Wastewater evaporating process and device system

A waste water, evaporation-drying technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, solution crystallization, etc., can solve the problem of affecting the operation and service life of equipment, complicated systems, and increasing the difficulty and cost of sewage treatment and other issues to achieve the effect of ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

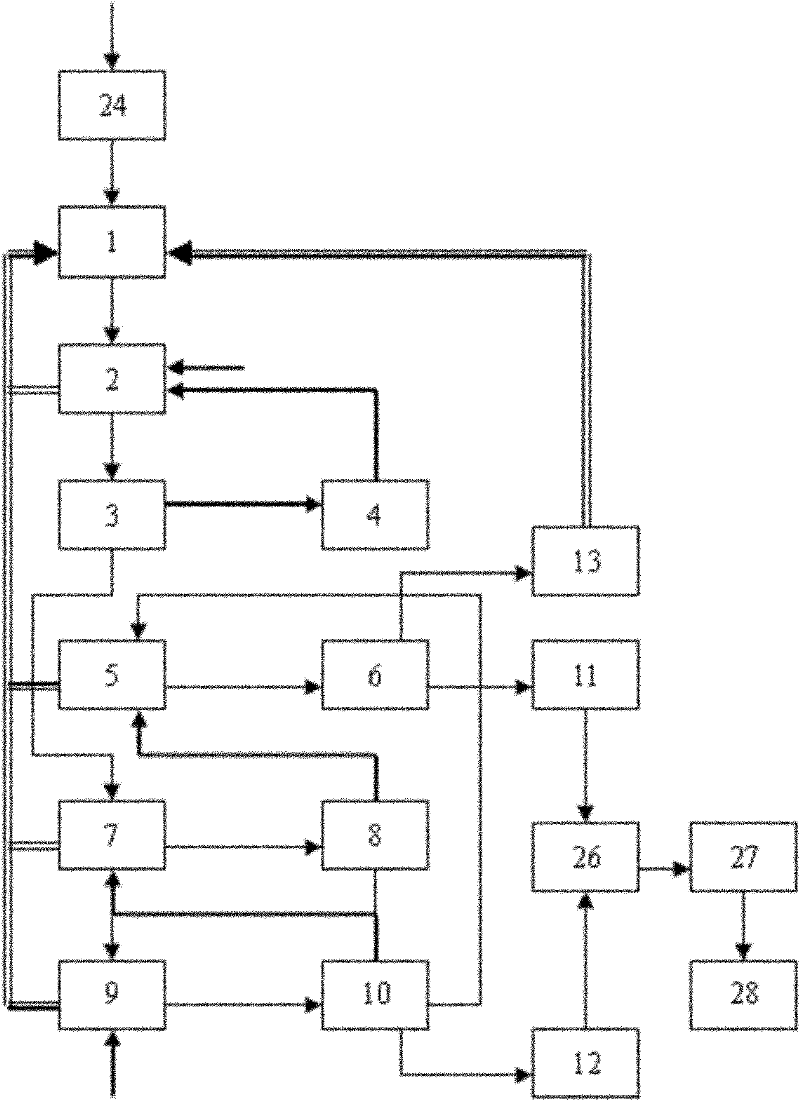

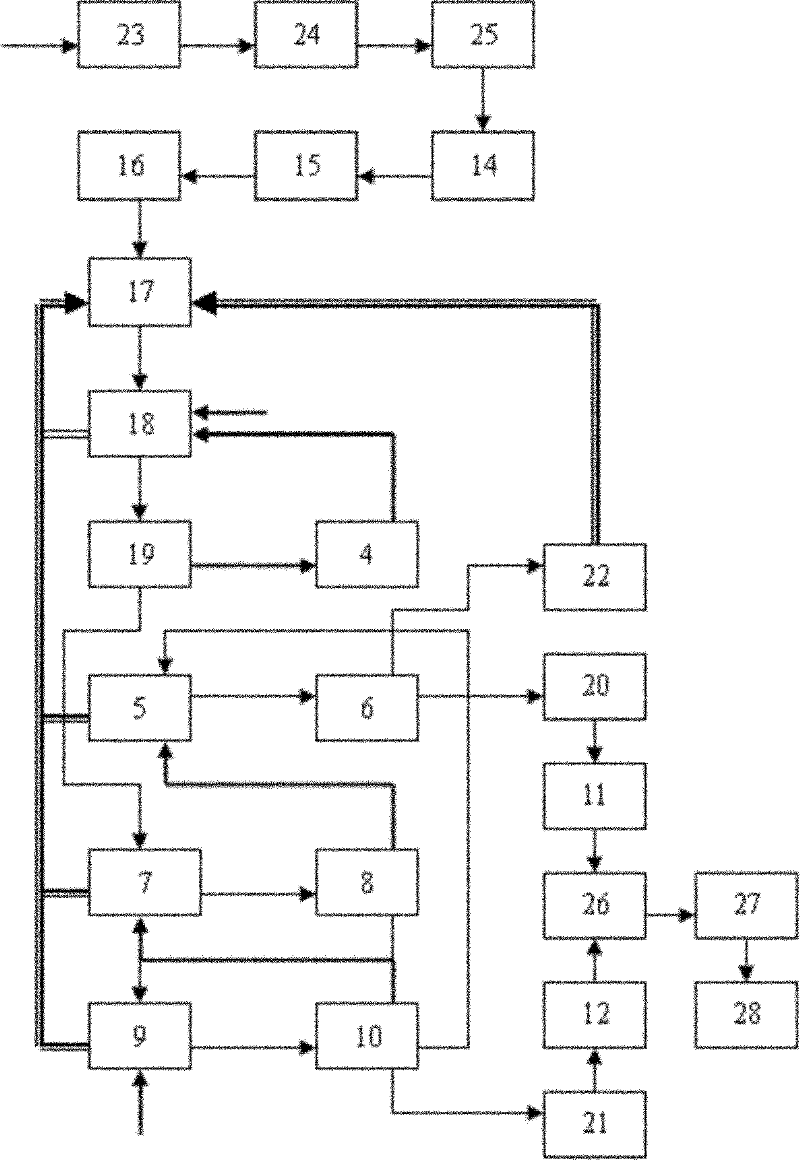

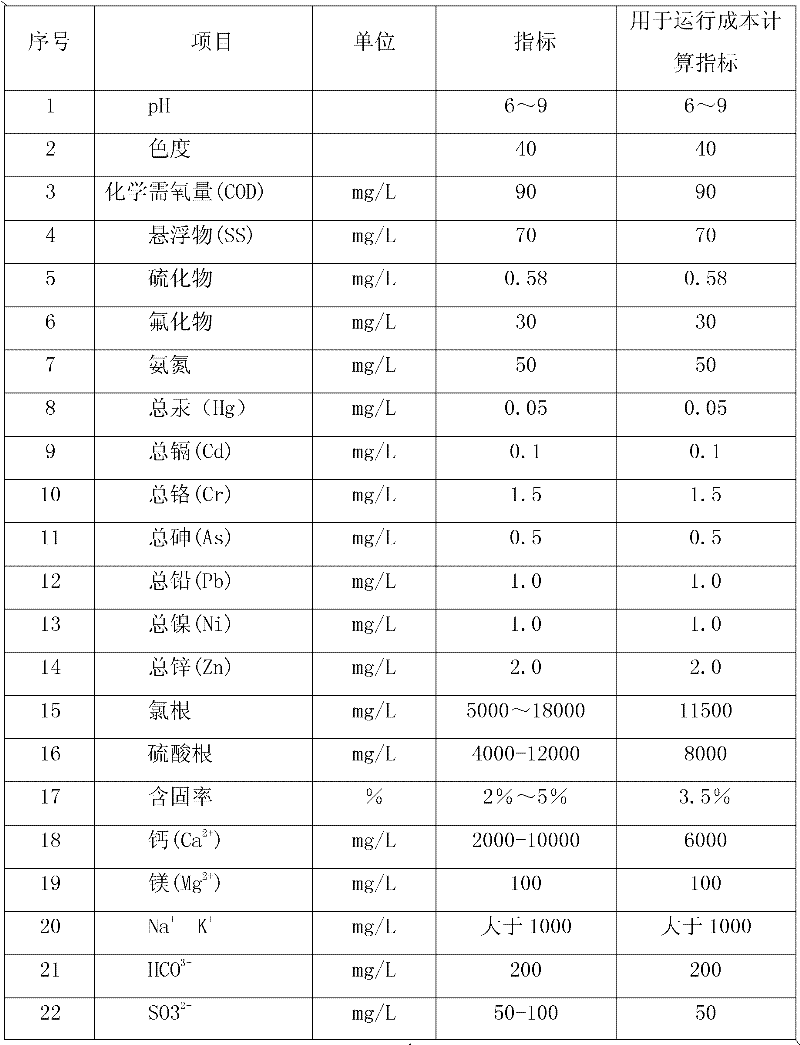

[0132] Embodiment 1 of the present invention: waste water evaporation process (referring to figure 1): The waste water to be treated first enters the pretreatment softening system, and is softened by Glauber's salt-lime-flue gas method (see the following table 11 for specific chemical consumption parameters), removes easily scaled cations, and then stores them in the regulating tank. Pump into the buffer tank, add scale inhibitor and defoamer to the buffer tank, the amount of scale inhibitor added is 25g / t, and the amount of defoamer added is 3g / t; the waste water comes out of the buffer tank and is fed by the feed pump Enter the preheater 1 of the MVR system (preferably a plate heat exchanger), and exchange heat with the steam condensate from the evaporator 2 and the forced circulation evaporation crystallization system; after the waste water is preheated, it enters the evaporator 2, first The fresh steam pre-evaporates the wastewater for about 100-200 minutes, reaching an ev...

Embodiment 2

[0153] Embodiment 2 of the present invention: waste water evaporation process (referring to figure 1 ): The wastewater to be treated first enters the pretreatment softening system, and then softens it with Glauber's salt-lime-flue gas method to remove the cations that are easy to scale, and then adds scale inhibitor at 25g / t, and then adds defoamer at 4g / t , into the preheater 1 of the MVR system for preheating, and then into the evaporator 2, into the fresh steam to pre-evaporate the wastewater, the resulting concentrated liquid and secondary steam enter the separator 3 for vapor-liquid separation, and the separated The secondary steam is compressed by the steam compressor 4 and sent to the evaporator 2 for recycling; the separated concentrated liquid enters the three-effect forced circulation evaporation and crystallization system for evaporation and crystallization in the mixed-flow evaporation method, and the concentrated liquid passes through the second effect and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com