Patents

Literature

31results about How to "Make up for expenses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

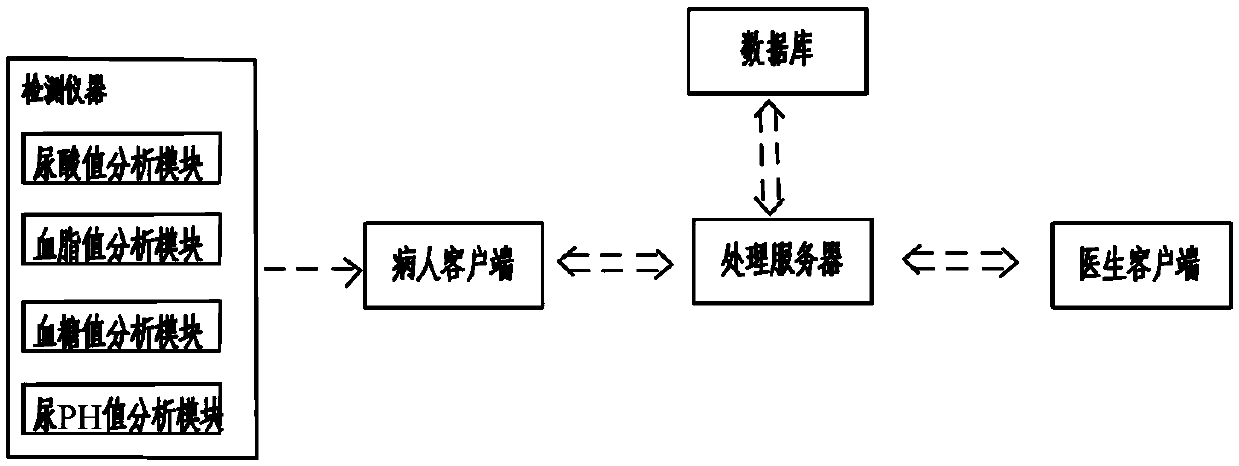

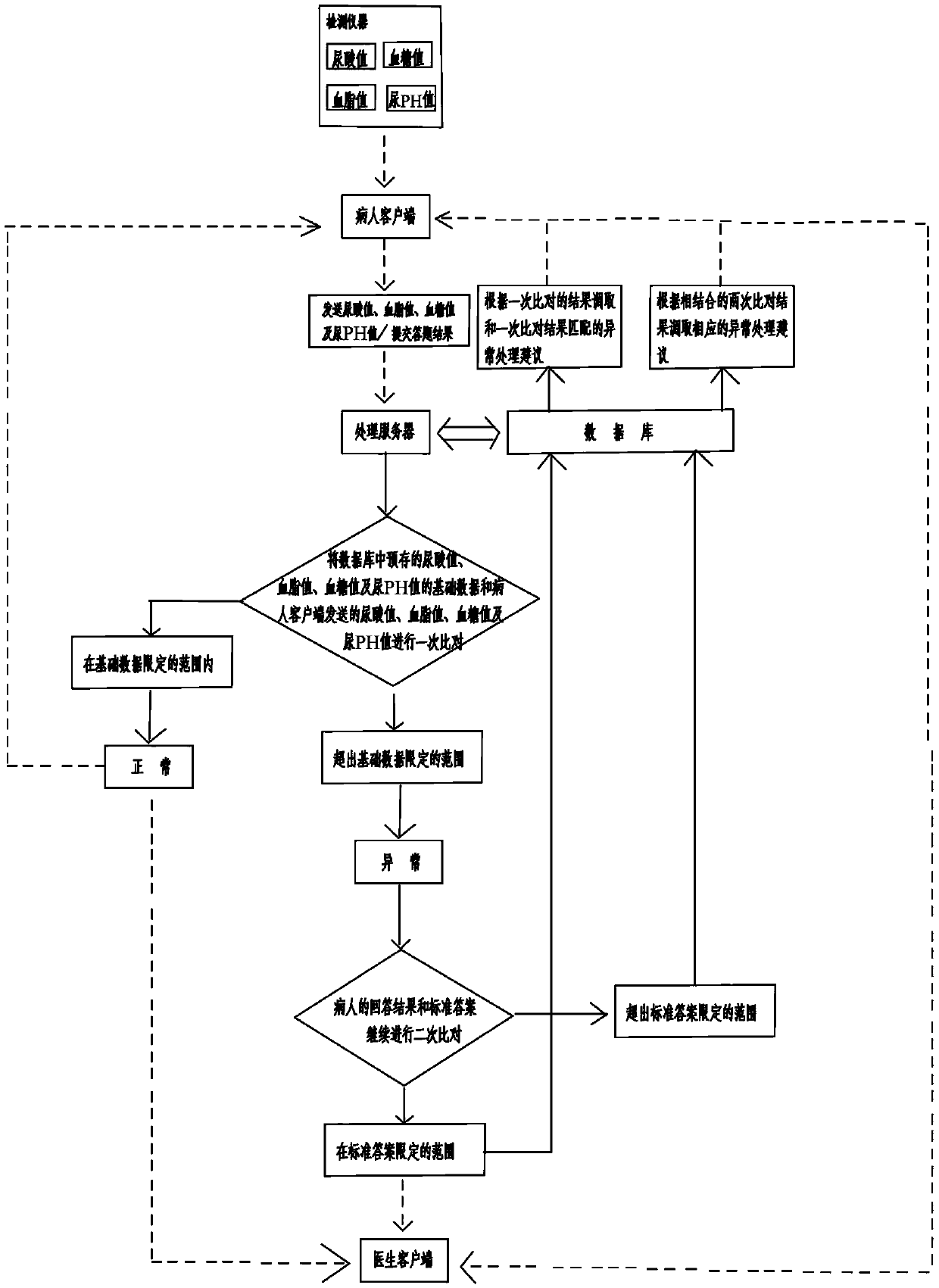

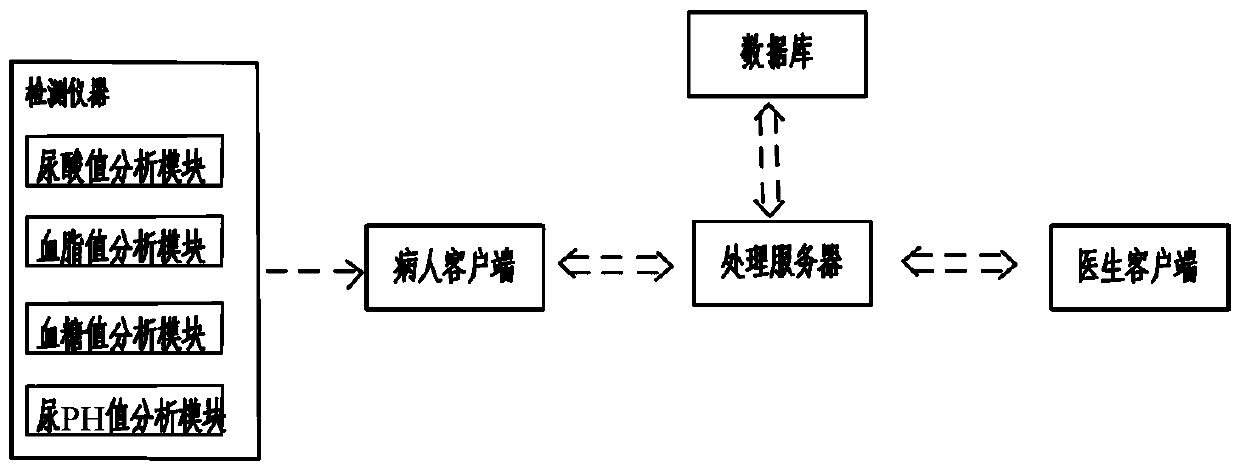

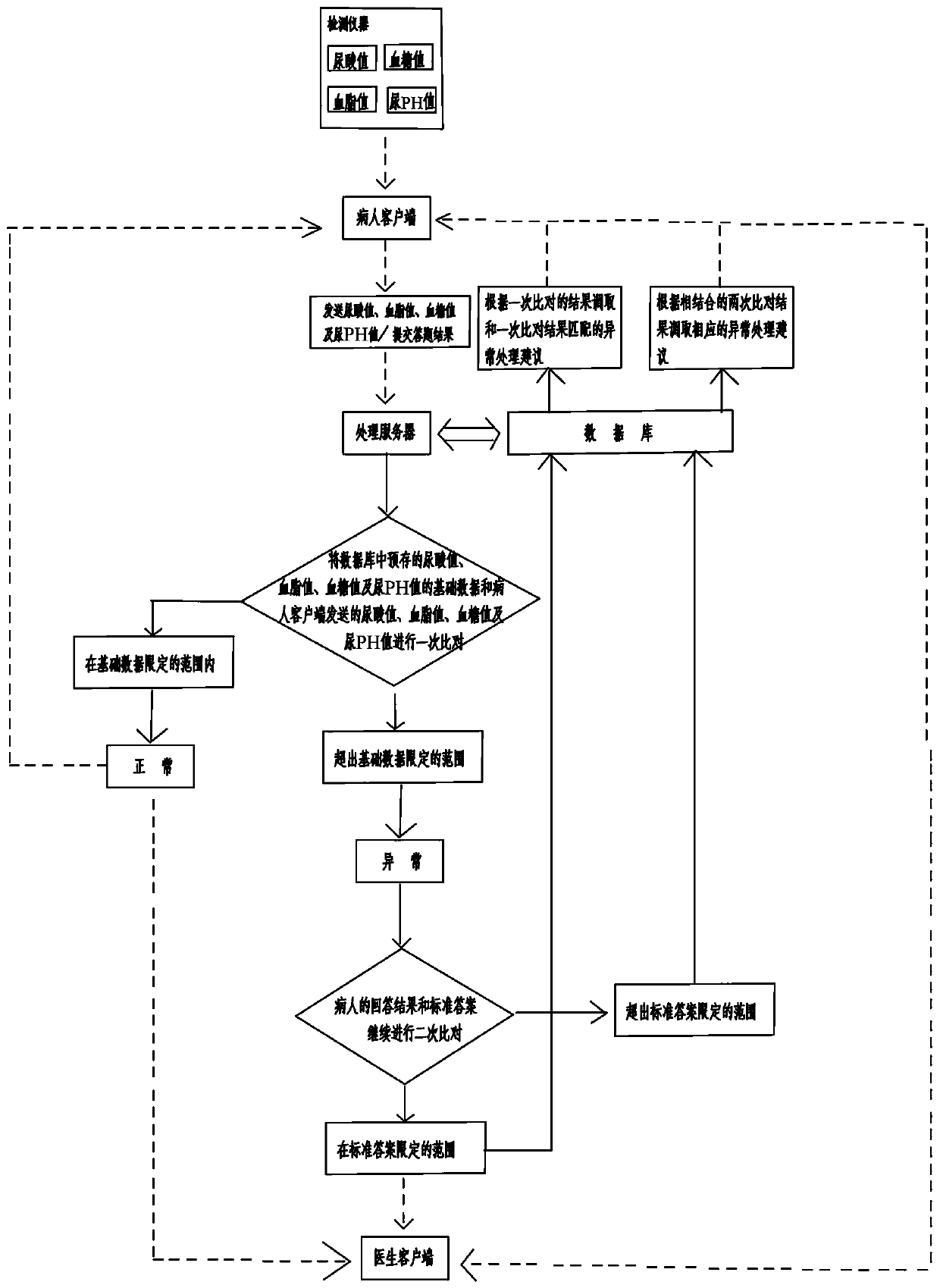

Domestic hyperuricemia and gout patient management system

ActiveCN105373702AMake up for expensesShorten the timeSpecial data processing applicationsPaymentMedical institution

The invention discloses a domestic hyperuricemia and gout patient management system and a management method therefor, relates to a health management system, and aims to solve the shortcomings existing in the existing conventional health management system. The invention provides the domestic hyperuricemia and gout patient management system, and the management system is characterized by comprising a detection instrument, a patient client, a database, a central processor and a doctor client. The domestic hyperuricemia and gout patient management system has the beneficial effects that the shortcomings of insufficiency of private doctors and expensive payment cost are overcame, so that the management system is suitable for doctors in many medical institutions for managing the hyperuricemia and gout patients; and the time of the doctors is saved, and the efficiency of the doctors is improved as well.

