Electric motor

A technology of motors and windings, applied in the field of motors, can solve problems such as motor output limitations, and achieve the effect of preventing temperature rise and preventing switching actions from being limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

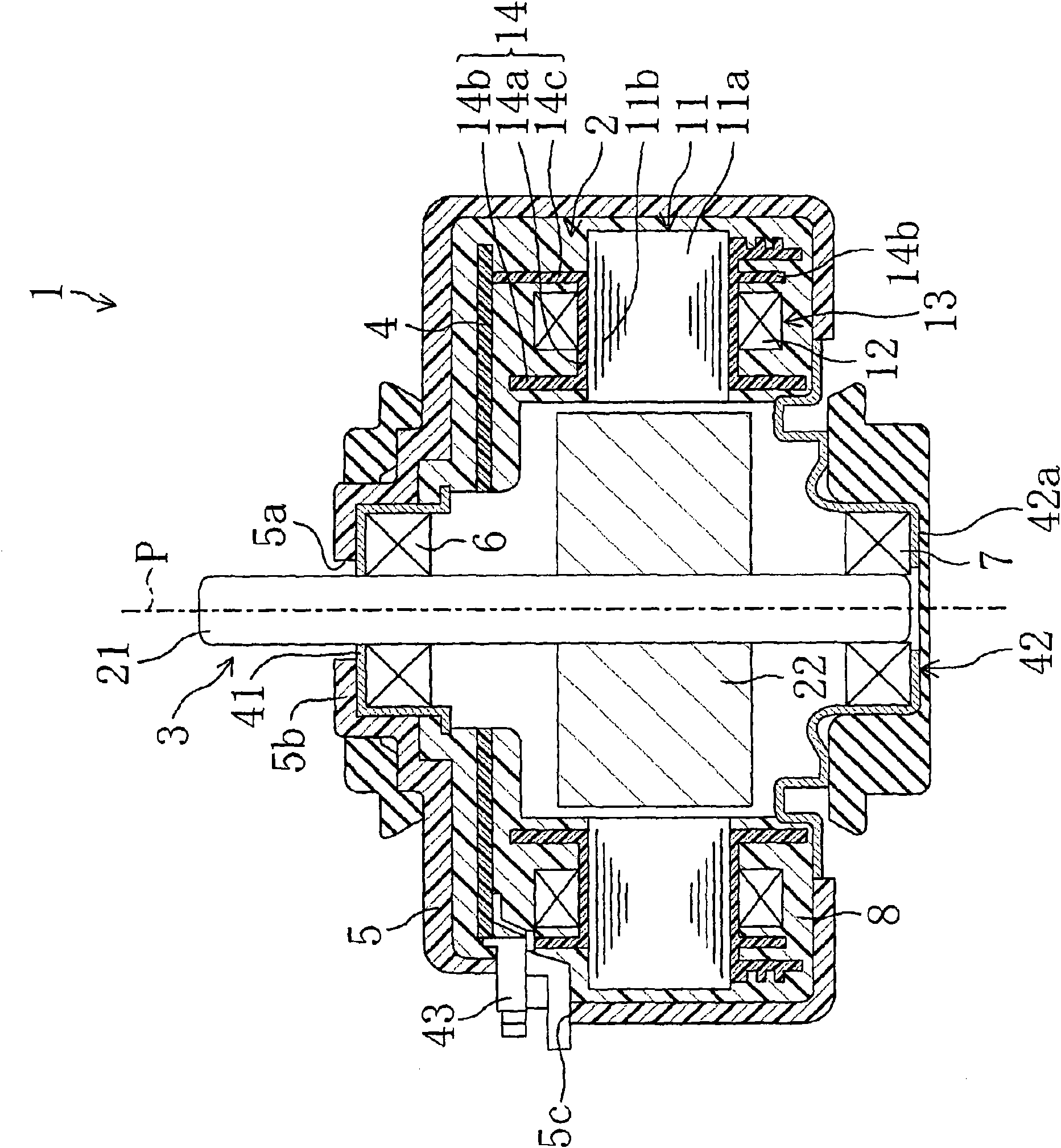

[0058] -the whole frame-

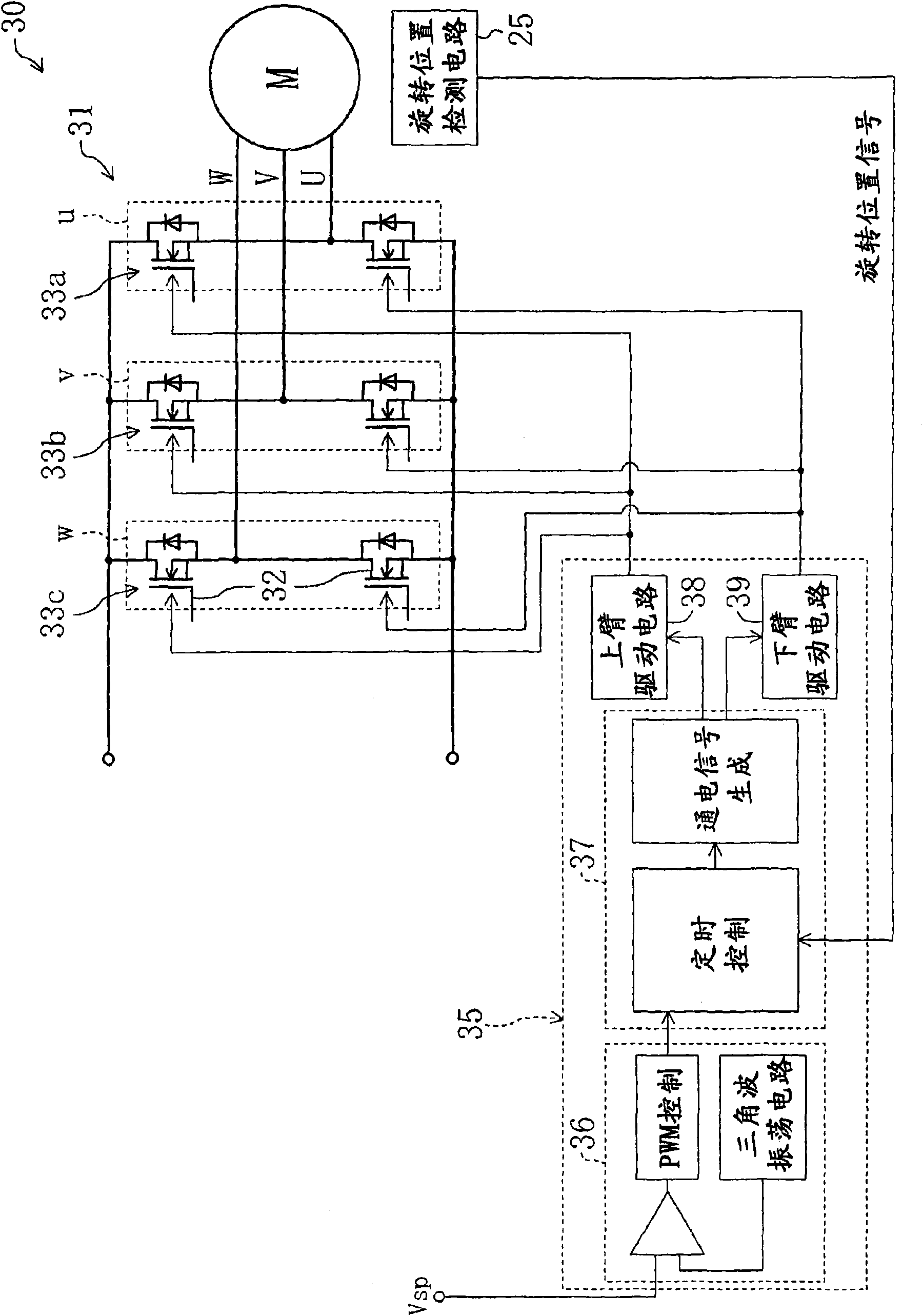

[0059] Embodiment 1 of the present invention will be described below. Such as figure 1 as well as figure 2 As shown, the motor 1 of this embodiment is a so-called brushless DC motor in which the rotor 3 is rotationally driven relative to the stator 2 by supplying electric power to the winding 13 of the stator 2 at predetermined timing by the control circuit 30 . Specifically, the electric motor 1 includes: a substantially cylindrical stator 2 in which a plurality of windings 13, 13, . rotor 3; a substrate 4 having a control circuit 30 for controlling the energization of the plurality of windings 13, 13, ... of the stator 2; shell5. That is, the motor 1 is configured to form a rotating magnetic field in the stator 2 by controlling the energization of the plurality of windings 13, 13, . . . Perform rotary drive.

[0060] The stator 2 includes: a stator core 11 formed by laminating a plurality of steel plates; and a plurality of coils 12 , 12 , ....

