Zero-emission comprehensive utilizing technology for continuous-casting secondary-cooling vapor and converter vaporizing vapor

A technology of evaporating steam and secondary cooling water, which is applied in the field of steelmaking, and can solve problems such as affecting the environment, not complying with energy saving, emission reduction and environmental protection, and heat energy not being utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

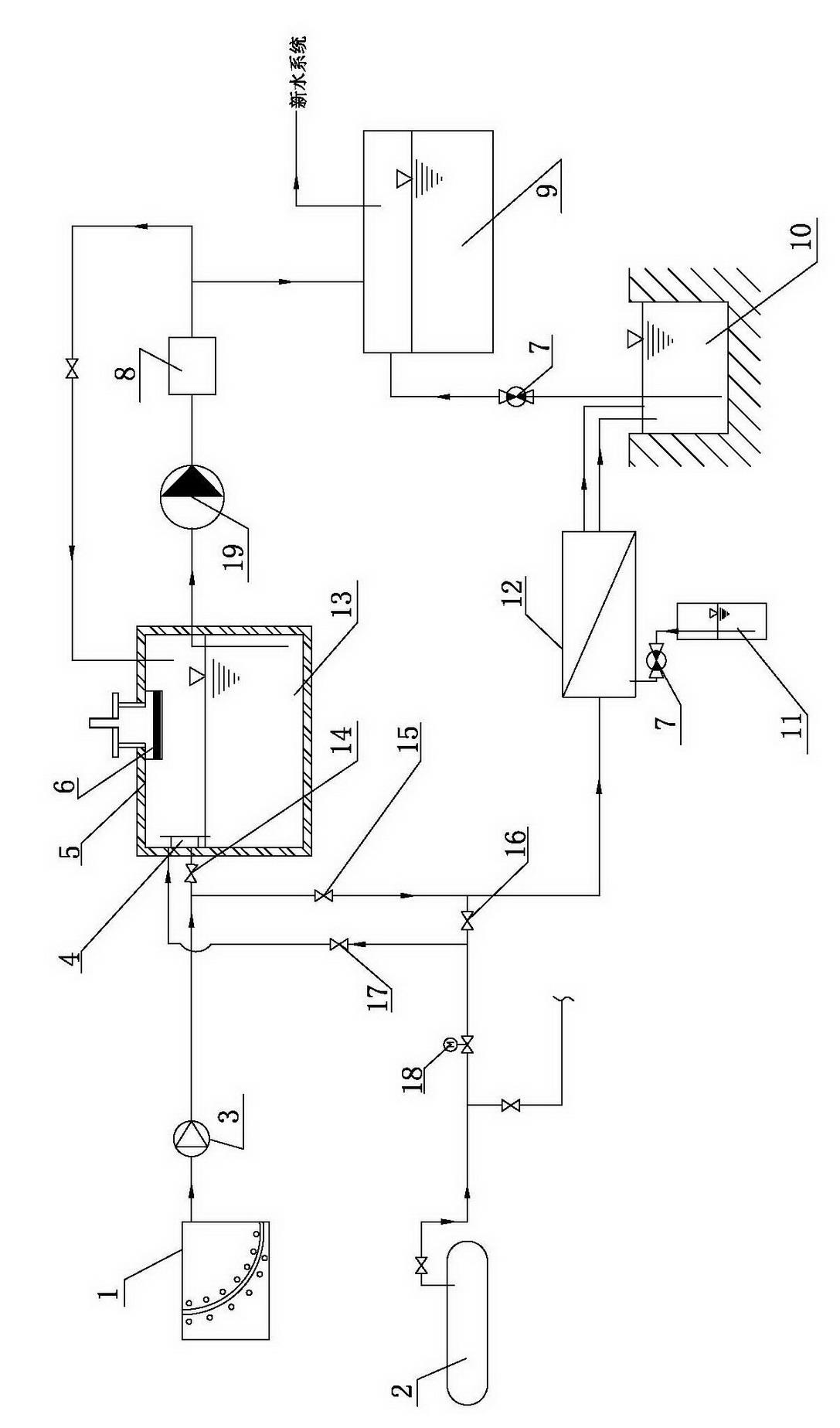

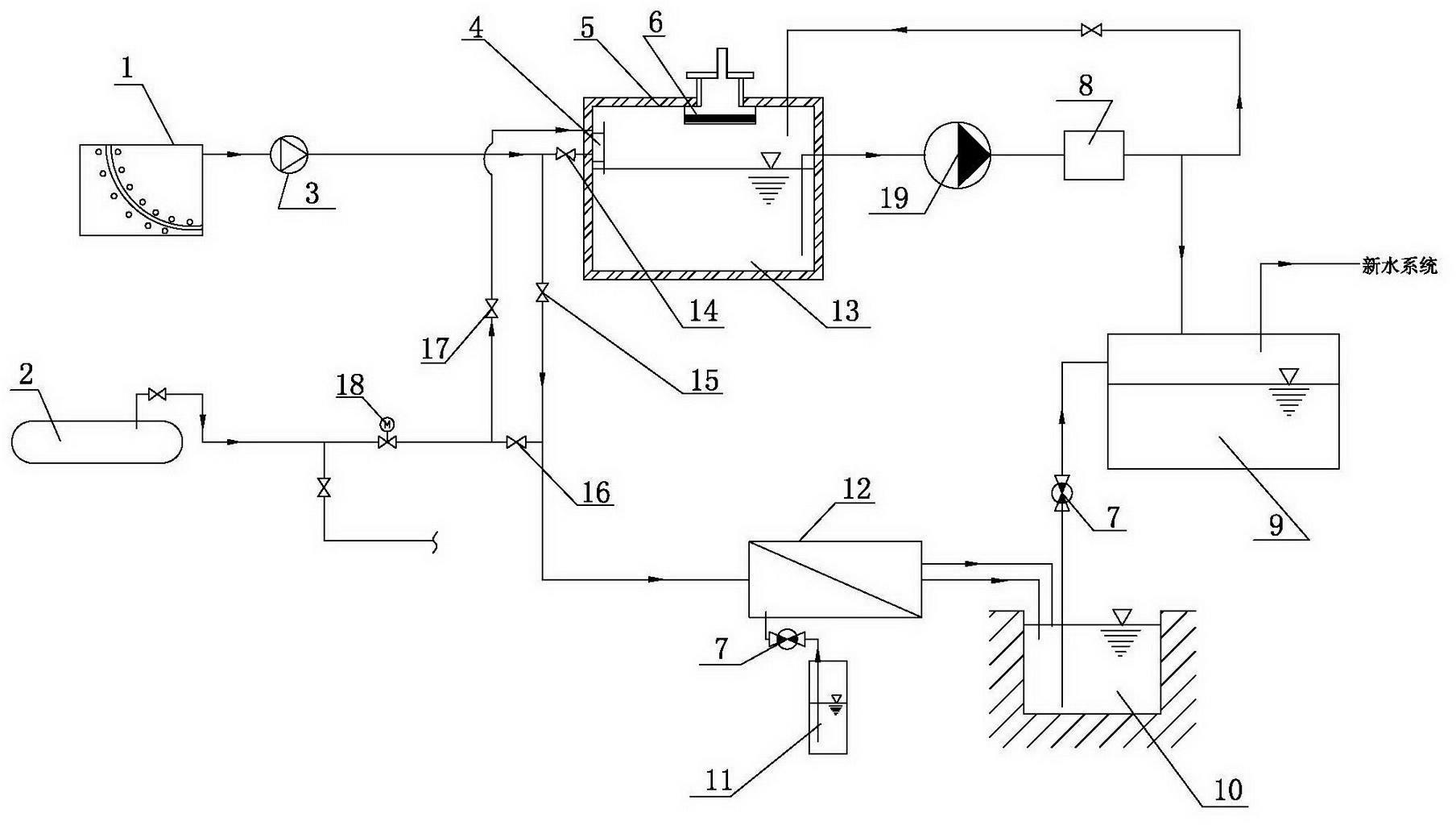

[0008] As shown in the figure, ① Heating period: the steam in the secondary cold steam room 1 of the continuous casting machine is transported to the heat preservation water tank 13 by the fan 3 through the valve 14 through the pipeline. The steam in the gas bag 2 used to store the converter vaporization steam is also delivered to the heat preservation water tank 13 through the pipeline, the overpressure relief valve 18 and the valve 17. The steam delivered to the thermal water tank 13 becomes 85-95°C hot water through the cooling and dehydration of the condensation plate 4 and the dehydration net 6 therein. The hot water is transported to the heating network 8 by the heating water pump 19 through the pipeline to provide heat medium for the heating network 8 . Most of the return water of the heat network 8 returns to the heat preservation water tank 13 through the pipeline for recycling, and the remaining part is sent into the fresh water filter pool 9 through the pipeline, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com