Salt-containing organic wastewater recycling and zero discharge process

A technology of organic waste water and recycling, applied in the direction of inorganic chemistry, water pollutants, multi-stage water treatment, etc., can solve problems such as failure to meet physical and chemical indicators of salt, ecological environment damage, and hinder zero discharge of high-salt waste water, and achieve reduction The effect of corporate environmental risk, reduction of hazardous waste disposal fees, and improvement of recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the present invention, main water quality index is the Na of 3160mg / L + , 2287 mg / L Cl - , 4635mg / L of SO 4 2- , 240ppm Ca 2+ , 160ppm Mg 2+ , COD of 400ppm, after a series of pretreatment processes in raw water, the removal rate of SS in wastewater is 96%, the removal rate of total hardness is 92%, Ca 2+ , Mg 2+ The treatment rate is 97%, the COD removal rate is 80%, SDI<3, TDS<10.5g / L.

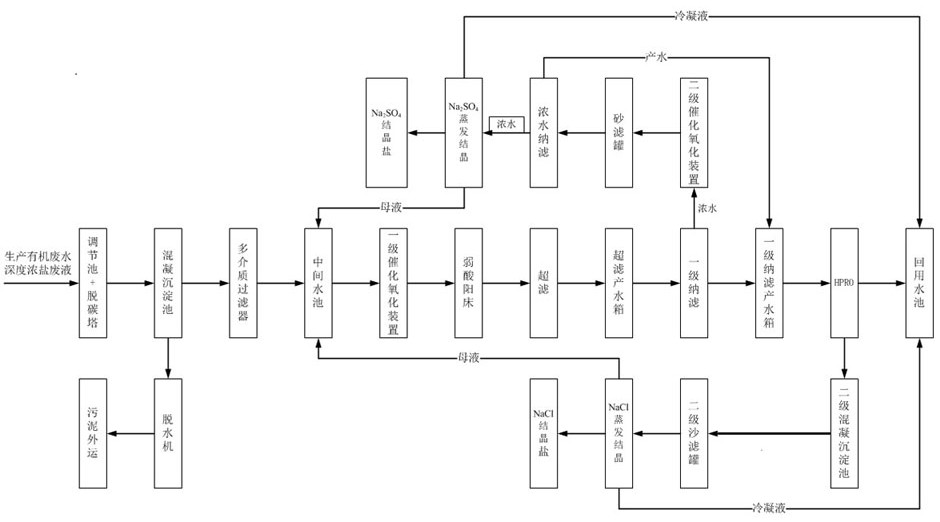

[0033] Such as figure 1 , a saline organic waste water recycling and zero discharge process, the steps are as follows:

[0034] S1: Saline organic wastewater enters the regulating tank and the decarbonization tower in turn to adjust the water quality and quantity of incoming water and remove free carbon dioxide. The hydraulic retention time of the regulating tank and the decarbonizing tank is 10 hours;

[0035]S2: The effluent after regulated decarburization enters the coagulation sedimentation tank, adding sodium carbonate, sodium hydroxide, flocculant polyaluminum chlorid...

Embodiment 2

[0043] In the present invention, main water quality index is the Na of 4742mg / L + , 3430 mg / L of Cl - , 6954mg / L of SO 4 2- , 310ppm Ca 2+ , 210ppm Mg 2+ , COD of 360ppm, after a series of pretreatment processes in the raw water, the SS removal rate in the wastewater is 94%, the total hardness removal rate is 93%, and the Ca 2+ , Mg 2+ The treatment rate is 98%, the COD removal rate is 81%, SDI<3, TDS<15.6g / L.

[0044] Such as figure 1 , a saline organic waste water recycling and zero discharge process, the steps are as follows:

[0045] S1: Salt-containing organic wastewater enters the regulating tank and the decarbonization tower in turn to adjust the quality and quantity of incoming water and remove free carbon dioxide; the hydraulic retention time of the regulating tank and the decarbonizing tank is 12 hours;

[0046] S2: The effluent after regulated decarburization enters the coagulation sedimentation tank, adding sodium carbonate, sodium hydroxide, flocculant pol...

Embodiment 3

[0054] In the present invention, main water quality index is the Na of 6823mg / L + , 4957 mg / L of Cl - , 9761mg / L of SO 4 2- , 340ppm Ca 2+ , 230ppm Mg 2+ , 460ppm of COD, raw water after a series of pretreatment processes, the removal rate of SS in wastewater is 92%, the removal rate of total hardness is 95%, Ca 2+ , Mg 2+ The treatment rate is 98%, the COD removal rate is 83%, SDI<3, TDS<23.8g / L.

[0055] Such as figure 1 , a saline organic waste water recycling and zero discharge process, the steps are as follows:

[0056] S1: Salt-containing organic wastewater enters the regulating tank and the decarbonization tower in turn to adjust the quality and quantity of incoming water and remove free carbon dioxide; the hydraulic retention time of the regulating tank and the decarbonizing tank is 12 hours;

[0057] S2: The effluent after regulated decarburization enters the coagulation sedimentation tank, adding sodium carbonate, sodium hydroxide, flocculant polyaluminum chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com