Turnover type cooling box and using method thereof

A cooling box and flip-type technology, which is applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve the problems of poor penetration effect and poor cold pile treatment effect, and achieve the improvement effect , reduce the time and dosage of medicine, improve the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

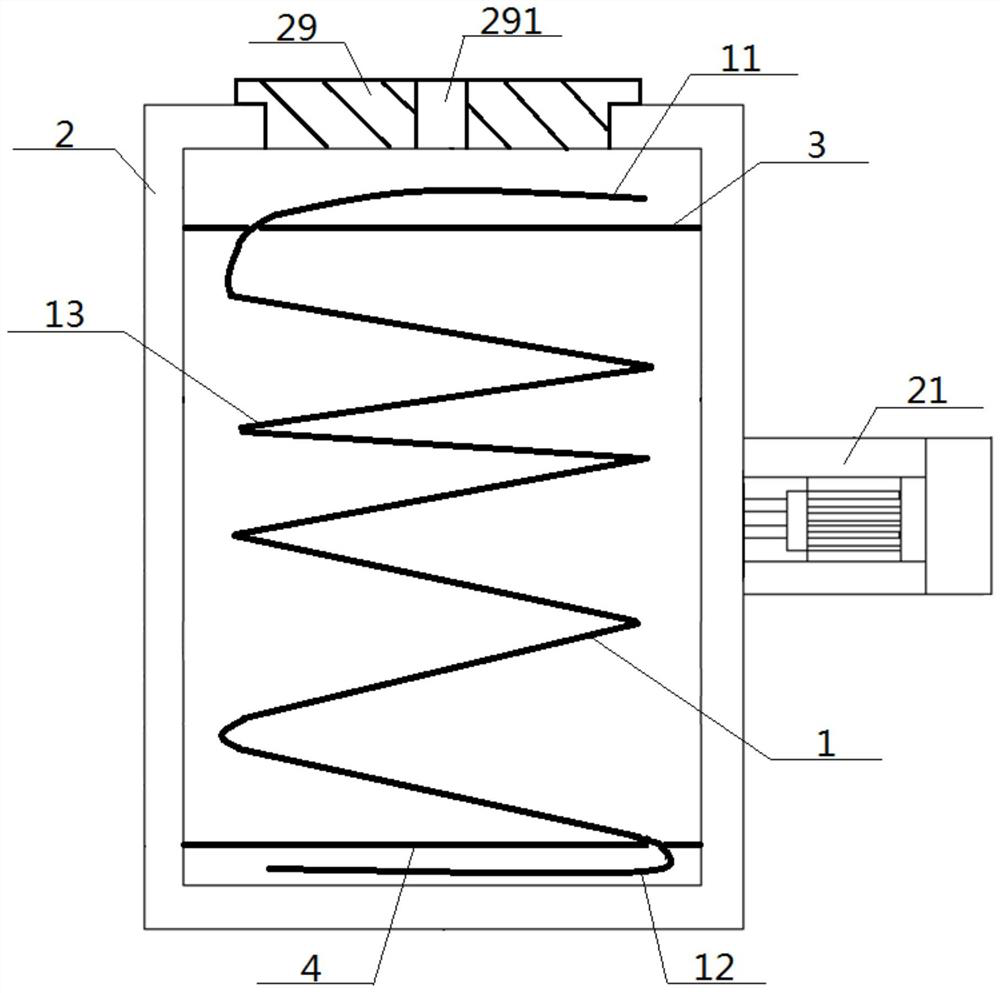

[0063] see figure 1 — Figure 11 , a flip-type cooling box, comprising an outer box body 2 and the cold stack liquid arranged inside the cold stack liquid, the textile fabric 1 to be treated is arranged in the cold stack liquid; the inside of the outer box body 2 is provided with a top clamp frame 3 and Bottom clamp frame 4, the top clamp frame 3 is set near the top of the outer box body 2, the bottom clamp frame 4 is set near the bottom of the outer box body 2, the head end 11 of the textile 1 is clamped in the top clamp frame 3 , the tail end 12 of the textile 1 is clamped in the bottom clamp frame 4, and the position between the head end 11 and the tail end 12 on the textile 1 is a concentrated part 13, and the concentrated part 13 is arranged on the top clamp frame 3 and the bottom clamp frame 4. Between the clamping frames 4, and the textile 1 is in contact with the cold stack liquid; the outer side of the outer box 2 is fixedly connected to the output end of the driving...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

