Method for producing vinegar with liquid pouring fermentation tower with woven cloth packing system

A technology of liquid pouring fermentation and woven cloth, which is applied in the fields of food and beverage, fermentation, textile, and microorganism, can solve the problems of time-consuming, increase production cost, pollute the environment, etc., and achieve the effect of improving unit utilization rate and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

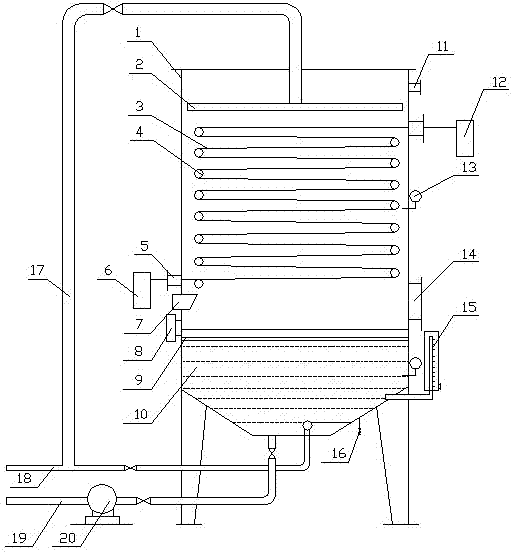

Image

Examples

Embodiment 1

[0027] (1) Liquefaction of raw materials: Take 1000kg of rice, add 1500kg of water, soak for 6 hours, and grind it into slurry by grinding wheel.

[0028] (2) Alcoholic fermentation: Add 3kg of amylase to the slurry, raise the temperature to 92°C, keep it warm for 15 minutes, boil it, and pump it into the alcohol fermentation tank. Add water to adjust the concentration to 9.5°Bé and adjust the temperature to 32°C. Add 2.4 kg of 50,000 units / g of glucoamylase and 2 kg of active dry yeast, mix well, and ferment at 30-34°C for 5 days.

[0029] (3) Plate and frame filter press: the fermented wine mash is filtered through a plate and frame to obtain sake liquid.

[0030] (4) Acetic acid fermentation: add water to the above-mentioned sake liquid to adjust the alcohol content to 6.5% (v / v), insert 800kg of acetic acid bacteria (AS1.41), and intermittently spray the filler system made of woven cloth after sterilization On the top, let the filling material absorb a large amount of ferm...

Embodiment 2

[0042] (1) Raw material liquefaction: take 1000kg of corn, add 1500kg of water, soak for 6 hours, and grind it into slurry by grinding wheel.

[0043] (2) Alcoholic fermentation: Add 3kg of amylase to the slurry, raise the temperature to 92°C, keep it warm for 15 minutes, boil it, and pump it into the alcohol fermentation tank. Add water to adjust the concentration to 9.5°Bé and adjust the temperature to 32°C. Add 2.4 kg of 50,000 units / g of glucoamylase and 2 kg of active dry yeast, mix well, and ferment at 30-34°C for 5 days.

[0044] (3) Plate and frame filter press: the fermented wine mash is filtered through a plate and frame to obtain sake liquor.

[0045] (4) Acetic acid fermentation: add water to the above-mentioned sake liquid to adjust the alcohol content to 6.5% (v / v), insert 800kg of acetic acid bacteria (AS1.41), and intermittently spray the filler system made of woven cloth after sterilization On the top, let the filling material absorb a large amount of fermen...

Embodiment 3

[0050] The used fermentation tower is different from Example 1 in that the diameter of the rollers is 0.008 meters, and the distance between the two rollers is 5 meters.

[0051] The woven fabric is a polyester needle-punched woven fabric with a thickness of 3 mm, and the filling volume is 9 / 10 of the volume of the tower.

[0052] All the other are with the technical scheme of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com