Solvent recovery method of Lyocell fibers

A recovery method and solvent technology, applied in the field of solvent recovery of Lyocell fiber, to achieve the effect of streamlining, effective and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

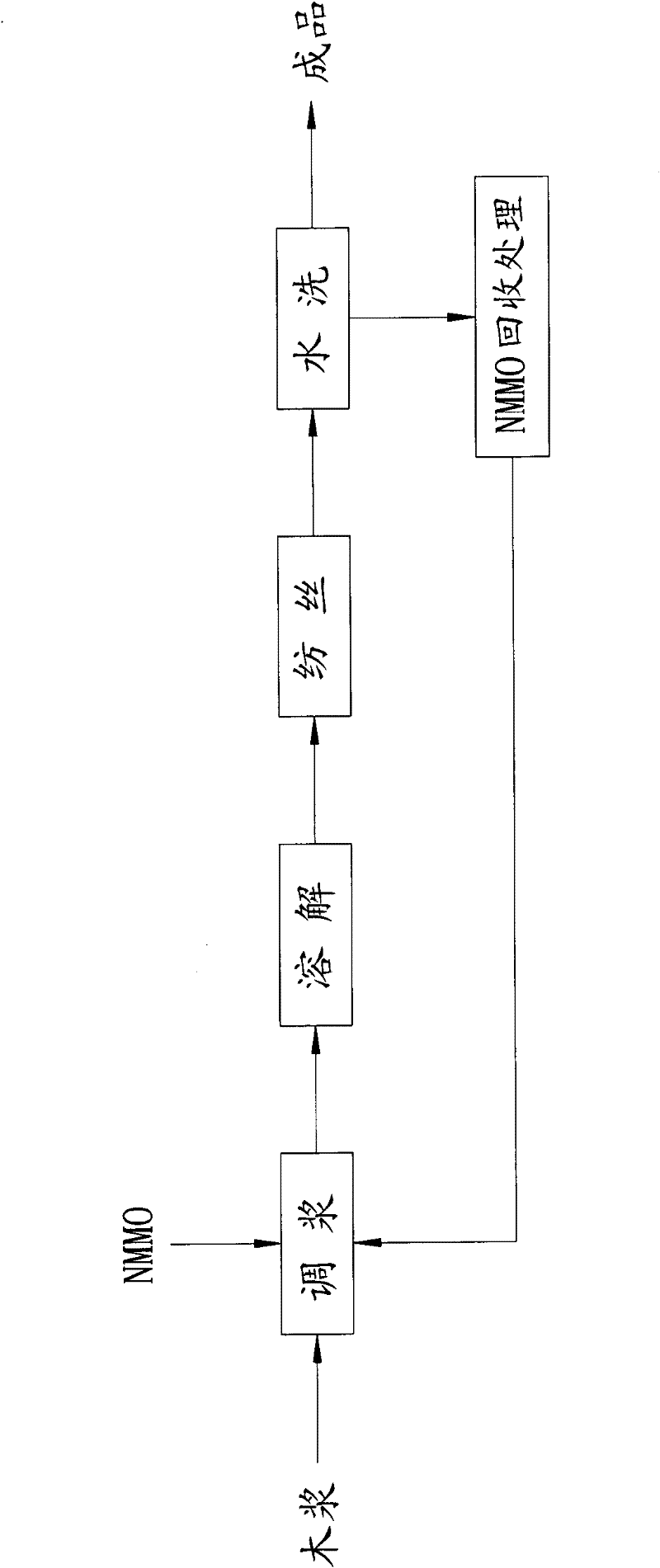

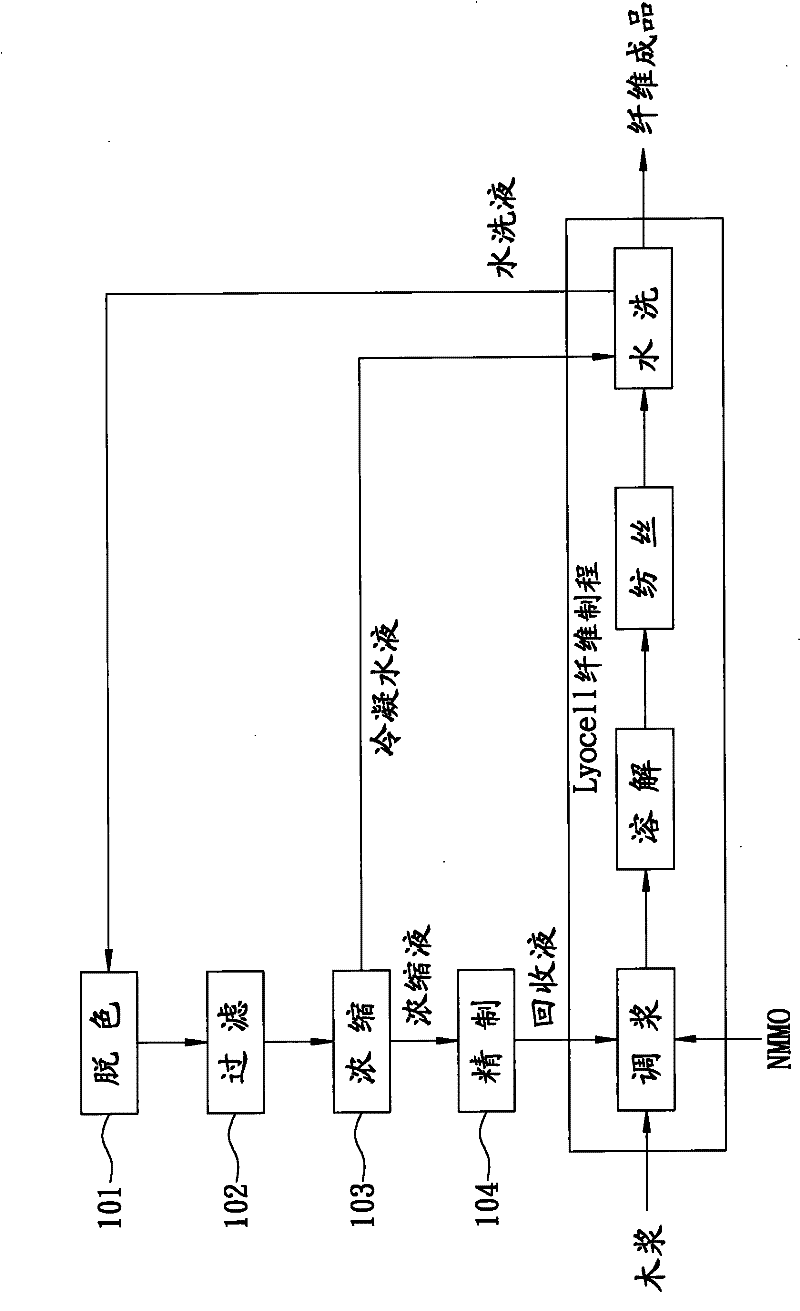

[0027] refer to figure 2 , a preferred embodiment of the solvent recovery method for Lyocell fibers of the present invention, used to reclaim a large amount of washing liquid containing low-concentration NMMO solvents produced by the Lyocell fiber process. The Lyocell fiber process mainly includes