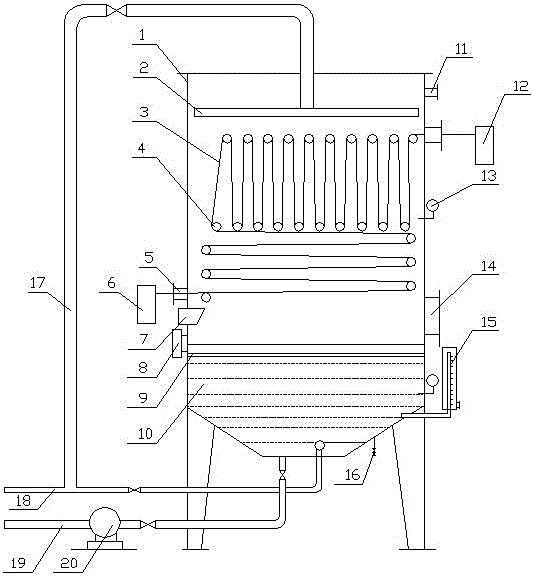

Liquid poured fermentation tower with knitted cloth packing system

A technology of liquid pouring fermentation and knitted fabrics, which is applied in the fields of textile, food and beverage, microorganism, and fermentation. It can solve the problems of inability to carry out long-term cycle production, increase production costs, and pollute the environment, so as to improve unit utilization and save costs. , high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] The diameter of the roller that is different from Example 1 is 0.008 meters, and the distance between the two rollers is 5 meters.

[0025] The knitted fabric is a polyester needle-punched knitted fabric with a thickness of 3 mm, and the filling volume is 9 / 10 of the volume of the tower.

[0026] All the other are with the technical scheme of embodiment 1.

Embodiment 3

[0028] Different from Example 1, the diameter of the rollers is 0.02 meters, and the distance between the two rollers is 10 meters.

[0029] The knitted fabric is a glass fiber knitted fabric with a thickness of 3 mm, and the filling volume is 1 / 20 of the volume of the tower.

Embodiment 4

[0031] The diameter of the rollers is 0.03 meters, and the distance between the two rollers is 0.1 meters.

[0032] The knitted fabric is a basalt fiber knitted fabric with a thickness of 3 mm, and the filling volume is 1 / 3 of the volume of the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com