Method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using cement kiln

A technology of co-processing and garbage fly ash, applied in the direction of solid waste removal, etc., can solve the problems of inadequate supervision, harm to the environment, vicious competition, etc., and achieve the effect of large cement production, stable working status, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

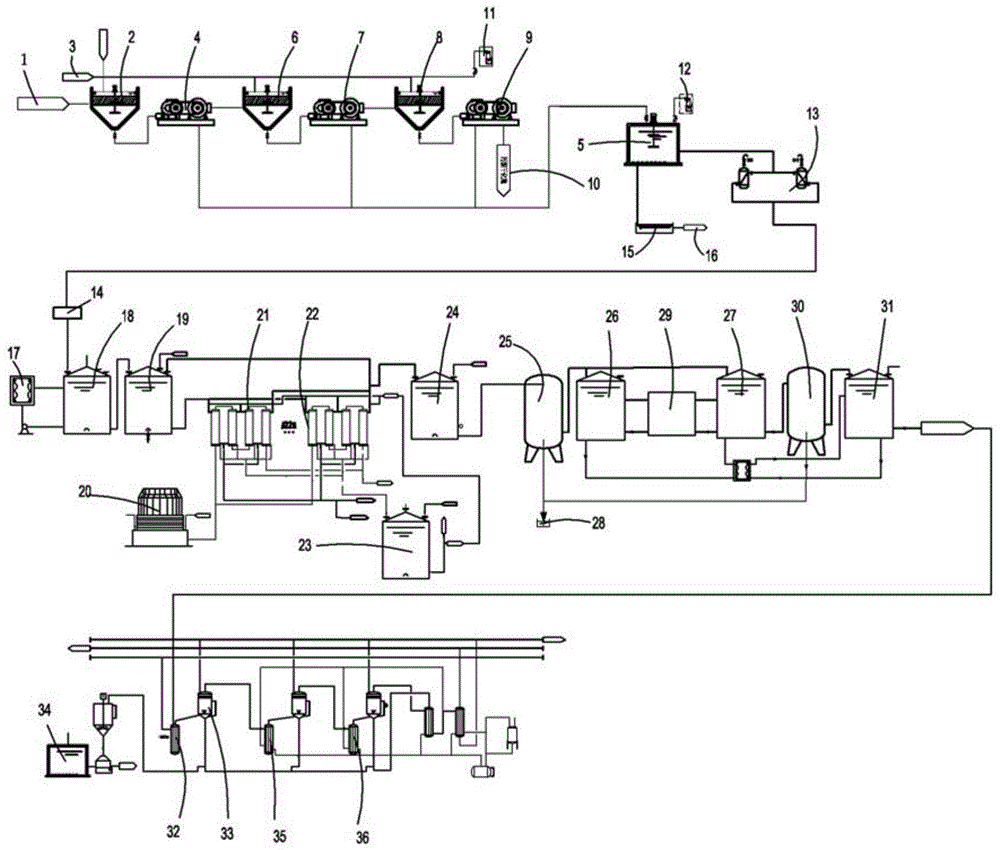

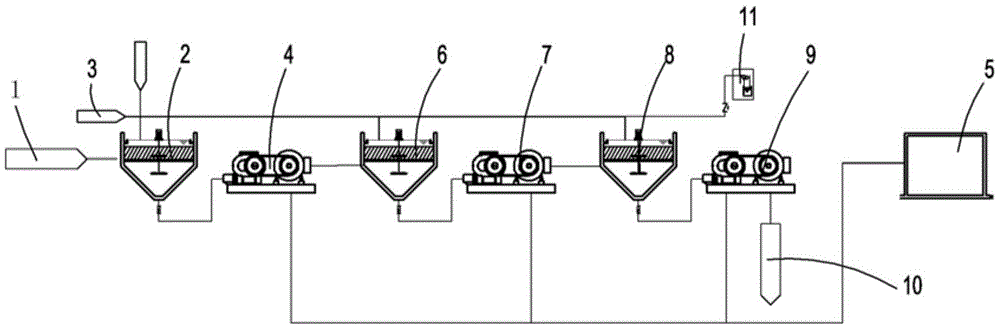

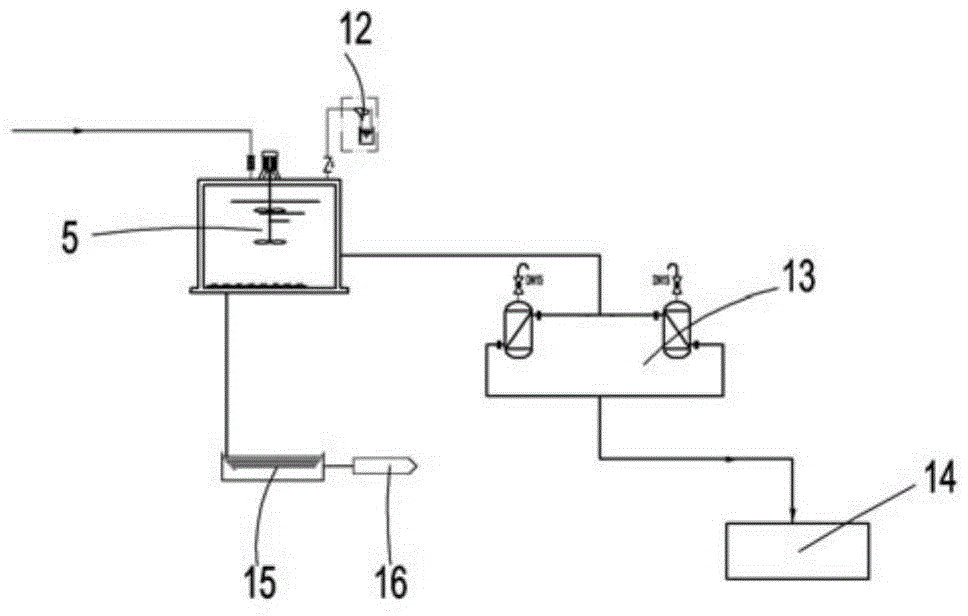

[0053] Examples, see attached Figure 1-7 , a method for co-processing waste fly ash cement kiln and harmless resource recycling, which includes the following process:

[0054] (1) Three-stage water washing and desalting process for waste incineration fly ash;

[0055] (2) Heavy metal removal process by coagulation and sedimentation;

[0056] (3) Membrane distillation concentration process;

[0057] (4) The process of removing very small amounts of miscellaneous salts;

[0058] (5) Three-effect evaporation crystallization process.

[0059] (1) The process of three-stage water washing and desalting of waste incineration fly ash comprises the following steps:

[0060] a. Water washing: Waste incineration fly ash is blown from storage 1 into mixer 2. The incineration fly ash is one ton, and a certain amount of water 3 is added, and the weight ratio of fly ash to water is 1:3, that is, 3 tons of water is added into the mixer , during the stirring process, add a solubilizing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com