Gas optimization scheduling device of iron and steel enterprise

A technology for optimizing dispatching and dispatching devices, which is applied in the energy industry, climate sustainability, electrical program control, etc., and can solve the problems of not considering the surplus of gas and the purchase cost of gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

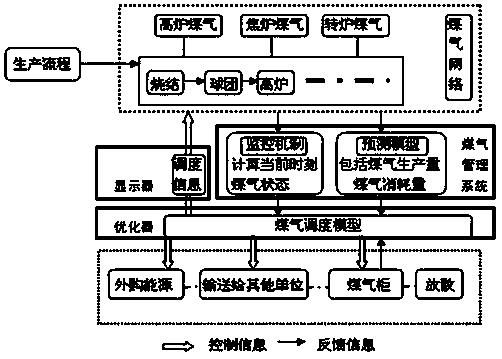

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

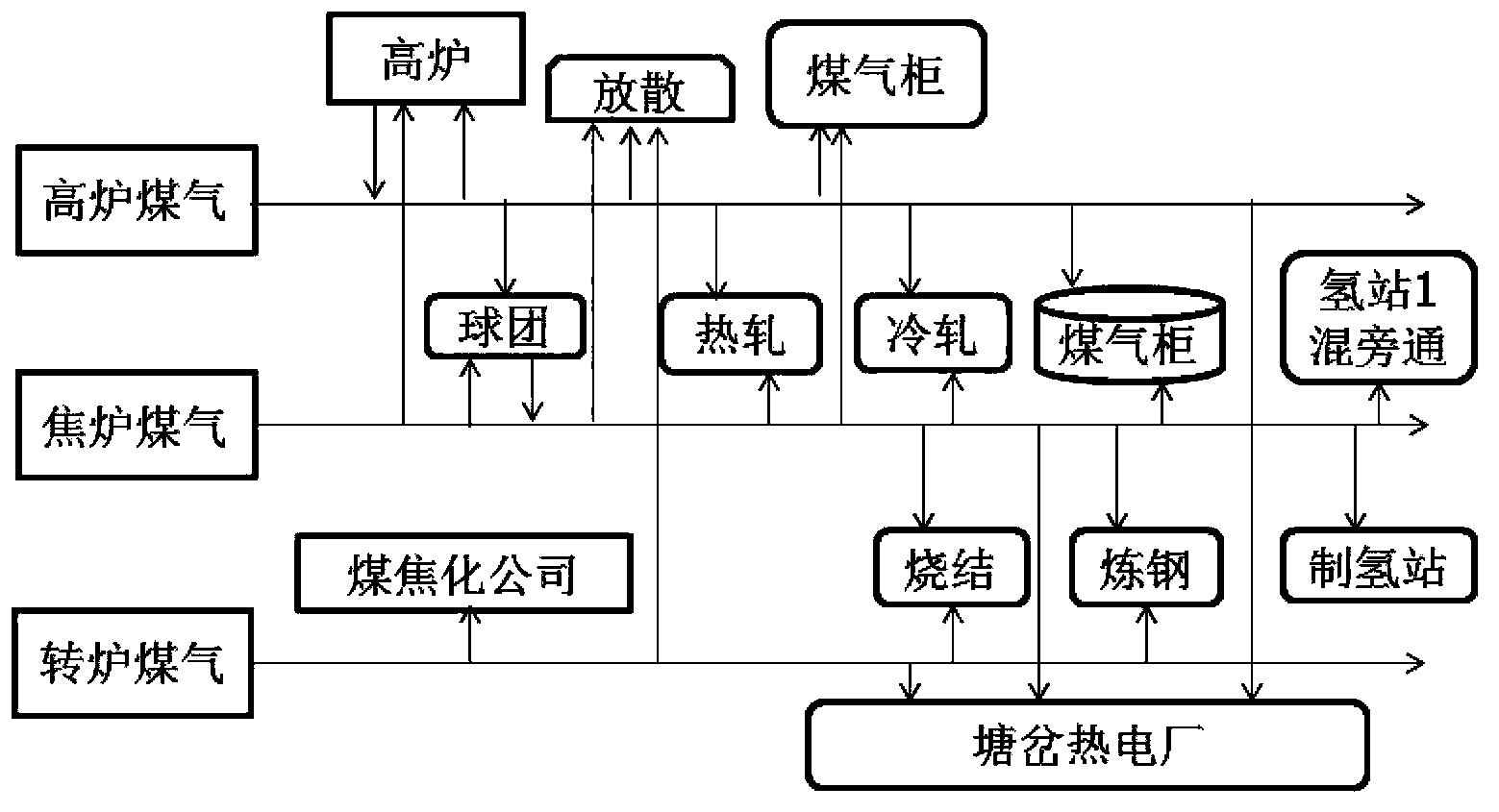

[0056] First of all, it is necessary to investigate the connection between processes and gas in iron and steel enterprises. These processes include hydrogen station mixing bypass, coal coking company, hot rolling plant, cold rolling plant, export to old areas, hydrogen station, steelmaking, hot blast stove, Pellet, sintering and Tangcha Thermal Power Plant, and their process numbers are incremented from zero, and the connections are shown in Table 1.

[0057]

[0058] Among them, there are 4 communication methods for the connection between the process and the gas. They are the No. 0 connection mode, that is, only coke oven gas can provide heat for the process, and the No. 1 connection mode is that the process can be jointly provided by coke oven gas and blast furnace gas. The No. 2 Unicom mode is that the coke oven gas and the converter gas can jointly provide heat for the process, and the No. 3 Unicom mode means that the process can provide the heat demand by the three type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com