Patents

Literature

30results about How to "Increased unit utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

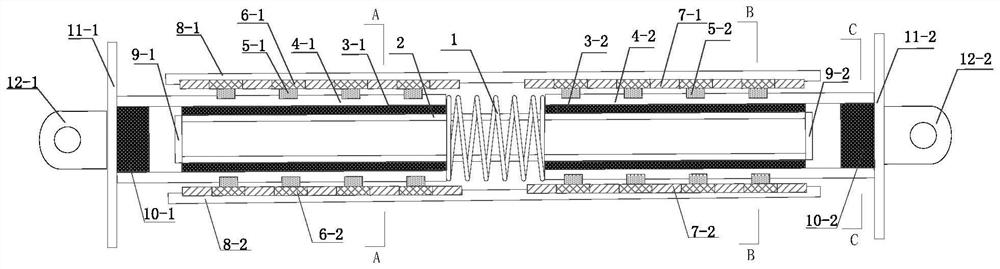

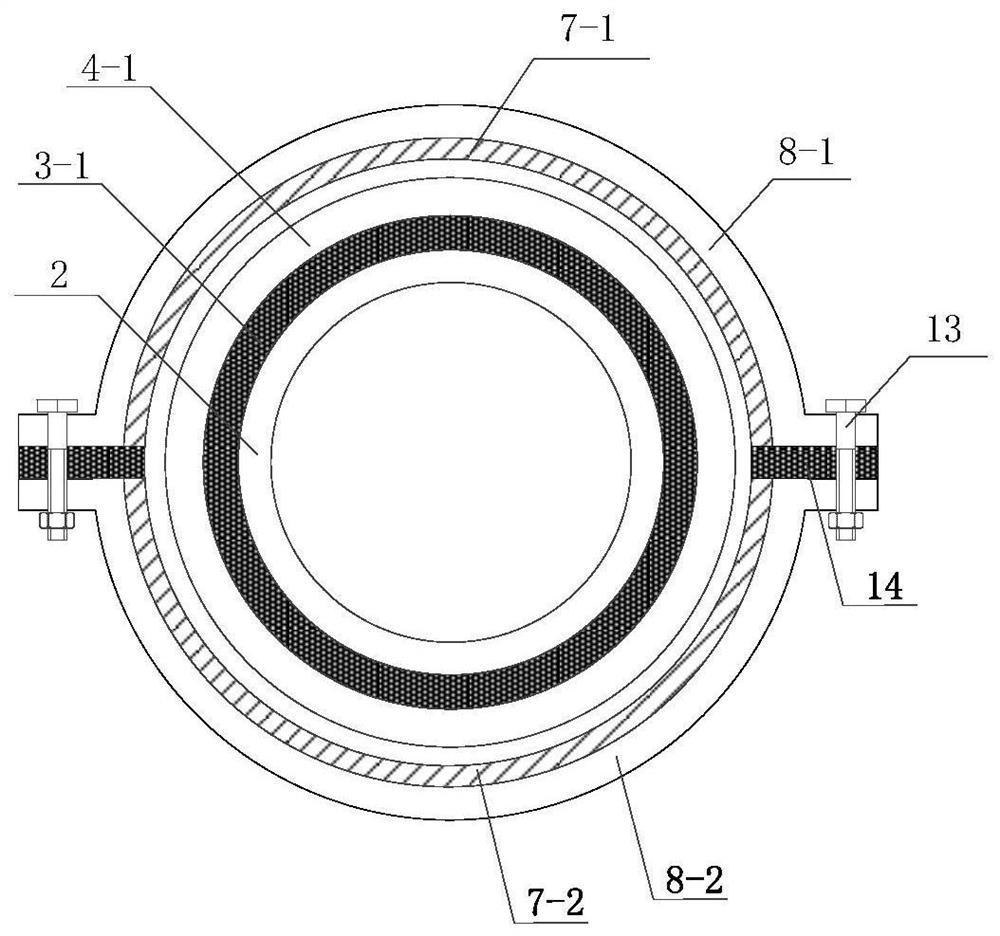

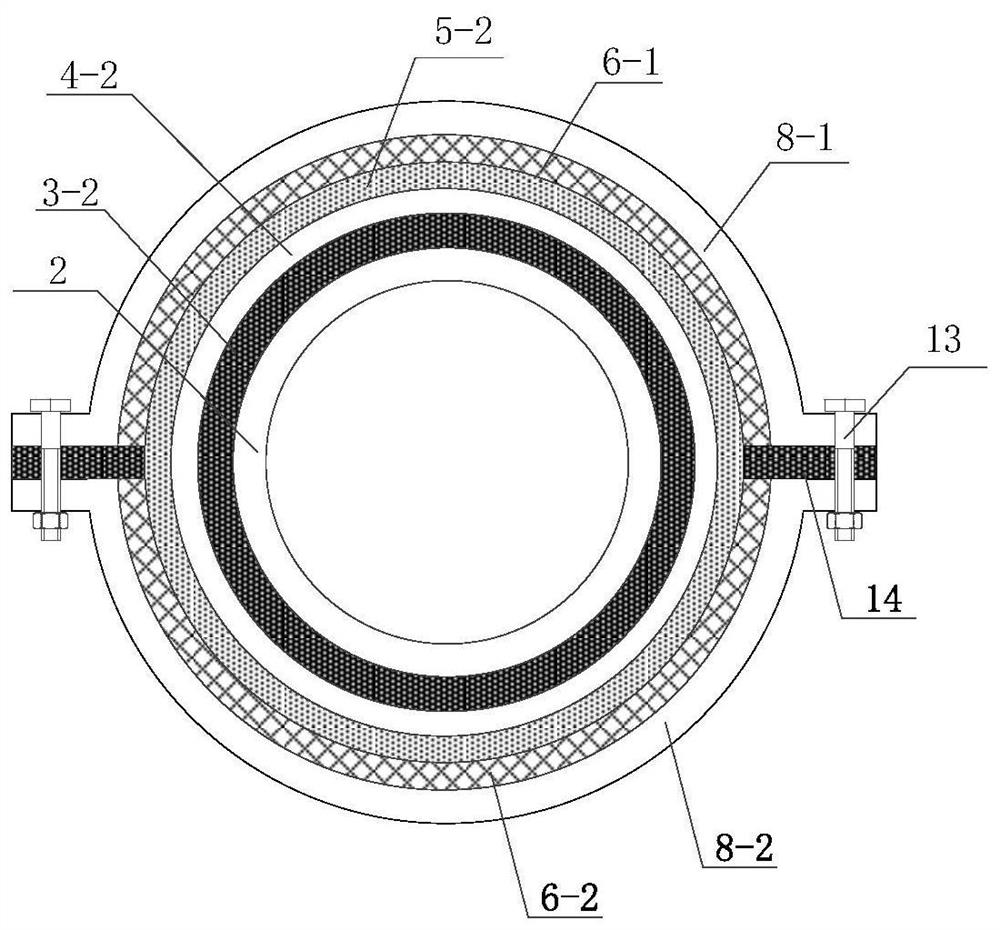

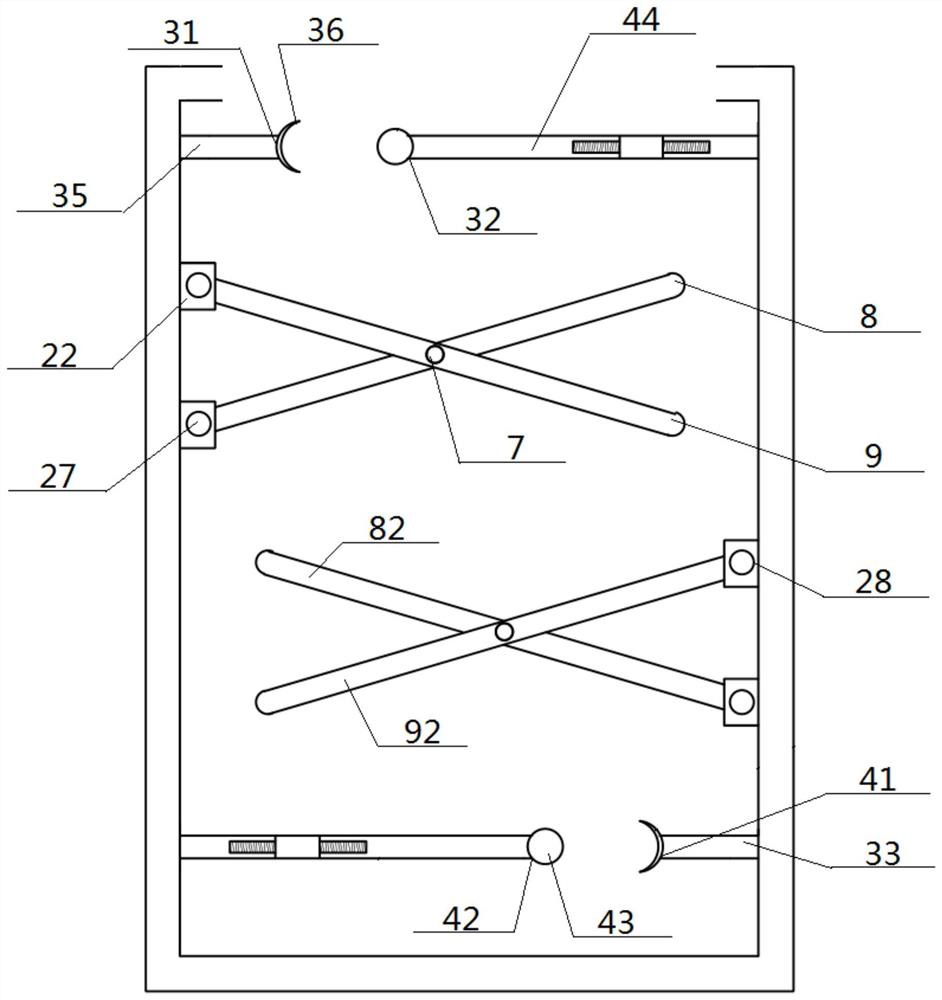

Variable-damping variable-rigidity viscoelasticity-friction composite damping device

ActiveCN111350291AImproved dissipation capacityReduce vibration responseProtective buildings/sheltersShock proofingViscoelastic dampingShock absorber

