Process for co-producing electrical carbon through anaerobic and pyrolysis coupling of organic waste

A technology of organic waste and pyrolysis, which is used in the removal of solid waste, waste fuel, waste treatment, etc., can solve the problems of secondary pollution of biogas residue, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

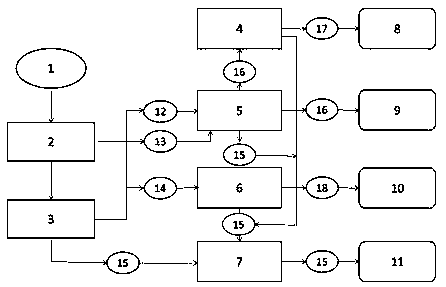

[0031] A process for the coupled anaerobic-pyrolysis co-production of electric charcoal from organic waste, comprising the following steps:

[0032] The residue obtained by anaerobic fermentation of organic waste is used as the reaction raw material for the pyrolysis reaction, and the biogas obtained by anaerobic fermentation and the pyrolysis gas obtained by the pyrolysis reactor are used to remove CO by pressure swing adsorption. 2 The energy gas is obtained, and the energy gas is passed into the local gas network for gas supply, and can also generate electricity through the internal combustion engine power generation system to supply power for the local power grid. The pyrolysis residue obtained from the pyrolysis reactor is mechanically modified to obtain a soil remediation agent, which is applied to the soil remediation area. The waste heat obtained from pyrolysis reactor, internal combustion engine power generation system, pressure swing adsorption and mechanical modific...

Embodiment 2

[0034] A process for the coupled anaerobic-pyrolysis co-production of electric charcoal from organic waste, comprising the following steps:

[0035] Add raw vinegar grains with solid content >30% and inoculum to an anaerobic fermentation tank for anaerobic fermentation, stir continuously, mix evenly, and produce 0.20-0.25m 3 / kg methane, after 30 days of fermentation, part of the vinegar residue was taken out, the biogas slurry was refluxed into the fermenter, and this operation was repeated every day to obtain anaerobic vinegar residue. The anaerobic vinegar grains are mixed evenly, dehydrated and dried, crushed to less than 3mm, and put into a fixed-bed pyrolysis reactor for pyrolysis. The pyrolysis atmosphere is a nitrogen atmosphere, and the pyrolysis temperature is 600°C. pyrolysis to H 2 、CH 4 , CO and other energy gases, the gas yield rate is 45%, and the biochar yield rate is 36%, of which the energy gas H 2 +CO+CH 4 The overall proportion is 84%. Overall, the sol...

Embodiment 3

[0037] A process for the coupled anaerobic-pyrolysis co-production of electric charcoal from organic waste, comprising the following steps:

[0038] Add organic waste 1 (slurry kitchen waste with a solid content of 40%) and anaerobic activated sludge (water content 95%) with a volume ratio of 1:1 into anaerobic fermentation tank 2 for the first anaerobic fermentation. Aerobic fermentation, the time of the first anaerobic fermentation is 35 days, and the reaction temperature of the first anaerobic fermentation is controlled to be 35°C;

[0039] The first anaerobic fermentation contains CO 2 with CH 4 The biogas 13 enters the pressure swing adsorption unit 5 through pressure swing adsorption of CO 2 , get energy gas 16;

[0040] After the solid-liquid separation of the anaerobic digestion reaction output obtained from the first anaerobic fermentation, the biogas slurry is refluxed into the anaerobic fermentation tank 2 for recycling, and new organic waste 1 is added, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com