Owner:深圳市免疫医学转化(龙华)研究院

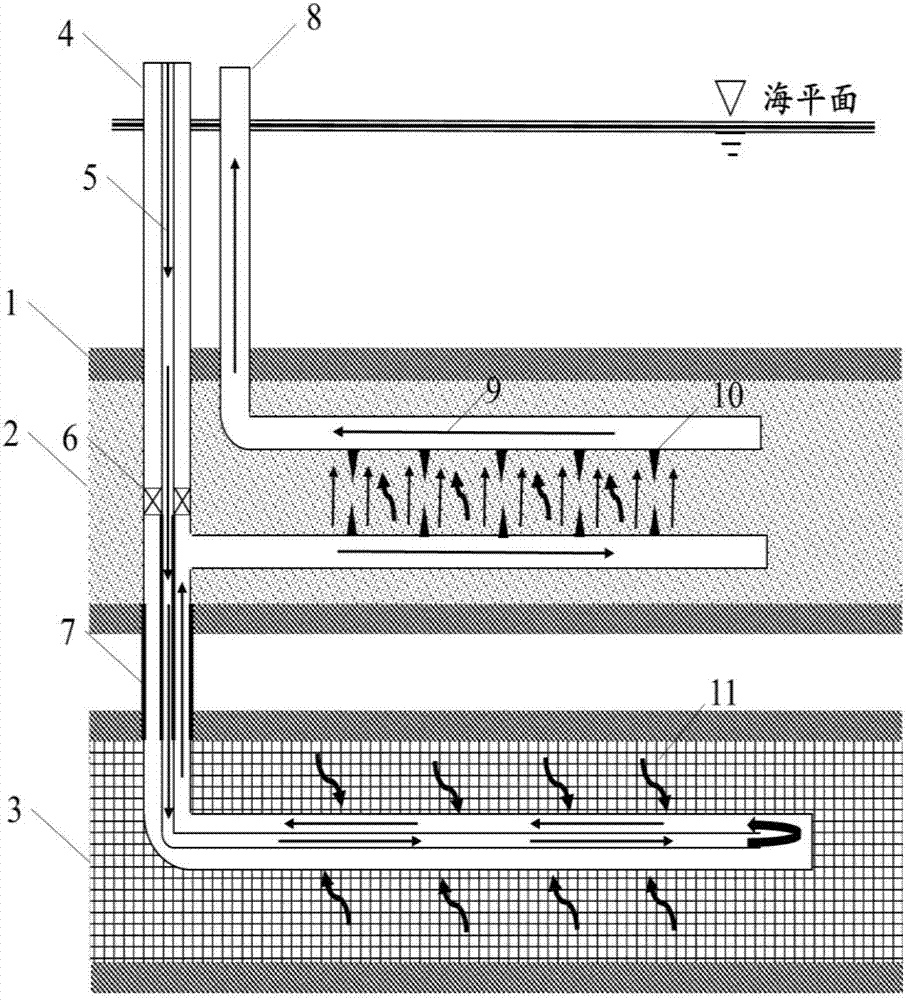

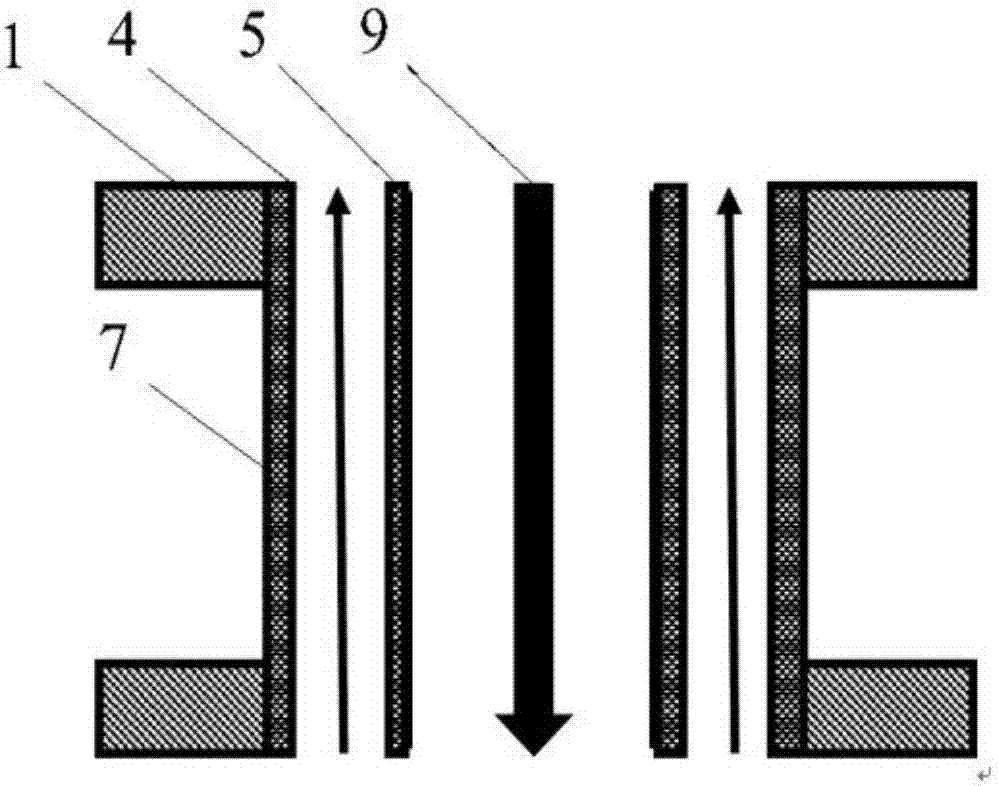

Well structure design and method for exploiting geothermal energy and gas hydrate reservoir at the same time of water injection

ActiveCN107143313AMake up utilizationMake up for expensesConstructionsOther heat production devicesGeothermal heatingHydraulic fracturing

The invention discloses a well structure design and method for exploiting geothermal energy and gas hydrate reservoir at the same time of water injection. The design mainly comprises a dual branch injection well and a horizontal producing well, wherein cold fluid is injected into the dual branch injection well, heated by a geothermal layer and returned to the gas hydrate reservoir; the self-carrying heat is transmitted to hydrate, and the hydrate dissociation is promoted. The method comprises the steps that a well group system which is composed of the dual branch injection well and the horizontal producing well is built on the sea level, wherein the dual branch injection well comprises a vertical mineshaft which extends from the sea level to the geothermal layer, a first branch mineshaft which is located on the gas hydrate reservoir and a second branch mineshaft which is located on the geothermal layer; the cold fluid is injected into a wellhead oil tube of the dual branch injection well, the cold fluid enters an oil sleeve annulus at the tail end of the second branch mineshaft and is subjected to heat exchange with the geothermal layer, after the heated fluid enters the gas hydrate reservoir, the heat is transmitted to the gas hydrate reservoir, the hydrate dissociation is caused, and mixed fluid which is composed of natural gas and injection fluid generated by the dissociation passes through a hydraulic power fracturing fracture under the gravity and pressure effect and is exploited by the horizontal producing well. According to the well structure design and method, the geothermal energy provides energy for the hydrate dissociation, the shortages such as low heat utilization efficiency and high exploiting cost in a traditional thermal excitation exploiting method are overcome, the device is simple, the operation is convenient, the economy is high, and the well structure design and method can provide guidance for reasonable exploiting of the gas hydrate reservoir.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

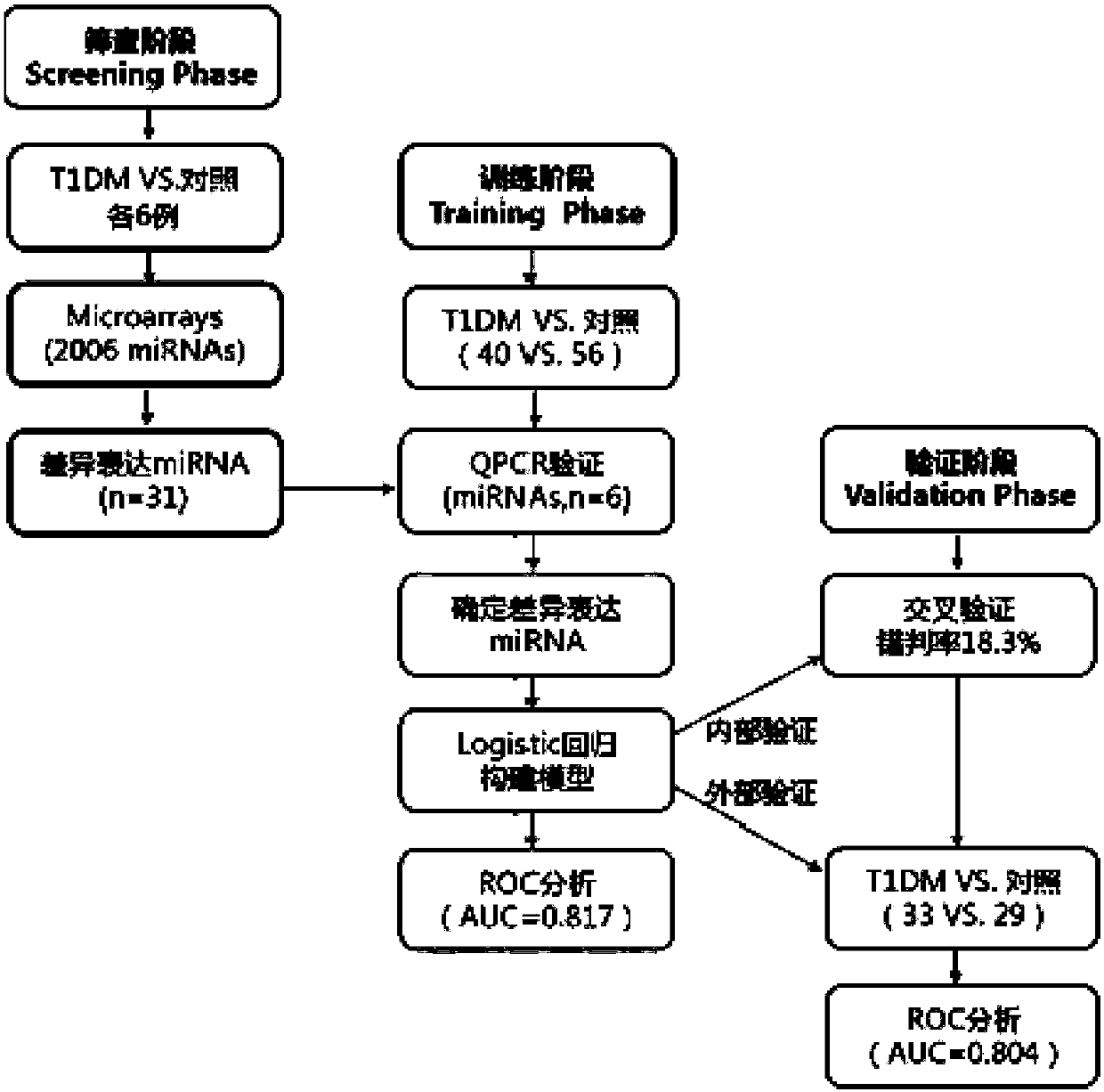

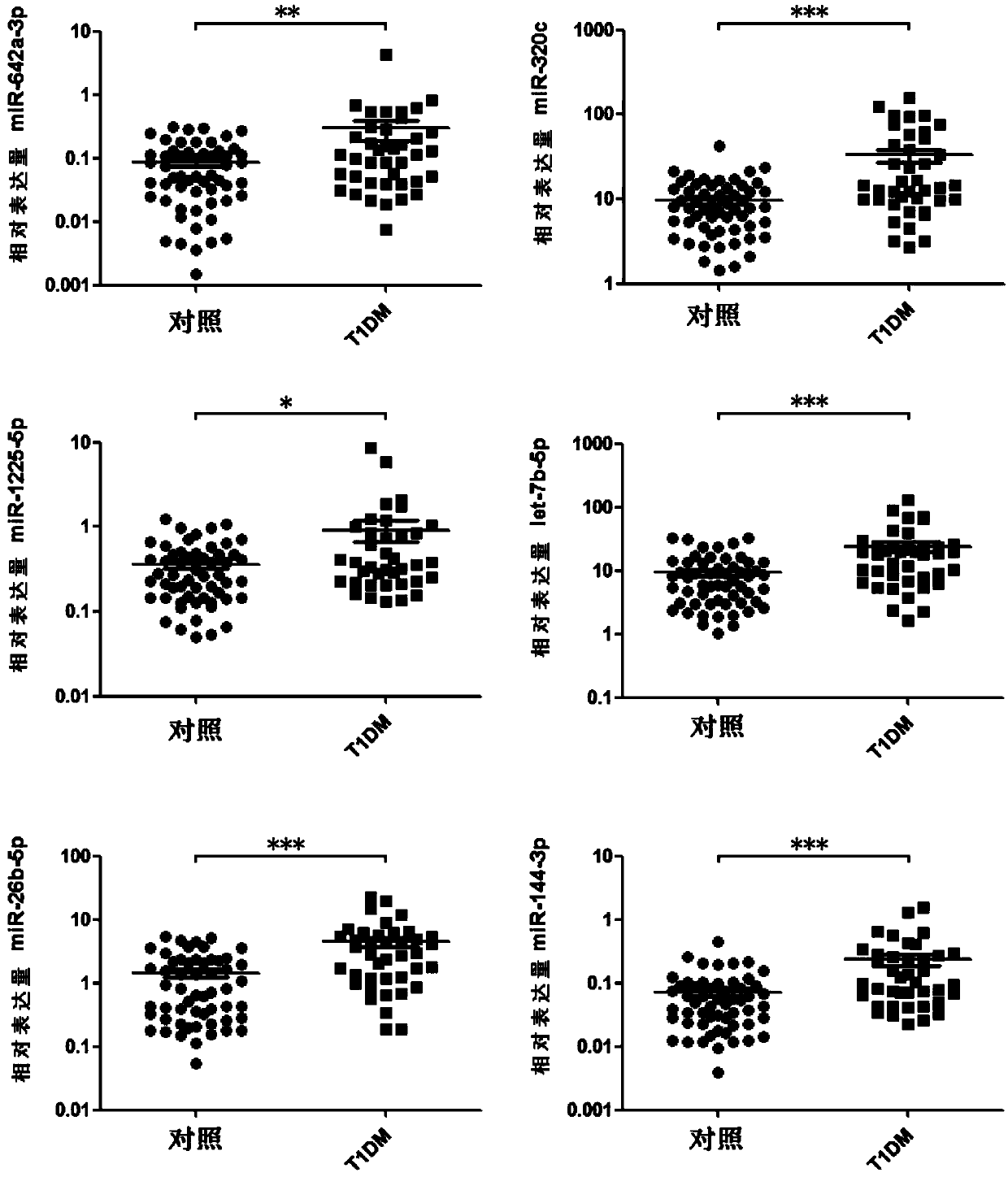

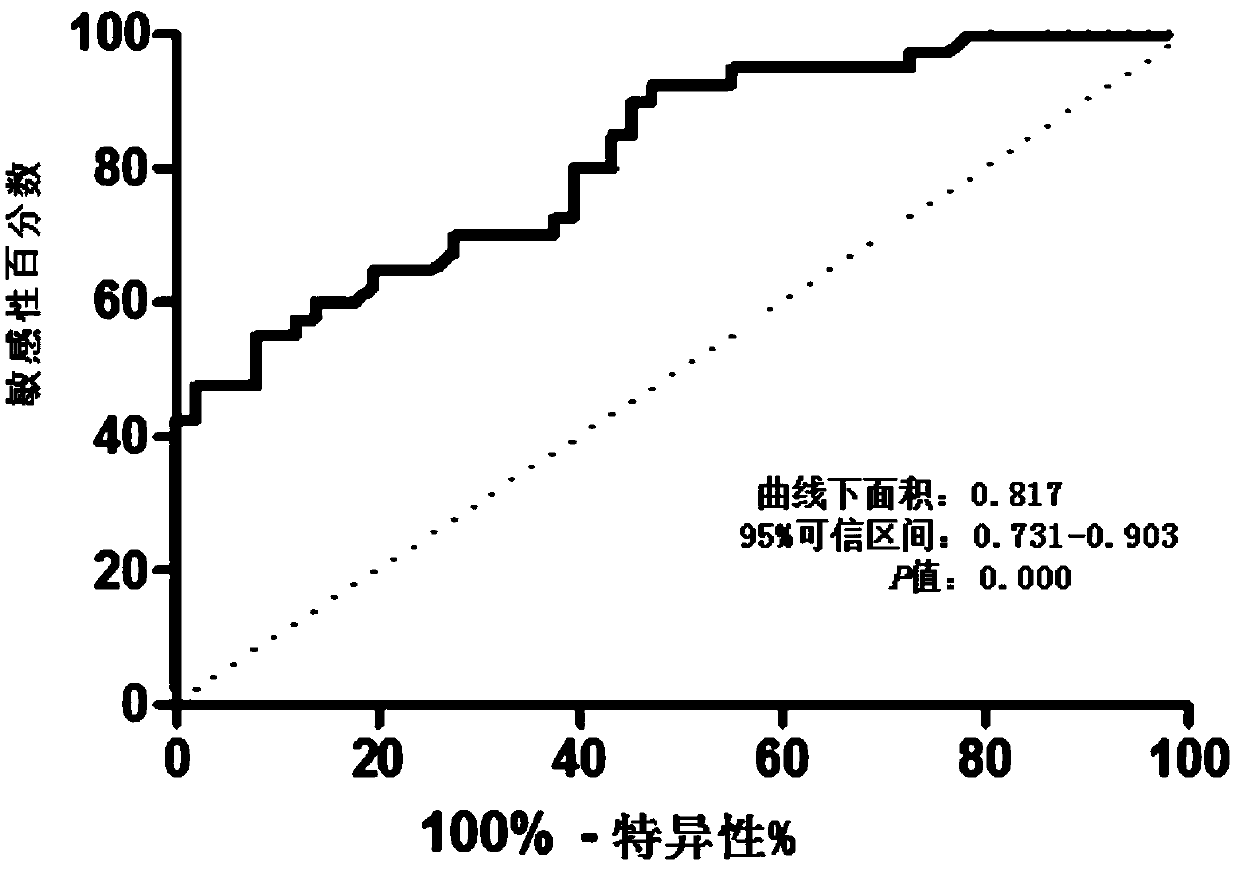

Type-1 diabetes markers and application thereof

InactiveCN108676868AGood diagnostic supportMake up for sensitivityMicrobiological testing/measurementDNA/RNA fragmentationDemographic dataSerum mirna

The invention discloses a set of type-1 diabetes markers, consisting of three miRNAs, including hsa-miR-642a-3p, hsa-miR-320c and hsa-miR-1225-5p; the invention also discloses the application of the markers in preparation of a type-1 diabetes diagnostic kit, and the kit contains reagents for quantifying the expression of the hsa-miR-642a-3p, hsa-miR-320c, hsa-miR-1225-5p. Compared with the known single biomarkers, utilizing a statistical method, and combining with multiple serum miRNAs and clinical demographic data to establish a type-1 diabetes serum miRNA-assisted diagnosis model, so the markers have better diagnostic support efficacy. The miRNA in circulation of a patient is utilized, the expression is stable, the storage and detection are easy, and clinical application is facilitated.