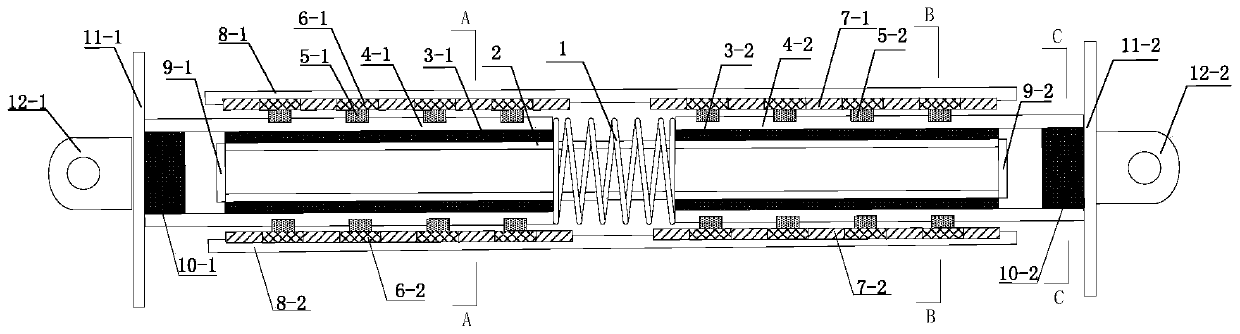

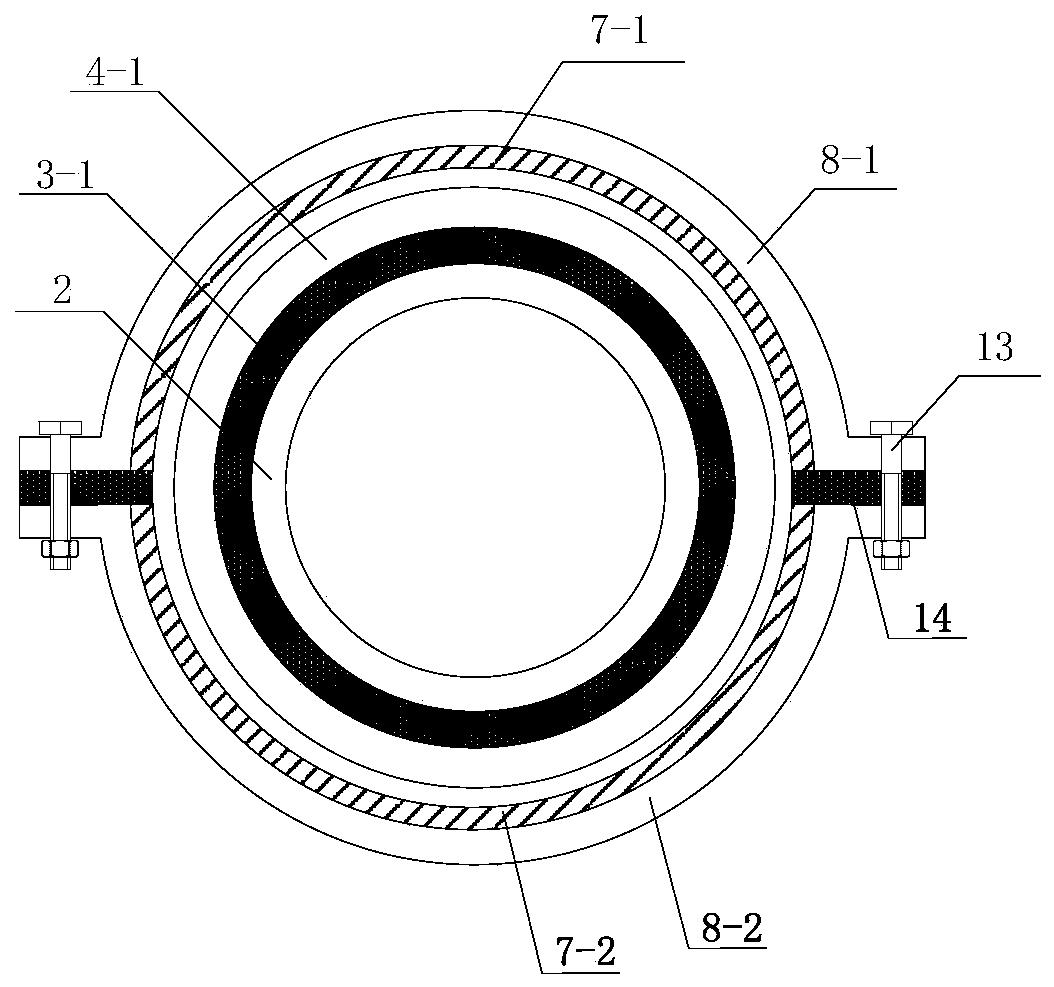

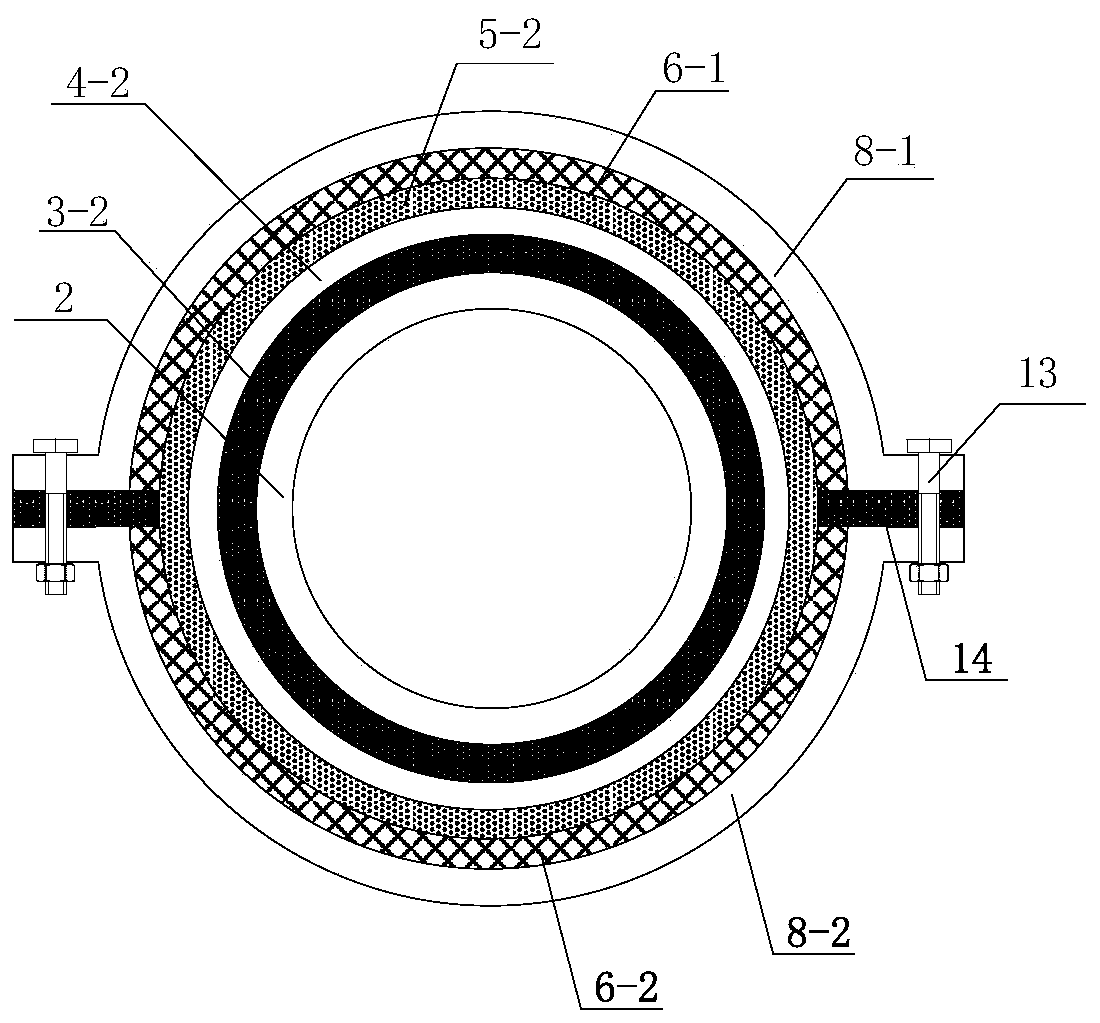

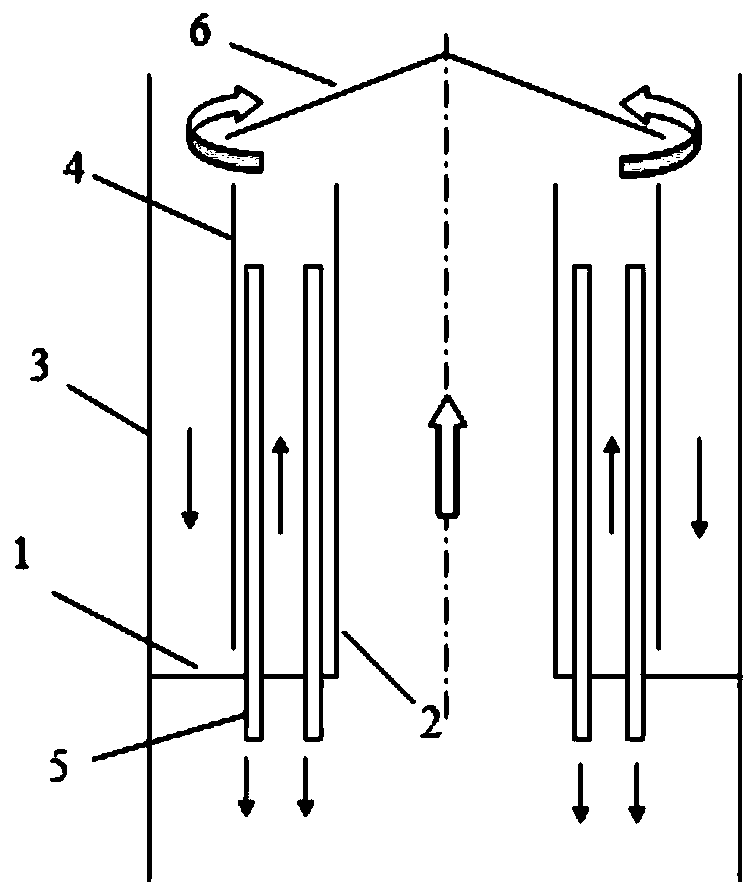

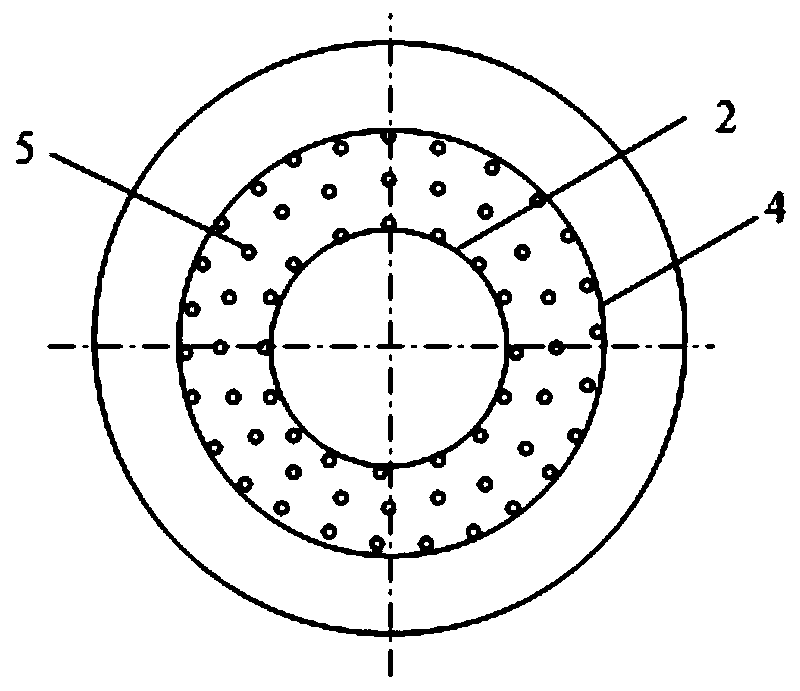

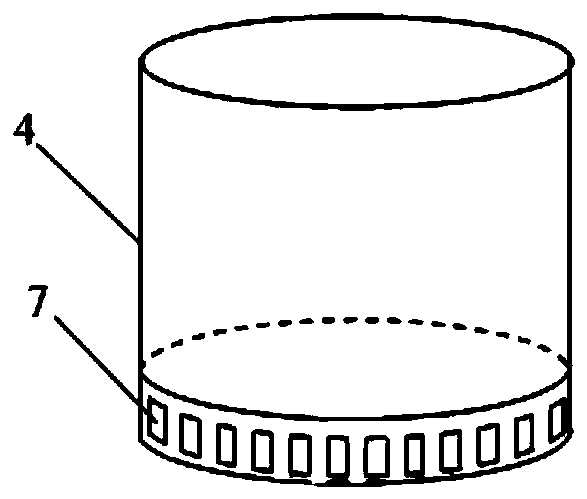

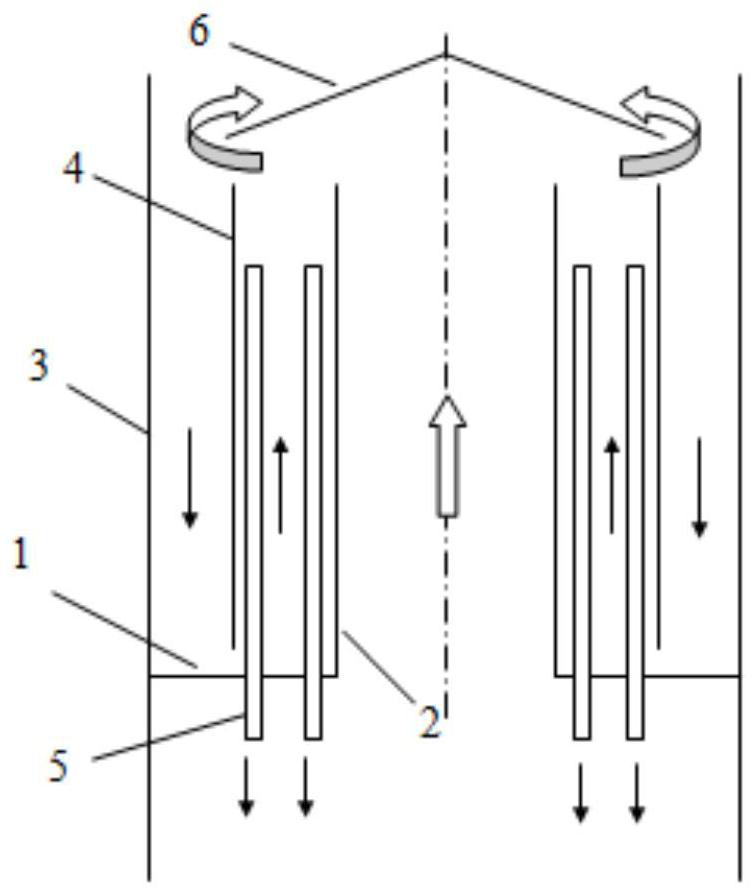

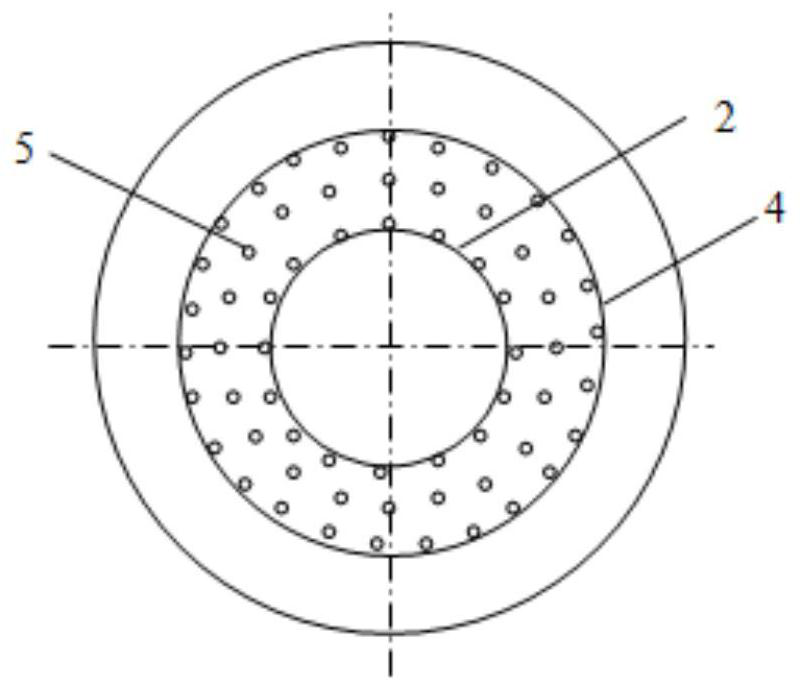

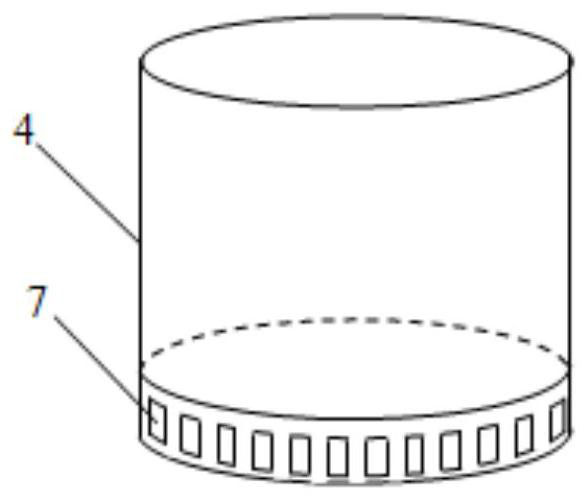

The invention discloses a variable-damping variable-rigidity viscoelasticity-friction composite damping device. The variable-damping variable-rigidity viscoelasticity-friction composite damping devicecomprises two symmetric cylinder type viscoelasticity damping device units and two cylinder type friction damping device units, the friction damping device units sleeve the outer sides of the cylinder type viscoelasticity damping device units, the cylinder type viscoelasticity damping device units sequentially comprise annular inner steel cylinders, annular viscoelasticity material layers and annular middle steel cylinders from inside to outside, elastic elements are sleeved with the middles of the annular inner steel cylinders, closed steel plates are mounted on two ends of the annular innersteel cylinders, cylinder viscoelasticity materials are mounted on inner sides of two ends of the annular middle steel cylinders, connecting anchorage steel plates are mounted on two ends of the annular middle steel cylinders, the friction damping device units sequentially comprise annular middle steel cylinders, annular friction pieces, annular friction plates and annular outer steel cylinders from inside to outside, the annular friction plates comprise first annular friction plates and second annular friction plates, and each annular outer steel cylinder is formed through connecting of an upper half annular outer steel cylinder and a lower half annular outer steel cylinder through bolt assembling.

