Method and device for deeply treating heavy metal wastewater

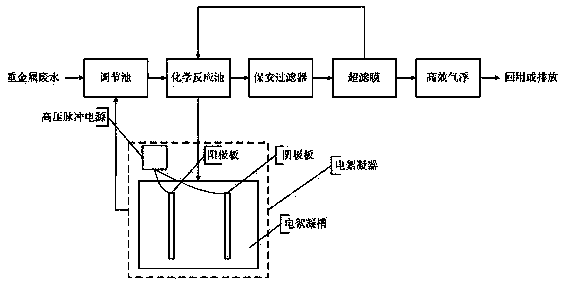

A technology for advanced treatment and heavy metals, applied in water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc. Wide application range, high separation efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Wastewater from an electroplating factory is treated with the method and device of the present invention, the treatment capacity is 10t / d, the surfactant is sodium lauryl sulfate and nonylphenol polyoxyethylene ether, ultrafiltration The average flux of membrane produced water has been maintained at 210L / m 2 .h; the reversing period of electrocoagulation is 20ms, and the removal rate of heavy metals is over 98%. The specific influent water quality and effluent water quality are shown in Table 1.

[0034] Table 1 Water quality before and after treatment of heavy metal waste liquid

[0035] project Raw water (mg / L) Water after treatment (mg / L) Cr 6+ 50-90 <0.2

Embodiment 2

[0036] Example 2: The heavy metal waste liquid of a certain chemical plant is treated by using the method and device of the present invention. The specific influent water quality and effluent water quality are shown in Table 2. The treatment capacity is 20t / d, the device has been in stable operation for 3 months, and the average flux of membrane produced water has been maintained at 150L / m 2 .h, the heavy metal removal rate remained above 98%.

[0037] Table 2 Influent and effluent water quality of heavy metal waste liquid

[0038] Test items Raw water (mg / L) Water after treatment (mg / L) pH 1.6-2.4 6-9 SS 2100-2700 <10

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com