Soybean seeding device

A sowing device, soybean technology, applied in the direction of sowing, planter parts, spaced quantitative sowing machinery, etc., can solve the problems of through hole blockage, seed damage, manual cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

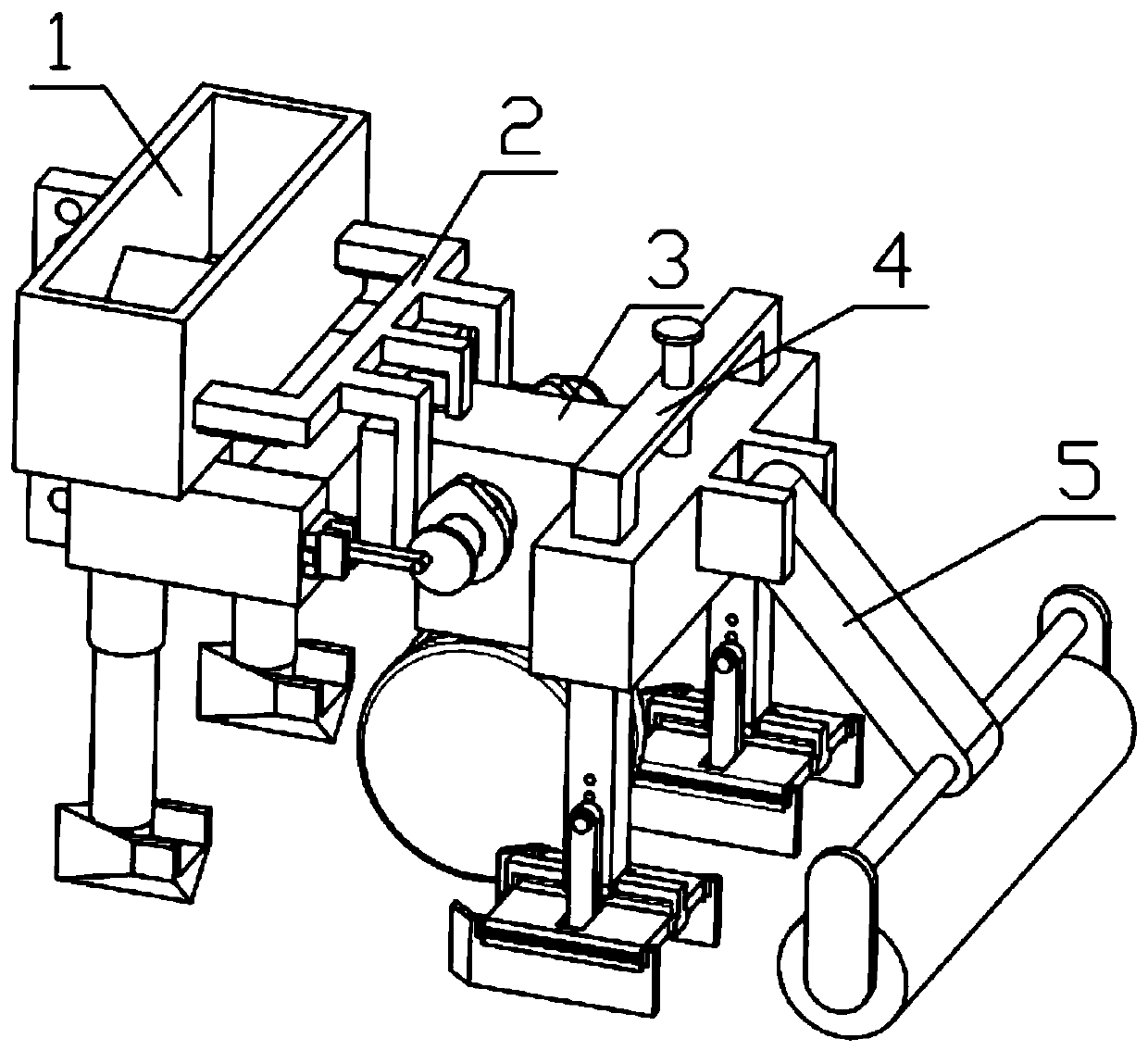

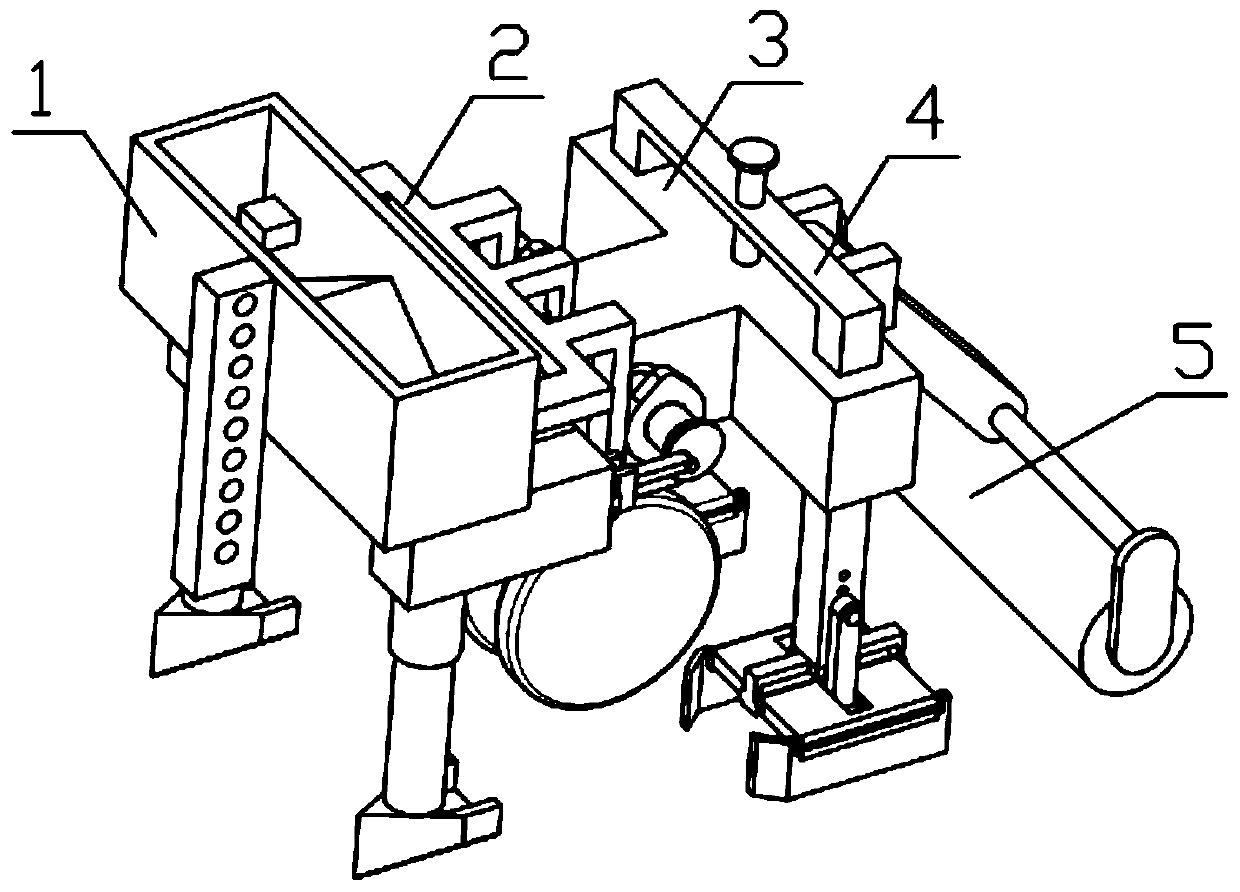

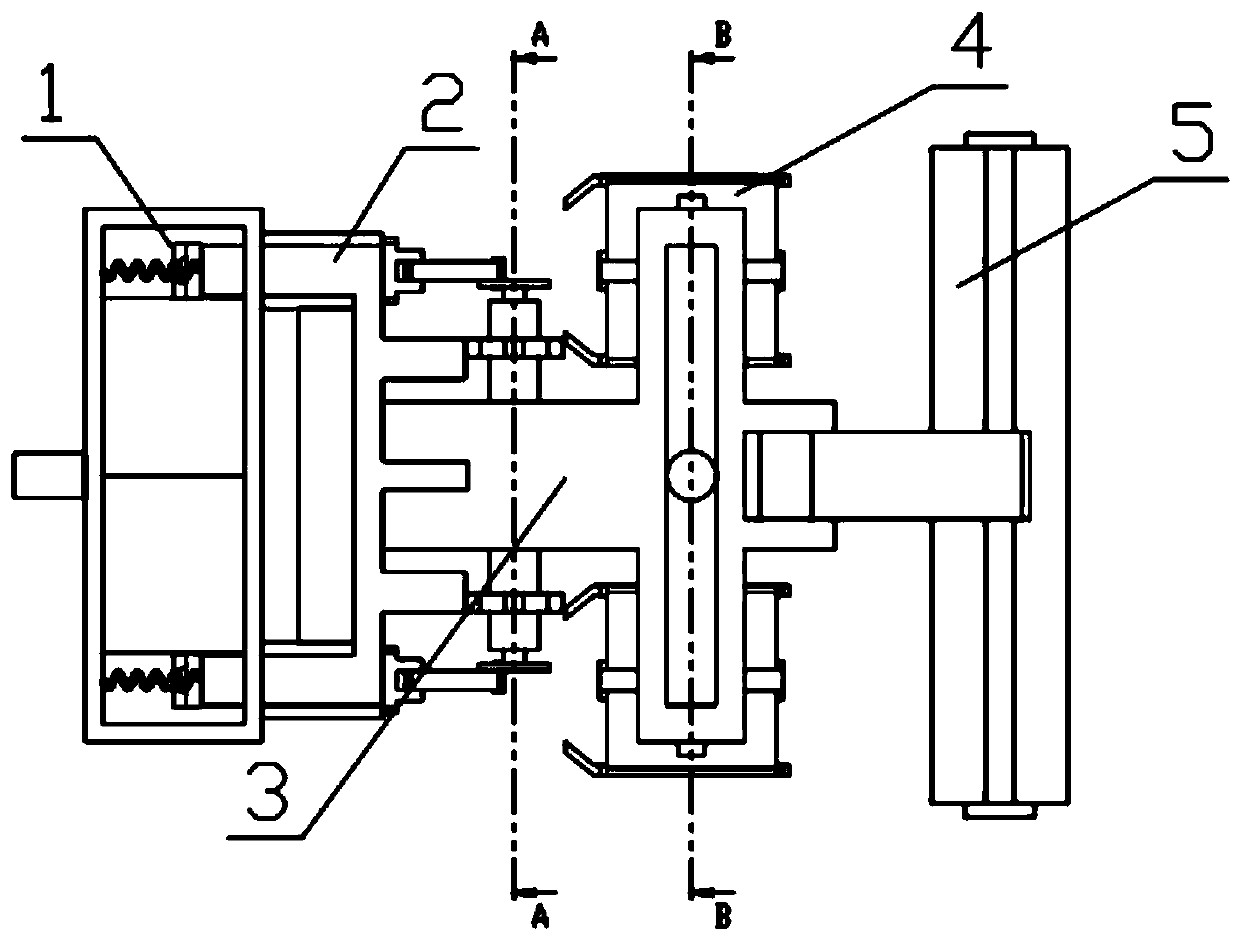

[0047] Combine below Figure 1-19 Description of this embodiment, a soybean sowing device, including a material storage and discharge mechanism 1, a discharge control mechanism 2, a connecting housing 3, a closing mechanism 4 and a compacting mechanism 5, and the discharge control mechanism 2 is movably installed on the In the groove provided on the material storage and discharge mechanism 1, the discharge control mechanism 2 is installed in the inner groove provided on the connecting shell 3, and the closing mechanism 4 is movably installed on the through hole provided on the connecting shell 3, compacting The mechanism 5 is movably installed on the connection housing 3 .