Owner:HUBEI UNIV OF ARTS & SCI

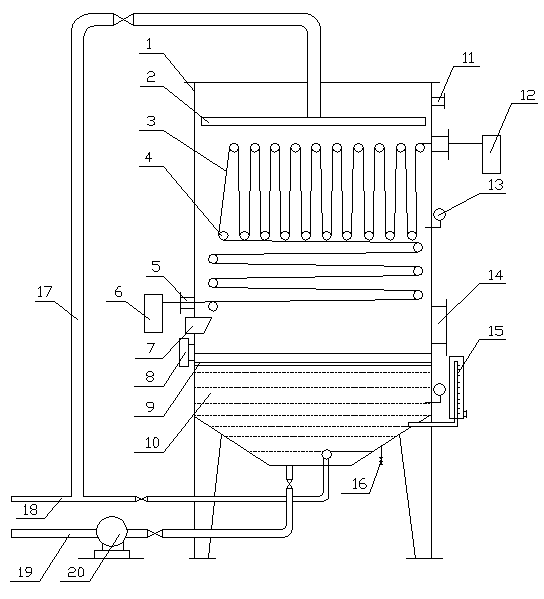

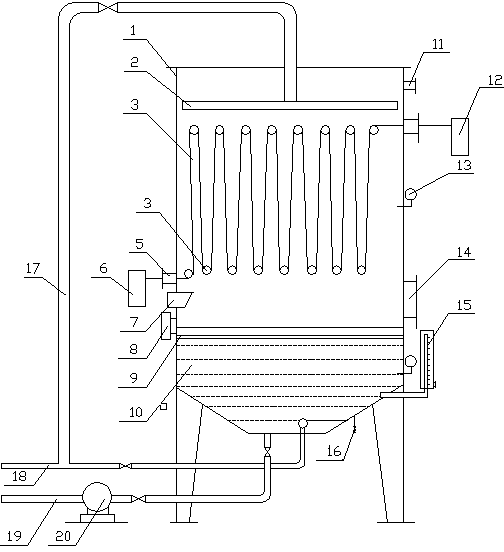

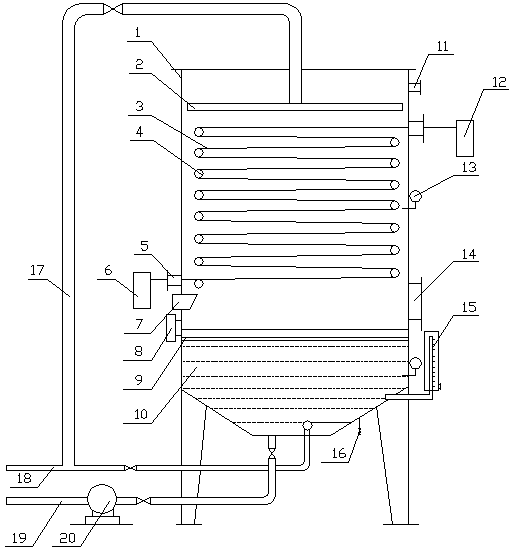

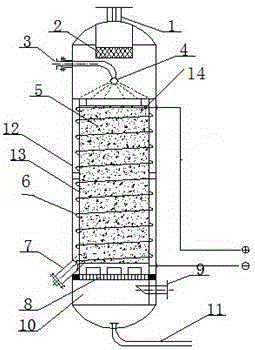

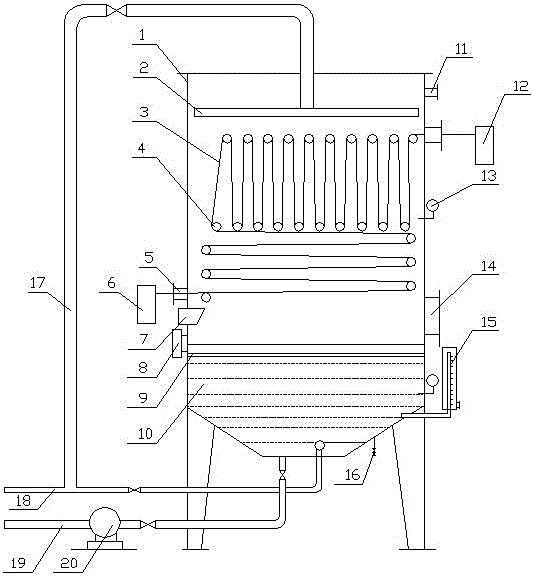

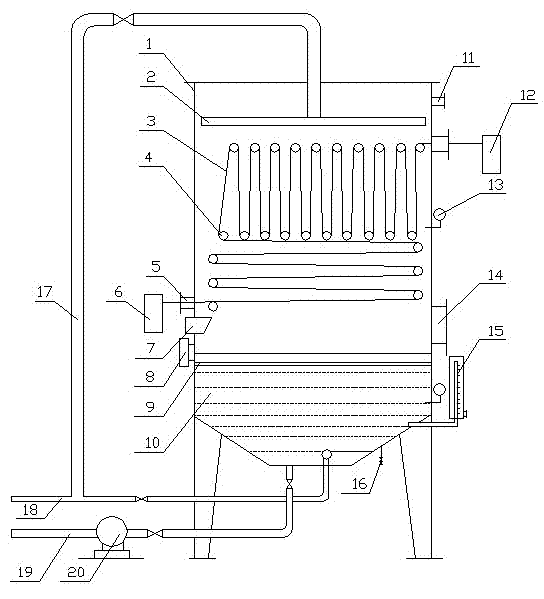

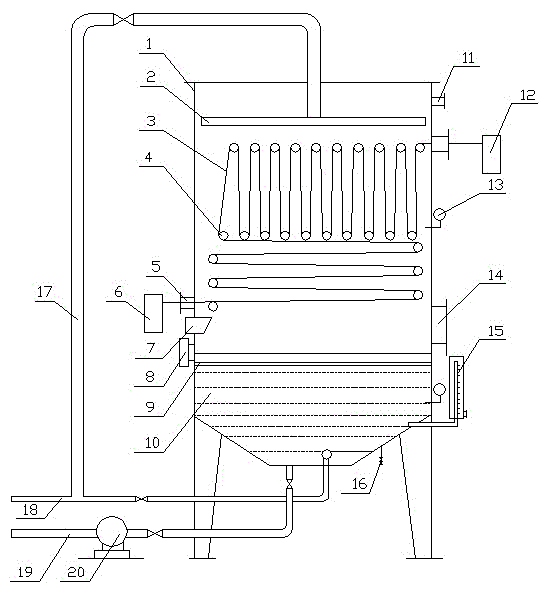

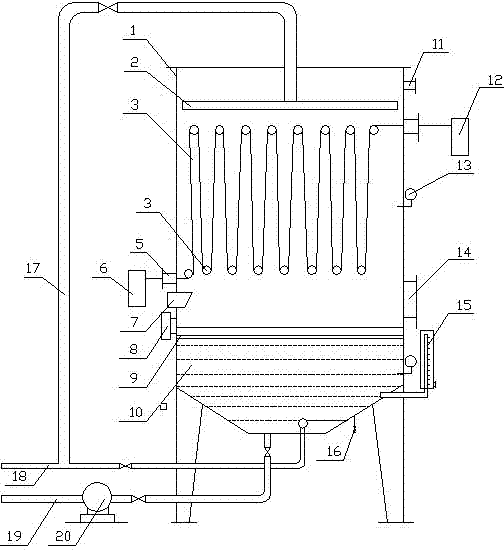

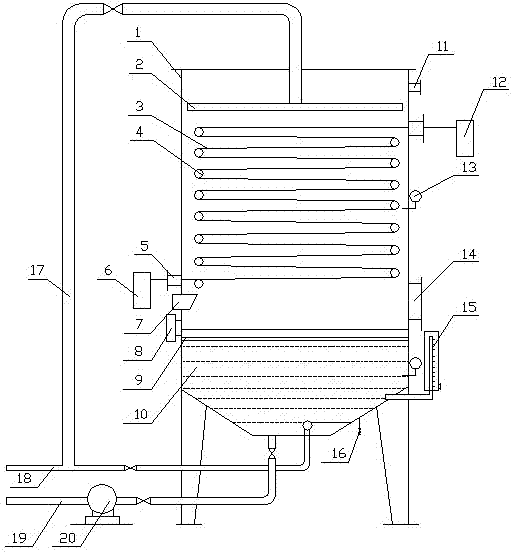

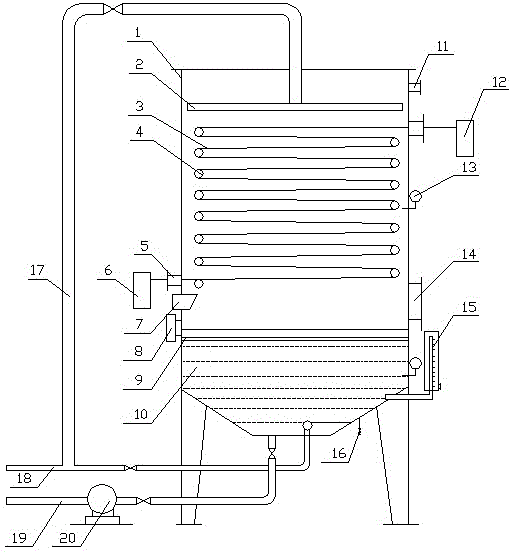

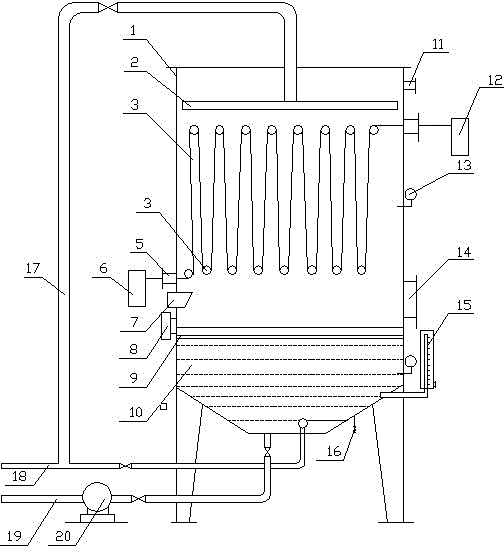

Method for producing kombucha beverage by liquid spraying fermentation tower filled with knitted fabric

InactiveCN103416545AIncreased unit utilizationMake up for expensesTea extractionMembrane configurationBacterial cellulose

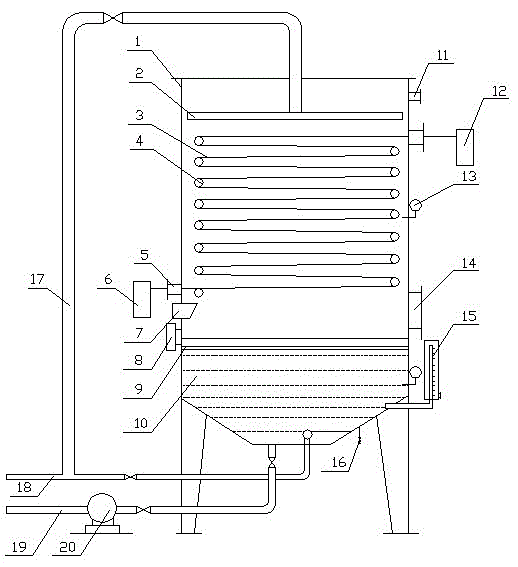

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with kintted fabric is disclosed. The liquid spraying fermentation tower filled with knitted fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with knitted fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a knitted fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The knitted fabric filling system comprises a roller disposed in the tower and knitted fabric wound on the roller, one end of the knitted fabric is connected with an unreeling apparatus and the other end of the knitted fabric is connected with a winding apparatus. The knitted fabric filling system is employed and the orientation movement of the knitted fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar by liquid spraying fermentation tower with non-woven fabric filling system

InactiveCN103421668ASolve liquidity problemsSolve productivityVinegar preparationChemistryWoven fabric

A method for producing vinegar by a liquid spraying fermentation tower with a non-woven fabric filling system is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed vinegar, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

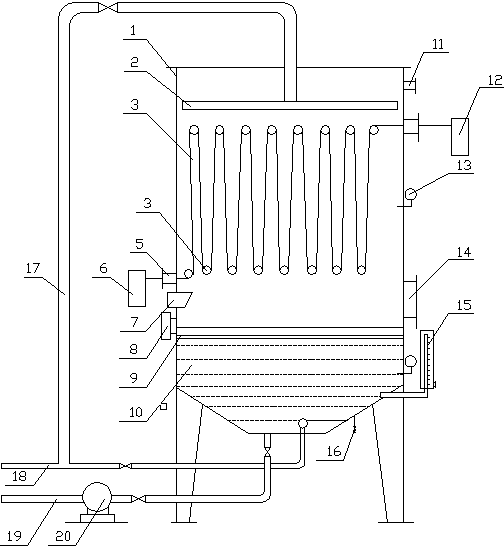

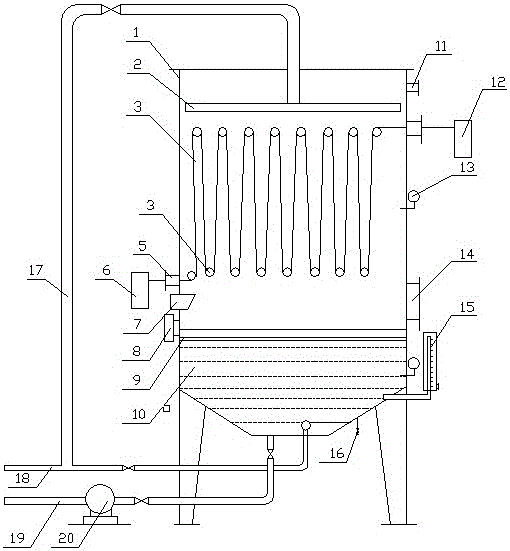

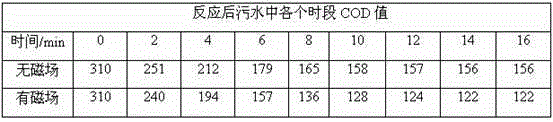

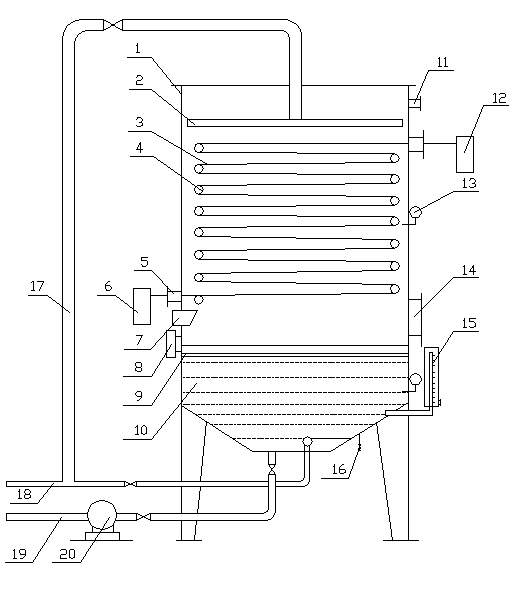

Liquid spraying fermentation tower provided with non-woven fabric filling system

InactiveCN103421673ASolve liquidity problemsSolve productivityBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provided with a non-woven fabric filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the non-woven fabric filling system. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the non-woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the non-woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

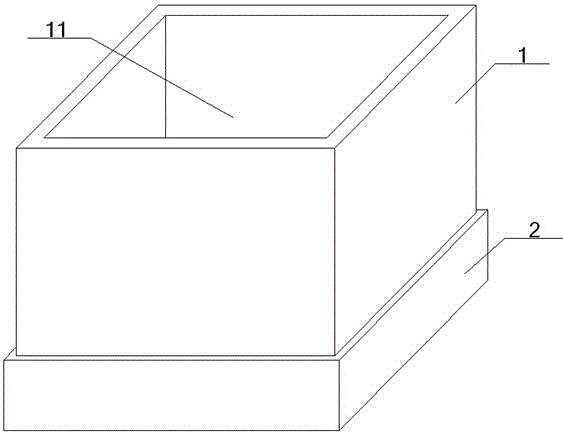

Connected graphite crucible applied to producing vanadium-nitrogen alloy products

The invention discloses a connected graphite crucible applied to producing vanadium-nitrogen alloy products. The connected graphite crucible comprises a crucible body and a push plate. The crucible body and the push plate are of an integrated structure, wherein the crucible body and the push plate are perpendicular to each other and are coaxially connected. A coaxial crucible cavity is formed in the crucible body, and a coaxial push plate cavity is formed in the push plate. The top of the crucible cavity is flush with the top of the crucible body, the bottom of the crucible cavity is communicated with the top of the push plate cavity, and the bottom of the push plate cavity is located between the bottom of the crucible body and the bottom of the push plate. Preferably, the crucible body, the crucible cavity, the push plate and the push plate cavity are all cuboids. Both the crucible body and the push plate are made of graphite. By the aid of the design, the uniformity of force-bearing points can be guaranteed when the push plate and the crucible body are stressed, the defects such as front-back arching caused by dislocation are overcome, and no gas layer separation exists in the connecting position of the crucible body and the push plate. Heat conduction efficiency is high, the service life is long, and batch manufacturing is easy.

Owner:湖北晶洋科技有限公司 +1

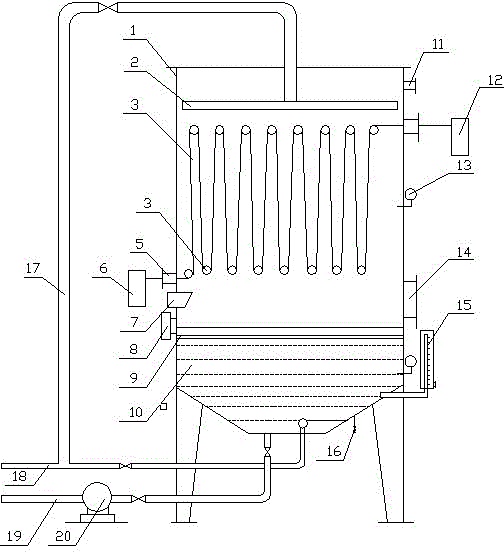

Method for producing kombucha beverage by liquid spraying fermentation tower filled with woven fabric

InactiveCN103416543AIncreased unit utilizationMake up for expensesTea extractionLiquid stateKombucha

