Zero-drainage technology and equipment for treatment of wastewater with high salt content

A waste water treatment, high salt content technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as danger, scaling, easy clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

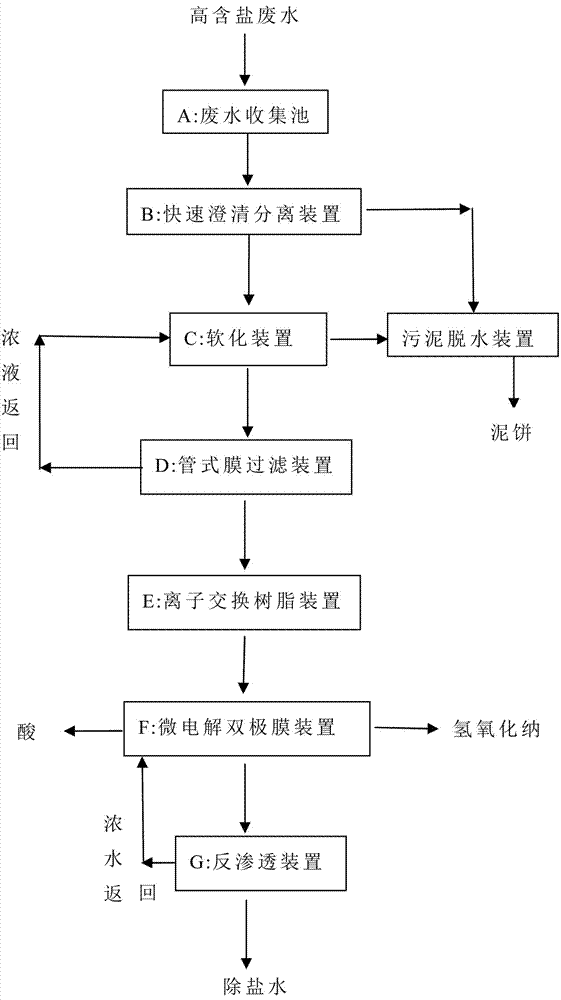

[0036] like figure 1Shown is an embodiment of a zero-discharge process for micro-electrolysis treatment of high-salt wastewater according to the present invention. Including the following steps:

[0037] A. Wastewater collection pool: Wastewater is drained in stages, and the water quality fluctuates greatly. The uniform water quality is adjusted here.

[0038] B. Rapid clarification and separation device: flocculate and group the suspended solids in high-salt wastewater, and quickly separate them from the wastewater, and compress the suspended solids into mud cakes.

[0039] C. Softening device: The supernatant liquid in the rapid clarification and separation device enters the device, and is treated by dosing to convert the magnesium and calcium in the water body from the ion state to the solid particle state.

[0040] D. Tubular membrane filtration device: separate the suspended solids in the softening device from the water, return the concentrated water from the tubular me...

Embodiment 2

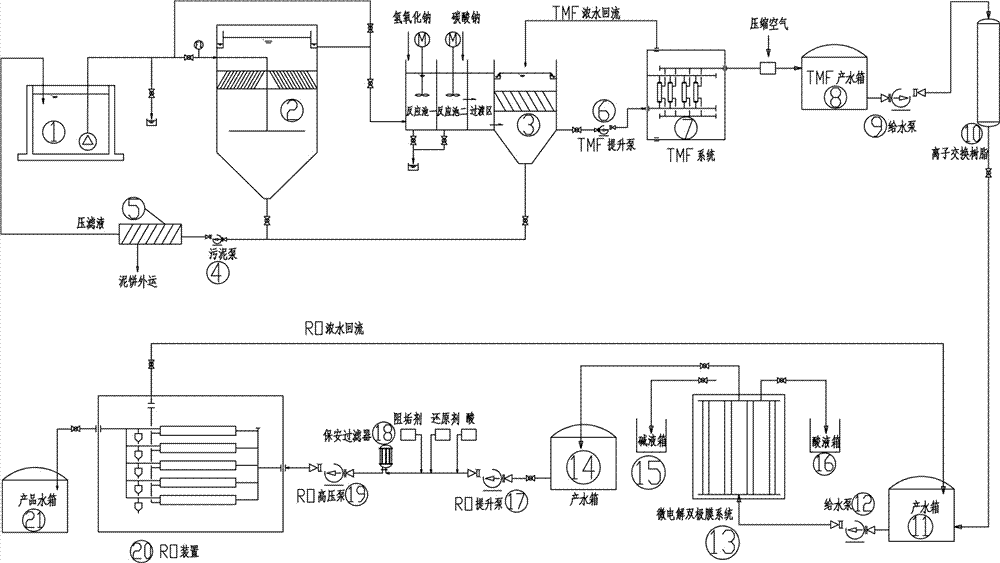

[0045] like figure 2 Shown is an embodiment of special equipment for a zero-discharge process of micro-electrolysis treatment of high-salt wastewater according to the present invention.

[0046] The devices and components installed in sequence according to the direction of water flow include: waste water collection tank 1 connected with the incoming water of high-salt waste water, rapid clarification and separation device 2, softening device 3, TMF lift pump 6, TMF system 7, TMF water production tank 8, ion Exchange feed water pump 9, ion exchange resin device 10, ion exchange water production tank 11, micro electrolysis feed water pump 12, micro electrolysis bipolar membrane device 13, intermediate production water tank 14, reverse osmosis RO lift pump 17, security filter 18, high pressure pump 19. Reverse osmosis RO device 20 and final product water tank 21; the waste water collection tank 1 is composed of a collection tank and a submersible pump located in the collection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com