Salting pickled vegetable brine recovery technique

A pickle brine and saline water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, food science, etc., can solve problems such as waste of resources, economic loss of enterprises, and amino acid recovery of undesigned brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

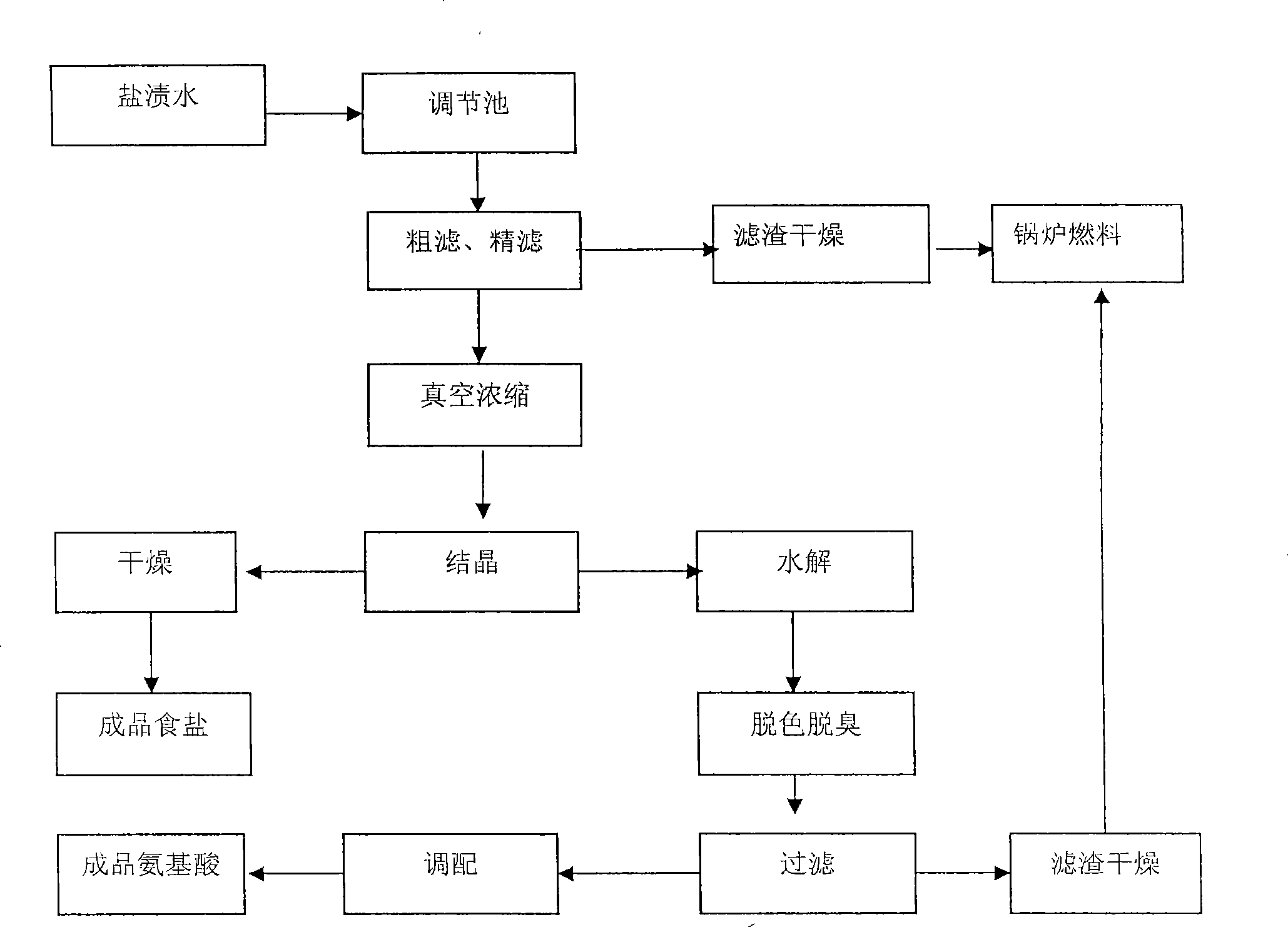

Image

Examples

example 1

[0020] The salted kimchi brine is coarsely filtered in the adjustment tank. The mesh diameter of the coarse filter is 0.15mm, and the mesh width is 0.25mm. The coarse filter liquid flows into the plate filter, and the filtered residue is transported to the drying field for drying and used as boiler fuel. , the filtrate enters the three-effect concentration equipment to obtain saturated salt water, which is pumped into the crystallizer to crystallize, and is centrifuged at 3000r / min to obtain salt. 1.12% vegetable amino acids.

example 2

[0022] The salted kimchi brine is coarsely filtered in the adjustment tank. The mesh diameter of the coarse filter is 0.30mm, and the mesh width is 0.70mm. The coarse filter liquid flows into the plate filter, and the filtered residue is transported to the drying field for drying and used as boiler fuel. , the filtrate enters the three-effect concentration equipment to obtain saturated salt water, which is pumped into the crystallizer to crystallize, and is centrifuged at 4000r / min to obtain salt. 1.05% vegetable amino acids.

example 3

[0024] The salted kimchi brine is coarsely filtered in the adjustment tank. The mesh diameter of the coarse filter is 0.25mm and the mesh width is 0.65mm. The coarse filter liquid flows into the plate filter, and the filtered residue is transported to the drying field for drying and used as boiler fuel. , the filtrate enters the three-effect concentration equipment to obtain saturated salt water, which is pumped into the crystallizer to crystallize, and is centrifuged at 5000r / min to obtain salt. 1.11% vegetable amino acids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com