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

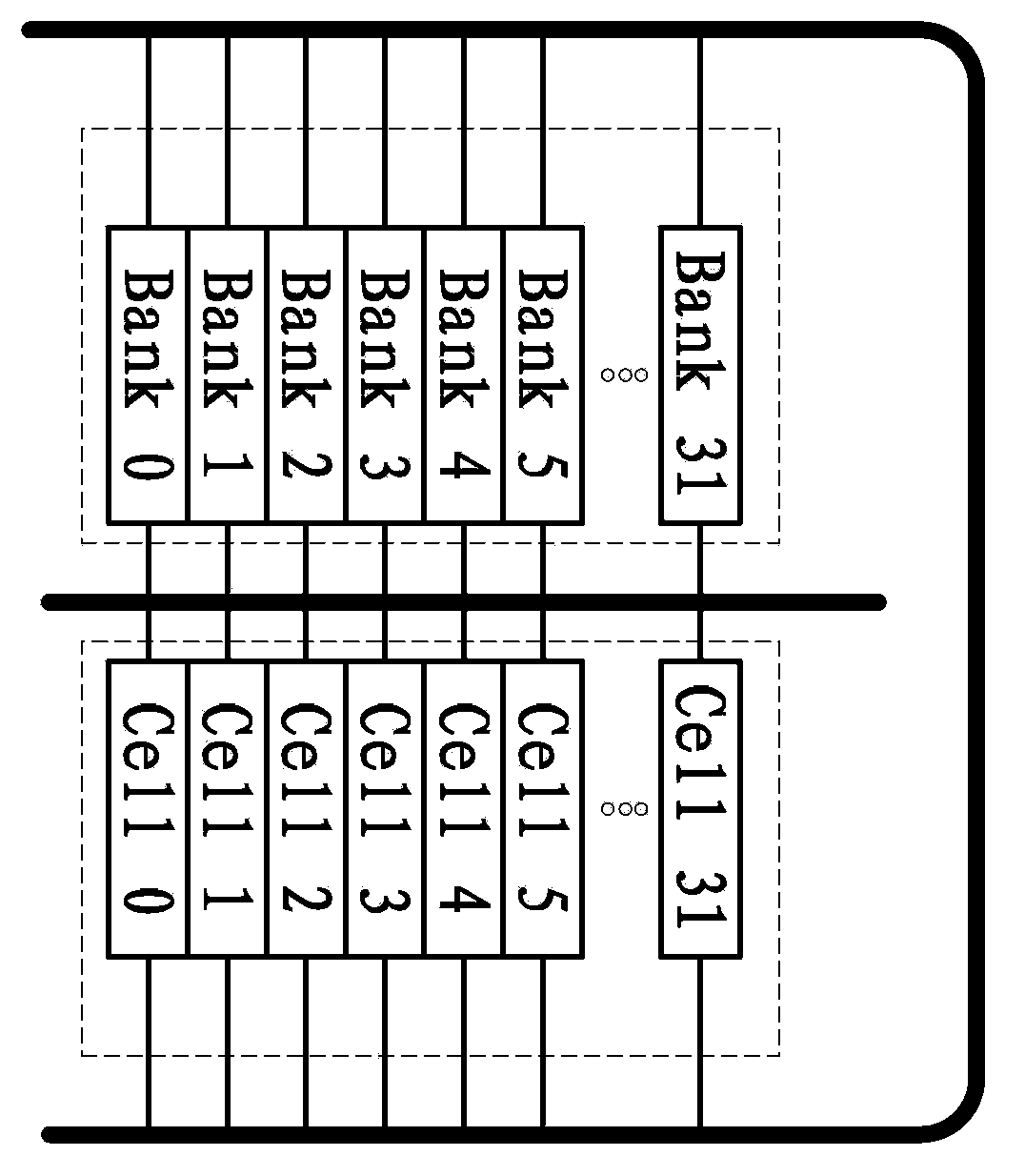

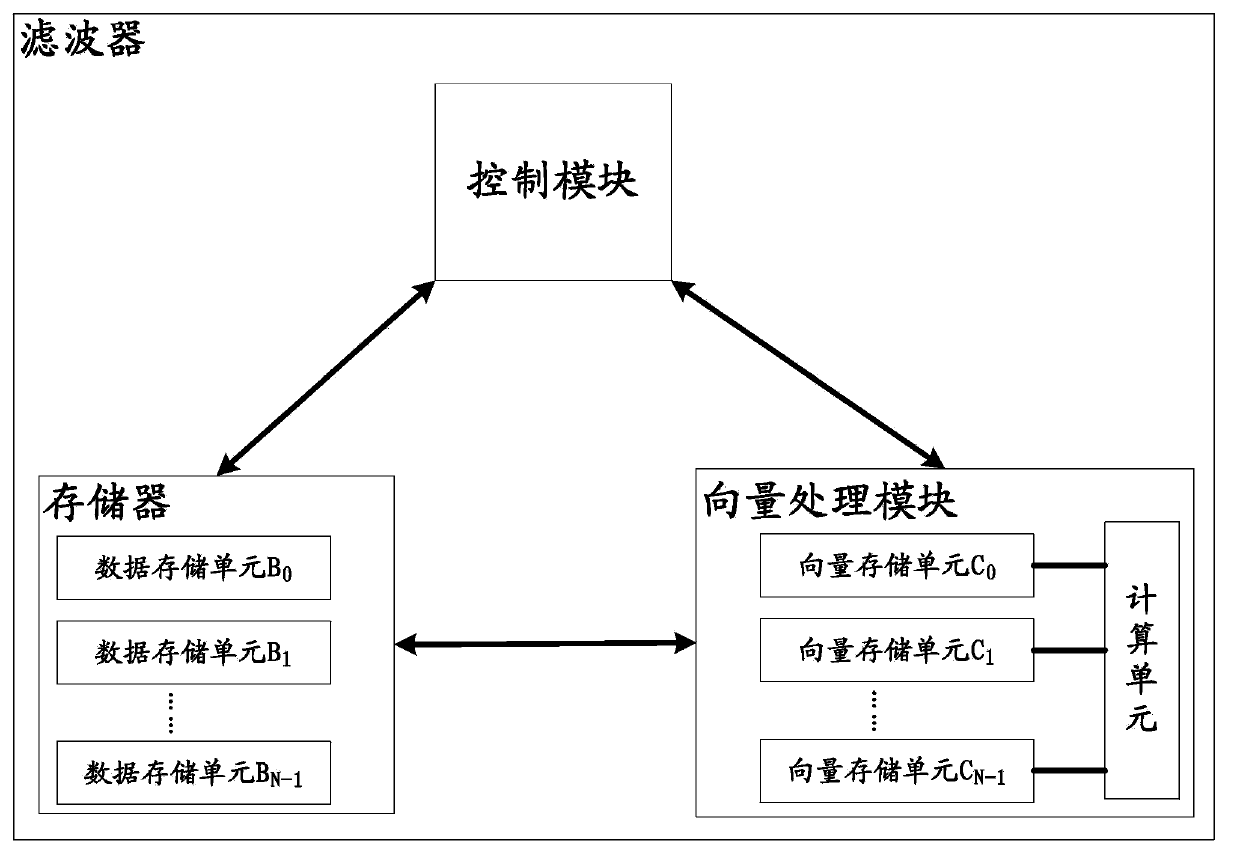

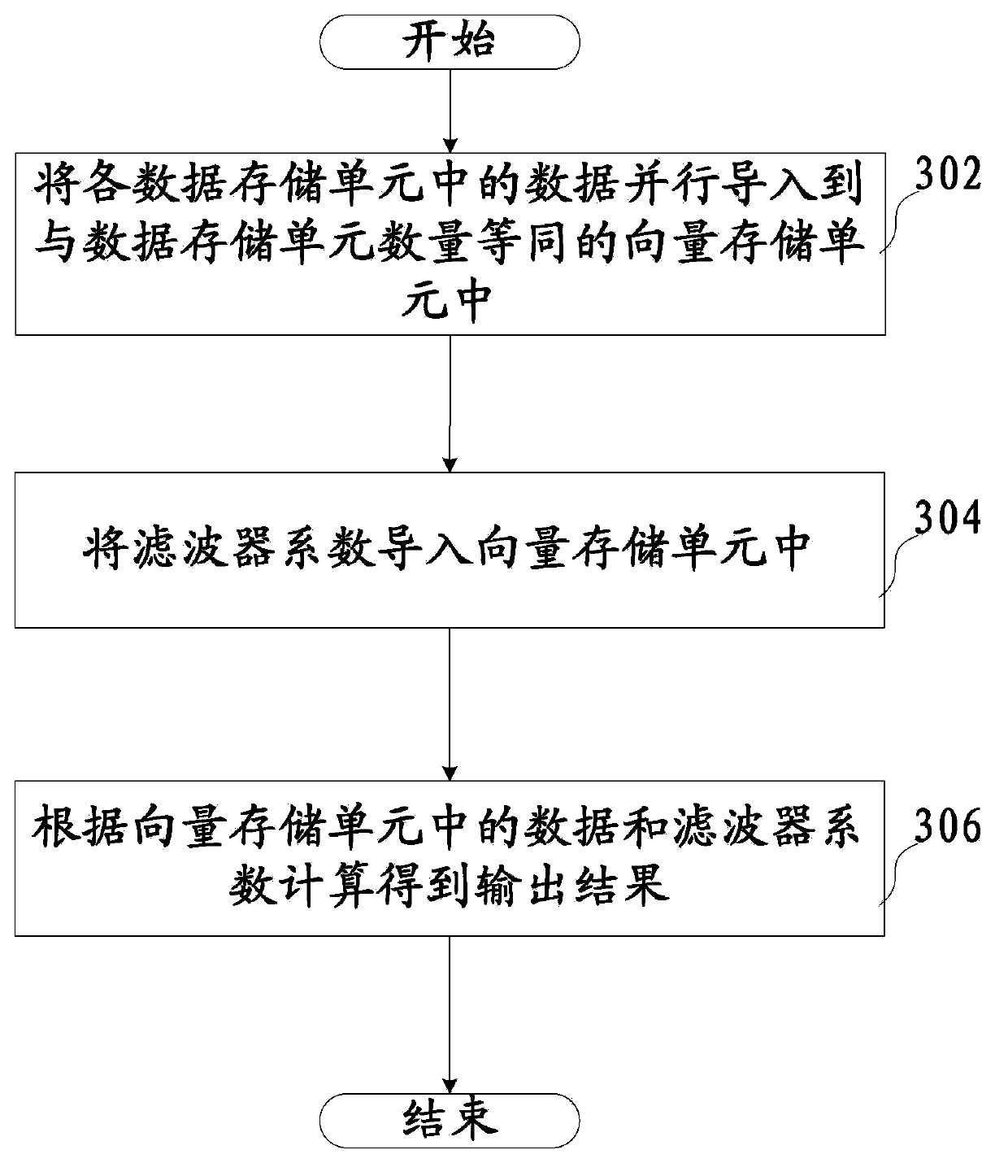

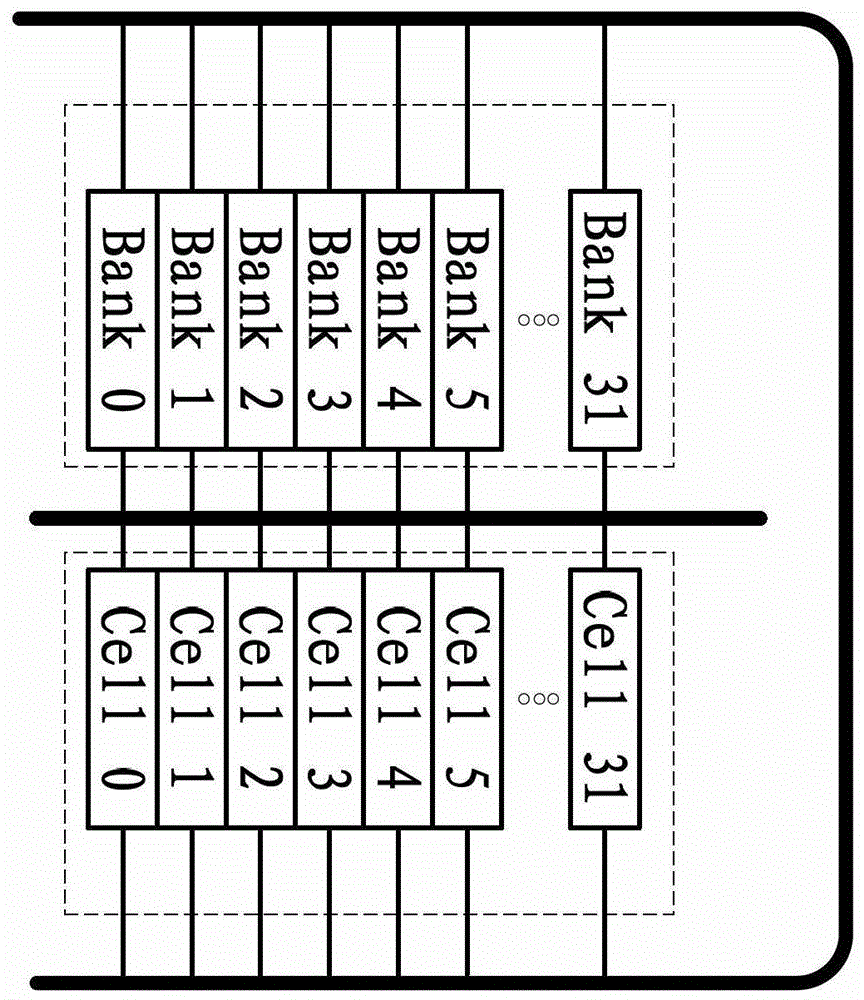

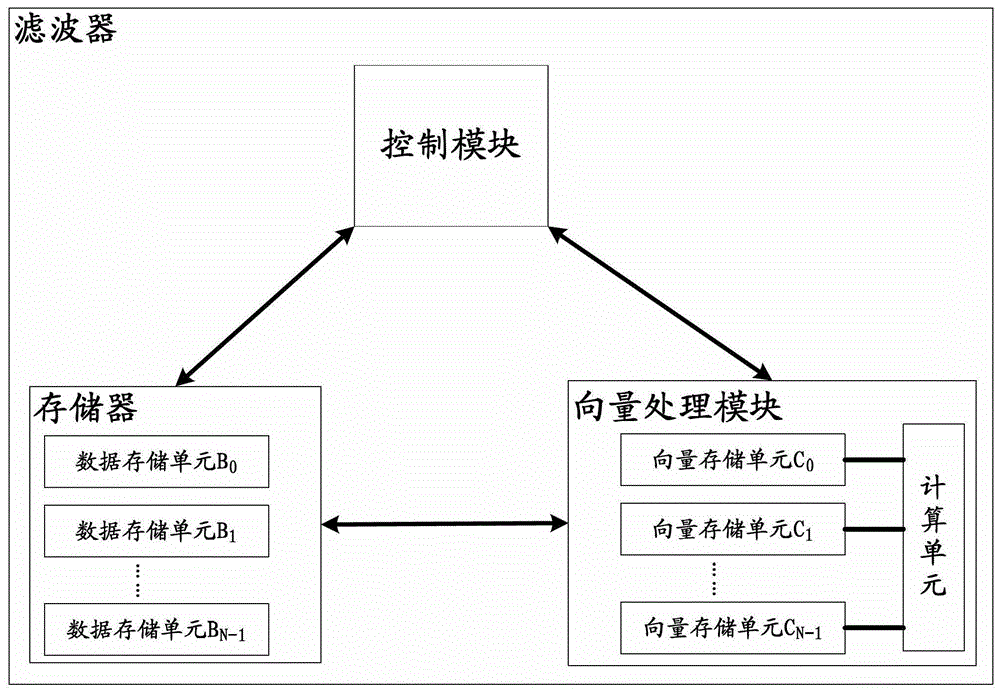

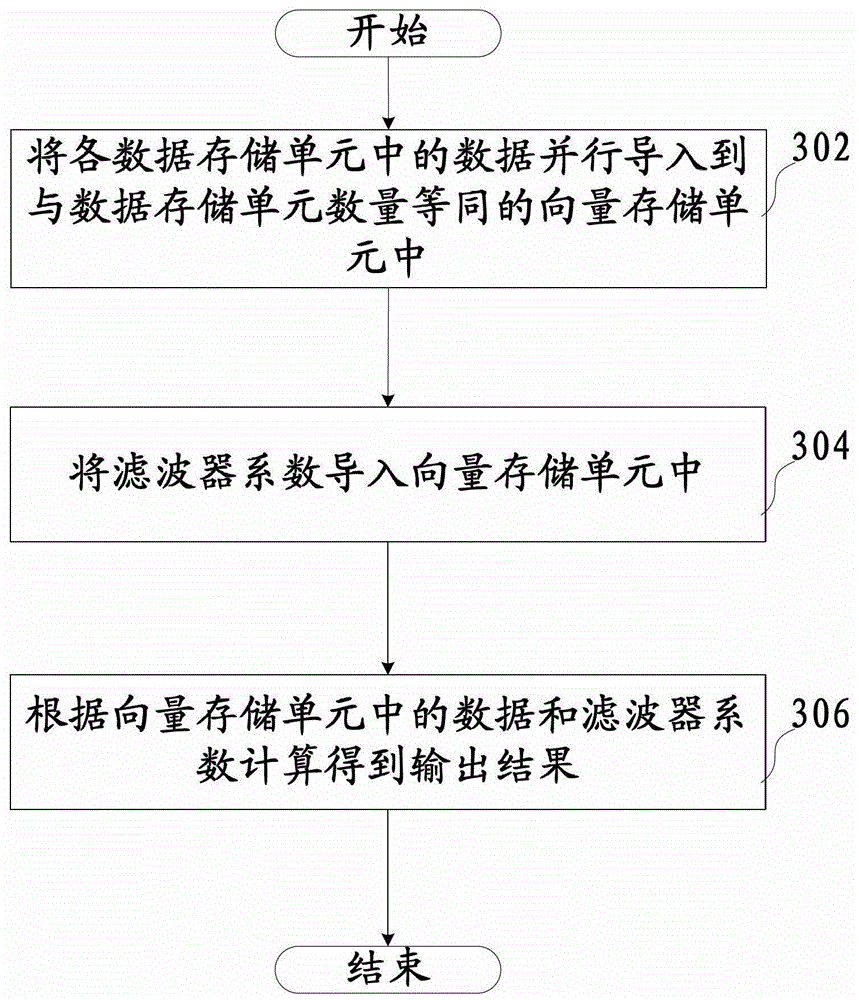

Filtering method and filter

ActiveCN103973264AIncrease profitTake advantage ofDigital technique networkProcessor registerComputer module

The present invention provides a filtering method and a filter. Data in data storage units in a register is input in parallel to vector storage units of a processing module, wherein the number of the vector storage units where data is input is equal to that of the data storage units; and the input data is calculated to obtain a filtering output result, so that each vector storage unit in the processing module is fully utilized, and the utilization of the processing module is improved. In the present invention, data in each data storage unit is arranged in columns, and the columns of data pass through K channels sequentially and are input to the vector storage units, wherein the value of K is the number of filter coefficients; and during data input, the data is offset and stored in ascending or descending order according to the sequence of the channels. Therefore, the unit utilization of the processing module is improved; and the filter can be reconstructed, is adjustable in the degree of parallelism, and uses a few on-chip resources.

Owner:SANECHIPS TECH CO LTD

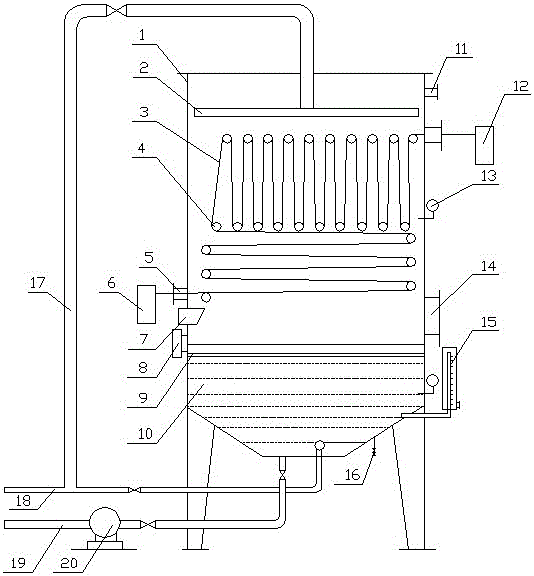

Solvent replacement condensation tower and method for producing anhydrous formaldehyde

ActiveCN109701293AImprove one-way yieldPromote absorptionChemical/physical/physico-chemical processesCarbonyl compound separation/purificationOrganic synthesisEngineering

