High-concentration ammonia nitrogen wastewater treatment system and treatment method

An ammonia nitrogen wastewater treatment system technology, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problem of large changes in water quality, increased mass transfer resistance, and low system stability. and other problems to achieve the effect of saving heat source, solving energy waste and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

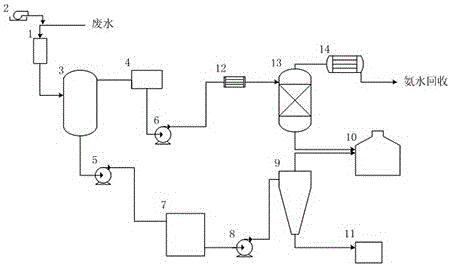

[0052] Example 1: 25°C high ammonia nitrogen wastewater has a flow rate of 8 tons / hour, a total ammonia nitrogen content of 10000 mg / L, and contains a certain amount of inorganic salt components. Mix with 33% NaOH alkali solution, after the pH reaches 11, enter the three-effect evaporation device, the temperature is 72°C, and the absolute pressure is 34KPa.

[0053] The high-concentration ammonia-containing wastewater evaporated efficiently is heated to 80°C by the rectification preheater, and then enters the rectification ammonia distillation tower. The bottom of the tower is 90°C, the top of the tower is 85°C, and the absolute pressure is 70KPa; Finally, concentrated ammonia water is obtained, and the tower bottom liquid enters the waste water collection tank.

[0054] The low-ammonia nitrogen and high-salt wastewater at the bottom of the three-effect evaporator enters the upper part of the scraper evaporator at a temperature of 70°C and an absolute pressure of 32KPa; the li...

Embodiment 2

[0055] Example 2: 25°C high ammonia nitrogen wastewater has a flow rate of 8 tons / hour, a total ammonia nitrogen content of 20,000 mg / L, and contains a certain amount of inorganic salt components. Mix with 33% NaOH alkali solution, after the pH reaches 11, enter the three-effect evaporation device, the temperature is 72°C, and the absolute pressure is 34KPa.

[0056] The high-concentration ammonia-containing wastewater evaporated efficiently is heated to 80°C by the rectification preheater, and then enters the rectification ammonia distillation tower. The bottom of the tower is 90°C, the top of the tower is 85°C, and the absolute pressure is 70KPa; Finally, concentrated ammonia water is obtained, and the tower bottom liquid enters the waste water collection tank.

[0057] The low-ammonia nitrogen and high-salt wastewater at the bottom of the three-effect evaporator enters the upper part of the scraper evaporator at a temperature of 70°C and an absolute pressure of 32KPa; the l...

Embodiment 3

[0058] Example 3: The flow rate of high ammonia nitrogen wastewater at 37°C is 8 tons / hour, the total ammonia nitrogen content is 10000 mg / L, and contains a certain amount of inorganic salt components. Mix with 38% NaOH alkali solution, after the pH reaches 11, enter the three-effect evaporation device, the temperature is 72°C, and the absolute pressure is 34KPa.

[0059] The high-concentration ammonia-containing wastewater evaporated efficiently is heated to 80°C by the rectification preheater, and then enters the rectification ammonia distillation tower. The bottom of the tower is 90°C, the top of the tower is 85°C, and the absolute pressure is 70KPa; Finally, concentrated ammonia water is obtained, and the tower bottom liquid enters the waste water collection tank.

[0060] The low-ammonia nitrogen and high-salt wastewater at the bottom of the three-effect evaporator enters the upper part of the scraper evaporator at a temperature of 70°C and an absolute pressure of 32KPa; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com