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

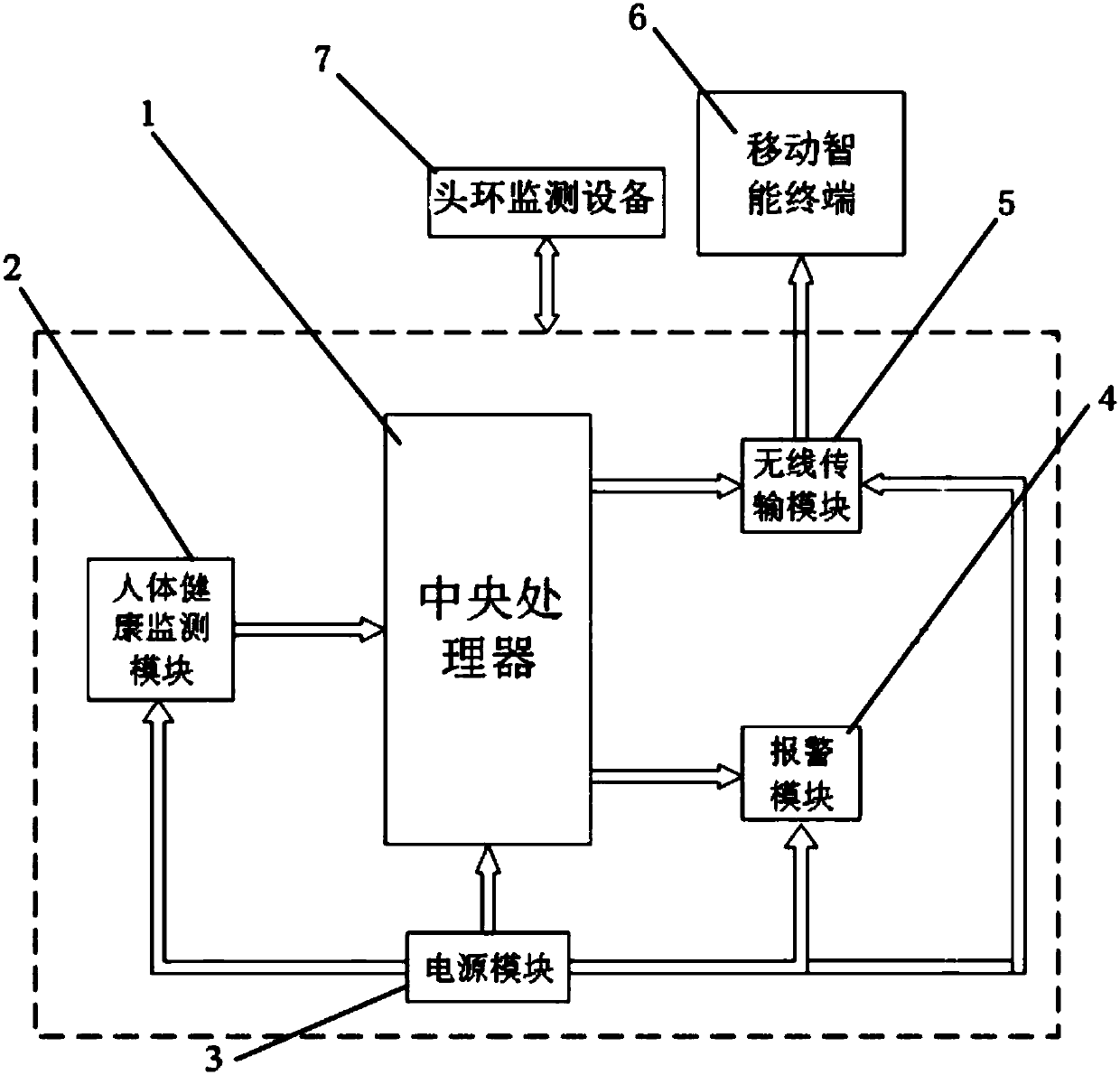

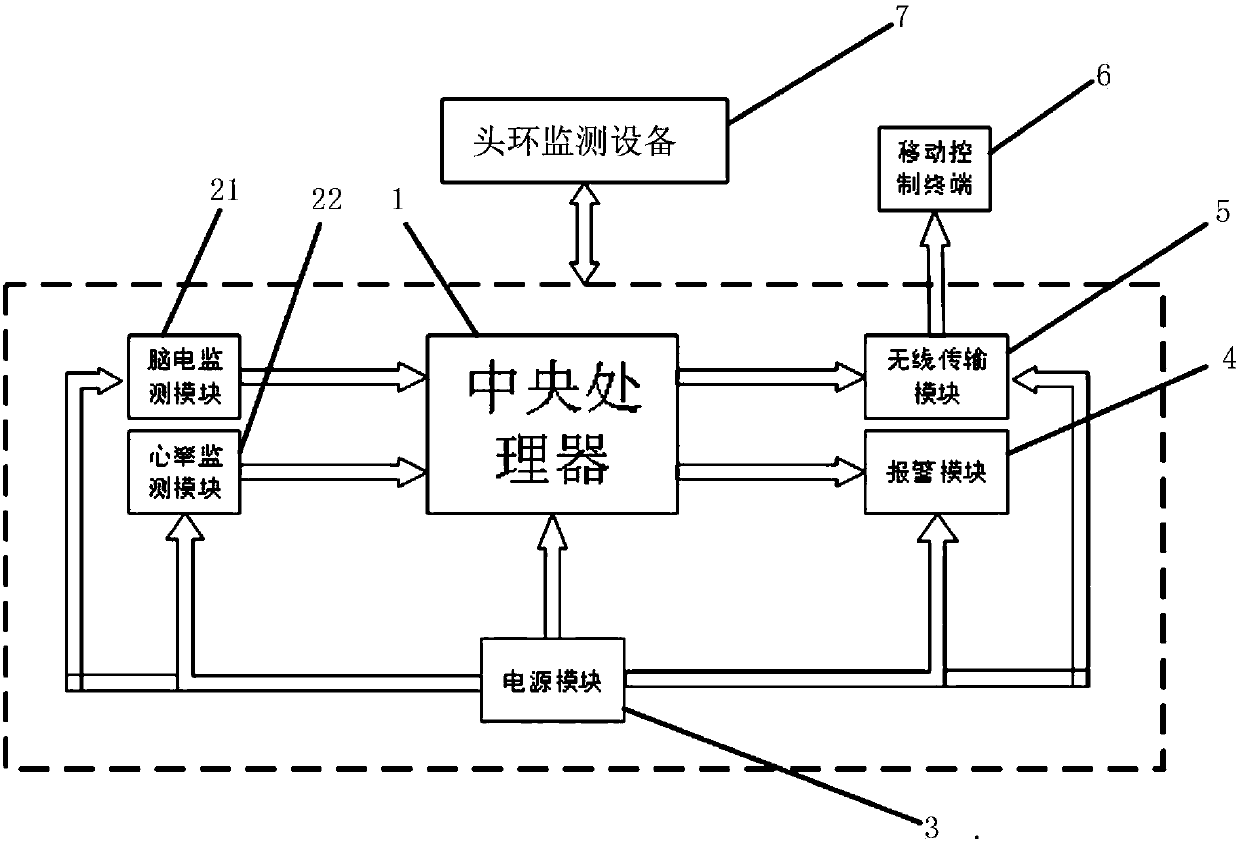

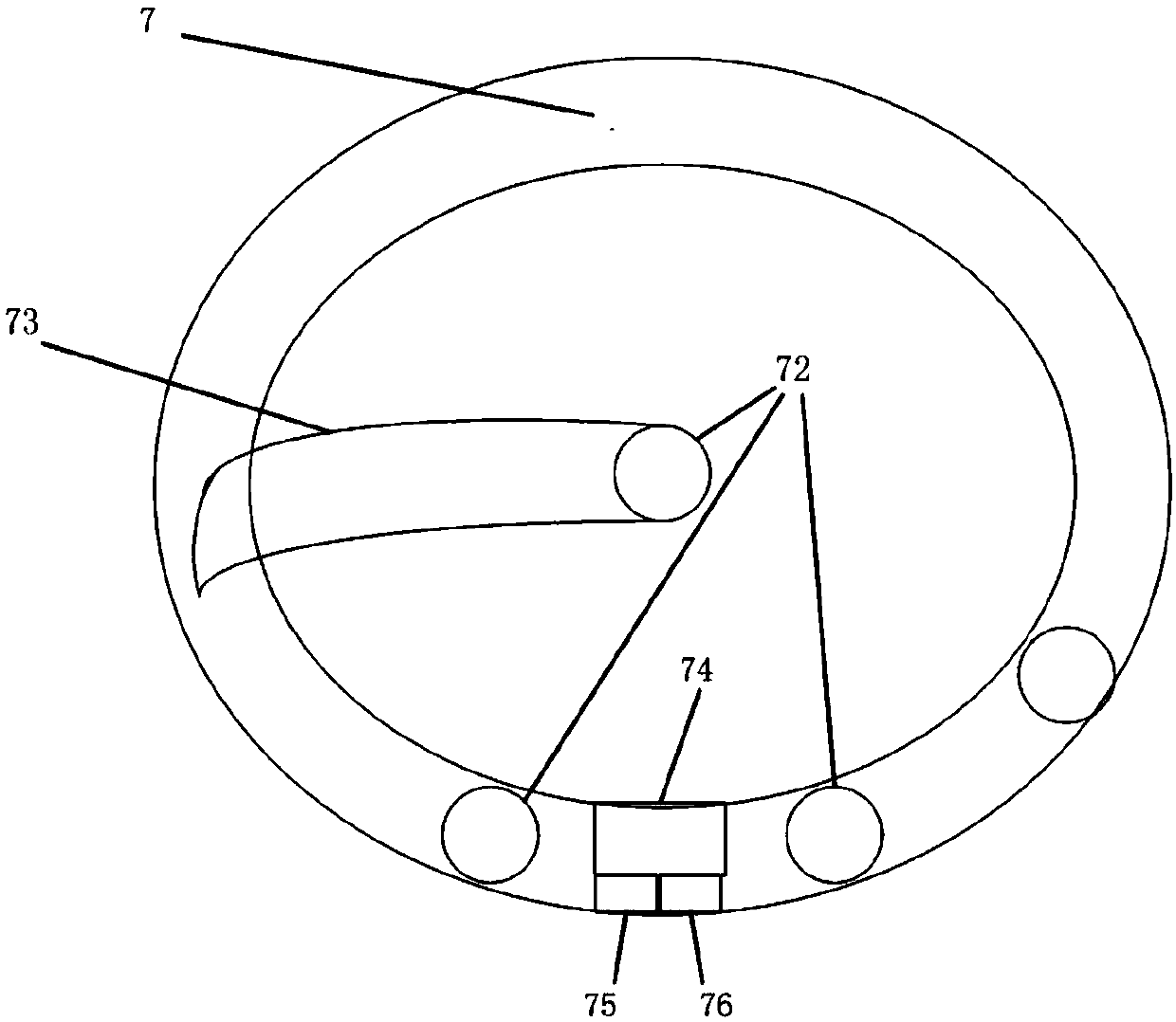

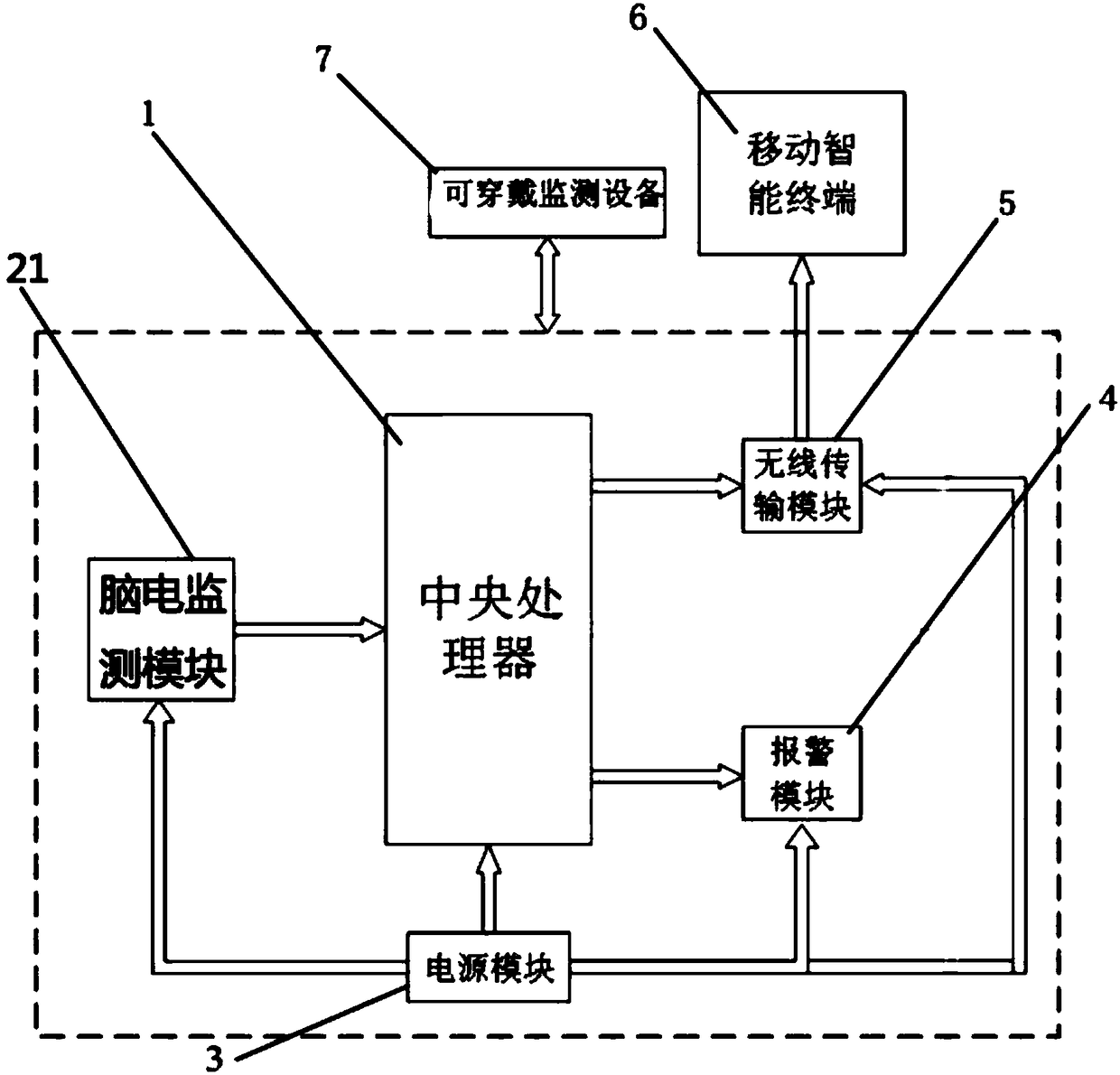

Intelligent wearable monitoring equipment for sleep apnea based on electroencephalogram and heart rate

InactiveCN108309288AMake up for complexityMake up for expensesDiagnostic recording/measuringSensorsHuman bodyApneustic breathing

The invention discloses intelligent wearable monitoring equipment for sleep apnea based on electroencephalogram and heart rate. The equipment comprises an equipment monitoring body, the equipment monitoring body is internally provided with a human body health monitoring module, a central processing unit, a power supply module and a warning module, wherein the human body health monitoring module isused for monitoring human body biological signals, the central processing unit is used for processing and analyzing the human body biological signals, the power supply module is used for supplying power, the warning module is used for determining the sleep apnea is serious and triggering a warning when analyzing and evaluating that the human body is in a sleep apnea condition; the human body health monitoring module transmits the monitored human body biological signals to the central processing unit, the central processing unit analyzes and processes the human body biological signals and transmits the human body biological signals to the warning module. The intelligent wearable monitoring equipment for the sleep apnea based on the electroencephalogram and the heart rate has the advantagesthat the defects that the universality, caused by complex operation, poor portability, high cost and the like, of specialized medical health monitoring equipment is poor, and simple and efficient health detection means are insufficient are made up.

