Method for preparing azeotropic ethanol through three-tower triple-effect differential pressure heat integration

A technology of heat integration and azeotropy, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of high energy consumption, achieve energy saving and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

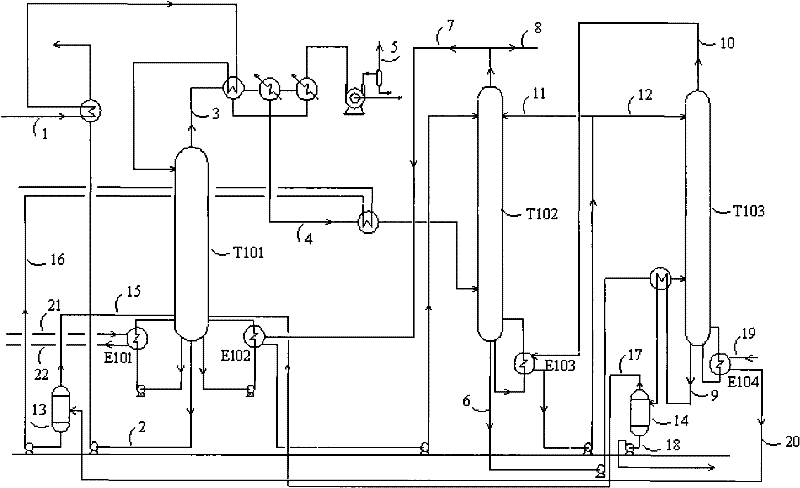

[0031] use figure 2 As shown in the flow process, the fermented mash 1 with an ethanol content of 9% by weight first exchanges heat with the waste mash 2, then exchanges heat with the crude wine gas 3, and then enters the upper part of the crude distillation tower (T101). After crude distillation, the tower The kettle obtains waste mash 2 with an ethanol content of less than 0.005% by weight, and the top of the tower obtains crude alcohol gas 3 with an ethanol content of 48% by weight. Wine condensate 4, noncondensable gas 5 is discharged out of bounds. The first reboiler (E101) of the crude distillation column is heated by the absolute ethanol gas 21 from the molecular sieve dehydration unit, the second reboiler (E102) of the crude distillation column is heated by the stream 7, and the gas from the flash tank 13 The flash gas 15 and the flash gas 17 from the flash tank 14 enter the crude distillation tower to directly heat the crude distillation tower.

[0032] The crude w...

Embodiment 2~4

[0038] use figure 2 In the flow shown, only the operating conditions of each column are changed. The specific operating conditions and steam consumption are shown in Table 1.

[0039] Table 1

[0040]

[0041] *The operating conditions of the first reboiler and the second reboiler of the crude distillation column are the same.

Embodiment 5

[0043] According to the steps of [Example 1], only the non-condensable gas enters the subsequent absorption section.

[0044] The number of trays in the crude distillation column is 26, the feeding position is the second tray from top to bottom, the operating pressure is 40kPa, the temperature at the top of the column is 60°C, and the temperature at the bottom of the column is 81°C. Refining column I tray number is 50, feed position is the 48th tray, operating pressure is 130kPa, tower top temperature is 85 ℃, and tower still temperature is 92 ℃. The number of trays in the finishing column III is 68, the feeding position is the 60th tray from top to bottom, the operating pressure is 500kPa, the temperature at the top of the tower is 125°C, and the temperature at the bottom of the tower is 153°C. The steam consumption is 1.2 tons of steam / ton of azeotropic ethanol product, and the energy consumption of each ton of azeotropic ethanol product can be saved by 25% compared with [Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com