Production method and device for sodium gluconate energy-saving triple effect concentration and crystallization

A technology of sodium gluconate and three-effect concentration, which is applied in the field of devices implementing the method, and can solve problems such as large steam consumption, low crystallization rate, and dark product color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

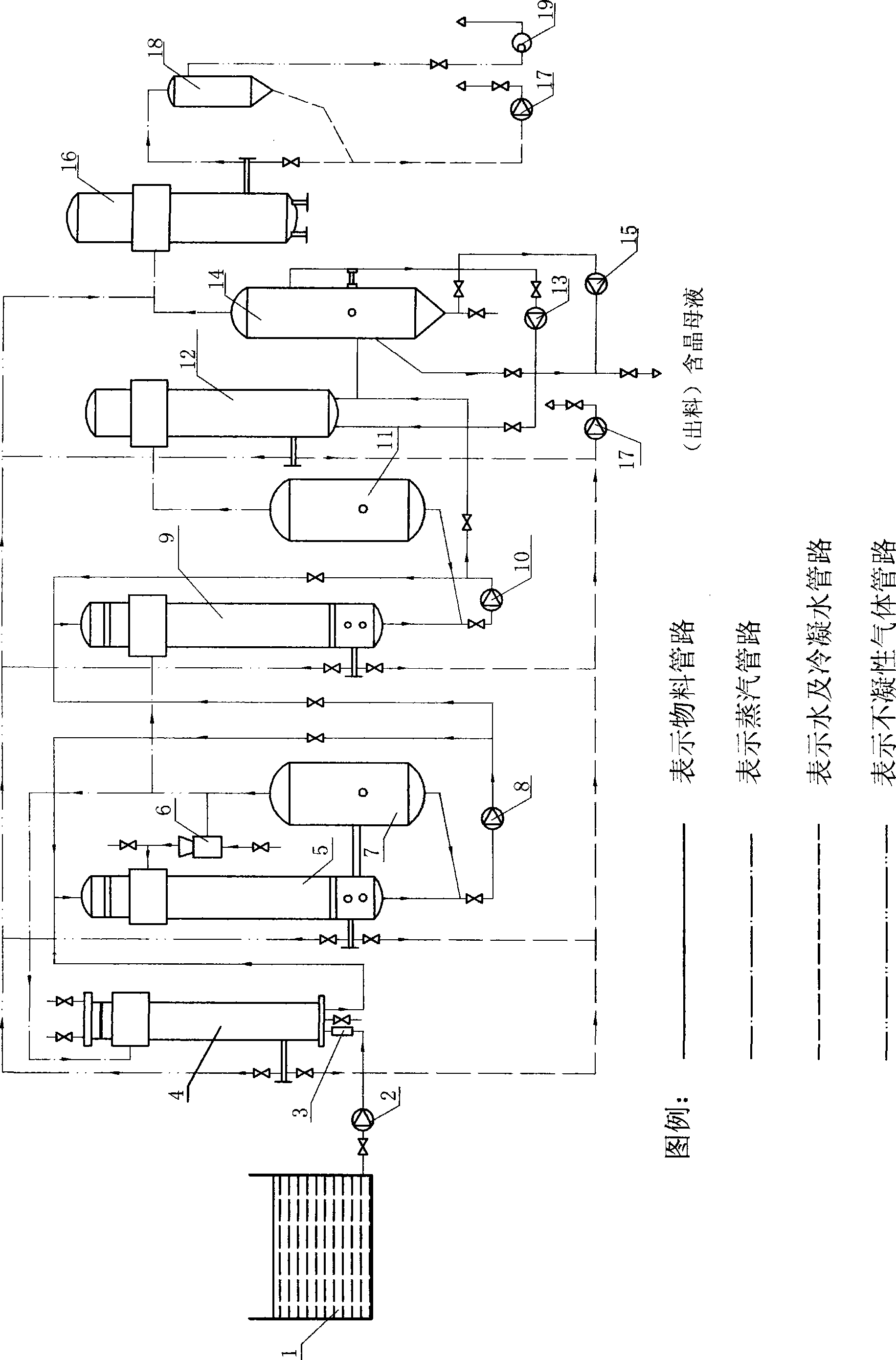

[0046] As shown in the accompanying drawing, a kind of production method of sodium gluconate energy-saving three-effect concentrated crystallization comprises the following continuous steps:

[0047] Feeding step, with feeding pump 2, sodium gluconate solution is pumped out from raw material tank 1;

[0048] In the preheating step, the pumped sodium gluconate solution is preheated by preheater 4;

[0049] In the first-effect concentration and separation step, the preheated sodium gluconate solution enters the first-effect heating evaporator 5 for heating, and then the sodium gluconate solution is sent to the first-effect separator 7 for evaporation. A part of sodium gluconate solution is sent into the next step by an effect discharge pump 8, and the remainder is sent back to an effect heating evaporator 5 to continue heating and evaporating;

[0050] Two-effect concentration and separation step, the high-concentration sodium gluconate solution of one-effect separator 7 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com