Owner:SHENZHEN YUXINXIN ELECTRONICS +1

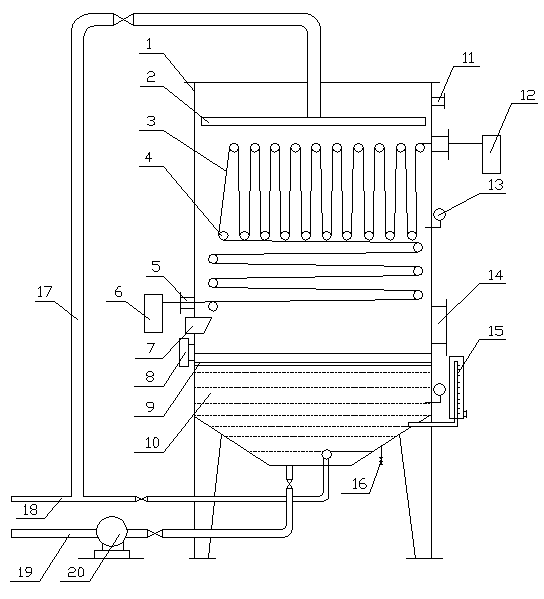

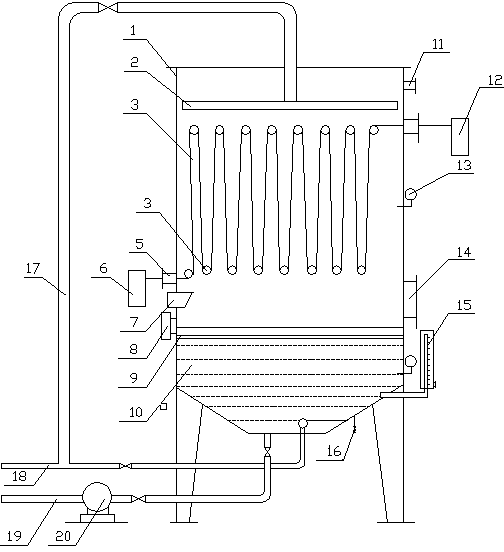

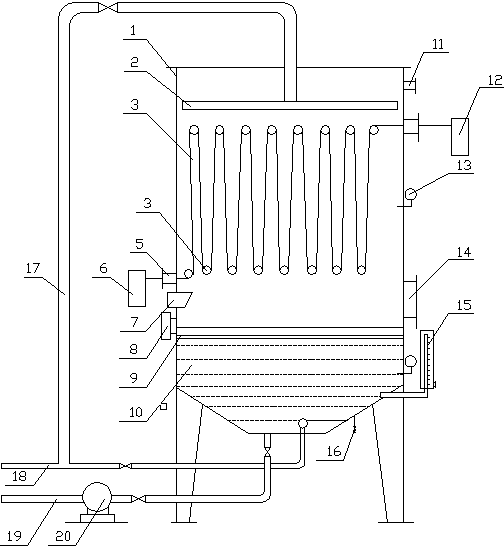

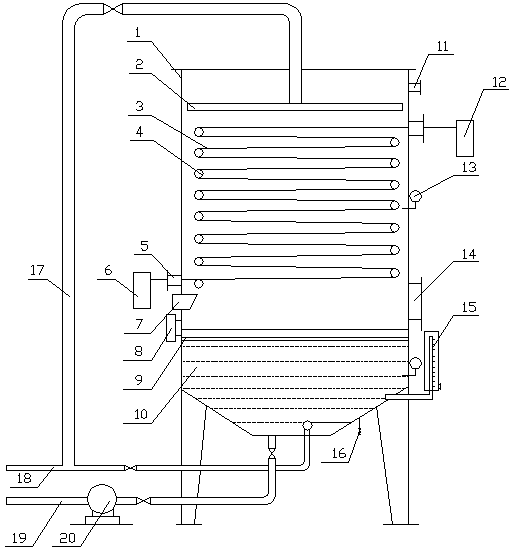

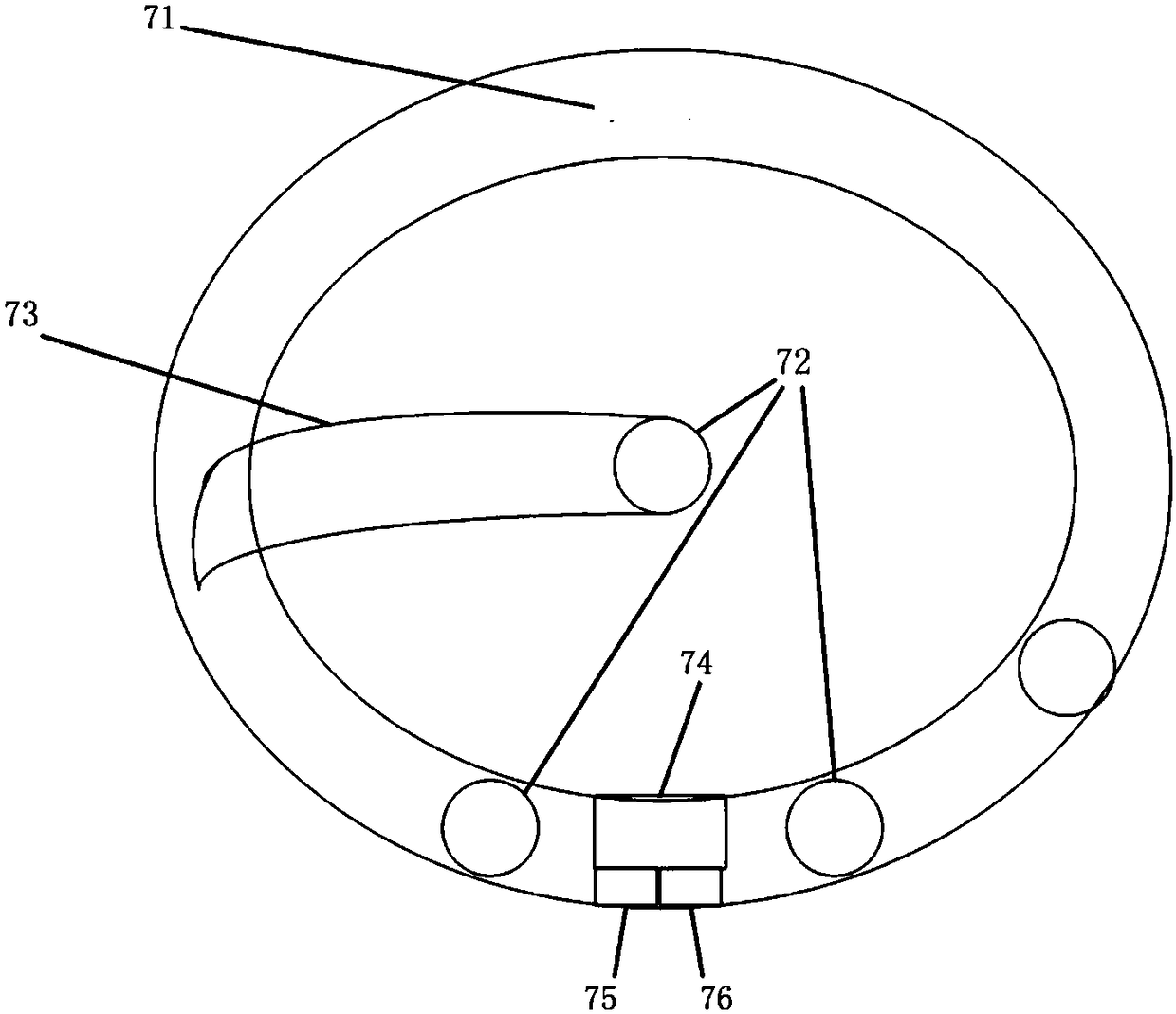

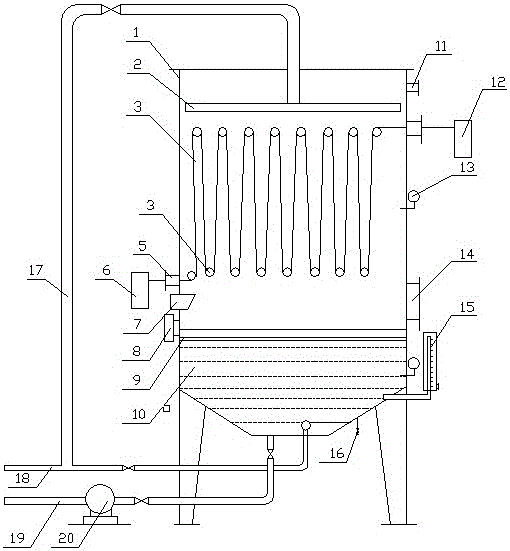

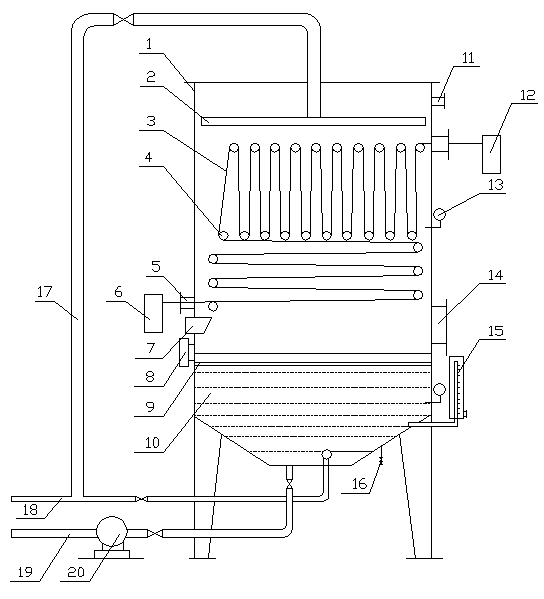

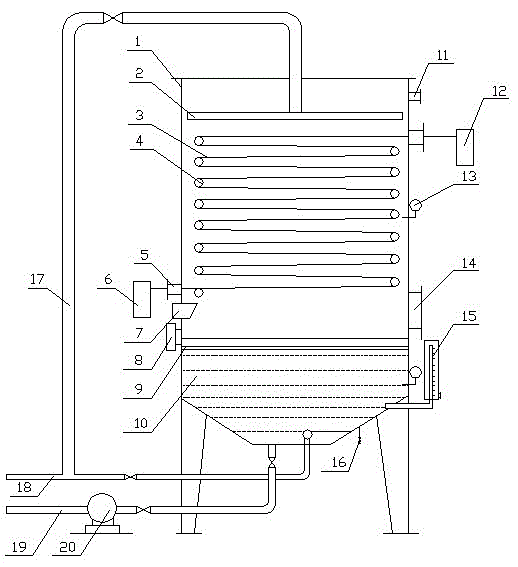

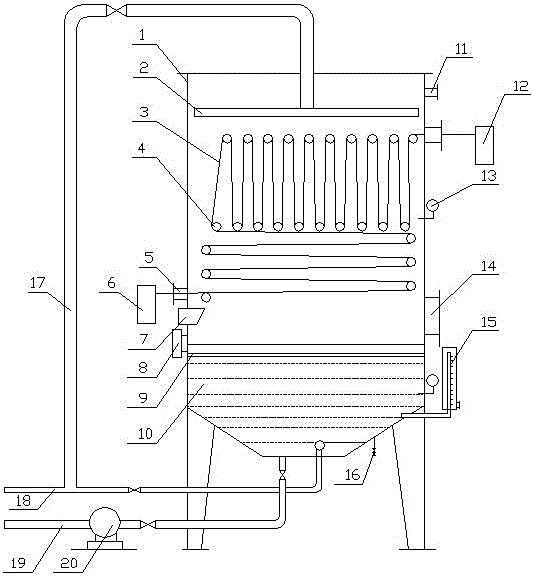

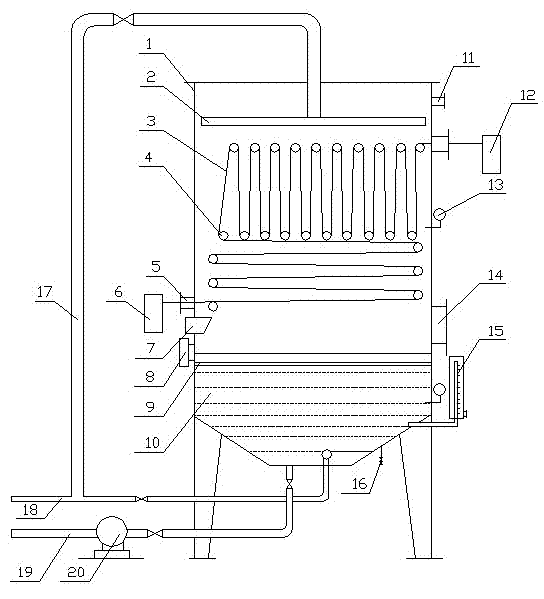

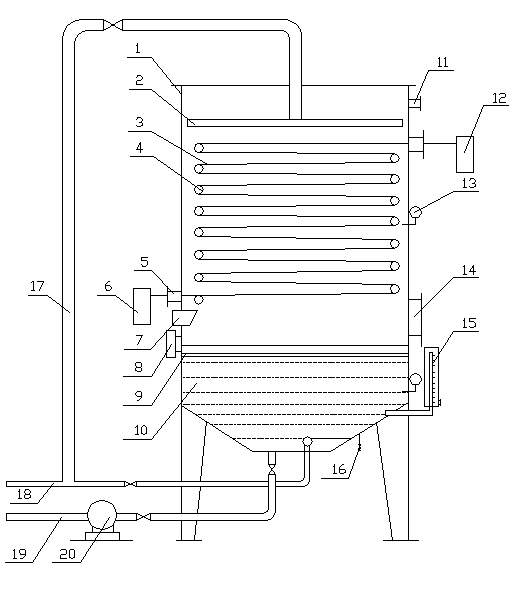

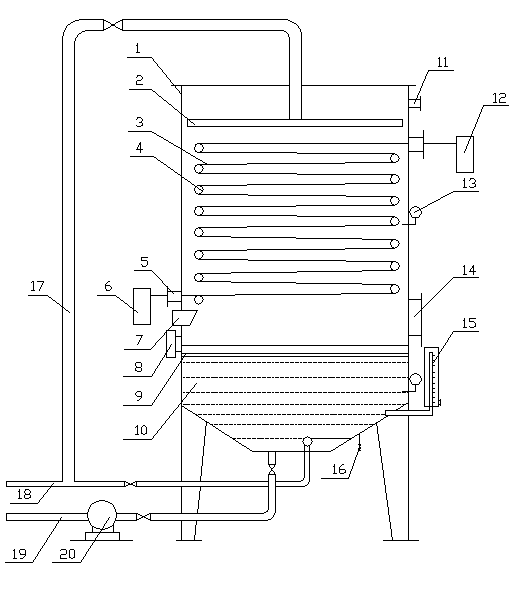

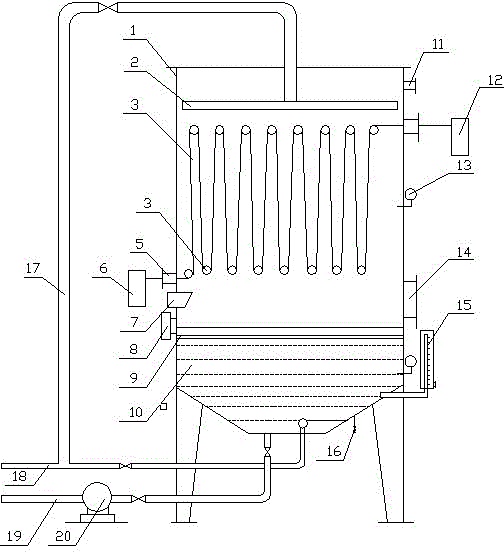

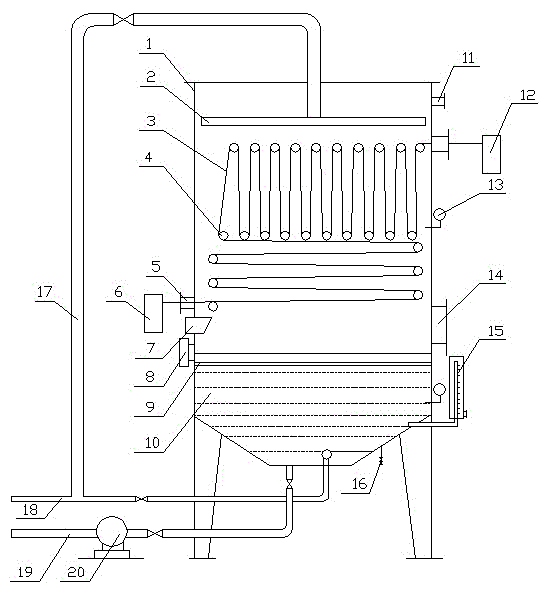

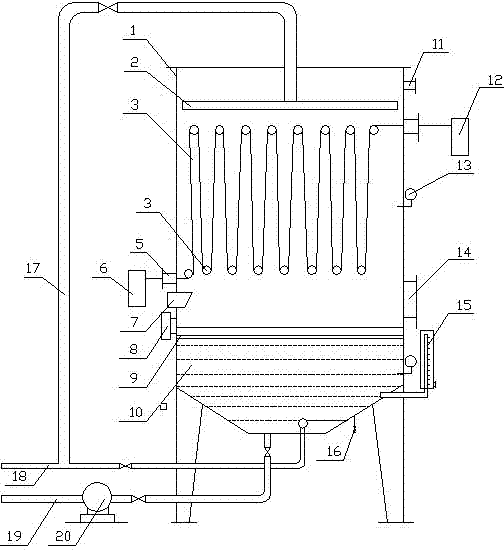

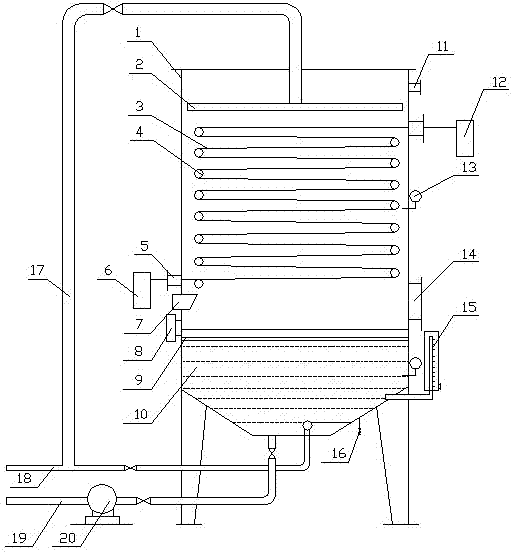

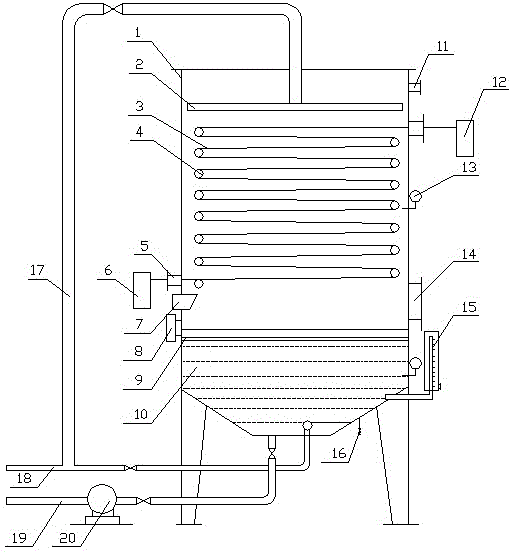

Method for producing kombucha beverage by liquid spraying fermentation tower filled with knitted fabric

InactiveCN103416545AIncreased unit utilizationMake up for expensesTea extractionMembrane configurationBacterial cellulose

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with kintted fabric is disclosed. The liquid spraying fermentation tower filled with knitted fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with knitted fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a knitted fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The knitted fabric filling system comprises a roller disposed in the tower and knitted fabric wound on the roller, one end of the knitted fabric is connected with an unreeling apparatus and the other end of the knitted fabric is connected with a winding apparatus. The knitted fabric filling system is employed and the orientation movement of the knitted fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar by liquid spraying fermentation tower with non-woven fabric filling system

InactiveCN103421668ASolve liquidity problemsSolve productivityVinegar preparationChemistryWoven fabric

A method for producing vinegar by a liquid spraying fermentation tower with a non-woven fabric filling system is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed vinegar, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

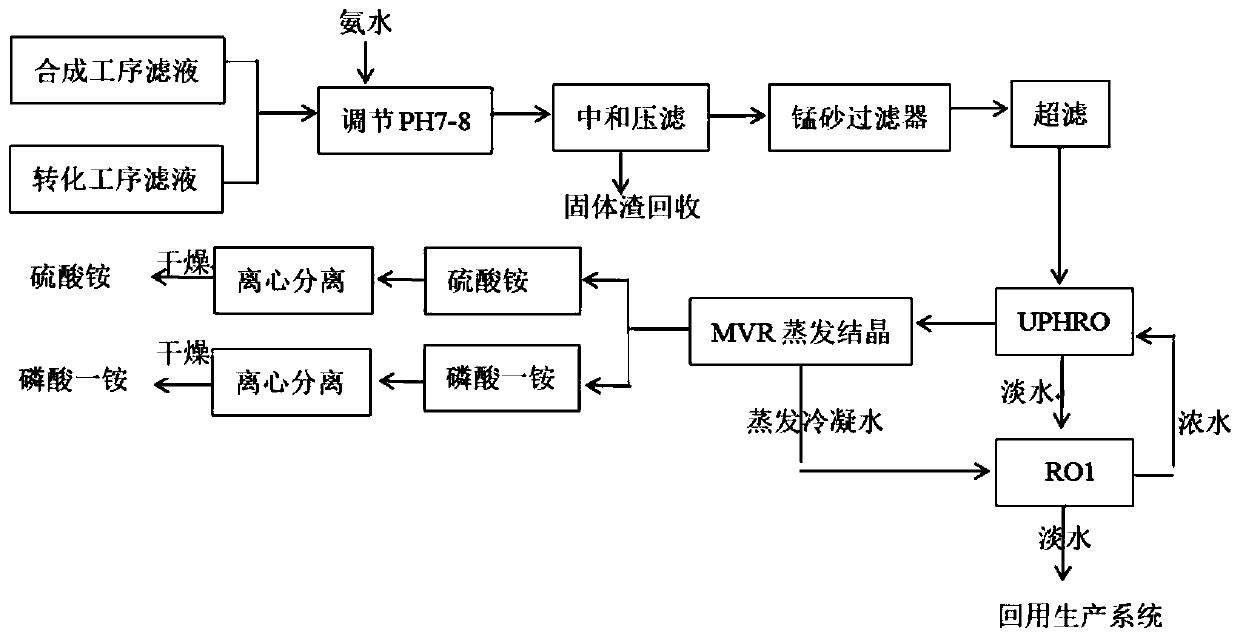

Method for resource utilization of wastewater in synthetic process of battery-grade iron phosphate

PendingCN110589788AMake up for expensesGood economic and environmental benefitsPhosphatesWater contaminantsAmmonium sulfateChemistry

