Trimellitic acid continuous production device through crystallization, centrifugation and anhydride formation

A technology of trimellitic acid and centrifugation into anhydride, which is used in crystallization separation, solution crystallization, evaporation separation crystallization, etc., can solve the problems of by-products, unstable equipment operation, and repeated heating is not conducive to reduce reaction side effects. The formation of products, the improvement of yield and product quality, the effect of being conducive to heat preservation and temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

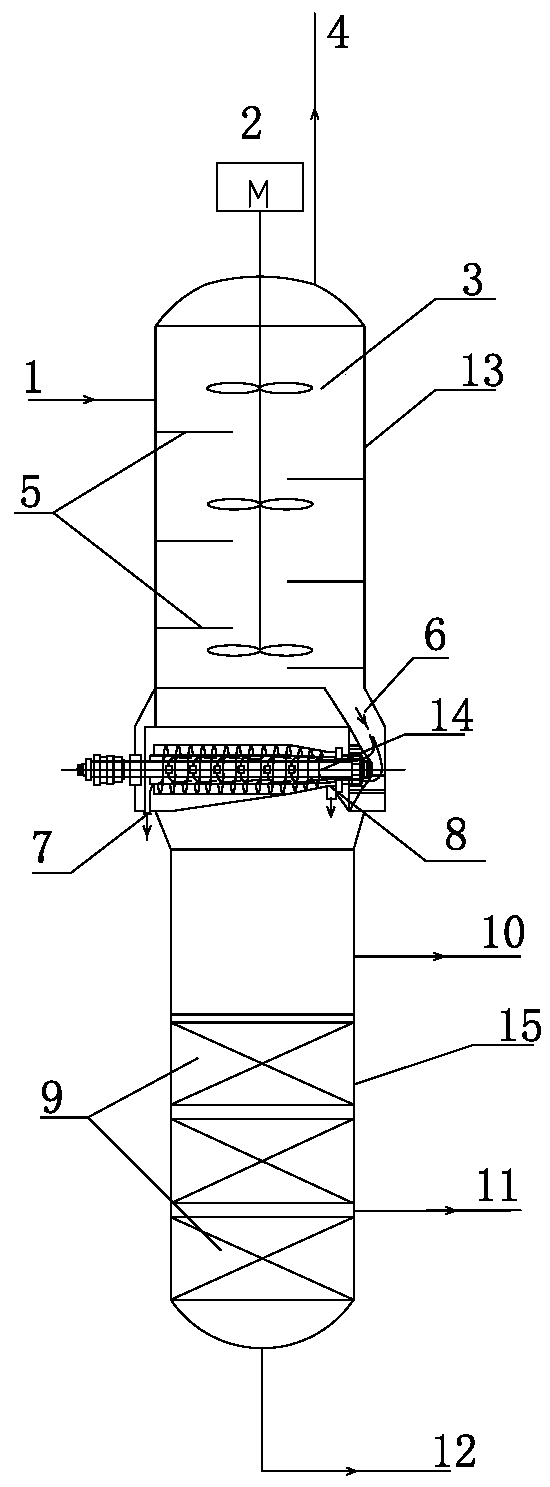

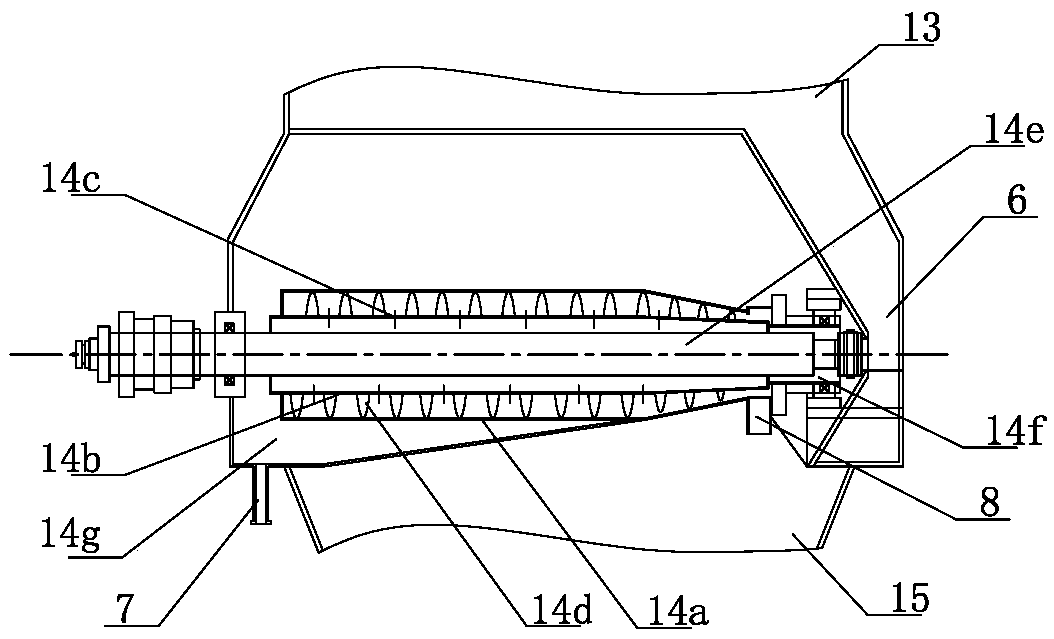

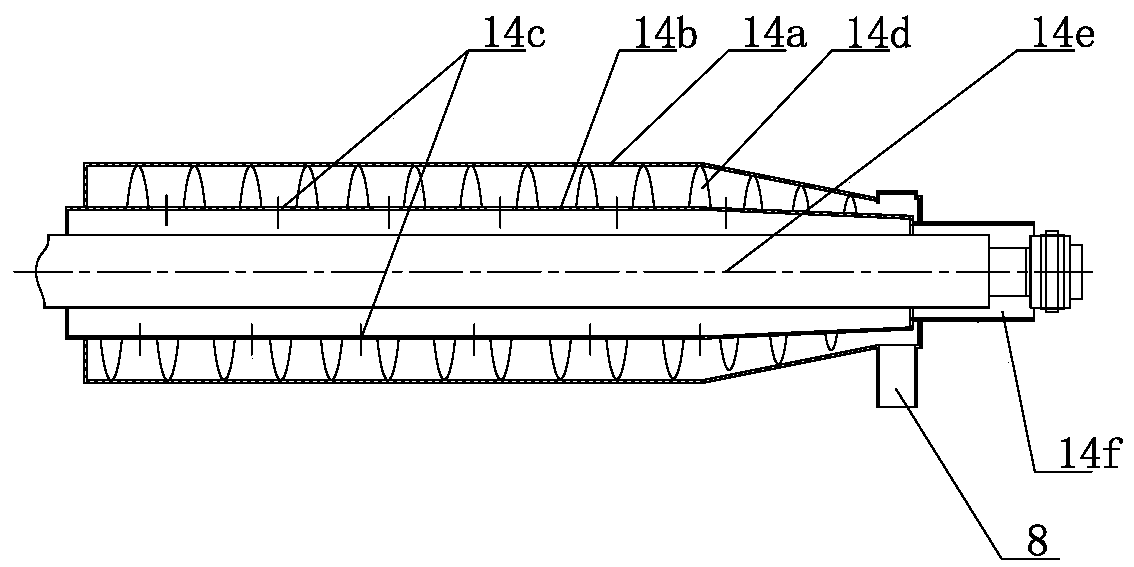

[0034] Such as Figure 1-3 As shown, it is a continuous crystallization and centrifugation anhydride-forming equipment for trimellitic anhydride, which includes a crystallization tower 13, a separation device 14 and an anhydride-forming tower 15. Between the tower 13 and the anhydride forming tower 15, the crystallization tower 13 is provided with a reaction liquid material inlet 1, and the top of the crystallization tower 13 is provided with a non-condensable gas outlet 4, and the crystallization tower 13 is provided with multi-layer stirring blades 3, and the stirring blades 3 are connected On the stirring shaft, the stirring shaft protrudes from the upper end of the crystallization tower 13 and is connected to the stirring motor 2. There are several arc-shaped partitions 5 on the inner wall of the crystallization tower 13, and the arc-shaped partitions 5 on the left and right sides avoid the stirring blades 3 And arranged in a staggered manner in the height direction; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com