Preparation method of full-tailings paste

A full tailings and system technology, applied in the mining field, can solve the problems affecting the filling efficiency of the paste, and achieve the effects of increasing mine income, improving stability, and stabilizing the concentration of the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0018] The present invention provides a whole tailings paste preparation method aiming at the problems such as the deficiency of the existing paste preparation concentration control method.

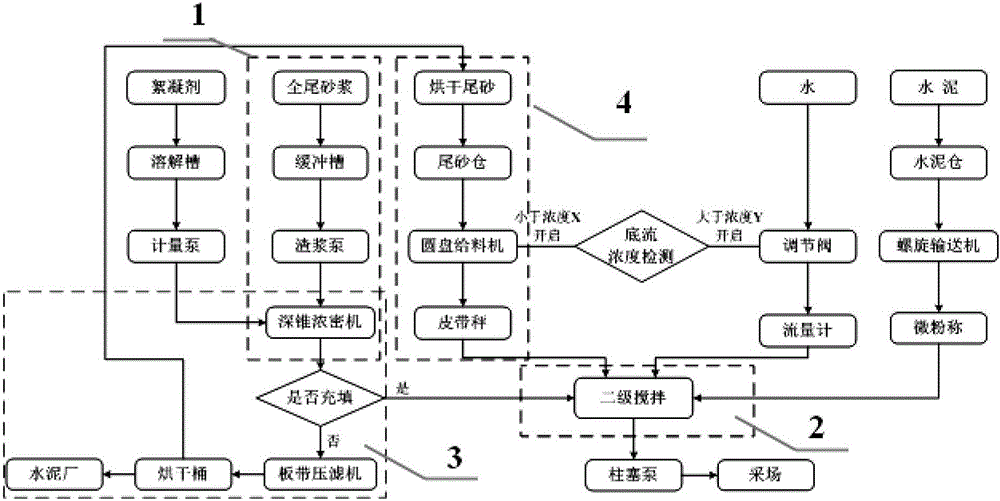

[0019] Such as figure 1 As shown, is the flow diagram of the method, using the method shown in the flow diagram to fill a copper-zinc ore with full tailings paste.

[0020] There are provincial highways and section expressways passing above a certain copper-zinc mine, and the mining area is located in a forest protection area. In order to prevent the surface subsidence caused by ore body mining and affect the normal operation of the road, at the same time, in order to prevent excessive tailings from the mining area from occupying the forest protection area After re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com