Novel without drainage of dioxin production technology for firing brick and tile and making brick and tile using with life garbage in city

A technology of municipal solid waste and dioxin, which is applied to the removal of solid waste, etc., can solve the problems of not keeping up with technology, not in place, high production cost, etc., and achieve considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

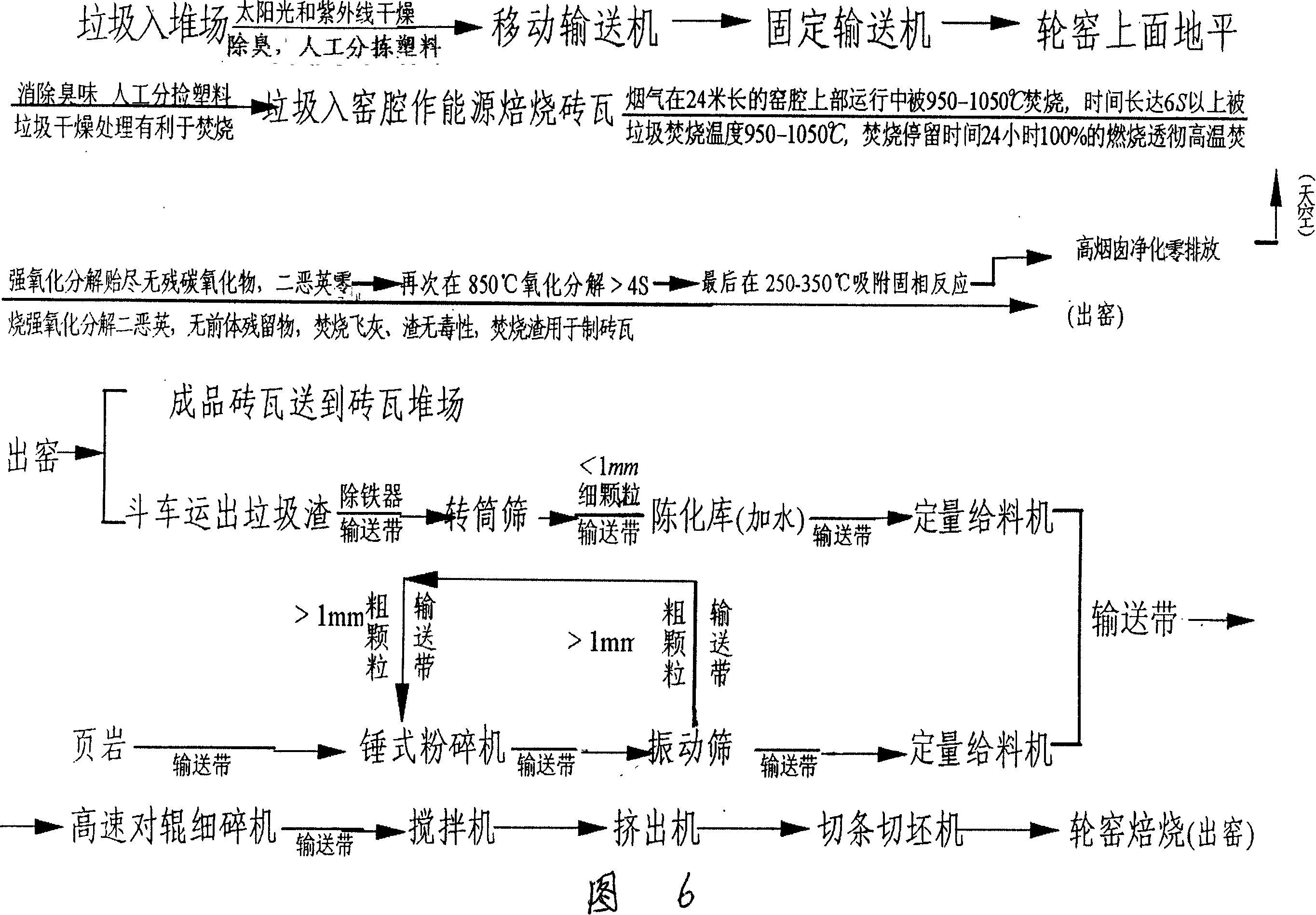

[0094] The following is a description of the process of the present invention in conjunction with the process circuit diagram:

[0095] 1. Garbage dump:

[0096] ①The municipal solid waste is dirty, smelly, and wet, so the dumping site 1 is required to be at least 30 meters away from the wheel kiln 6, and the space left is for the brick and tile finished products to go out of the kiln and be stacked in the brick and tile yard 20.

