Solvent replacement condensation tower and method for producing anhydrous formaldehyde

A solvent and condensation technology, which is applied in the field of solvent displacement condensation tower and production of anhydrous formaldehyde, can solve the problem of low yield of formaldehyde in one pass, achieve the effect of increasing yield of formaldehyde in one pass, simple structure, and improved unit utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

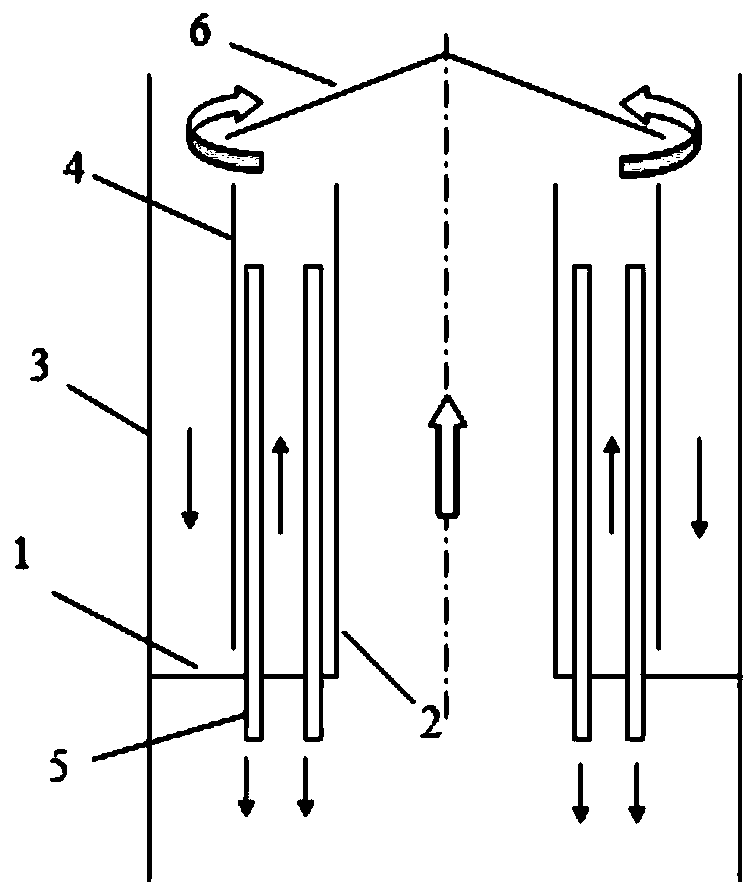

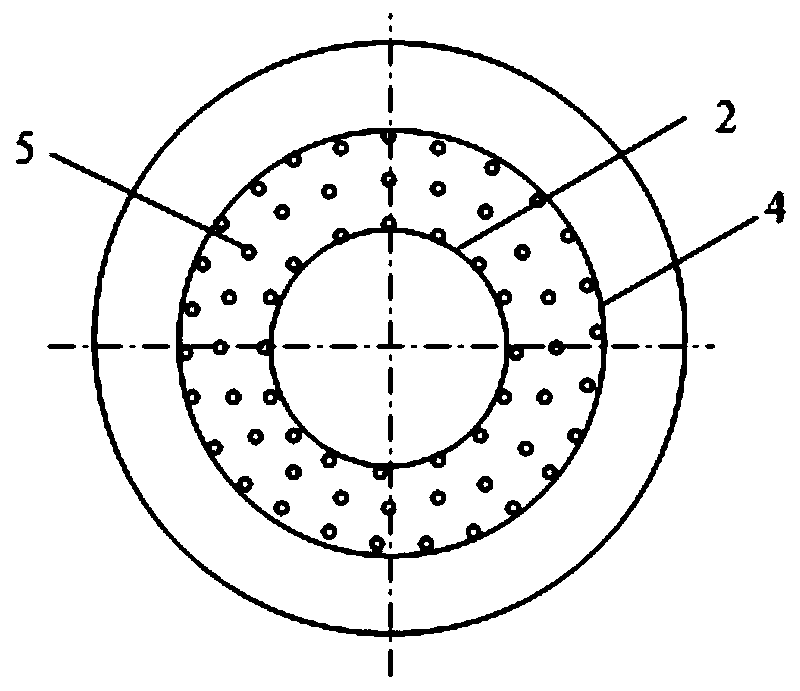

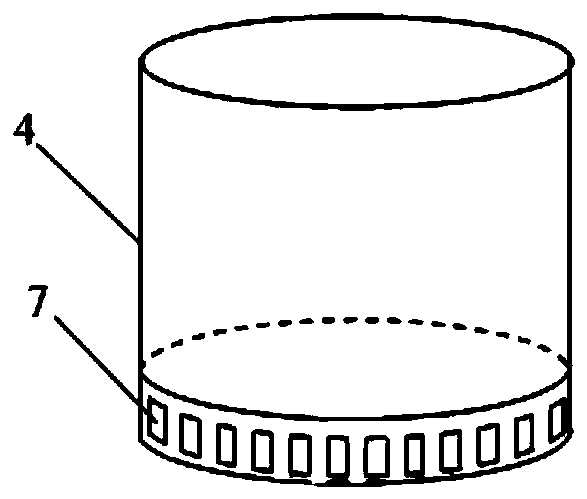

[0052] as attached figure 1 , 2 , As shown in 3, a ring-shaped diversion distribution groove is set in a rectification tower with an inner diameter of φ200mm. The specific dimensions are: the outer diameter of the annular plate 1 is φ200mm, the inner diameter is φ60mm, the diameter of the circular baffle 4 is φ140mm; the height of the circular air riser 2 and the circular baffle 4 is 240mm, and the inner diameter of the downcomer 5 is 4mm , close to the outer side of the circular riser 2 and the inner side of the circular baffle 4, a total of 18 pieces are arranged in two circles, and the height of the downcomer 5 is 180mm; the openings 7 at the bottom of the circular baffle 4 are circular holes at equal intervals, and the circular holes The diameter is 8mm, 20 in total, and the hole spacing is 22mm.

[0053] During installation, assemble the annular diversion distribution groove of the above structure and CY700 corrugated wire mesh packing into a tower section with flange c...

Embodiment 2