The invention discloses a solvent replacement condensation tower and a method for producing anhydrous formaldehyde, and mainly relates to the technical field of organic synthesis. The solvent replacement condensation tower is composed of a plurality of annular flow-guide distribution grooves and filler sections which are alternately arranged; each annular flow guide distribution groove comprises an outer groove, an inner groove, a central gas rising tube, and liquid descending tubes arranged in the inner groove. During use, a material fed from outside and a liquid flowing down from the upper part of the inner tower first flow downwards along the outer groove, passe through an opening at the bottom of a baffle to enter the inner groove, then flow upwards, and finally flow to the surface offiller under the annular flow-guide distribution grooves from the plurality of liquid descending tubes for carrying out mass exchange with a gas phase. Liquid flows through a filler section, enters the outer groove of the next-stage annular flow-guide groove, and then sequentially flows through the inner groove and the liquid descending pipes to enter the next-stage filler section until flowing tothe bottom of the tower. Gas rises along filler gaps in the tower to enter the gas rising tube of the annular flow-guide distribution grooves, bypasses an umbrella-shaped baffle plate to enter the previous-stage filler layer, and flows out from the tower top according to the process step by step.

Owner:潍坊惠丰化工有限公司 +1

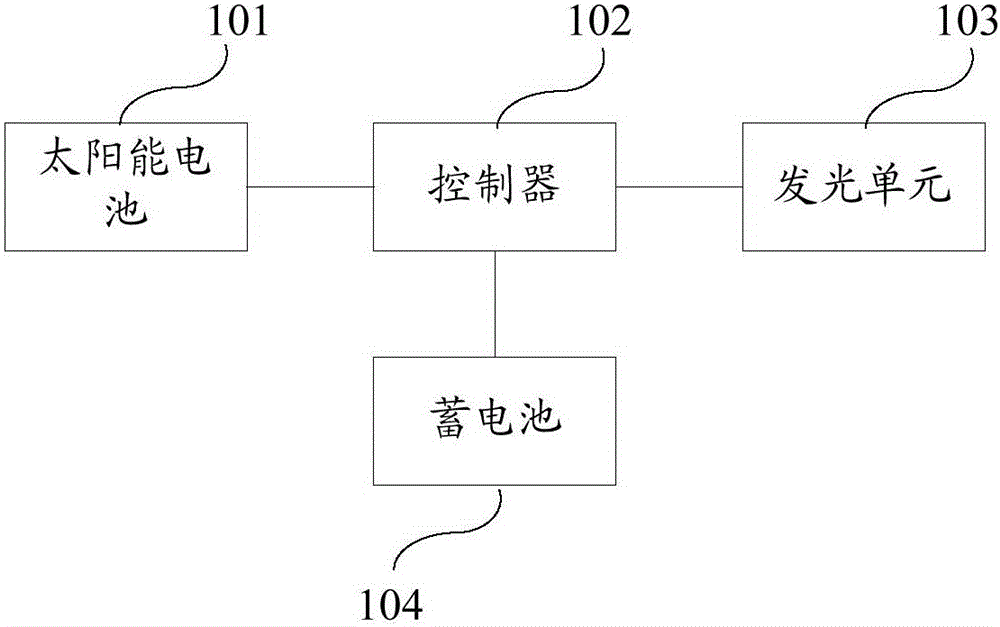

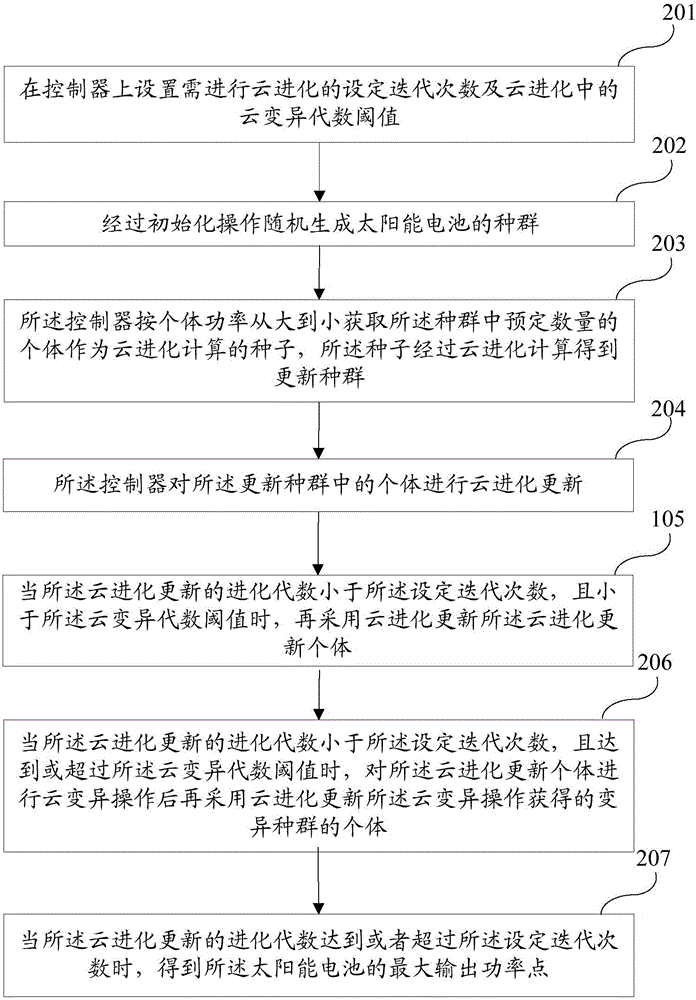

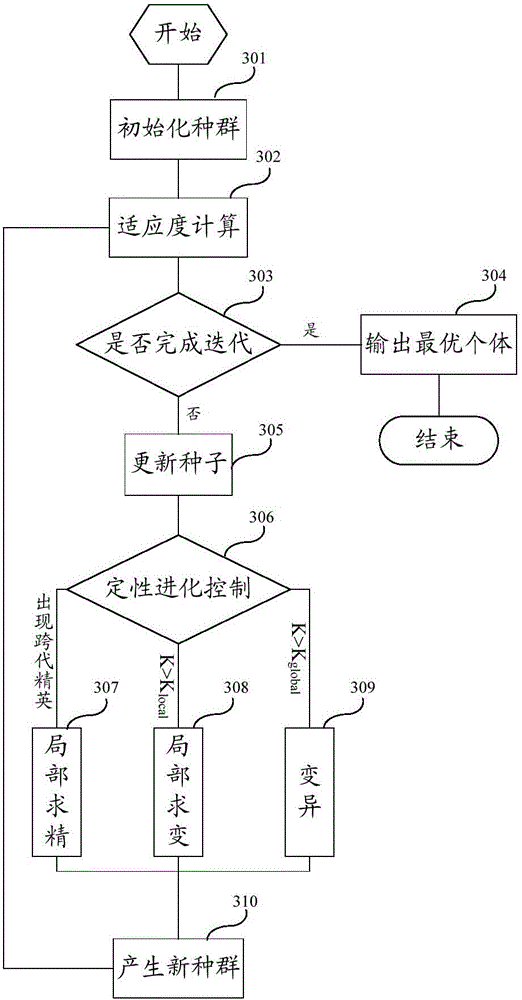

Method and system for tracking maximum power point of solar street lamp based on cloud evolution

