Liquid spraying fermentation tower provided with woven fabric filling system

A liquid pouring fermentation and weaving technology, which is applied in the fields of textile, food and beverage, microorganism, and fermentation, can solve the problems of long-term cycle production, increase of production cost, and environmental pollution, so as to improve the unit utilization rate and save The effect of high cost and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

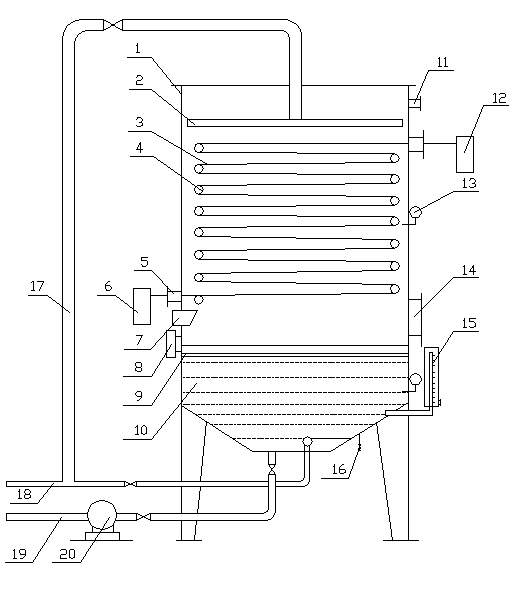

[0020] The structural representation of the liquid pouring fermentation tower of the present embodiment is as follows: figure 1 Shown, comprise tower body 1, the top in tower body 1 is provided with return shower tray 2, and the upper part in tower body is packing system, and the bottom is fermented liquid 10, is provided with false bottom 9 between packing system and fermented liquid; Below the surface of the fermentation broth. An exhaust hole 11 is arranged on the upper part of the tower body, and an air inlet hole 7 is arranged on the middle part. There is a sight glass at the liquid level of the fermentation broth to observe the reaction in the tower. A manhole 14 for operators to enter and exit is provided at the lower part of the tower body, a thermometer 13 is respectively provided at the packing system and the fermentation liquid, a flow meter 15 is provided at the lower part of the tower body, and a sampling port 16 is provided at the bottom of the tower body. A fe...

Embodiment 2

[0026] The difference from Example 1 is that the diameter of the rollers is 0.004 meters, and the distance between the two rollers is 1 meter.

[0027] The woven fabric is a polyester needle-punched woven fabric with a thickness of 3 mm, and the filling volume is 1 / 3 of the volume of the tower.

[0028] All the other are with the technical scheme of embodiment 1.

Embodiment 3

[0030] The diameter of the roller that is different from Example 1 is 0.008 meters, and the distance between the two rollers is 5 meters.

[0031] The woven fabric is a polyester needle-punched woven fabric with a thickness of 3 mm, and the filling volume is 9 / 10 of the volume of the tower.

[0032] All the other are with the technical scheme of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com