The invention discloses a method for resource utilization of wastewater in the synthetic process of battery-grade iron phosphate. The method comprises the following steps: a, adding ammonia water to adjust the pH value of the wastewater generated in the synthetic process of the iron phosphate to 7-8 to obtain a solution; b, filtering the solution for multiple times to obtain a product, namely a filtrate without suspended solids; c, pumping the filtrate into an ultrahigh-pressure reverse osmosis device, and performing a reaction to obtain concentrated water A and fresh water A; d, introducing the concentrated water A into an MVR evaporative crystallization device, carrying out vacuum concentration evaporative crystallization to obtain an ammonium sulfate and monoammonium phosphate mixture and evaporation condensate water, and carrying out centrifugal separation on the ammonium sulfate and monoammonium phosphate mixture to respectively obtain ammonium sulfate and monoammonium phosphate;e, mixing the fresh water A and the evaporation condensate water, and pumping the mixed water into a primary reverse osmosis device to obtain concentrated water B and fresh water B; and f, pumping theconcentrated water B into an ultrahigh-pressure reverse osmosis device, and recovering the fresh water B. The method has the beneficial effect that the treatment cost of the wastewater can be saved.

Owner:襄阳泽东新能源发展有限公司

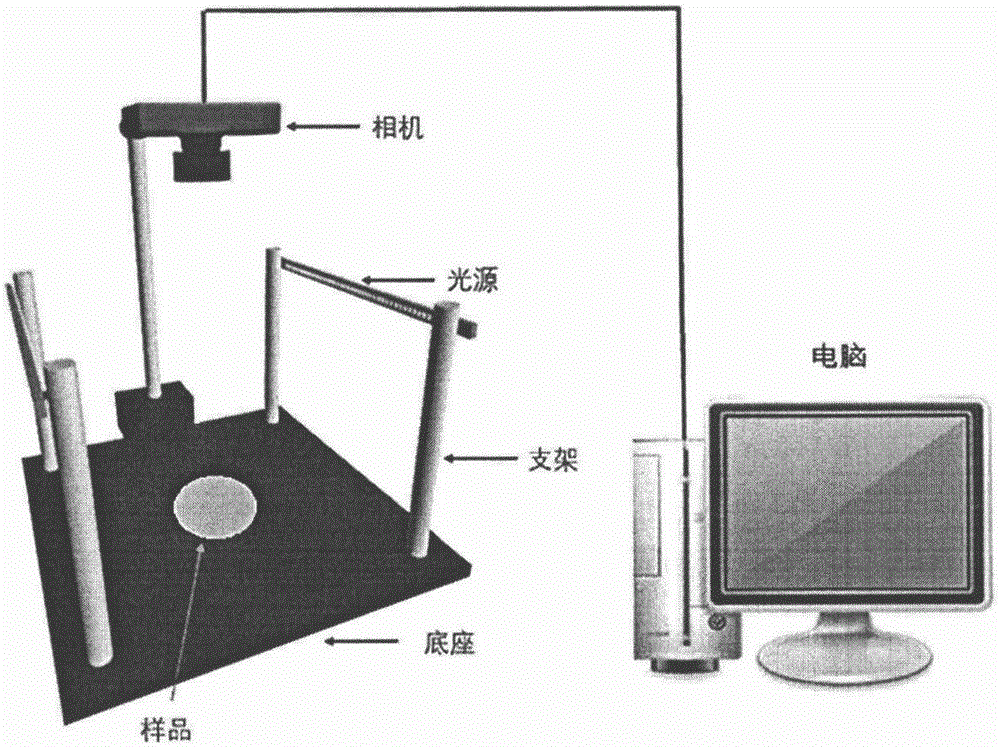

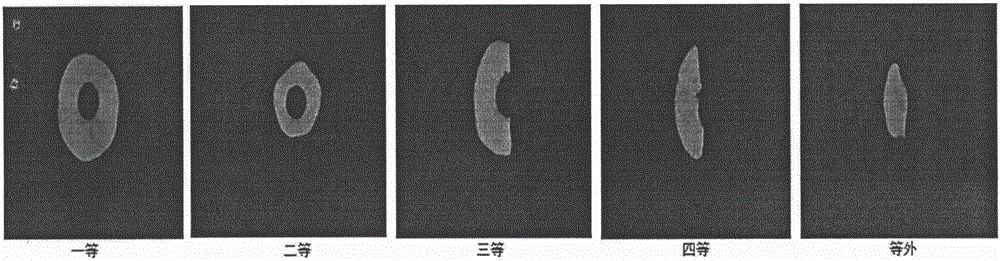

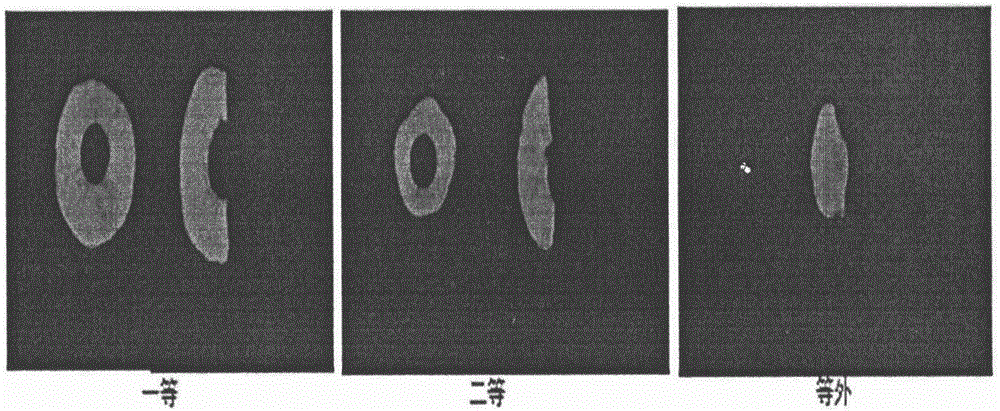

Lossless grading method for quality of crisp apple chips

ActiveCN106290359AAchieve lossless gradingImprove accuracyInvestigation of vegetal materialImaging FeatureComputer vision

The invention relates to a lossless grading method for quality of crisp apple chips through the crisp apple chip external quality grading standard and the computer vision technique, and belongs to the novel crisp apple chip quality lossless grading technology. Crisp chip images are acquired through a computer vision device and processed, size, shape, color and grain feature parameters are extracted, and the feature parameters are optimized. The mode recognition technology is utilized for analyzing various grades of crisp apple chip image features, and therefore lossless grading of the crisp apple chips is achieved. The method is easy and convenient to operate, fast in detection and accurate in grading, and the defects that a traditional grading mode consumes time and labor, and is high in cost, likely to be influenced by subjective factors and large in mechanical damage are overcome.