[0055] as attached figure 1 , 2 As shown in , 3, another annular diversion distribution groove is set in a rectification tower with an inner diameter of φ200mm. The specific dimensions are: the outer diameter of the annular plate 1 is φ200mm, the inner diameter is φ60mm, the diameter of the circular baffle 4 is φ140mm; the height of the circular air riser 2 and the circular baffle 4 is 500mm, and the inner diameter of the downcomer 5 is 4mm , close to the outer side of the circular riser 2 and the inner side of the circular baffle 4, a total of 18 pieces are arranged in two circles, and the height of the downcomer 5 is 440mm; the openings 7 at the bottom of the circular baffle 4 are circular holes at equal intervals. The diameter is 8mm, 20 in total, and the hole spacing is 22mm.

[0056] During installation, assemble the annular diversion distribution groove of the above structure and CY700 corrugated wire mesh packing into a tower section with flange connections at both en...

Embodiment 3

[0058] Place one section of the tower section assembled in Example 1 on the upper end, place two identical sections of the tower section assembled in Example 2 in the middle and the lower end, and rely on flange connection to form a main tower section of a solvent displacement condensation tower, equipped with a top condenser 14. Phase separation tank 15 and tower bottom reboiler 19. The condenser 14 has a heat transfer area of 4 m 2 and is cooled with circulating water; the reboiler 19 has a heat transfer area of 5 m 2 and is heated with heat transfer oil; the volume of the phase separation tank 15 is 75 L.

[0059] Attached Figure 4 Experiments are carried out on the process of the above-mentioned technology, operated under normal pressure, the concentration of formaldehyde solution is 48.5%, the flow rate is 20kg / h, the feed temperature is 80°C, and the feed position is the top of the second tower section; the solvent is benzyl alcohol, and the flow rate is 48kg / h , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com