Method for resource utilization of wastewater in synthetic process of battery-grade iron phosphate

A synthesis process, iron phosphate technology, applied in chemical instruments and methods, phosphate, phosphorus oxyacids, etc., can solve the problems of increasing wastewater treatment costs, wastewater is not suitable for biological treatment, etc., and achieve good environmental protection and economic benefits , the effect of making up for the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

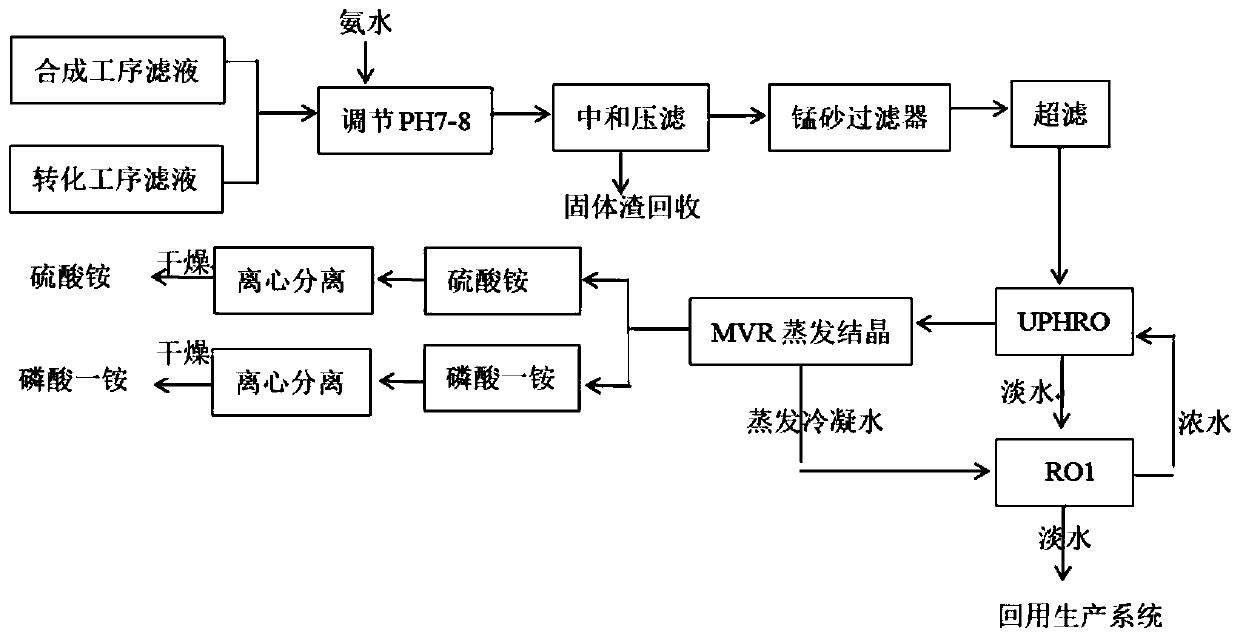

[0032] After mixing the filtrate from the synthesis step and the conversion step in the synthesis process of battery-grade ferric phosphate, add ammonia water to neutralize while stirring, and adjust the pH of the solution to 7. Then the mixed solution is pumped into a plate-and-frame filter for filtration to obtain solid slag and a sulfate solution containing high-concentration ammonium salt and phosphate.

[0033] The above-mentioned sulfate solution containing high concentration of ammonium salt and phosphate is pumped into the manganese sand filter for further filtration, so that the content of suspended particles and iron ions in the filtrate is further reduced, so that SS≤5ppm, Fe≤0.1ppm. The filtrate passing through the manganese sand filter is then introduced into the ultrafiltration device through a pump, so that the filtrate index can meet the water inlet requirements of ultra-high pressure reverse osmosis (UPHRO). The ultra-filtered water is subjected to ultra-high ...

Embodiment 2

[0035] After mixing the filtrate from the synthesis step and the conversion step in the synthesis process of battery-grade ferric phosphate, add ammonia water for neutralization while stirring, and adjust the pH of the solution to 7.5. Then the mixed solution is pumped into a plate and frame filter for filtration to obtain solid slag and a sulfate solution containing high concentrations of ammonium salt and phosphate.

[0036] Pump the above solution into a manganese sand filter for further filtration to further reduce the suspended particles and iron ion content in the filtrate so that SS≤5ppm and Fe≤0.1ppm. The filtrate passing through the manganese sand filter is then introduced into the ultrafiltration device through a pump, so that the filtrate index can meet the water inlet requirements of ultra-high pressure reverse osmosis (UPHRO). The ultra-filtered water is subjected to ultra-high pressure reverse osmosis (UPHRO) to concentrate the initial concentration of waste liqu...

Embodiment 3

[0038] After mixing the filtrate from the synthesis process and the conversion process in the battery-grade iron phosphate synthesis process, adding ammonia water to neutralize while stirring, and adjusting the pH of the solution to 8. Then the mixed solution is pumped into a plate and frame filter for filtration to obtain solid slag and a sulfate solution containing high concentrations of ammonium salt and phosphate.

[0039]Pump the above solution into a manganese sand filter for further filtration to further reduce the suspended particles and iron ion content in the filtrate so that SS≤5ppm and Fe≤0.1ppm. The filtrate passing through the manganese sand filter is then introduced into the ultrafiltration device through a pump, so that the filtrate index can meet the water inlet requirements of ultra-high pressure reverse osmosis (UPHRO). The ultra-filtered water is subjected to ultra-high pressure reverse osmosis (UPHRO) to concentrate the initial concentration of waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com