Owner:NANJING AGRICULTURAL UNIVERSITY

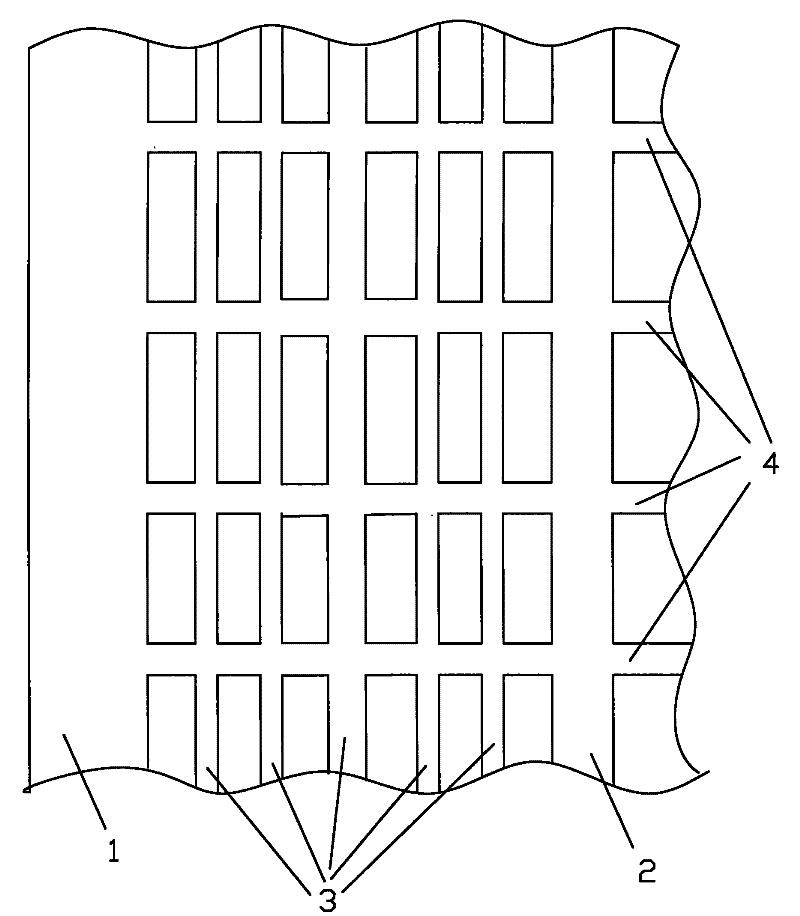

Liquid spraying fermentation tower provided with non-woven fabric filling system

InactiveCN103421673ASolve liquidity problemsSolve productivityBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provided with a non-woven fabric filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the non-woven fabric filling system. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the non-woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the non-woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with woven fabric

InactiveCN103416543AIncreased unit utilizationMake up for expensesTea extractionLiquid stateKombucha

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

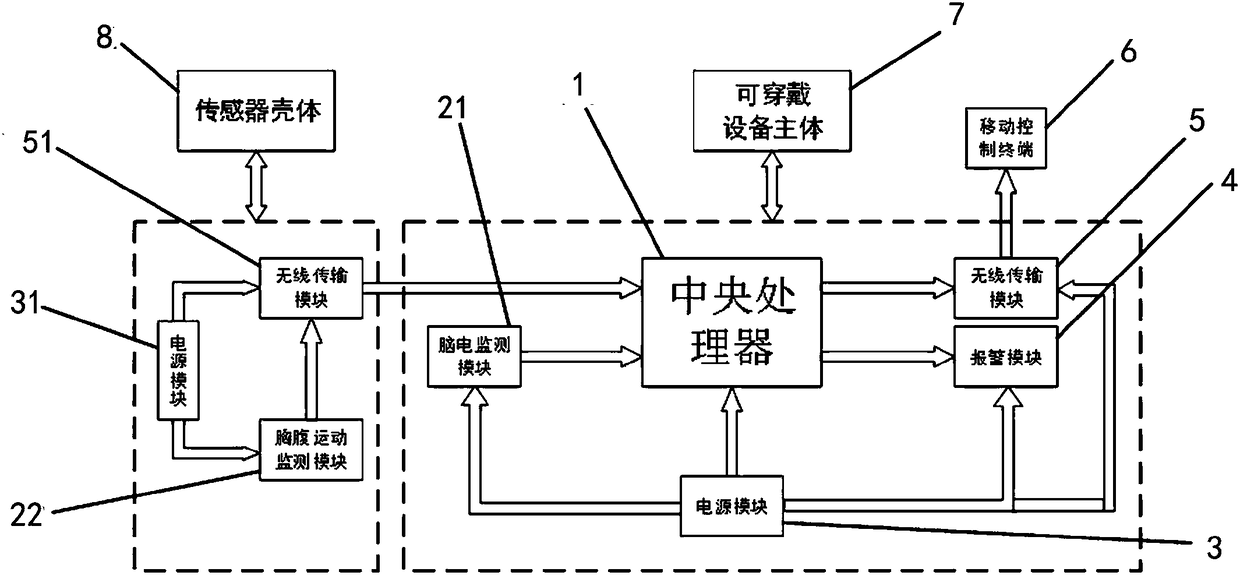

Sleep apnea intelligent wearable device based on electroencephalogram and thoracoabdominal motion

InactiveCN108186012AIncrease contactMake up for complexitySensorsTelemetric patient monitoringCare giverComputer science

The invention discloses a sleep apnea intelligent wearable device based on electroencephalogram and thoracoabdominal motion, comprising: a wearable device monitoring body having an electroencephalogram monitoring module inside which is used for monitoring human electroencephalogram; a central processing unit for processing and analyzing the human electroencephalogram; a power module for providingpower; a warning module for receiving a warning signal from the central processing unit and sending a warning to a user and nursing personnel. A body health monitoring module transmits a monitored body biological signal to the central processing unit; the central processing unit analyzes and processes the body biological signal and sends the processed signal to the warning module. By using the sleep apnea intelligent wearable device based on electroencephalogram and thoracoabdominal motion, the defects of monitoring means of electroencephalogram and respiratory medical monitoring equipment canbe made up.

Owner:SHENZHEN YUXINXIN ELECTRONICS +1

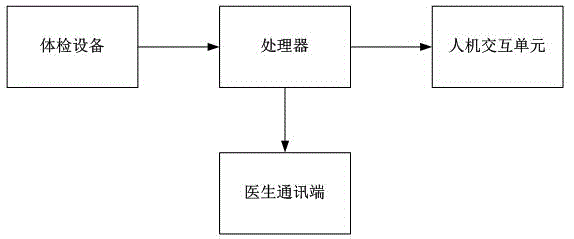

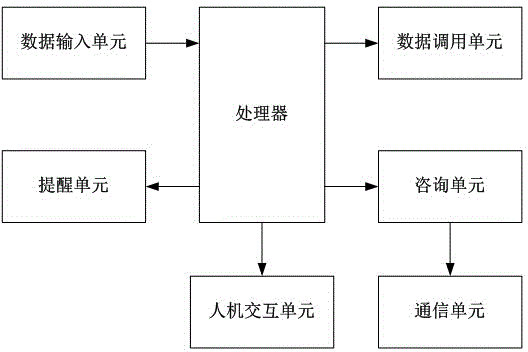

Health management system

InactiveCN104978486AMake up for the lack of quantityMake up for expensesSpecial data processing applicationsPaymentAnalysis data

The invention relates to a health management system and belongs to the field of health physical examination. The system comprises a physical examination device for detecting and outputting physical examination data, a processor and a database, wherein the processor is connected with the physical examination device and used for receiving the physical examination data of the physical examination device; and the database is connected with the processor and used for sending the data to the processor according to an instruction of the processor. According to the system, common health physical examination devices are integrated, body state data detected by the physical examination devices is collected and transmitted to the processor for analysis and conclusion, and the body state data and case data in the database are compared and analyzed to obtain a health conclusion of a person taking physical examination, so that the function of a family doctor is substituted, the defects of family doctor shortage and high payment expense are made up for, and the problems in the prior art that a health physical examination product only can display detection data and cannot analyze the data to obtain a detection result are solved.

Owner:WUHU YANGYU ELECTROMECHANICAL TECH DEV

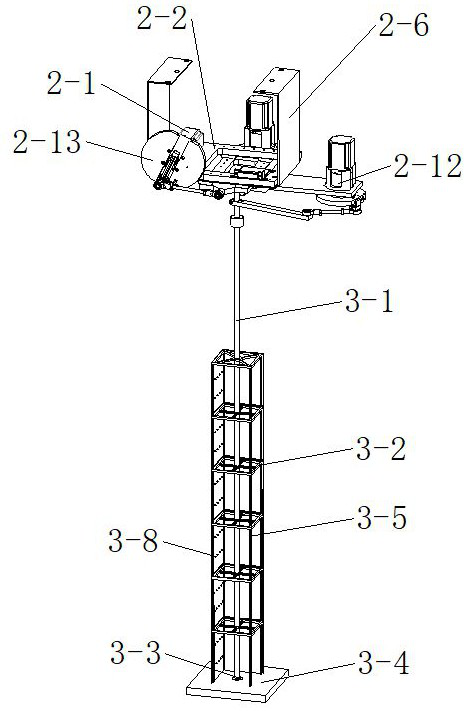

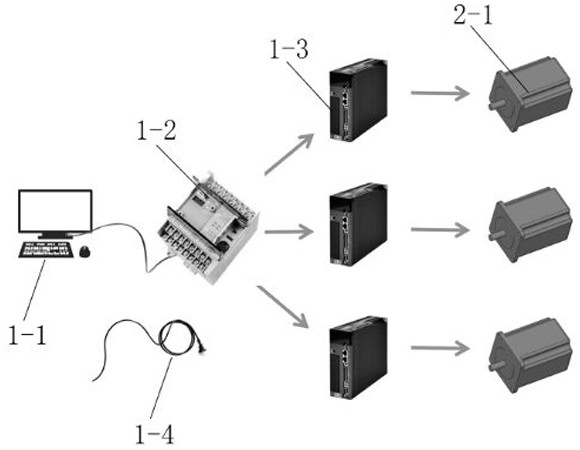

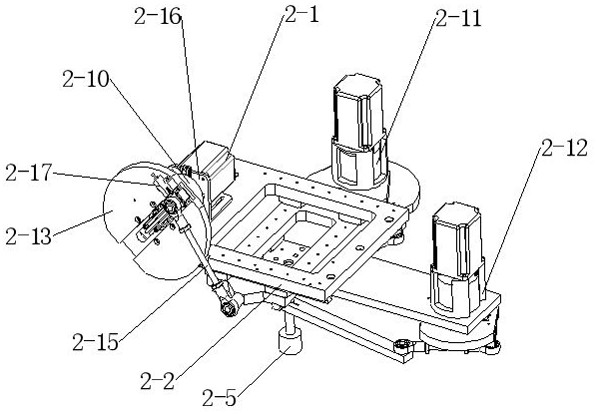

Driving type wind tunnel test system for simulating actual vibration form of structure

ActiveCN114323550AAvoid the tedious manual adjustmentImprove fluencySustainable transportationAerodynamic testingNumerical controlThree degrees of freedom

The invention provides a driving type wind tunnel test system for simulating the actual vibration form of a structure. The driving type wind tunnel test system comprises a numerical control circuit assembly, a driving type vibration assembly and a multi-degree-of-freedom structure assembly. The numerical control circuit assembly comprises a circuit controller and a motor driver, the motor driver receives an instruction of the controller and controls a servo motor in the driving type vibration assembly to rotate, the driving type vibration assembly is connected with a numerical control circuit, and the driving type vibration assembly comprises the servo motor and a three-way bottom plate. The servo motor drives the three-direction bottom plate assembly to vibrate in the X direction, the Y direction and the Z direction. And the lower part of the three-way bottom plate is connected with the multi-degree-of-freedom structure assembly and drives the multi-degree-of-freedom structure assembly to perform three-degree The wind tunnel test system realizes amplitude-modulated, frequency-modulated and phase-modulated structural three-direction vibration, successfully simulates a nonlinear vibration form which is closer to reality under a driving device, improves the simulation precision, ensures the test result, and can better test important mechanical data such as fluid wind pressure and torsional force of a building structure.

Owner:WUHAN UNIV

Liquid poured fermentation tower with non-woven packing system

InactiveCN103421673BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsSpray towerPulp and paper industry

The invention discloses a liquid spraying fermentation tower provided with a non-woven fabric filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the non-woven fabric filling system. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the non-woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the non-woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

