Low-temperature deabsorption repairing process used for polluted soil

A polluted soil, low temperature technology, applied in the field of contaminated soil remediation, can solve the problems of high concentration of chemical remediation agents, soil secondary pollution, etc., to achieve the effect of avoiding secondary pollution, ensuring clean discharge, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

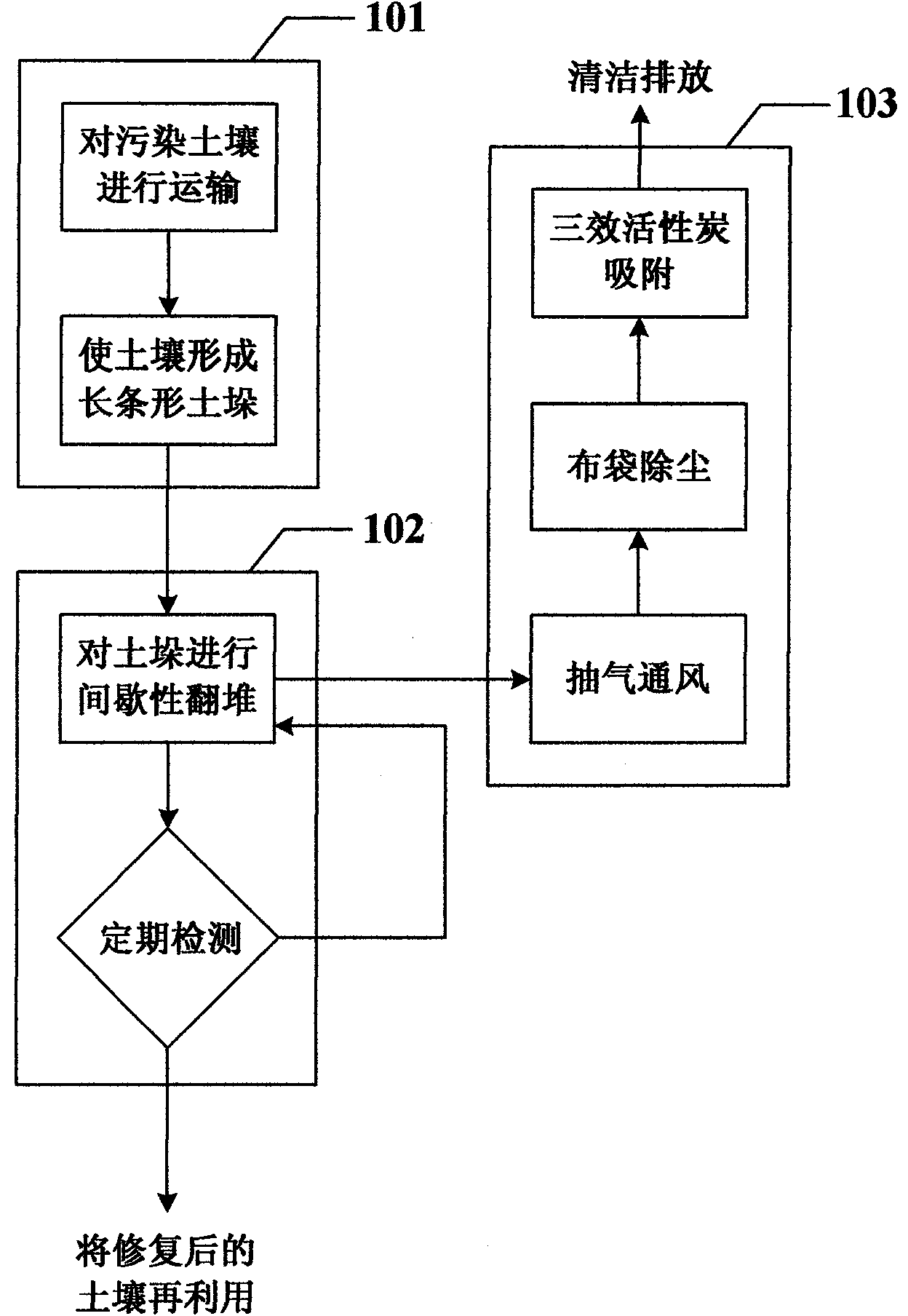

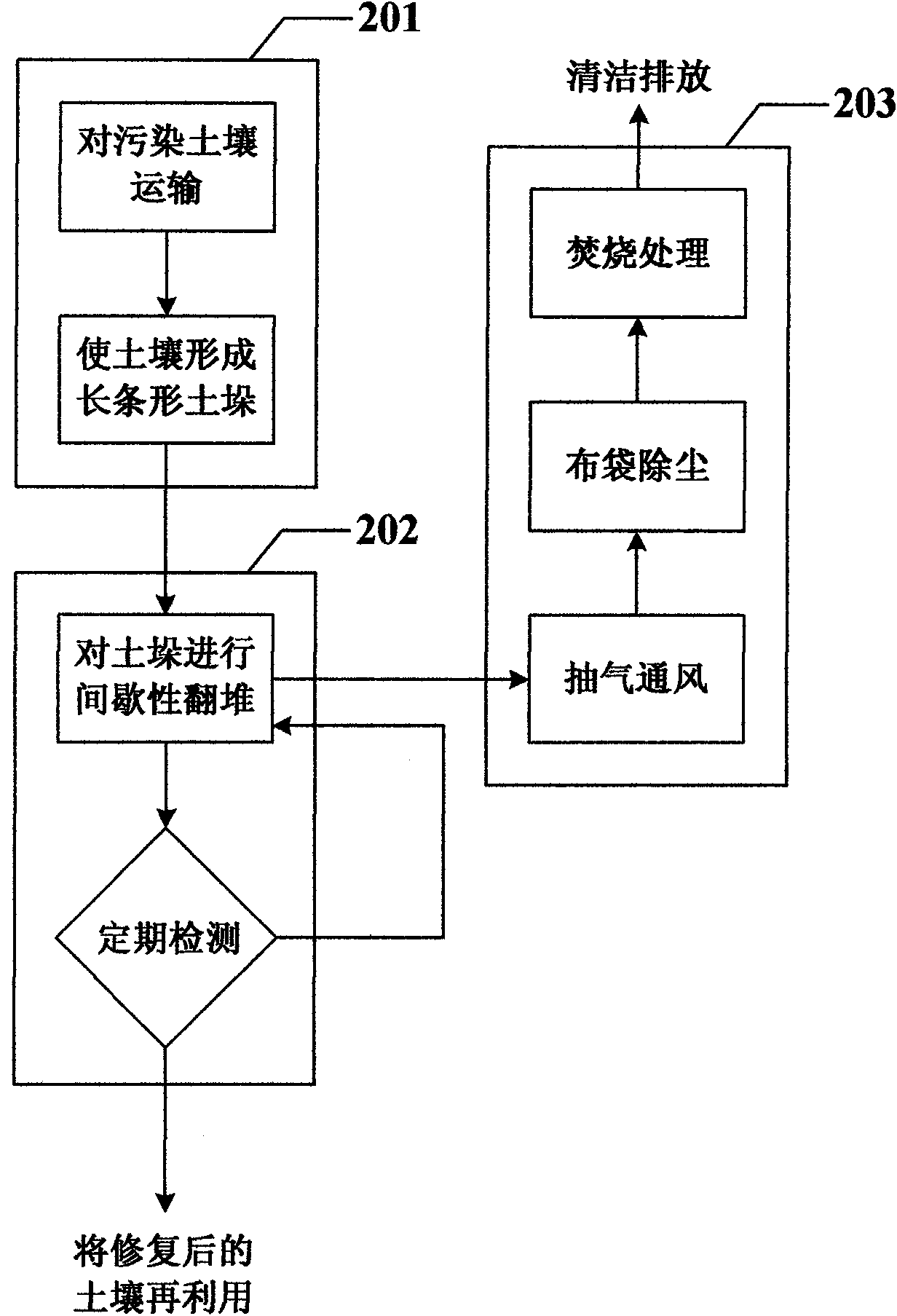

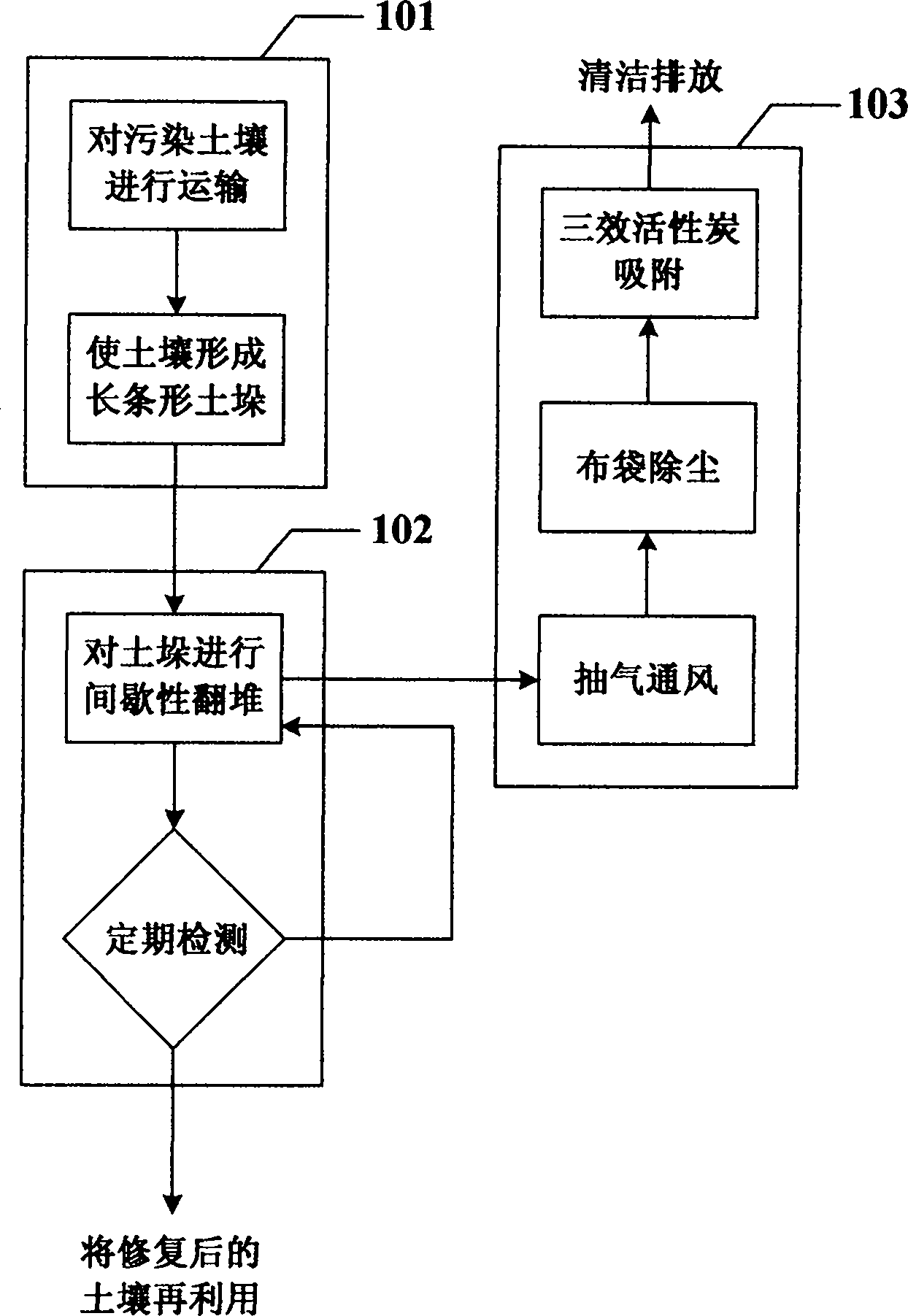

[0018] Such as figure 1 As shown, the present invention provides a low-temperature desorption remediation process for contaminated soil. When the harmful pollutants in the soil are relatively low, the process consists of three steps: contaminated soil preparation stage, low-temperature desorption treatment stage, and tail gas treatment stage. ,

[0019] In the contaminated soil preparation stage (101): after the contaminated soil is transported to the low-temperature desorption workshop, the contaminated soil is formed into multiple strip-shaped soil piles through equipment;

[0020] In the low-temperature desorption treatment stage (102): perform intermittent turning operations on the soil piles through the soil turning equipment, so that the pollutants in the soil can be volatilized and removed, and regularly detect the turned soil;

[0021] In the tail gas treatment stage (103): the volatilized gas with pollutants is exported through the centrifugal exhaust fan, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com