Method for producing kombucha beverage by liquid spraying fermentation tower filled with woven fabric

A technology of liquid pouring fermentation and woven cloth, which is applied in the fields of textile, microorganism, food and beverage, and fermentation, can solve the problems of increasing production cost, time-consuming and polluting the environment, and achieves the effect of saving cost and improving unit utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

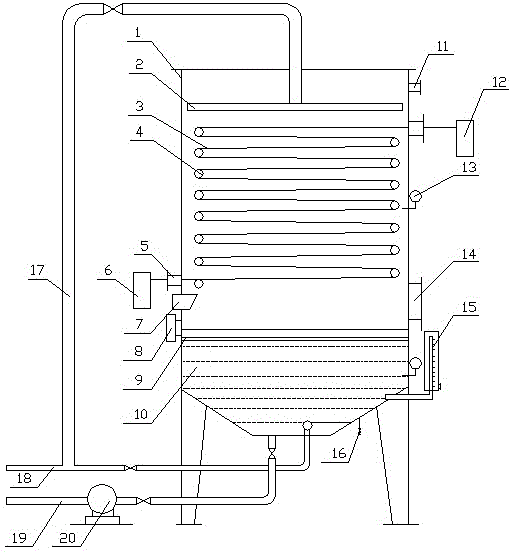

Image

Examples

Embodiment 1

[0032] The method for producing the kombucha beverage with the liquid pouring fermentation tower of the woven cloth type filler of the present embodiment comprises the following process steps:

[0033] (1) Preparation of sugar tea liquid: take raw tea leaves / sugar / water ratio 1 / 10 / 100, brew tea leaves and sugar with boiling water, keep boiling slightly for 1~10 minutes, let the tea leaves settle, take the supernatant, Sterilize at 108°C-121°C for 10-25 minutes, and set aside;

[0034] 2) Prepare the liquid bacterial liquids of Saccharomyces cerevisiae and Acetobacter xylinum respectively:

[0035] A. Preparation of Saccharomyces cerevisiae liquid: use an inoculation loop to take a ring of purified Saccharomyces cerevisiae bacteria lawn from the slant of the glucose yeast extract (GYC) solid medium to the sterilized and cooled liquid containing glucose yeast extract Place the test tube of the culture medium in an incubator at 25°C to 35°C for 3 to 7 days; obtain a liquid bacte...

Embodiment 2

[0051] The method for producing the kombucha beverage with the liquid pouring fermentation tower of the woven cloth type filler of the present invention comprises the following process steps:

[0052] (1) Preparation of sugar tea liquid: take the raw material tea leaves / sugar / water ratio 1 / 10 / 100, brew tea leaves and sugar with boiling water, keep boiling for 1 minute, let the tea leaves settle, take the supernatant, and brew at 108 Sterilize at ℃ for 25 minutes, and set aside;

[0053] 2) Prepare the liquid bacterial liquids of Saccharomyces cerevisiae and Acetobacter xylinum respectively:

[0054] A. Preparation of Saccharomyces cerevisiae liquid: use an inoculation loop to take a ring of purified Saccharomyces cerevisiae bacteria lawn from the slant of the glucose yeast extract (GYC) solid medium to the sterilized and cooled liquid containing glucose yeast extract culture medium in a test tube, placed in an incubator at 25°C for 7 days; to obtain a liquid bacterial liquid ...

Embodiment 3

[0062] The method for producing the kombucha beverage with the liquid pouring fermentation tower of the woven cloth type filler of the present invention comprises the following process steps:

[0063] (1) Preparation of sugar tea liquid: take the raw material tea leaves / sugar / water ratio 1 / 10 / 100, brew tea leaves and sugar with boiling water, keep boiling for 10 minutes, let the tea leaves stand still, take the supernatant, and brew at 121 Sterilize at ℃ for 10 minutes, and set aside;

[0064] 2) Prepare the liquid bacterial liquids of Saccharomyces cerevisiae and Acetobacter xylinum respectively:

[0065] A. Preparation of Saccharomyces cerevisiae liquid: use an inoculation loop to take a ring of purified Saccharomyces cerevisiae bacteria lawn from the slant of the glucose yeast extract (GYC) solid medium to the sterilized and cooled liquid containing glucose yeast extract culture medium in a test tube, placed in an incubator at 35°C for 3 days; to obtain a liquid bacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com