InactiveCN106202875AIncreased unit utilizationTracking is fast and highly accurateArtificial lifeSpecial data processing applicationsEvolution algebraSolar street light

The invention discloses a method for tracking a maximum power point of a solar street lamp based on cloud evolution. The method comprises the following steps: setting a set iteration number needing to carry out the cloud evolution and a cloud variation algebraic threshold in the cloud evolution on a controller; randomly generating a population of solar cells; obtaining a predetermined number of individuals in the population according to the power of the individuals from large to small, and carrying out cloud evolution calculation to obtain an updated population; carrying out cloud evolution update on the individuals in the updated population; when the evolution algebra of the cloud evolution update is less than the cloud variation algebraic threshold, updating the cloud evolution update individuals again by adopting the cloud evolution; when the evolution algebra of the cloud evolution update is less than the set iteration number and reaches or exceeds the cloud variation algebraic threshold, carrying out a cloud variation operation on the cloud evolution update individuals, and adopting the cloud evolution to update the obtained individuals of a variant population; and when the evolution algebra of the cloud evolution update reaches or exceeds the set iteration number, obtaining the maximum output power point of the solar cells. By adopting the method disclosed by the invention, the maximum power point of the solar street lamp can be accurately tracked.

Owner:TAIHUA WISDOM IND GRP CO LTD

Immobilization method of free enzyme

PendingCN113403298AEasy reunionIncreased unit utilizationOn/in inorganic carrierMacromoleculeSmall molecule

The invention discloses an immobilization method of a free enzyme. According to the method, a microemulsion suspension technology is adopted for the first time, the free enzyme is adsorbed on a covalently modified inorganic carrier in situ, and the defects that the free enzyme is not easy to separate in the catalytic process, the traditional immobilized enzyme is poor in structural stability, the unit utilization efficiency of the enzyme is low and the like are effectively overcome. The loading capacity of the obtained immobilized enzyme reaches 200mg / g, the size of the enzyme is nanoscale, the average diameter is 3.5-6.5nm, the dispersion is uniform, and the agglomeration phenomenon is avoided. In addition, the process does not need a harsh preparation environment, the enzyme activity retention rate can reach 100%, and the mechanical loss rate is less than 0.05%. The method is suitable for synthesizing enzymes for catalyzing macromolecules and micromolecules, and has universality.

Owner:WANHUA CHEM GRP CO LTD

Liquid poured fermentation tower with non-woven packing system

InactiveCN103421673BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsSpray towerPulp and paper industry

The invention discloses a liquid spraying fermentation tower provided with a non-woven fabric filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the non-woven fabric filling system. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the non-woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the non-woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A filtering method and filter

ActiveCN103973264BIncrease profitTake advantage ofDigital technique networkProcessor registerDegree of parallelism

The present invention provides a filtering method and a filter. Data in data storage units in a register is input in parallel to vector storage units of a processing module, wherein the number of the vector storage units where data is input is equal to that of the data storage units; and the input data is calculated to obtain a filtering output result, so that each vector storage unit in the processing module is fully utilized, and the utilization of the processing module is improved. In the present invention, data in each data storage unit is arranged in columns, and the columns of data pass through K channels sequentially and are input to the vector storage units, wherein the value of K is the number of filter coefficients; and during data input, the data is offset and stored in ascending or descending order according to the sequence of the channels. Therefore, the unit utilization of the processing module is improved; and the filter can be reconstructed, is adjustable in the degree of parallelism, and uses a few on-chip resources.

Owner:SANECHIPS TECH CO LTD

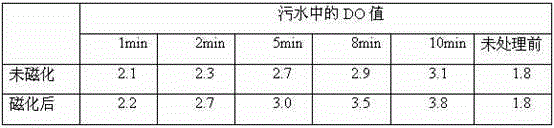

Method and device for electromagnetically enhanced gas dissolution in liquid

ActiveCN103406082BImprove solubilityReduce energy consumptionEnergy based chemical/physical/physico-chemical processesParamagnetismDissolution

Owner:KUNMING UNIV OF SCI & TECH

Method for producing bacterial cellulose with liquid pouring fermentation tower of woven cloth type filler

InactiveCN103421858BIncreased unit utilizationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

A method for producing bacterial cellulose by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed vinegar, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

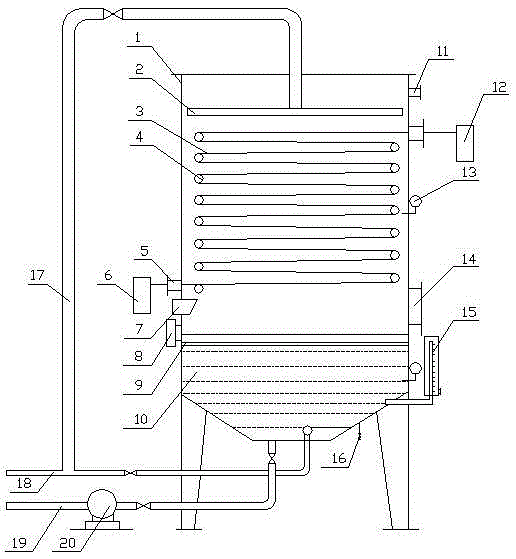

Liquid spraying fermentation tower provided with knitted fabric filling system

InactiveCN103421674AIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provide with a knitted fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the knitted fabric type filling system. The knitted fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the knitted fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the knitted fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of solvent displacement condensation tower and the method for producing anhydrous formaldehyde

ActiveCN109701293BImprove one-way yieldPromote absorptionChemical/physical/physico-chemical processesCarbonyl compound separation/purificationOrganic synthesisTower

The invention discloses a solvent displacement condensation tower and a method for producing anhydrous formaldehyde, and mainly relates to the technical field of organic synthesis. The solvent displacement condensation tower is composed of several annular diversion distribution grooves and packing sections alternately, and the annular diversion distribution groove includes outer Tank, inner tank and central riser and downcomer arranged in the inner tank. When in use, the external feed and the liquid flowing down from the top of the tower first flow down the outer tank, pass through the opening at the bottom of the baffle into the inner tank and then flow upward, and finally flow from the multiple downcomers in the inner tank to the ring guide. The packing surface below the flow distribution groove performs mass exchange with the gas phase. After the liquid flows through the packing section, it enters the outer tank of the next-level annular diversion tank, and then flows through the inner tank and downcomer in turn to enter the next packing section until it reaches the bottom of the tower. The gas rises along the packing gap in the tower and enters the gas riser of the annular diversion distribution groove, bypasses the umbrella-shaped baffle and enters the upper packing layer, and then gradually flows out from the top of the tower.

Owner:潍坊惠丰化工有限公司 +1

Liquid poured fermentation tower with woven cloth packing system

InactiveCN103421672BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

Owner:ZHONGYUAN ENGINEERING COLLEGE

Liquid poured fermentation tower with knitted cloth packing system

InactiveCN103421674BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyFermentation broth

The invention discloses a liquid spraying fermentation tower provide with a knitted fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the knitted fabric type filling system. The knitted fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the knitted fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the knitted fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A Viscoelasticity-Friction Composite Damper with Variable Damping and Variable Stiffness

ActiveCN111350291BImproved dissipation capacityReduce vibration responseProtective buildings/sheltersShock proofingViscoelastic dampingClassical mechanics

The invention discloses a viscoelastic-friction compound damper with variable damping and variable stiffness, which comprises two symmetrical cylindrical viscoelastic damper units and two cylindrical friction damper units, the friction damper units are sleeved on a circular Outside of the cartridge viscoelastic damper unit. The cylindrical viscoelastic damper unit is sequentially composed of an annular inner steel cylinder, an annular viscoelastic material layer, and an annular middle steel cylinder from the inside to the outside. The middle part of the annular inner steel cylinder is provided with an elastic element, and both ends of the annular inner steel cylinder are provided with closed steel plates. , the inner sides of both ends of the annular middle steel cylinder are provided with cylindrical viscoelastic materials, and the two ends of the annular middle steel cylinder are provided with connecting anchor steel plates; the friction damper unit is sequentially composed of annular middle steel cylinder, annular friction plate, Annular friction plate, annular outer steel cylinder. The annular friction plate is divided into a first annular friction plate and a second annular friction plate. The annular outer steel cylinder is composed of an upper half annular outer steel cylinder and a lower half annular outer steel cylinder connected by bolts.

Owner:HUBEI UNIV OF ARTS & SCI

Method for producing vinegar with liquid pouring fermentation tower with knitted cloth packing system

InactiveCN103421669BIncreased unit utilizationMake up for expensesVinegar preparationPolymer scienceMechanical engineering

A method for producing vinegar using a liquid pouring fermentation tower with a knitted cloth packing system, the fermentation step adopts a liquid pouring fermentation tower with a knitted cloth packing system, and the liquid pouring fermentation tower with a knitted cloth packing system includes Tower body, the top of the tower body is provided with a shower tray, the upper part of the tower body is a knitted cloth packing system, the lower part is a fermentation liquid, and a false bottom is provided between the packing system and the fermentation liquid; the knitted cloth packing system includes a The roller in the tower and the knitted fabric wound on the roller, one end of the knitted fabric is connected to the unwinding device, and the other end is connected to the winding device. The invention uses a knitted cloth-type packing system, utilizes the directional movement of the knitted cloth, and takes away the "sea moon"-bacterial cellulose produced by the fermentation of liquid poured vinegar and its aggregated bacterial cellulose film system. The method completely solves the problem that the film blocks the gaps between the filling materials, and the air and fermentation liquid cannot flow normally, so that the fermentation production of vinegar is terminated.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Liquid spraying fermentation tower provided with woven fabric filling system

InactiveCN103421672AIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provided with a woven fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the woven fabric type filling system. The woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with non-woven fabric

InactiveCN103416544BIncreased unit utilizationMake up for expensesTea extractionLiquid statePulp and paper industry

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with non-woven fabric is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing bacterial cellulose with liquid pouring fermentation tower with non-woven fabric filler

InactiveCN103421859BIncreased unit utilizationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryKombucha

A method for producing bacterial cellulose by a liquid spraying fermentation tower filled with non-woven fabric is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of bacterial cellulose is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with knitted fabric

InactiveCN103416545BIncreased unit utilizationMake up for expensesTea extractionPulp and paper industryKombucha

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar with liquid pouring fermentation tower with non-woven fabric packing system

InactiveCN103421668BIncreased unit utilizationMake up for expensesVinegar preparationBiotechnologyEngineering

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar with liquid pouring fermentation tower with woven cloth packing system

InactiveCN103421667BIncreased unit utilizationMake up for expensesVinegar preparationPolymer scienceMechanical engineering

A method of liquid pouring and fermentation tower of a weave -type filler system to produce vinegar. Its fermentation steps adopt a liquid pouring fermentation tower with woven fabric fille.The fermentation tower includes the tower body. The top of the tower is equipped with a golf dish. The upper part of the tower is a woven -type filler system.The filler system includes rolling wheels set in the tower and the woven fabric wrapped around the roller. One end of the machine fabric is connected to the roll device, and the other end is connected to the roll -up device.The present invention uses a weave-type filler system, and uses the directional movement of the weaving of the machine to take away the "sea moon"-bacterial cellulose and the bacterial cellulose film system produced by liquid pouring vinegar fermentation production.Thoroughly solve the gap between the film blocking the filling material, the air and fermentation solution cannot flow normally to terminate the problem of fermentation to produce vinegar.