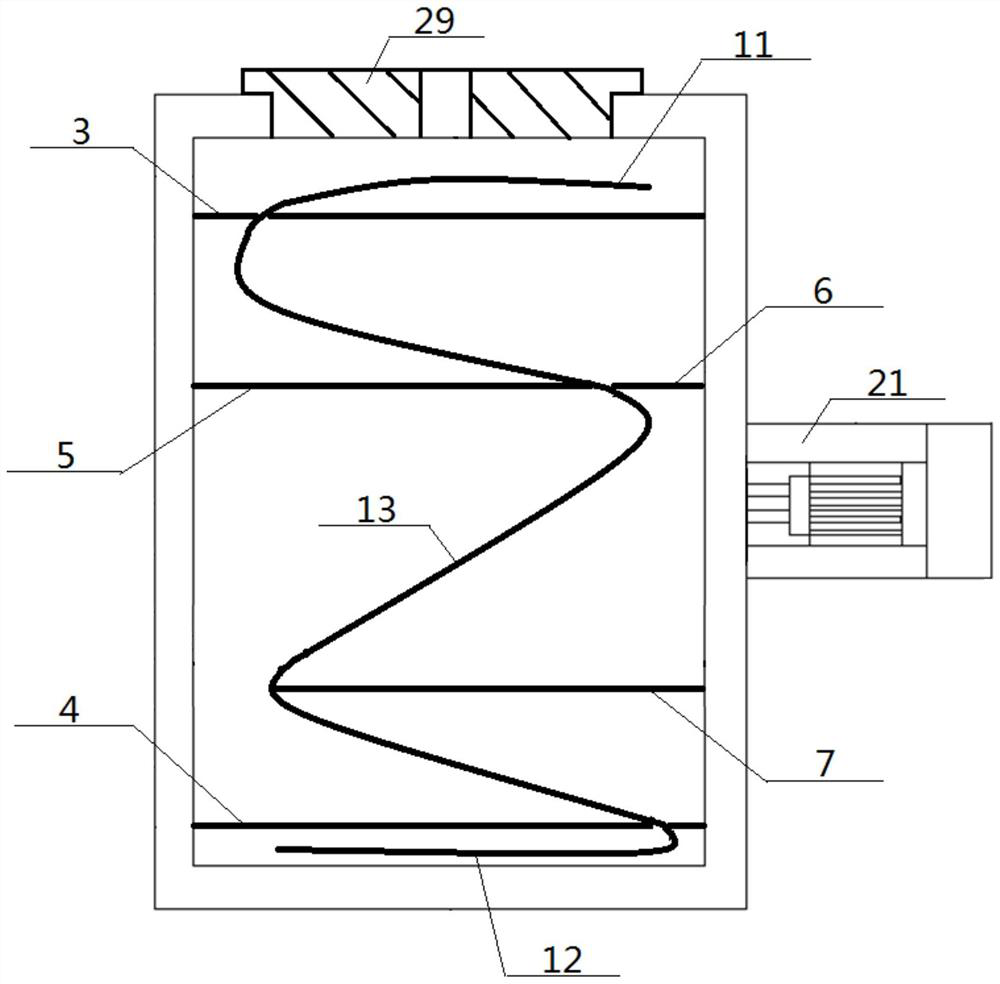

[0067] The outer box 2 is also provided with a middle top device 5, the number of the middle top device 5 is at least one, and the type of the middle top device 5 is any one or any combination of the middle clamp frame 6 and the support frame 7 ;

[0068] The central part of the middle clamp frame 6 clamps the concentrated part 13;

[0069] The inner end of the support frame 7 is connected to the inner side of the outer box body 2 , and the outer end of the support frame 7 supports the centralized part 13 laterally.