Embodiment approach 2

[0092] Below, according to Figure 7 as well as Figure 8 A motor according to Embodiment 2 will be described. The motor according to the second embodiment differs from the first embodiment only in the structure of the semiconductor chip, so the same reference numerals are assigned to the same structures, and only the different parts will be described below.

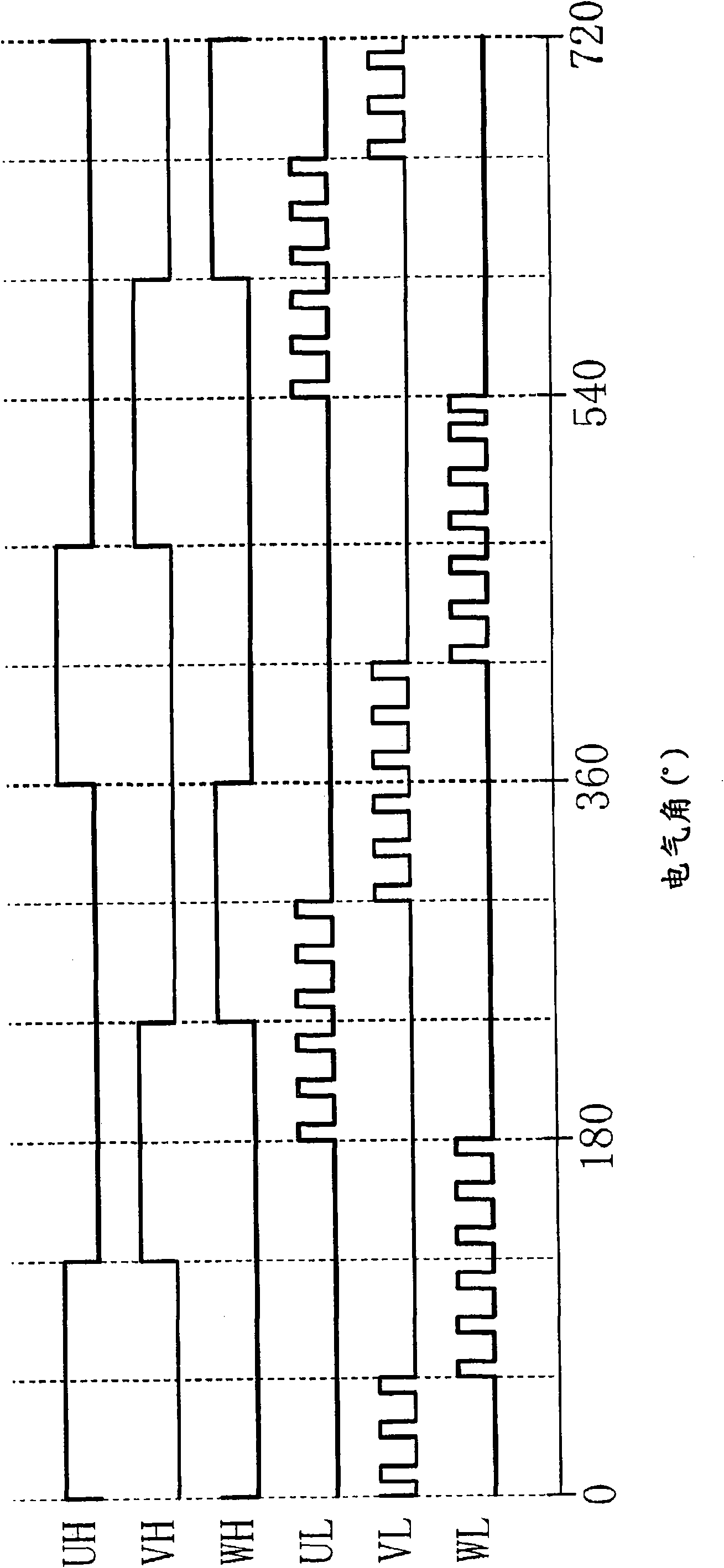

[0093] Specifically, as Figure 7 As shown, the six switching elements 32 constituting the switching circuit 51 of the control circuit are composed of semiconductor chips uH, uL, vH, vL, wH, and wL, respectively. That is, compared to the number of semiconductor chips in the first embodiment described above, which is three, this embodiment is different in that the number of semiconductor chips described above is six.

[0094] Figure 8 Show six semiconductor chips uH, uL, vH, vL, wH, wL on the substrate 4 (in Figure 8 Indicated by the dotted line) on the configuration. as it should Figure 8 As shown, even in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com