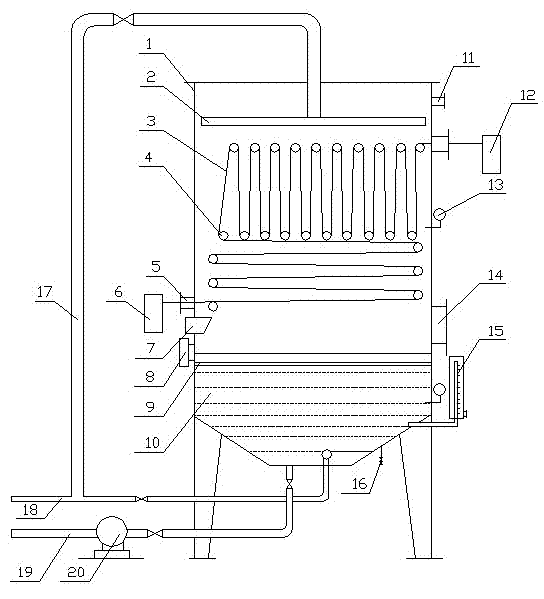

Method for producing vinegar with liquid pouring fermentation tower with knitted cloth packing system

A technology of liquid pouring fermentation and knitting cloth type, which is applied in the fields of textile, fermentation, microorganism, food and beverage, can solve the problems of increasing production cost, time-consuming and polluting the environment, and achieves the effect of saving cost and improving unit utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Liquefaction of raw materials: Take 1000kg of rice, add 1500kg of water, soak for 6 hours, and grind it into slurry by grinding wheel.

[0029] (2) Alcoholic fermentation: Add 3kg of amylase to the slurry, raise the temperature to 92°C, keep it warm for 15 minutes, boil it, and pump it into the alcohol fermentation tank. Add water to adjust the concentration to 9.5°Bé and adjust the temperature to 32°C. Add 2.4 kg of 50,000 units / g of glucoamylase and 2 kg of active dry yeast, mix well, and ferment at 30-34°C for 5 days.

[0030] (3) Plate and frame filter press: the fermented wine mash is filtered through a plate and frame to obtain sake liquid.

[0031] (4) Acetic acid fermentation: add water to the above-mentioned sake liquid to adjust the alcohol content to 6.5% (v / v), insert 800kg of acetic acid bacteria (AS1.41), and spray intermittently on the filler system made of knitted cloth after sterilization , so that the filling material absorbs a large amount of fe...

Embodiment 2

[0043] (1) Raw material liquefaction: take 1000kg of corn, add 1500kg of water, soak for 6 hours, and grind it into slurry by grinding wheel.

[0044] (2) Alcoholic fermentation: Add 3kg of amylase to the slurry, raise the temperature to 92°C, keep it warm for 15 minutes, boil it, and pump it into the alcohol fermentation tank. Add water to adjust the concentration to 9.5°Bé and adjust the temperature to 32°C. Add 2.4 kg of 50,000 units / g of glucoamylase and 2 kg of active dry yeast, mix well, and ferment at 30-34°C for 5 days.

[0045] (3) Plate and frame filter press: the fermented wine mash is filtered through a plate and frame to obtain sake liquor.

[0046] (4) Acetic acid fermentation: add water to the above-mentioned sake liquid to adjust the alcohol content to 6.5% (v / v), insert 800kg of acetic acid bacteria (AS1.41), and spray intermittently on the filler system made of knitted cloth after sterilization , so that the filling material absorbs a large amount of fermen...

Embodiment 3

[0051] Different from Example 1, the diameter of the rollers is 0.02 meters, and the distance between the two rollers is 10 meters.

[0052] The knitted fabric is a glass fiber knitted fabric with a thickness of 3 mm, and the filling volume is 1 / 20 of the volume of the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com