Embodiment 3

[0071] Basic content is the same as embodiment 2, the difference is:

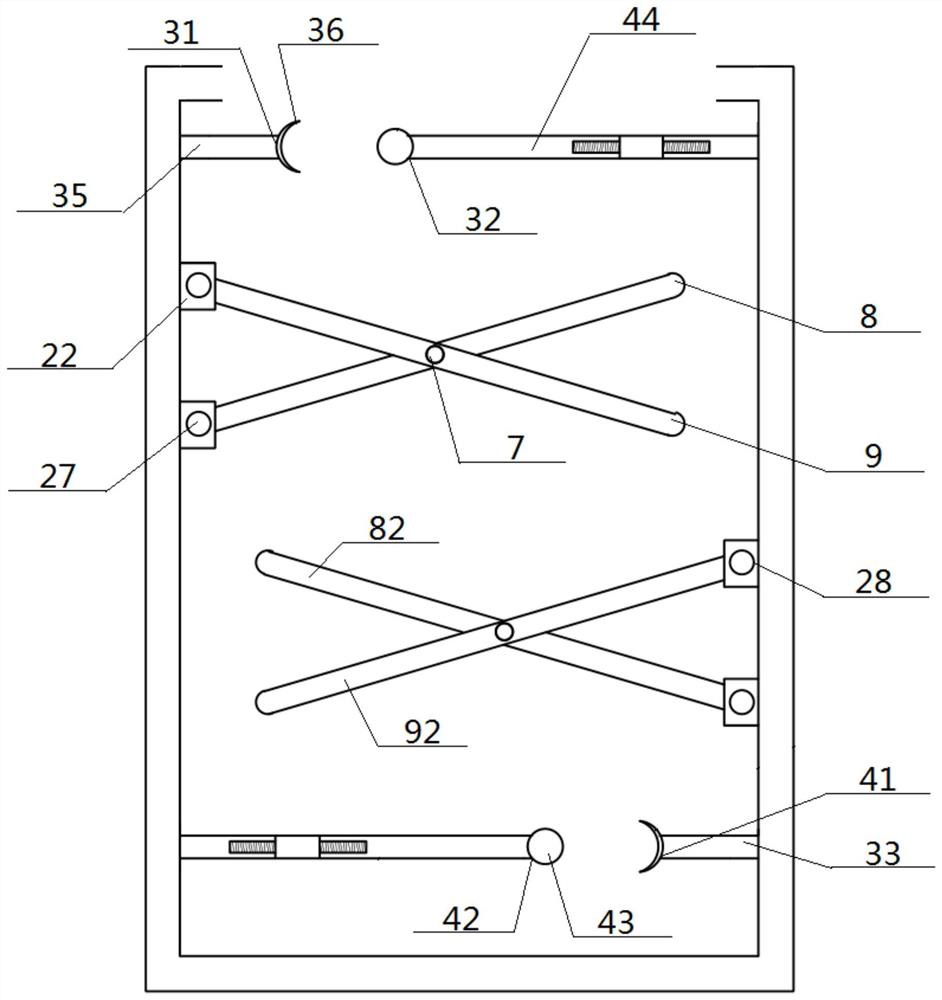

[0072] The top clamp frame 3 includes a left fixed part 31 and a right telescopic part 32 clamped and matched with it, and the bottom clamp frame 4 includes a right fixed part 41 and a left telescopic part 42 clamped and matched with it; Part 31, the structure of right fixing part 41 is consistent, all comprises the front fixing unit 33, rear fixing unit 34 that are arranged parallel to each other; Groove 36, the inner end of described connecting side bar 35 is connected with the inner side of outer box body 2, the outer end of connecting side bar 35 is connected with the inner end of butt joint groove 36, the outer end of butt joint groove 36 is connected with The right telescoping part 32 is clamped and fitted in the opposite direction. The right telescopic part 32 and the left telescopic part 42 have the same structure, and both include a docking longitudinal rod 43, a front telescopic rod 44 and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com