specific Embodiment approach 2

[0049] Combine below Figure 1-19 Describe this embodiment, this embodiment will further explain the first embodiment, the storage and discharge mechanism 1 includes a storage box 1-1, a power connection plate 1-2, a diverter block 1-3, a middle square column 1- 4. The inner threaded pipe 1-5, the outer threaded pipe 1-6, the ditching piece 1-7, the power connection plate 1-2 are fixedly installed on one side of the material storage box 1-1, and the diverter block 1-3 is fixedly installed on the Inside the material storage box 1-1, two through holes are arranged on the bottom plate inside the material storage box 1-1, the diverter block 1-3 is located between the two through holes, and the number of the middle square column 1-4 has two One, the middle square column 1-4 is fixedly installed on the material storage box 1-1, respectively located at the two ends of the material storage box 1-1, there are two internal threaded pipes 1-5, and the internal threaded pipes 1-5 Fixedly...

specific Embodiment approach 3

[0051] Combine below Figure 1-19 Describe this embodiment, this embodiment will further explain the second embodiment, the discharge control mechanism 2 includes a toggle frame 2-1, a material control assembly 2-2, a multifunctional shaft 2-3, and a driving wheel 2- 4. The toggle frame 2-1 is in contact with the multifunctional shaft 2-3. There are two material control components 2-2, which are respectively installed on both sides of the multifunctional shaft 2-3. The material control component 2-2 It is movably installed on the multifunctional shaft 2-3, the drive wheel 2-4 is installed on the multifunctional shaft 2-3, and the material control assembly 2-2 is movably installed on the groove provided on the middle square column 1-4; Frame 2-1 comprises toggle top frame 2-1-1, toggle pin 2-1-2, baffle plate 2-1-3, slider 2-1-4, support spring 2-1-5, support spring One end of 2-1-5 is fixedly installed on the top frame 2-1-1, and the other end is fixedly installed on the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com