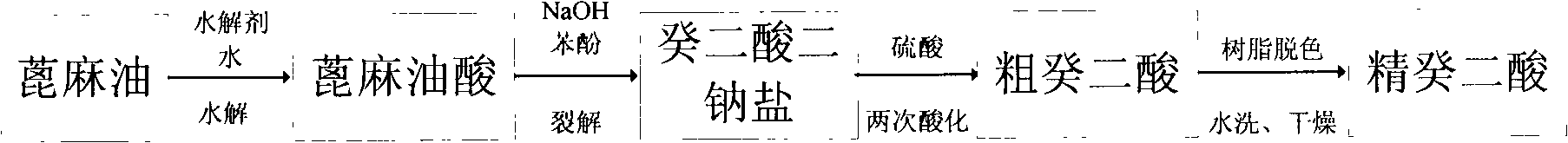

Process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling

An evaporative crystallization and resource utilization technology, applied in evaporation, solution crystallization, extraction water/sewage treatment, etc., can solve the problems of sodium sulfate treatment, high energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the treatment process of the present invention is used to recycle the phenol-containing nitric acid liquid with the following characteristics: the temperature of the phenol-containing nitric acid liquid is about 80° C., the pH value is about 2, and about 5wt% of sebacic acid is mixed. The phenol content is 8000mg / L, and the sodium sulfate content is 25wt%.

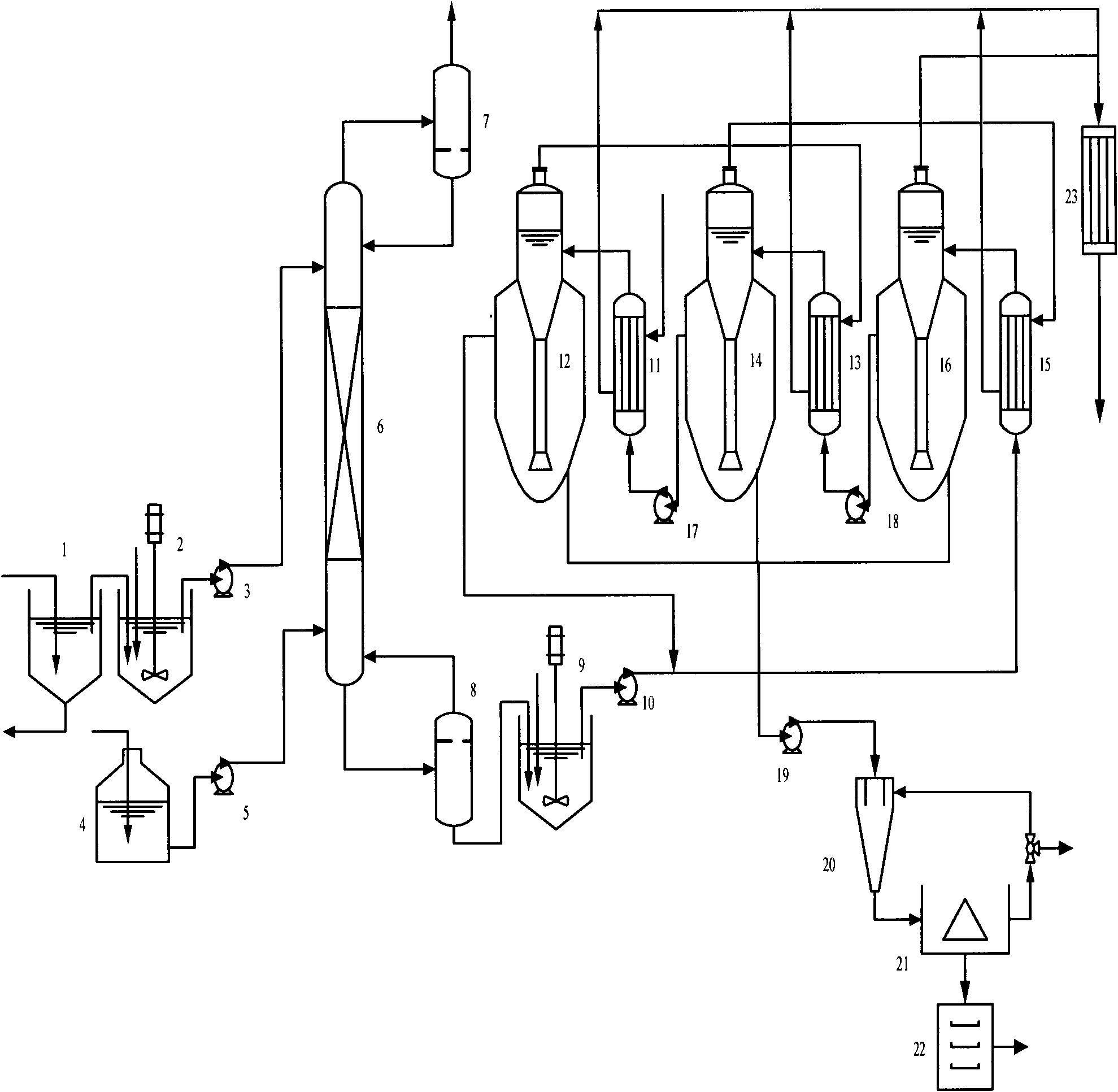

[0028] Combine below figure 1 The treatment process of the present invention will be described.

[0029] like figure 1 Shown is the device used in this embodiment for extracting the phenol-containing nitric acid liquid produced in the production process of coupled sebacic acid by evaporative crystallization, which mainly includes two parts: an extraction tower and an evaporative crystallizer. The principle of the whole process is: adjust the pH value of the phenol-containing nitrate solution to be 3-7, then enter from the upper part of the extraction tower 6, and reversely contact the ricinolei...

Embodiment 2

[0035] The temperature of the phenol-containing nitrate solution treated in this example is about 70°C, the pH value is about 1.5, mixed with about 5wt% sebacic acid, the phenol content is 6000 mg / L, and the sodium sulfate content is 20wt%.

[0036] In the present embodiment, the pH value of the phenol-containing nitrate solution adjusted in the first pH value adjustment tank 2 is 7; The number of plates is 31, and the volume ratio of the ricinoleic acid entering at the bottom of the extraction tower (6) and the phenolic nitric acid solution entered at the top is 1: 20; In the adjustment tank 9, the pH value was adjusted to 10; the three-effect evaporative crystallizer was operated with negative pressure, and the operating absolute pressure was 0.09 MPa; in this implementation, other processes were the same as those in Example 1, except that the above conditions were changed.

[0037] The phenol removal rate of the dephenolized wastewater discharged from the bottom of the seco...

Embodiment 3

[0040] The temperature of the phenol-containing nitrate solution treated in this example is about 60°C, the pH value is about 1.5, mixed with about 4wt% sebacic acid, the phenol content is 7000 mg / L, and the sodium sulfate content is 18wt%.

[0041] In the present embodiment, the pH value of the phenolic nitrate solution adjusted in the first pH value adjusting tank 2 is 4; The number of plates is 36, and the volume ratio of the ricinoleic acid entered at the bottom of the extraction tower (6) and the phenolic nitric acid solution entered at the top is 1: 10; In the adjustment tank 9, the pH value was adjusted to 8; the three-effect evaporation crystallizer was operated with negative pressure, and the operating absolute pressure was 0.01 MPa; in this implementation, other processes were the same as those in Example 1, except that the above conditions were changed.

[0042] The phenol removal rate of the dephenolized wastewater discharged from the bottom of the second oil-water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com