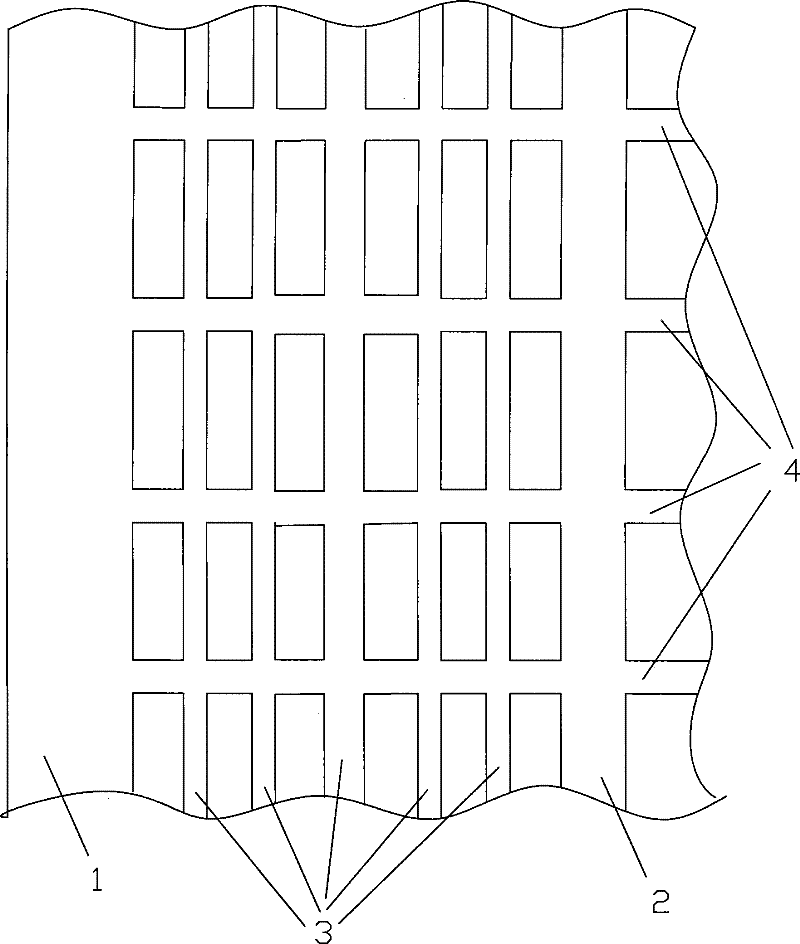

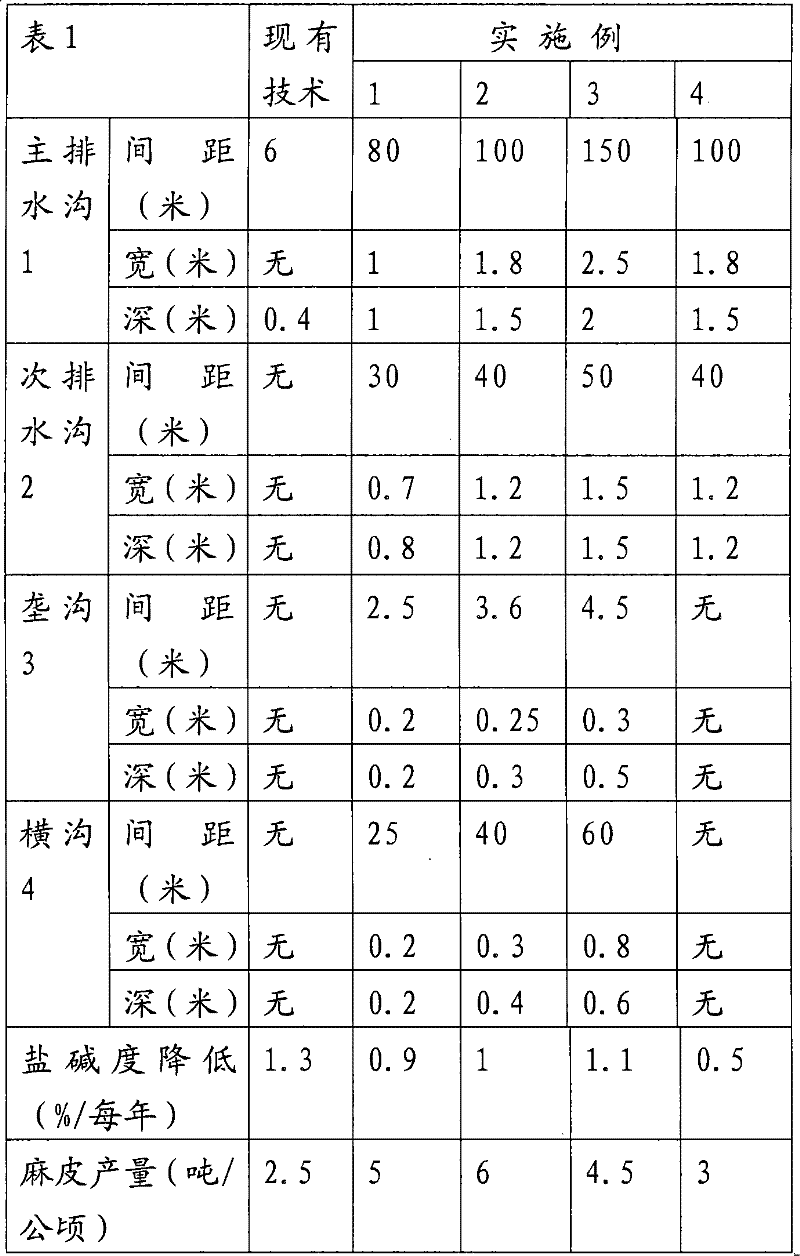

The method of improving saline-alkali land

InactiveCN101347790BDischarge in timeLow costContaminated soil reclamationEngineeringImproved method

The invention discloses a method for improving saline-alkali land, which includes constructing a drainage system, and the drainage system includes a main drainage ditch and a secondary drainage ditch which is narrower and shallower than the main drainage ditch arranged between the main drainage ditch; The main drainage ditch and the secondary drainage ditch are arranged along substantially the same direction; through natural rainfall or artificial irrigation, the drainage system flushes the saline-alkali in the saline-alkali land to the river system. By reasonably setting the interval and size of the main drainage ditch and the secondary drainage ditch, the salt dissolved in the saline-alkali land can be discharged from the saline-alkali land through the drainage system in time, and the purpose of drainage and salt removal is achieved. At the same time, by reasonably setting the interval and size of the main drainage ditch and the secondary drainage ditch, the main drainage ditch and the secondary drainage ditch do not need to be repaired very densely, which greatly saves the treatment cost of constructing the drainage system.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

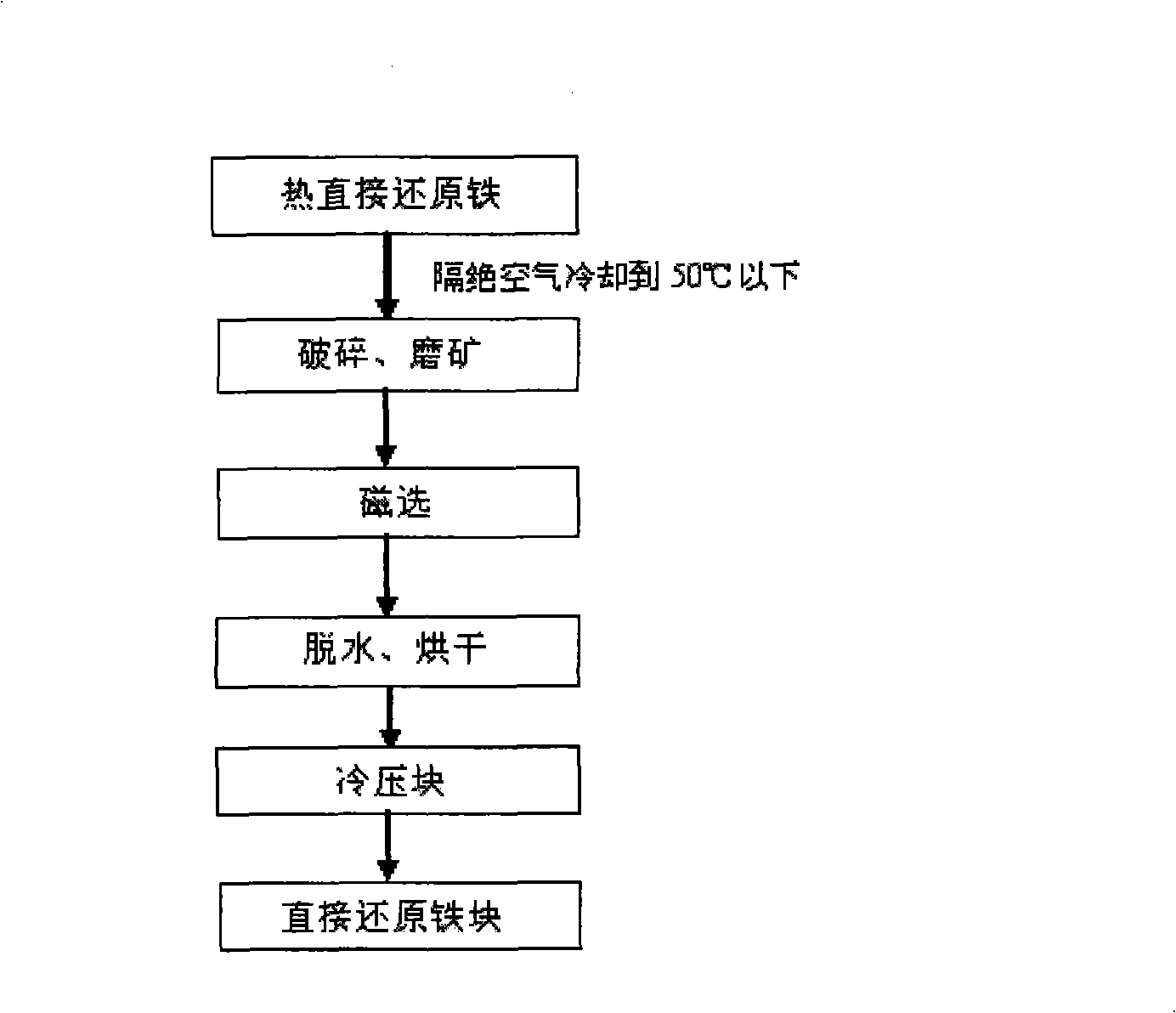

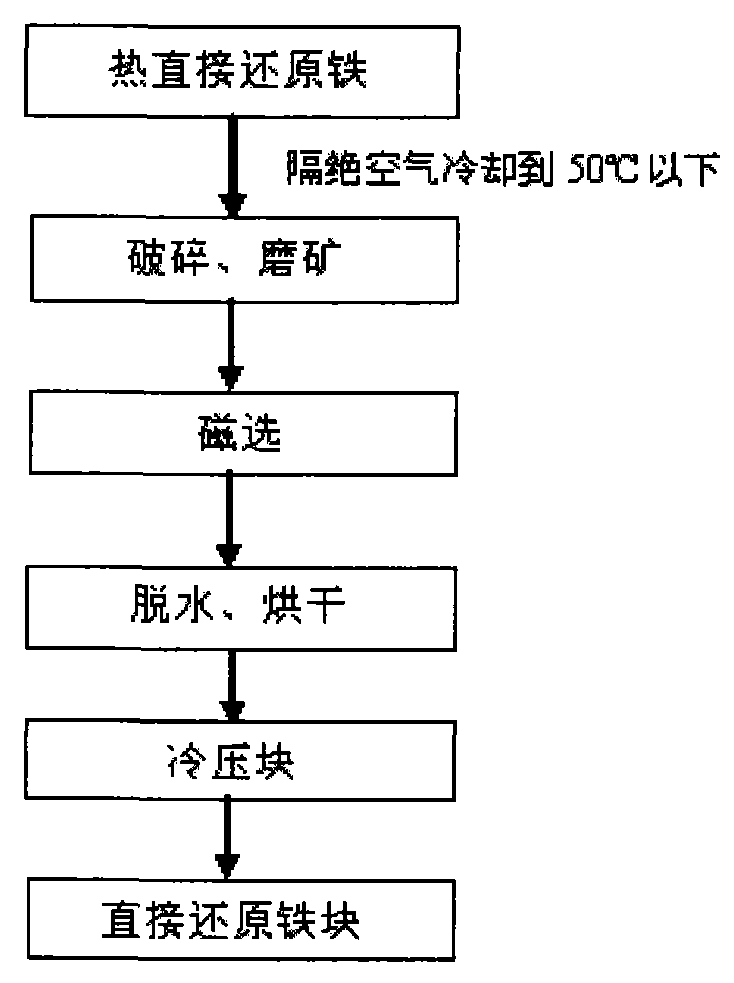

Method for improving quality of direct reduced iron by rotary hearth furnace

InactiveCN101538633BQuality improvementRelaxing stringent requirements for qualityRotary drum furnacesMagnetic separationSteelmakingFiltration

The invention provides a method for improving quality of direct reduced iron by a rotary hearth furnace. The method breaks and fine grinds the iron which is directly reduced by the rotary hearth furnace to fine powder of 2mm, carries out the magnetic separation under the condition that the strength of a magnetic field is 110-160kA / m for selecting iron powder and gangue, compresses into the direct reduced iron product with the density of being greater than 4t / m<3> after filtration and drying and then directly pours into a furnace for steelmaking. The method can not only remove residual carbon and ash mixed in the direct reduced iron by the rotary hearth furnace, but also remove most of S brought by coal powder and the gangue in iron ores, thereby significantly improving the quality of the direct reduced iron, being directly used for steelmaking in an electric furnace and a rotary furnace and effectively reducing the production cost; tests prove that the direct reduced iron during the grinding and selection process can not generate the secondary oxidation basically, the recovery rate of the metal iron is generally higher than 95 percent, the highest can achieve 99 percent, and the metal loss is less.

Owner:WUKUN STEEL

Liquid spraying fermentation tower provided with knitted fabric filling system

InactiveCN103421674AIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provide with a knitted fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the knitted fabric type filling system. The knitted fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the knitted fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the knitted fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

