Coating process for notch type lithium ion battery

A lithium ion battery and coating process technology, applied in the field of coating process of lithium ion battery, can solve the problems of increasing the internal resistance of the battery, short-circuiting the finished battery, reducing the battery performance, etc., so as to reduce the use of tape and improve the quality of the product. , The effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, the pole piece of the notched lithium ion battery coating process is manufactured according to the following method steps:

[0029] (1) Add lithium cobaltate, conductive agent ks-6, polyvinylidene fluoride, and N-methylpyrrolidone into the mixer at a ratio of 93:3:4:150, and stir in vacuum for 5 hours to form a slurry;

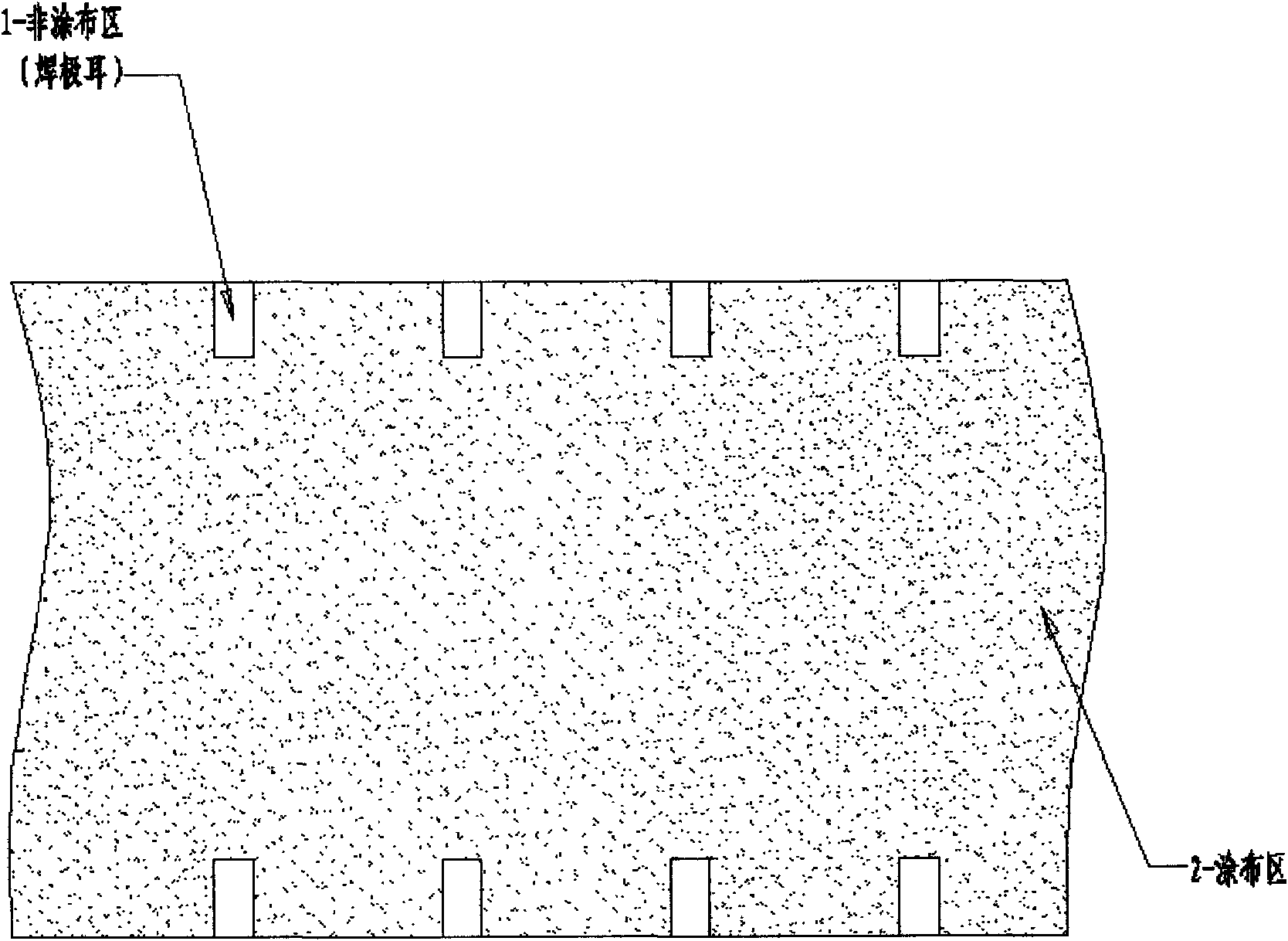

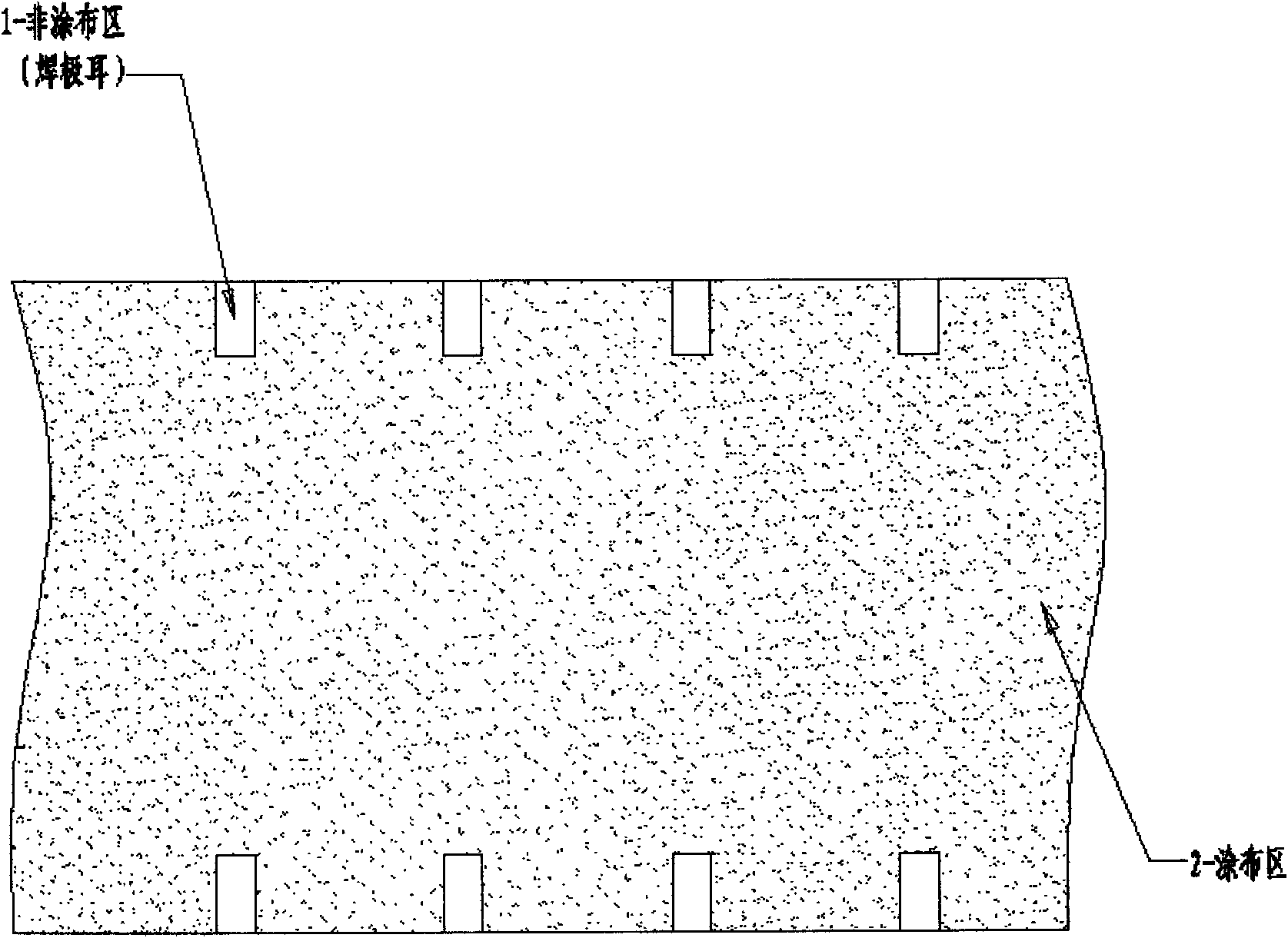

[0030] (2) Adjust the speed and tension of the coating machine roll to coat the pole piece. The overall width of the coated pole piece is 40cm, and the interval coating area is distributed on both sides along the coating direction, and the length of the uncoated part is 2cm. The width is 0.8cm, and the pole piece coated with this coating method is the notched lithium ion battery coated pole piece. In the figure, 1 is a non-coating area for welding with tabs, and 2 are coating areas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com