Garbage percolate treatment method

A technology of landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment, can solve the problems of inability to flexibly adapt to changes in the water quality of the landfill, and achieves reduction of sludge treatment volume and extension of service life and life. , the effect of reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

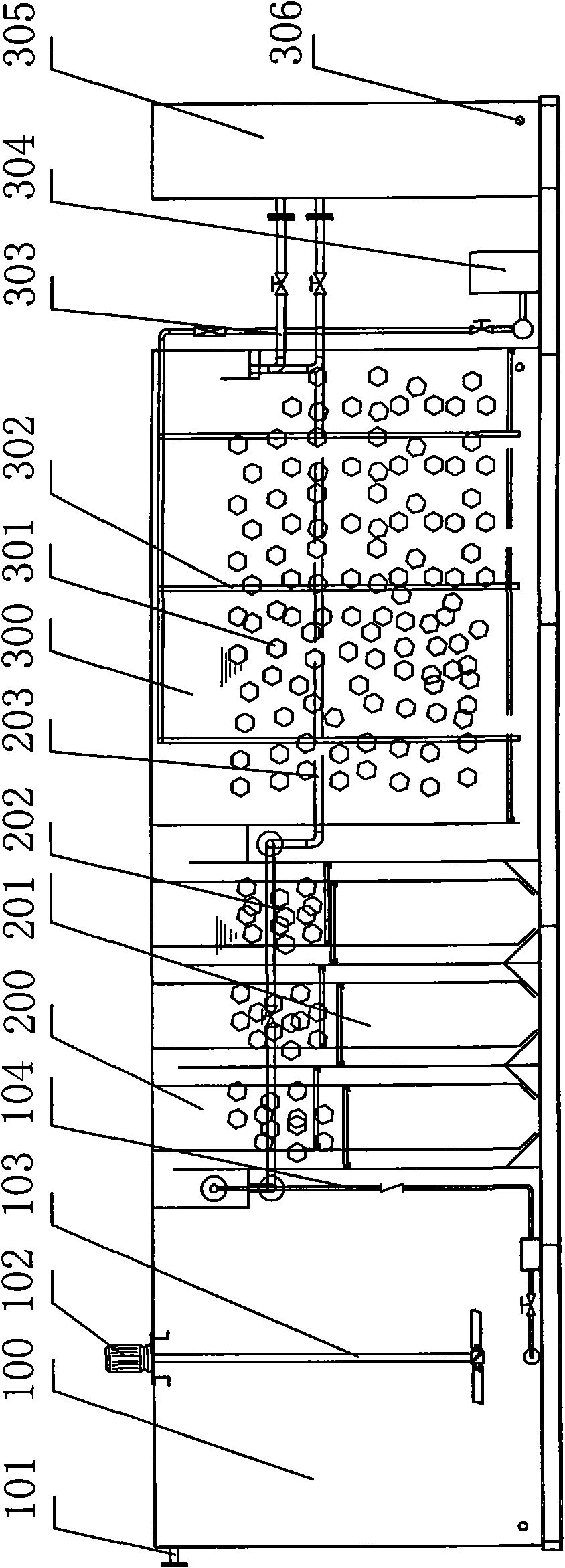

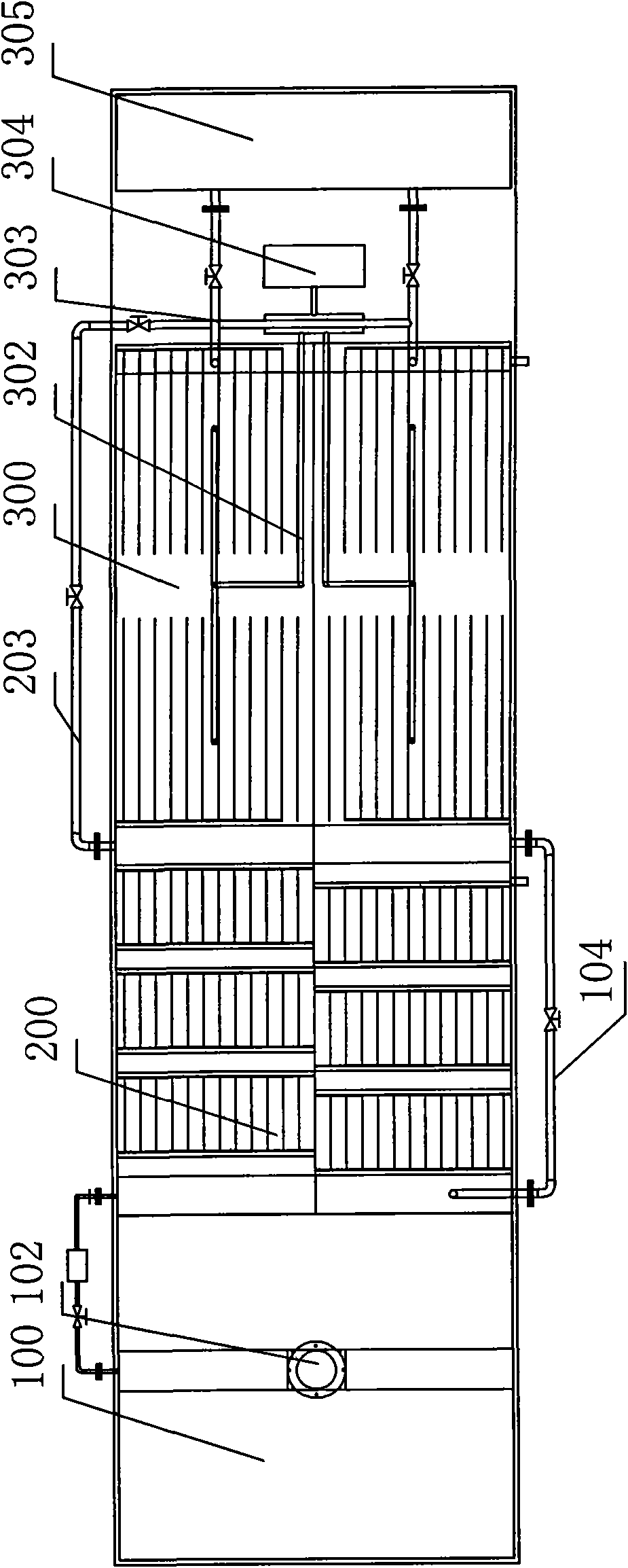

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

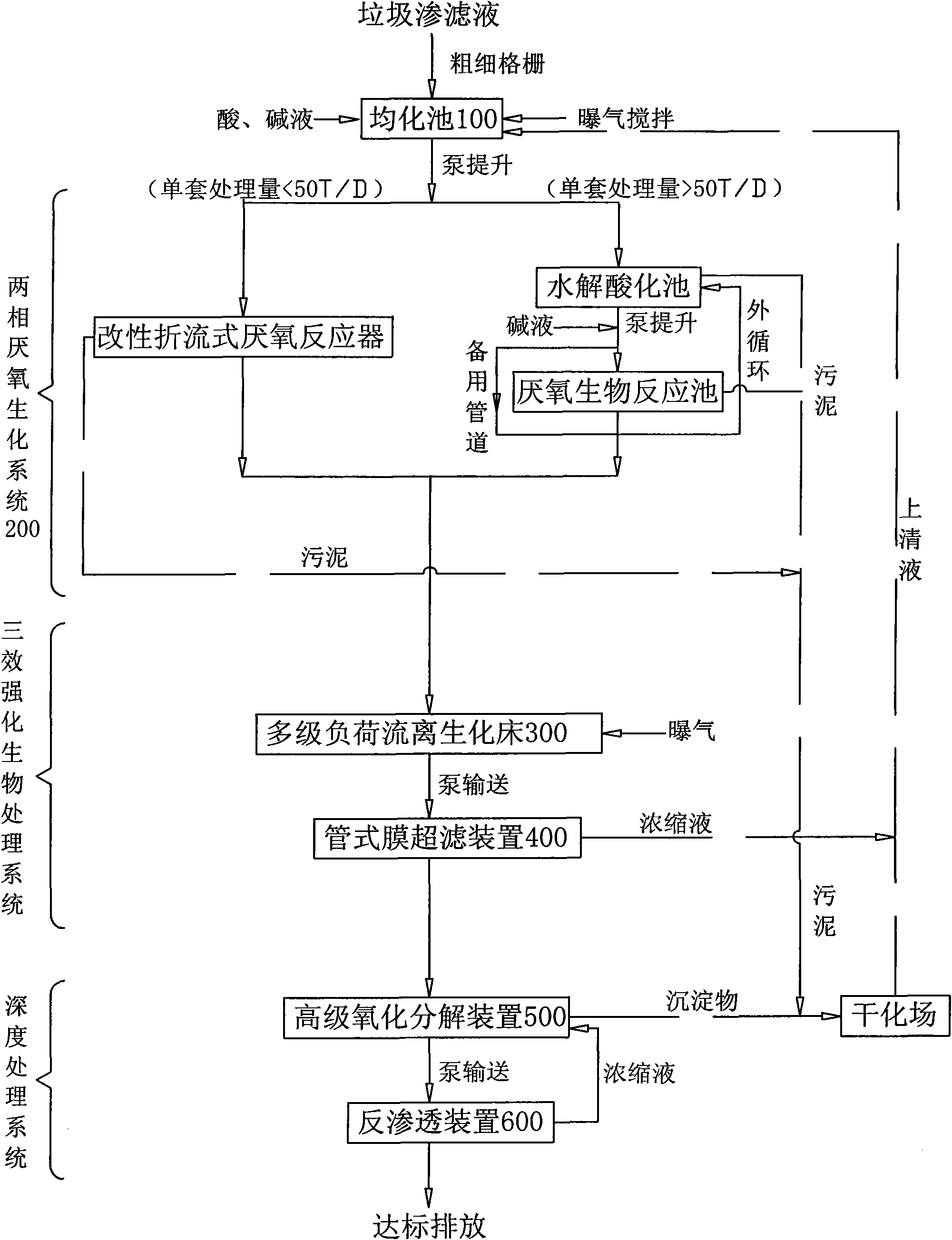

[0036] Such as Figure 1 to Figure 5 As shown, the landfill leachate treatment method of the present invention mainly includes the following steps.

[0037] Step 1: The landfill leachate is filtered through two thick and thin grids to remove larger suspended solids or drifts, and then enters the water inlet 101 of the homogenization tank 100. At the same time, the reflux liquid of the subsequent process, including the concentrated liquid produced by the ultrafiltration membrane system and Cleaning solution, reverse osmosis cleaning solution and supernatant produced by the drying field also flow back into the homogenization tank 100 to dilute and buffer the landfill leachate. Acid and alkali are added to the homogenization tank 100 to control seepage. The pH value of the filtrate is stirred or aerated and stirred by the stirring device 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com