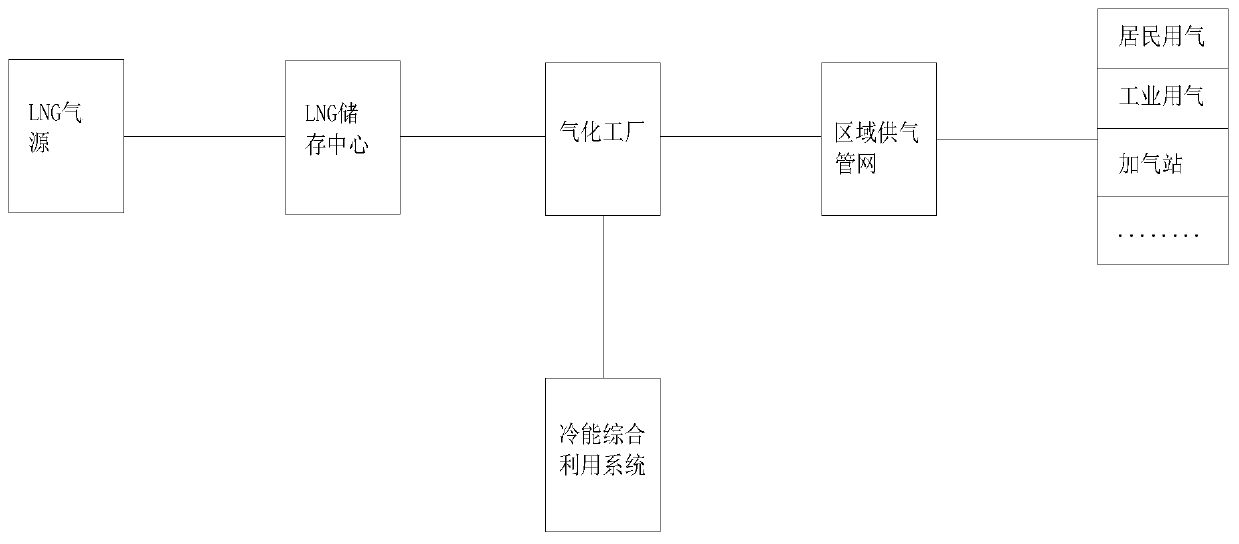

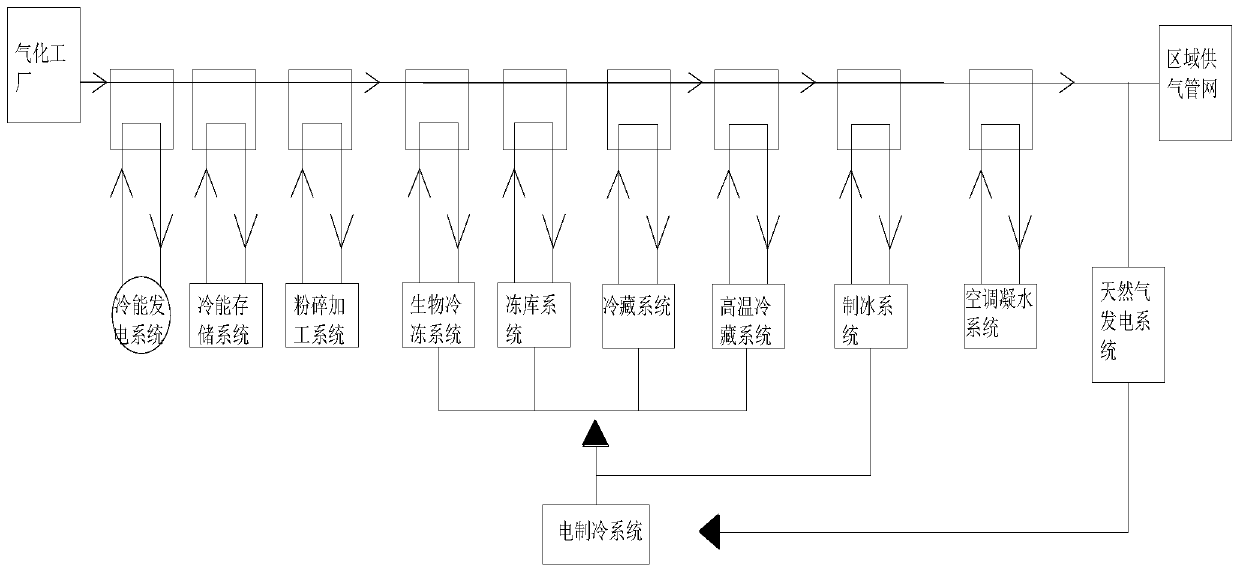

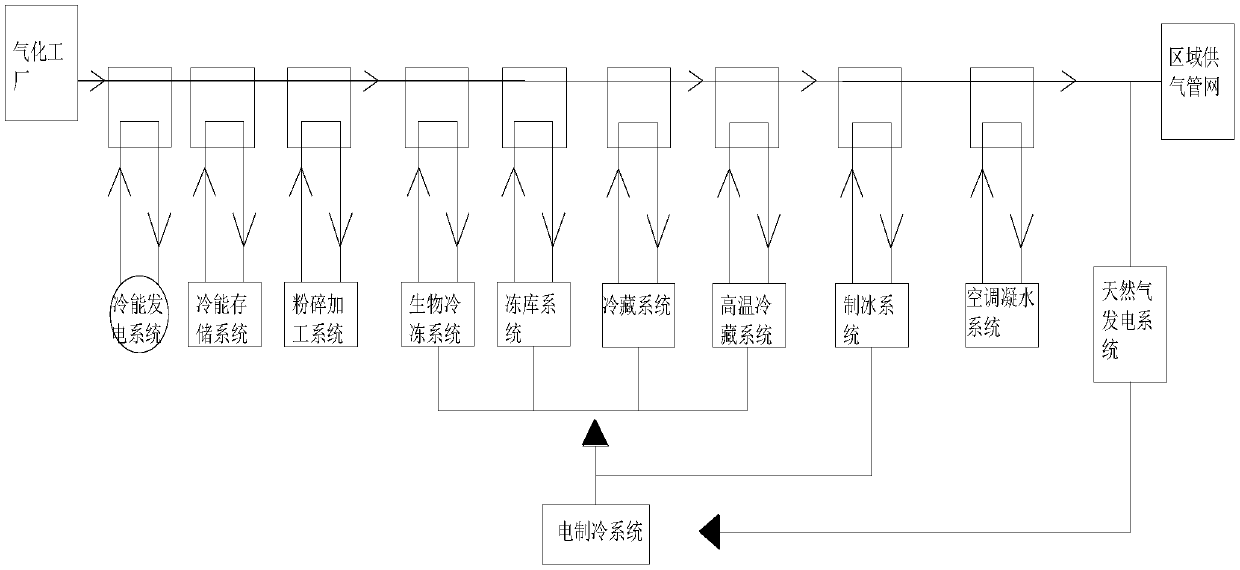

LNG centralized gasification comprehensive utilization system and method

ActiveCN106195625BSolve the problem of upgrading and upgradingAvoid lostSolidificationLiquefactionProcess engineeringRefrigeration

The invention provides an LNG concentrated gasification and comprehensive utilization system and method. The system comprises an LNG storage center. Liquefied natural gas in the LNG storage center is switched into an area gas supply pipe network after being gasified through a gasification plant. The terminal of the area gas supply pipe network is connected with various categories of area gas utilization users. The gasification plant is further connected with a cold energy comprehensive utilization system. The cold energy comprehensive utilization system comprises a main heat exchange system and exchanges cold energy with the gasification plant through the main heat exchange system. A smashing processing system, a biological refrigeration system, a freezer system and a high-temperature cold storage system are sequentially connected to the main heat exchange system from low temperature to high temperature. According to the method, by starting and stopping all the systems, the optimal utilization state is achieved, and the green and sustainable application mode is truly achieved.

Owner:重庆齐祥新能源投资有限公司

Liquid poured fermentation tower with woven cloth packing system

InactiveCN103421672BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

Owner:ZHONGYUAN ENGINEERING COLLEGE

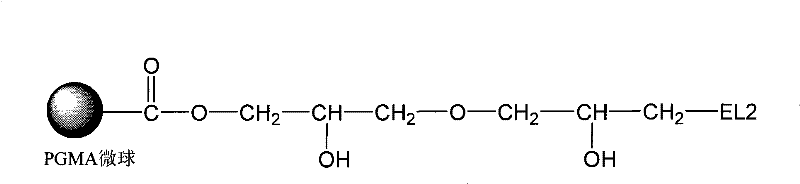

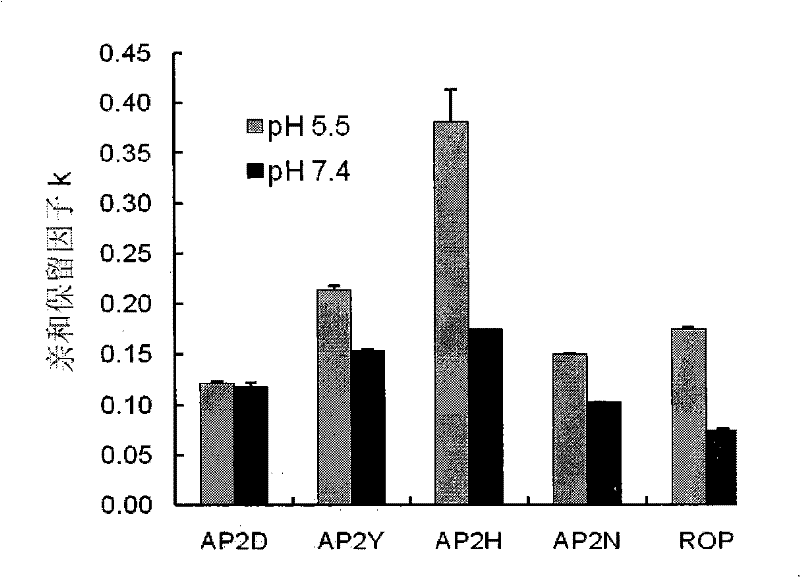

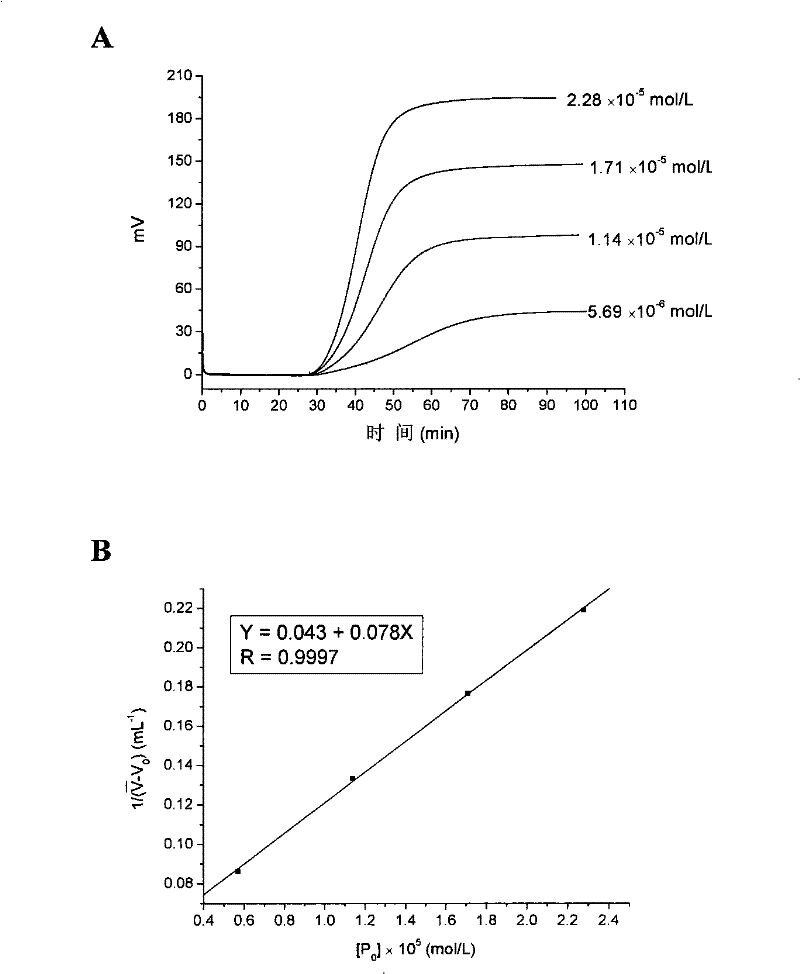

Polypeptide for detecting human cancer cells, and application thereof

ActiveCN101781357BImprove bindingStrong specificityPeptide/protein ingredientsPharmaceutical non-active ingredientsAlkaneHuman cancer

The invention discloses polypeptide for detecting human cancer cells, and application thereof. The polypeptide consists of 1), 2), 3) or 4) as follows: 1) at least five amino acid residues from an amino terminal of a sequence 1 in a sequence table; 2), at least five amino acid residues from an amino terminal of a sequence 2 in the sequence table; 3) at least five amino acid residues from an aminoterminal of a sequence 3 in the sequence table; and 4) at least five amino acid residues from an amino terminal of a sequence 4 in the sequence table, wherein the polypeptide also contains substituent groups which are akoxyl groups, alkane acyl groups or amide groups, and the amino acid residues forming the polypeptide are L-type and / or D-type. The polypeptide overcomes the disadvantages of troublesome preparation, poor stability, high expenses, weak penetrating power and the like of antibodies and other biological preparations, and can be used for preparing diagnostic reagents and therapeutic medicaments for liver caner and other malignant tumors.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Liquid poured fermentation tower with knitted cloth packing system

InactiveCN103421674BIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyFermentation broth

The invention discloses a liquid spraying fermentation tower provide with a knitted fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the knitted fabric type filling system. The knitted fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the knitted fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the knitted fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar with liquid pouring fermentation tower with knitted cloth packing system

InactiveCN103421669BIncreased unit utilizationMake up for expensesVinegar preparationPolymer scienceMechanical engineering

A method for producing vinegar using a liquid pouring fermentation tower with a knitted cloth packing system, the fermentation step adopts a liquid pouring fermentation tower with a knitted cloth packing system, and the liquid pouring fermentation tower with a knitted cloth packing system includes Tower body, the top of the tower body is provided with a shower tray, the upper part of the tower body is a knitted cloth packing system, the lower part is a fermentation liquid, and a false bottom is provided between the packing system and the fermentation liquid; the knitted cloth packing system includes a The roller in the tower and the knitted fabric wound on the roller, one end of the knitted fabric is connected to the unwinding device, and the other end is connected to the winding device. The invention uses a knitted cloth-type packing system, utilizes the directional movement of the knitted cloth, and takes away the "sea moon"-bacterial cellulose produced by the fermentation of liquid poured vinegar and its aggregated bacterial cellulose film system. The method completely solves the problem that the film blocks the gaps between the filling materials, and the air and fermentation liquid cannot flow normally, so that the fermentation production of vinegar is terminated.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A family management system for patients with hyperuricemia and gout

ActiveCN105373702BMake up for expensesShorten the timeMedical communicationInstrumentsHome basedMedical treatment

A family management system for patients with hyperuricemia and gout and its management method, relating to a health management system. In order to solve the drawbacks of the existing traditional health management model, the present invention provides a family management system for patients with hyperuricemia and gout The patient management system is characterized in that the management system includes a detection instrument, a patient client, a database, a central processor and a doctor client; the beneficial effect of the present invention is to make up for the shortcomings of the lack of private doctors and the high cost of payment It is suitable for doctors in a large number of medical institutions to manage hyperuricemia and gout patients, saving doctors' time and improving efficiency.

Owner:深圳市免疫医学转化(龙华)研究院

Liquid spraying fermentation tower provided with woven fabric filling system

InactiveCN103421672AIncreased unit utilizationMake up for expensesBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryTower

The invention discloses a liquid spraying fermentation tower provided with a woven fabric type filling system. The liquid spraying fermentation tower comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The filling system is the woven fabric type filling system. The woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that bacterial cellulose and bacterial cellulose membrane system aggregated thereby, which are produced by fermentation production of liquid sprayed vinegar, are taken away. The problem is thoroughly solved that membranes block the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid. Because high value of the bacterial celluloses is determined by functionality of the bacterial celluloses, the woven fabric filler overgrowing with the bacterial celluloses can be sold as a specific commodity or developed secondarily and processed elaborately, so that the cost for buying the woven fabric filler is made up, and thus cost is substantially saved and a new profit is brought.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing bacterial cellulose by liquid spraying fermentation tower filled with woven fabric

InactiveCN103421858AMake up for expensesLow costBioreactor/fermenter combinationsBiological substance pretreatmentsWoven fabricMembrane configuration

A method for producing bacterial cellulose by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed vinegar, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of vinegar is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with non-woven fabric

InactiveCN103416544BIncreased unit utilizationMake up for expensesTea extractionLiquid statePulp and paper industry

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with non-woven fabric is disclosed. The liquid spraying fermentation tower filled with non-woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with non-woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a non-woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The non-woven fabric filling system comprises a roller disposed in the tower and non-woven fabric wound on the roller, one end of the non-woven fabric is connected with an unreeling apparatus and the other end of the non-woven fabric is connected with a winding apparatus. The non-woven fabric filling system is employed and the orientation movement of the non-woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with knitted fabric

InactiveCN103416545BIncreased unit utilizationMake up for expensesTea extractionPulp and paper industryKombucha

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar with liquid pouring fermentation tower with non-woven fabric packing system

InactiveCN103421668BIncreased unit utilizationMake up for expensesVinegar preparationBiotechnologyEngineering

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing vinegar with liquid pouring fermentation tower with woven cloth packing system

InactiveCN103421667BIncreased unit utilizationMake up for expensesVinegar preparationPolymer scienceMechanical engineering

A method of liquid pouring and fermentation tower of a weave -type filler system to produce vinegar. Its fermentation steps adopt a liquid pouring fermentation tower with woven fabric fille.The fermentation tower includes the tower body. The top of the tower is equipped with a golf dish. The upper part of the tower is a woven -type filler system.The filler system includes rolling wheels set in the tower and the woven fabric wrapped around the roller. One end of the machine fabric is connected to the roll device, and the other end is connected to the roll -up device.The present invention uses a weave-type filler system, and uses the directional movement of the weaving of the machine to take away the "sea moon"-bacterial cellulose and the bacterial cellulose film system produced by liquid pouring vinegar fermentation production.Thoroughly solve the gap between the film blocking the filling material, the air and fermentation solution cannot flow normally to terminate the problem of fermentation to produce vinegar.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing kombucha beverage by liquid spraying fermentation tower filled with woven fabric

InactiveCN103416543BIncreased unit utilizationMake up for expensesTea extractionLiquid stateEngineering

A method for producing kombucha beverage by a liquid spraying fermentation tower filled with woven fabric is disclosed. The liquid spraying fermentation tower filled with woven fabric is employed in a fermentation step. The liquid spraying fermentation tower filled with woven fabric comprises a tower body, wherein a return spray plate is disposed on the top portion in the tower body, a woven fabric filling system is disposed on the upper portion in the tower body, a fermentation liquid is disposed on the lower portion of the tower body, and a false bottom is disposed between the filling system and the fermentation liquid. The woven fabric filling system comprises a roller disposed in the tower and woven fabric wound on the roller, one end of the woven fabric is connected with an unreeling apparatus and the other end of the woven fabric is connected with a winding apparatus. The woven fabric filling system is employed and the orientation movement of the woven fabric is utilized, so that Haiyue produced by fermentation production of liquid sprayed kombucha, which means bacterial cellulose and bacterial cellulose membrane system aggregated thereby, is taken away. The method helps to thoroughly solve the problem that the membrane blocks the gaps in the filler and then the fermentation production of kombucha beverage is terminated because of the failure of normal flow of the air and the fermentation liquid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com