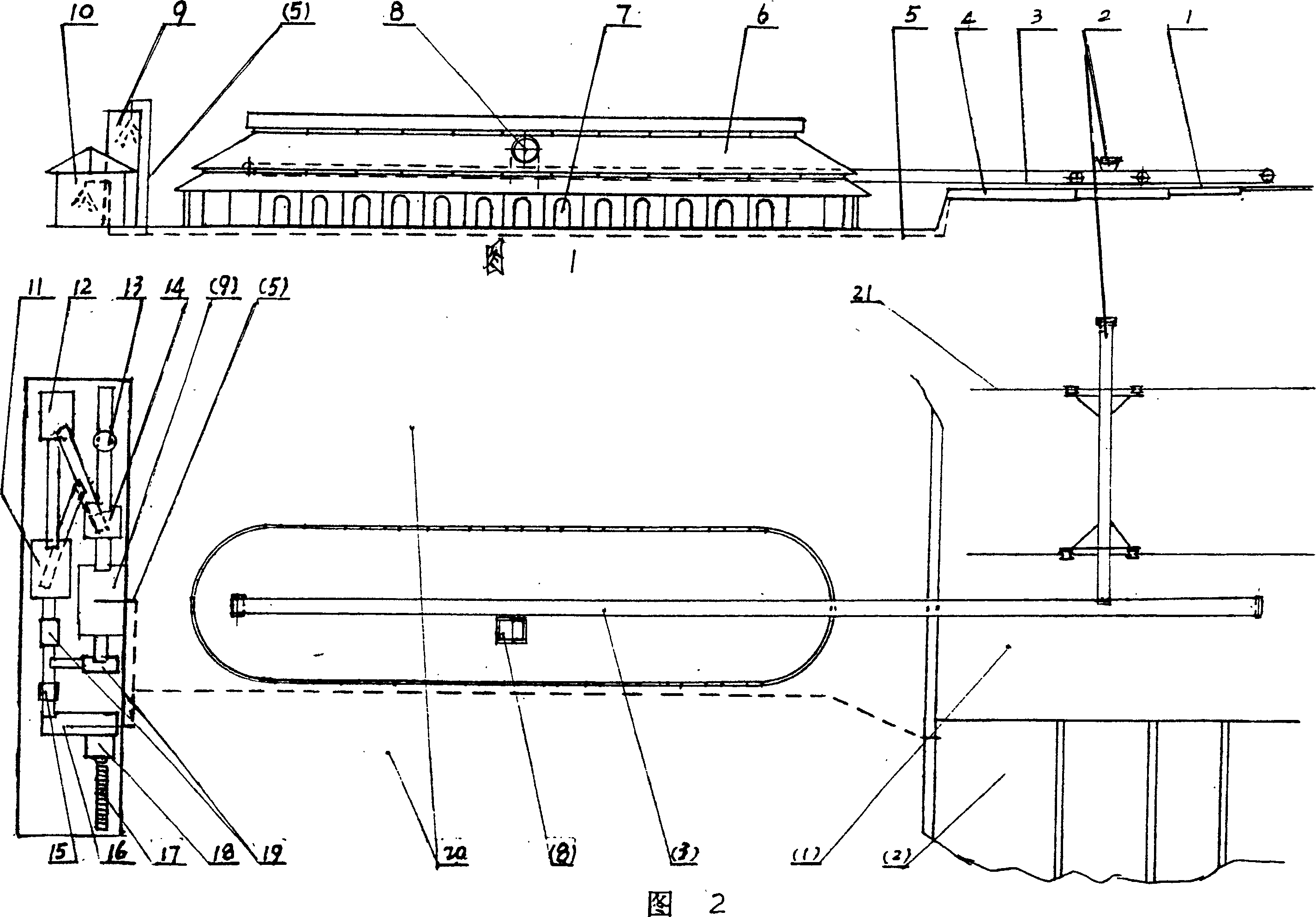

[0097] ② Garbage dump site 1 has an open terrain and is convenient for stacking, drying and sorting garbage. There is mobile (long 20-30m can integrally move) conveyor 2, which can move on two rails 21 in the garbage dump 1, and rubbish is transported to the fixed conveyor 3 by the mobile conveyor 2 and then on the wheel kiln 6.

[0098] 2. Garbage is odorless and leaves the city to dry and dispose of garbage

[0099] ① The sanitation department should disinfect garbage stations, cars, barrels and other containers every day, and leave the city in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com