pulping, dissolving, spinning and washing Four processing steps. In addition to the NMMO solvent used to dissolve the cellulose raw material, the washing liquid produced by the fiber manufacturing process also contains a small amount of NMM. NMM is formed by the cracking of NMMO due to heating during the process of dissolving cellulose. of. A preferred embodiment of the recovery method includes the following steps.

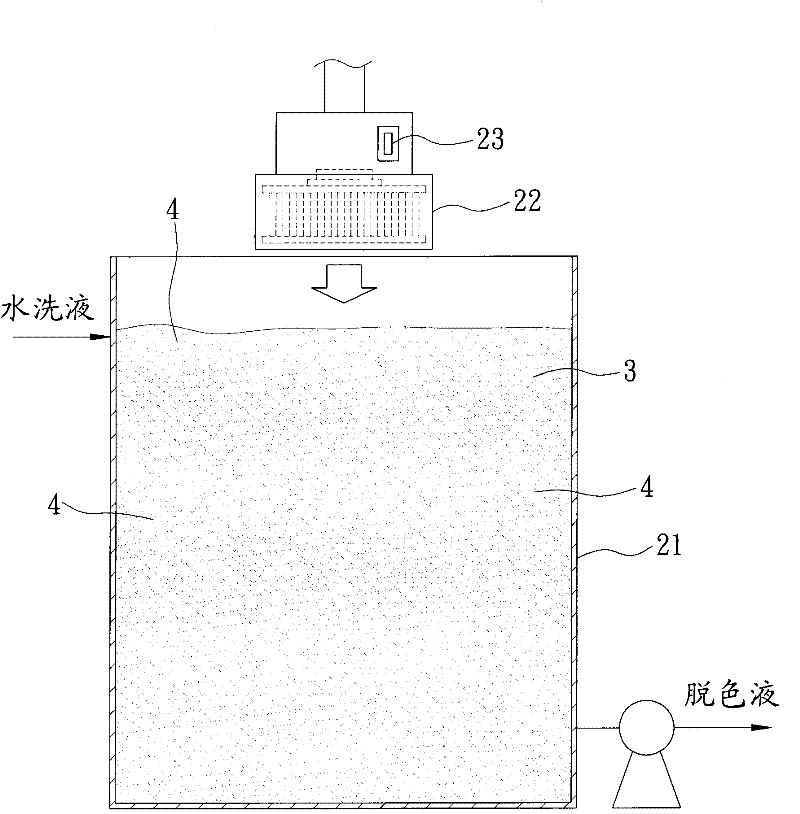

[0028] Step 101 is decolorization. Since the dissolution step of the Lyocell fiber manufacturing process is accompanied by heating to improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com