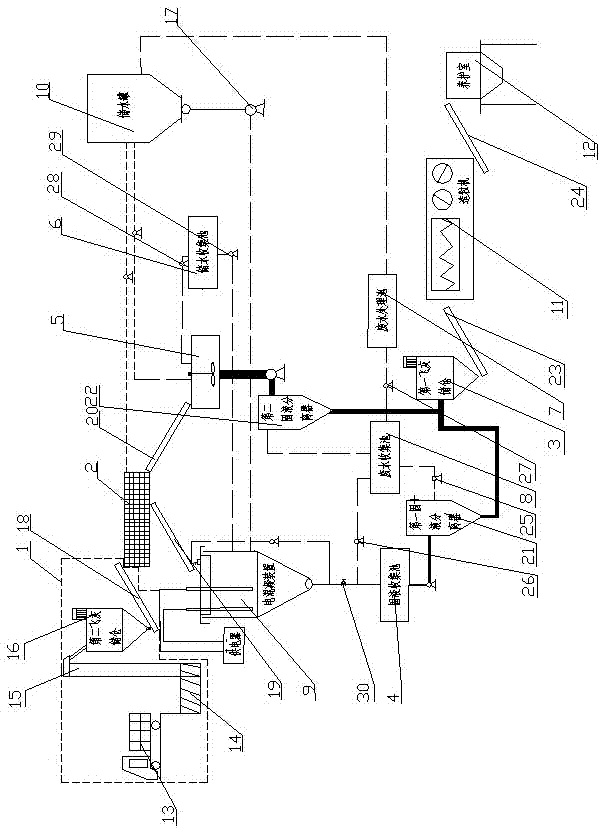

Waste incineration fly ash treatment system based on reduction

A waste incineration fly ash and treatment system technology, applied in the field of environmental protection technology and equipment, can solve the problems of large water consumption, high cost of sewage treatment and evaporation, high cost of solid-liquid separation, etc., and achieve economic and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

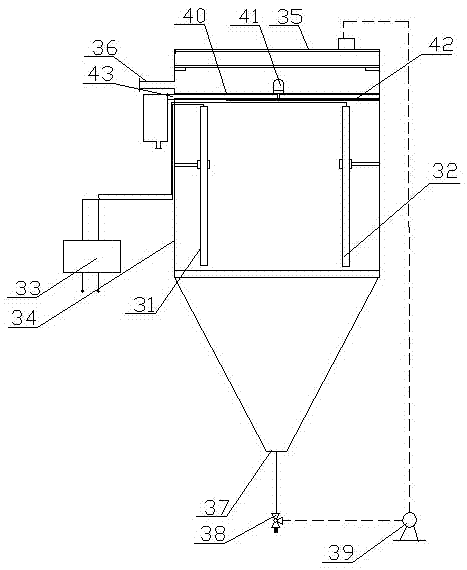

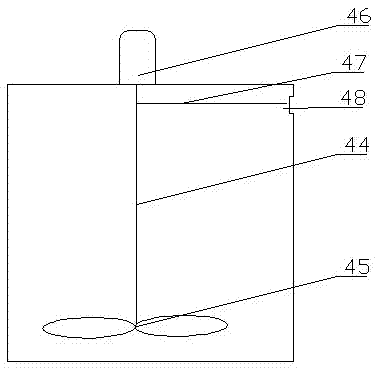

[0050] S1: Feed fly ash with an initial moisture content of 5% and 17.5wt% CaO and water into the wet vibrating screen 2 with a sieve diameter of 38 μm at a solid-to-liquid ratio of 30:1, and stop the vibration after running for 0.5 hours. Collect 70% of the large-particle fly ash and mix it with water at a ratio of 1:6 and enter the washing tank 5 to stir and react for 2 hours, then enter the second solid-liquid separator 22 for separation for 0.5 hours, the liquid enters the waste water collection tank 8, and the solid enters the first fly ash Storage bin 3.

[0051] S2: Collect 30% of the small particle fly ash and the water in the water storage tank 10 and the water storage tank 6 into the electric coagulation device 9 with a solid-to-liquid ratio of 1:6, react for 1 hour at a temperature of 20°C and a current of 10A, and then enter The solid-liquid collection tank 4 then enters the first solid-liquid separator 21 for separation for 0.5h, the liquid enters the waste water ...

Embodiment 2

[0055] The operation steps are basically the same as in Example 1, only the parameters are different, and the specific parameters of the present embodiment are as follows:

[0056] S1: Feed fly ash with an initial moisture content of 5% and 17.5wt% CaO and water into the wet vibrating screen 2 with a sieve diameter of 50 μm at a solid-to-liquid ratio of 30:1, and stop the vibration after running for 0.5 hours. Collect 70% of the large particle fly ash and mix it with water at a ratio of 1:8 and enter it into the washing tank 5 for stirring and reacting for 2 hours, then enter the second solid-liquid separator 22 for separation for 0.5 hours, the liquid enters the waste water collection tank 8, and the solid enters the first fly ash Storage bin 3.

[0057] S2: Collect 30% of the small particle fly ash and the water in the water storage tank 10 and the water storage tank 6 into the electric coagulation device 9 with a solid-to-liquid ratio of 1:20, react for 1 hour at a temperat...

Embodiment 3

[0061] The operation steps are basically the same as in Example 1, only the parameters are different, and the specific parameters of the present embodiment are as follows:

[0062] S1: Feed fly ash and water with an initial moisture content of 3.5% and 20wt% CaO into the wet vibrating screen 2 with a sieve diameter of 75 μm at a solid-to-liquid ratio of 6:1, and stop the vibration after running for 0.5 hours. Collect 70% of the large-particle fly ash and mix it with water at a ratio of 1:6 and enter the washing tank 5 to stir and react for 2 hours, then enter the second solid-liquid separator 22 for separation for 0.5 hours, the liquid enters the waste water collection tank 8, and the solid enters the first fly ash Storage bin 3.

[0063] S2: Collect 30% of the small particle fly ash and the water in the water storage tank 10 and the water storage tank 6 into the electric coagulation device 9 with a solid-to-liquid ratio of 1:6, react for 1 hour at a temperature of 20°C and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com