Owner:ZHONGYUAN ENGINEERING COLLEGE

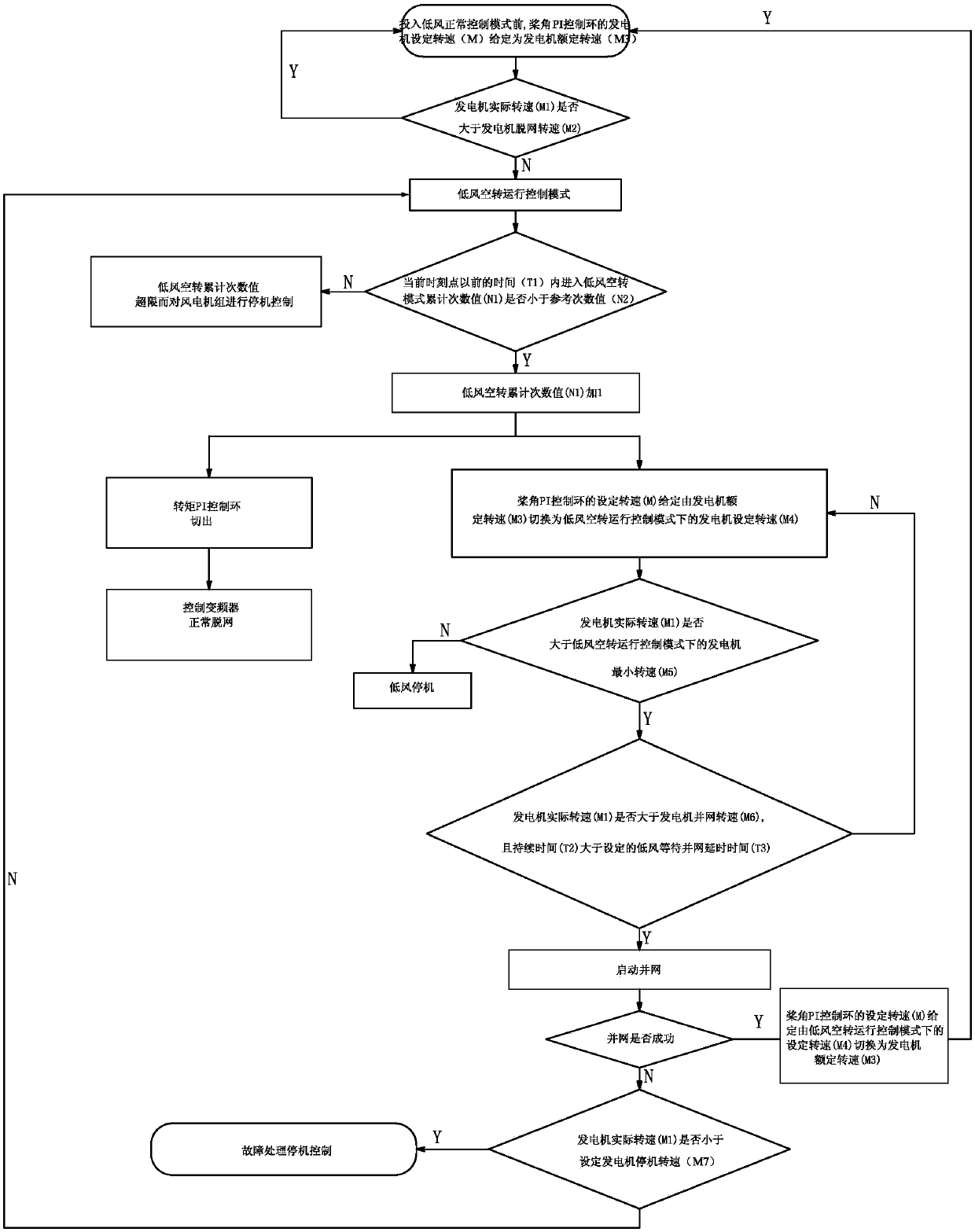

Control method and system of wind turbine generator and wind turbine generator

ActiveCN109519326AIncreased unit utilizationAvoid shockWind motor controlSingle network parallel feeding arrangementsElectricityControl system

The invention provides a control method of a wind turbine generator. The control method at least comprises a low-wind normal running control mode, a low-wind idle running control mode and a low-wind grid-connected control mode. The control method, a control system based on the control method and the wind turbine generator have the advantages that the unit use rate of the wind turbine generator inthe low-wind-speed segment can be improved, the mechanical impact and damage to the wind turbine generator during repeated starting and stopping can be avoided, meanwhile, the power grid impact due towind turbine generator repeated grid off-line and connection can be avoided, and power consumption of negative power running of the wind turbine generator can be reduced.

Owner:CHENGDU FORWARD TECH +1

Method for producing kombucha beverage by liquid spraying fermentation tower filled with woven fabric

InactiveCN103416543BIncreased unit utilizationMake up for expensesTea extractionLiquid stateEngineering

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing bacterial cellulose with liquid pouring fermentation tower with non-woven fabric filler

InactiveCN103421860BIncreased unit utilizationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryKombucha

A method for producing bacterial cellulose by a liquid spraying fermentation tower filled with non-woven fabric is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of bacterial cellulose is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

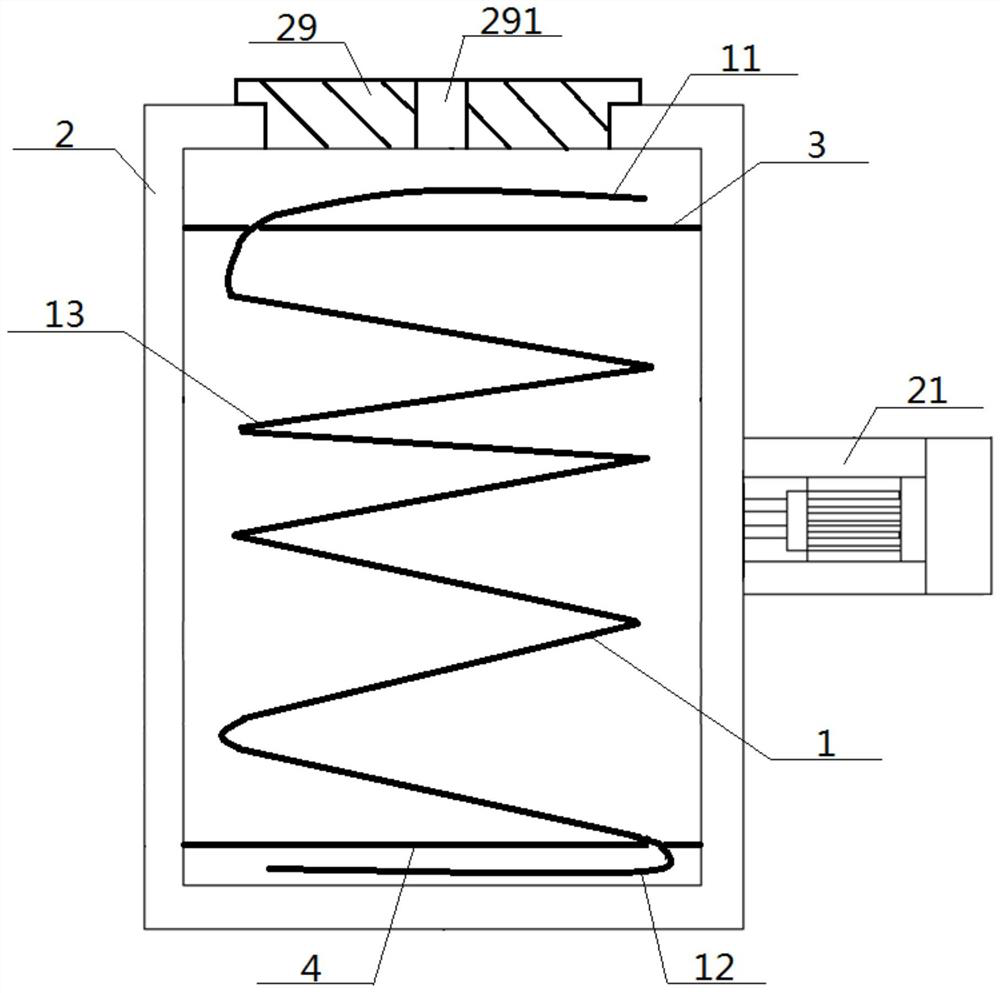

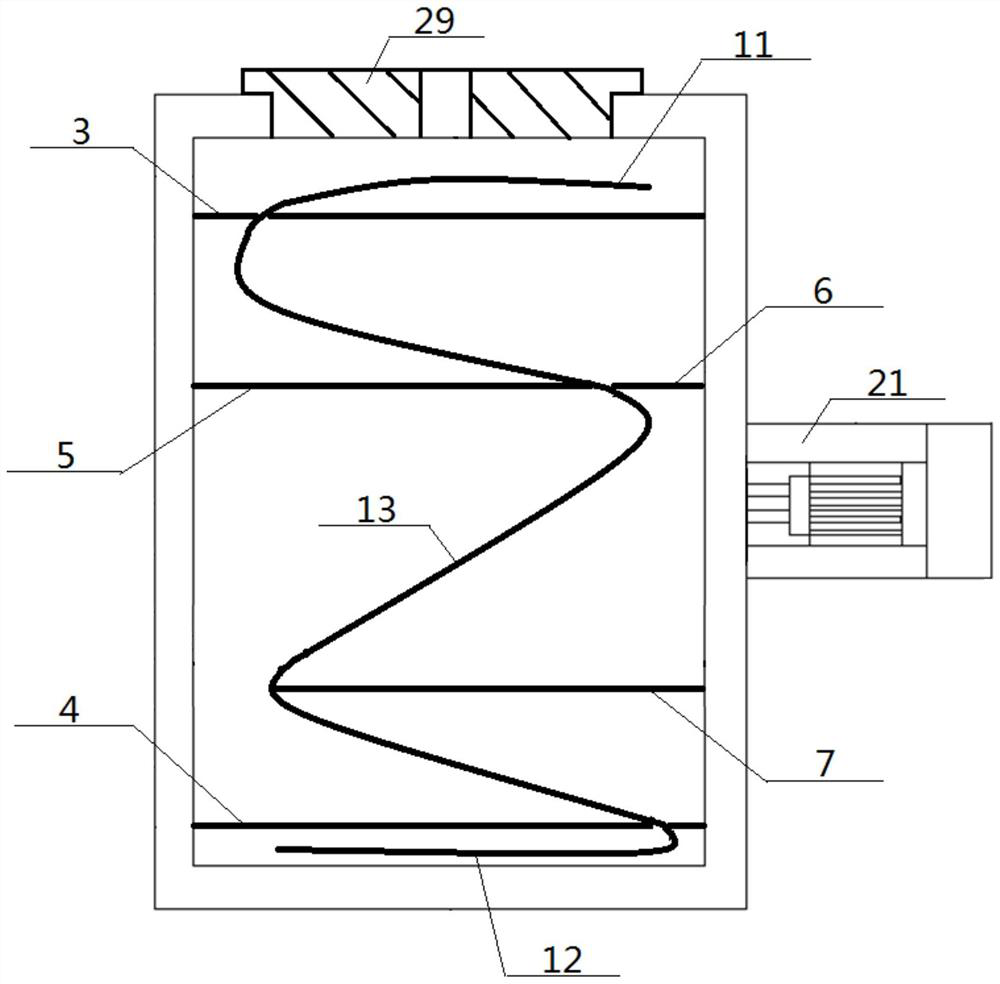

Turnover type cooling box and using method thereof

PendingCN114075726AEasy to handleComprehensive contactTextile treatment containersLiquid/gas/vapor textile treatmentEngineeringMechanical engineering

A turnover type cooling box comprises an outer box body and a cold batch liquid arranged in the outer box body, a top clamping frame and a bottom clamping frame are arranged in the outer box body, the top clamping frame is arranged close to the top of the outer box body, the bottom clamping frame is arranged close to the bottom of the outer box body, the head end of a textile fabric is clamped in the top clamping frame, the tail end of the textile fabric is clamped in the bottom clamping frame, and the top clamping frame and the bottom clamping frame are arranged in the outer box body. the part, between the head end and the tail end, of the textile fabric is a concentration part, the concentration part is arranged between the top clamping frame and the bottom clamping frame, the textile fabric is in contact with the cold-batch liquid, and the outer side part of the outer box body is fixedly connected with the output end of the driving machine; and preferably, the concentration part is of a Z-shaped structure which is sequentially stacked in a reciprocating mode in the vertical direction. According to the design, the permeation effect is relatively good, the cold batch treatment effect is relatively good, the treatment time is relatively short, and the dosage of chemicals is relatively small.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com